Why Freeze Coil Protection Matters for Your Mortuary Operation

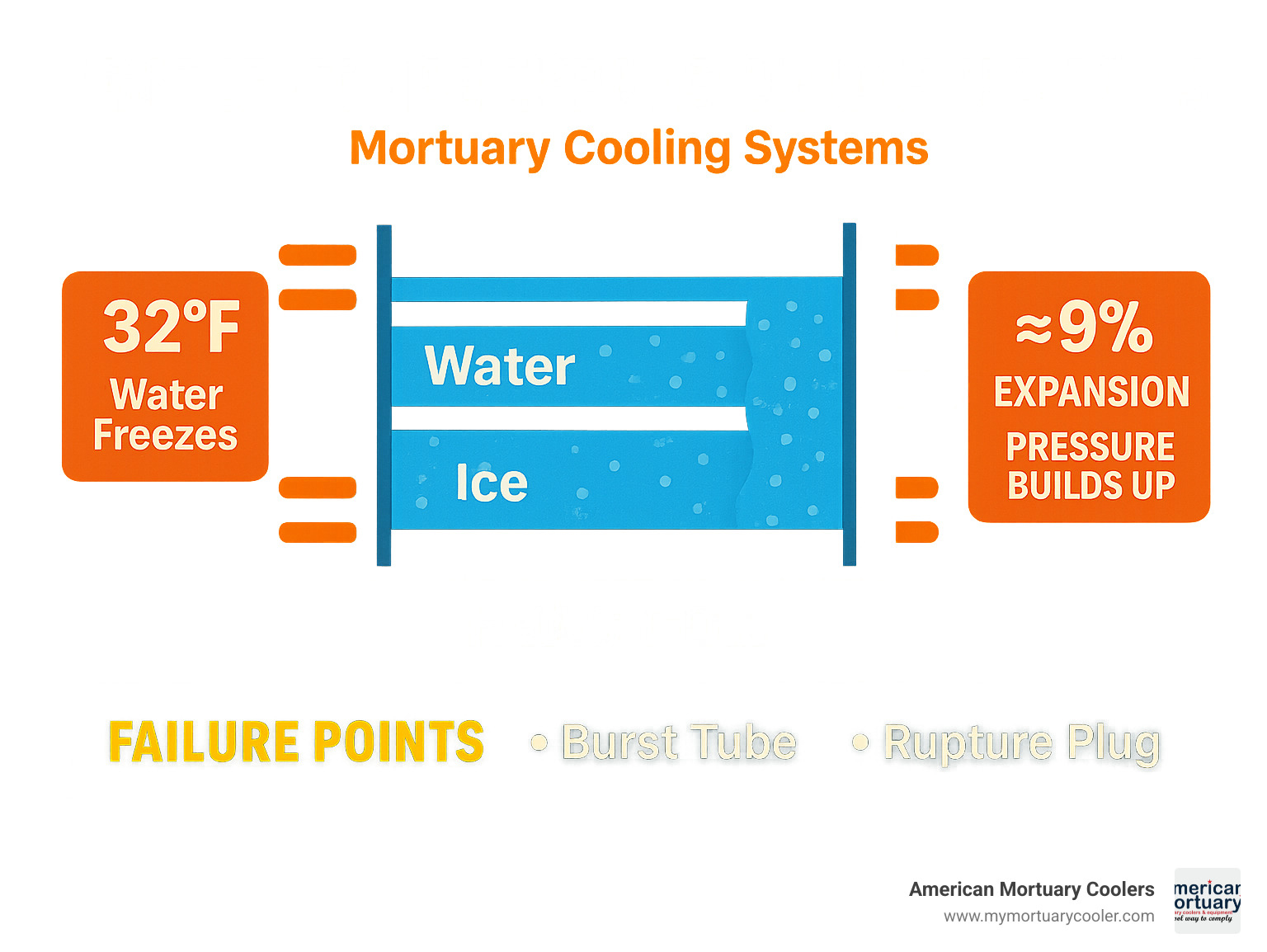

Freeze coil damage is one of the most expensive mistakes you can make in mortuary cooling systems. When water freezes inside HVAC coils, it expands by roughly 9%, creating pressures that can burst tubes within minutes and leave you with thousands in repair costs plus critical downtime.

What is a freeze coil?

- A water or steam coil in HVAC systems that's vulnerable to freezing damage

- Contains tubes that carry heated or chilled fluids for temperature control

- Prone to bursting when internal water freezes and expands

- Protected by specialized valves or rupture plugs in freeze-resistant designs

At temperatures 32°F and below, water can freeze and expand, causing excessive pressures that result in HVAC coil damage within a matter of minutes. Yet many facility managers make simple mistakes that leave their systems completely vulnerable to freeze events.

From ignoring airflow restrictions to skipping routine defrost maintenance, these beginner errors can shut down your mortuary operation when families need you most. Even worse, some "solutions" like glycol actually hurt your system's efficiency while driving up energy costs.

We're American Mortuary Coolers, a national-level mortuary cooler supplier with extensive experience helping funeral homes prevent costly freeze coil failures through proper equipment selection and maintenance practices.

What Is a Freeze Coil and How Does It Work?

A freeze coil is any water or steam coil in your HVAC system that's vulnerable to freezing damage. In your mortuary operation, these coils maintain precise temperatures but become your biggest vulnerability when winter hits.

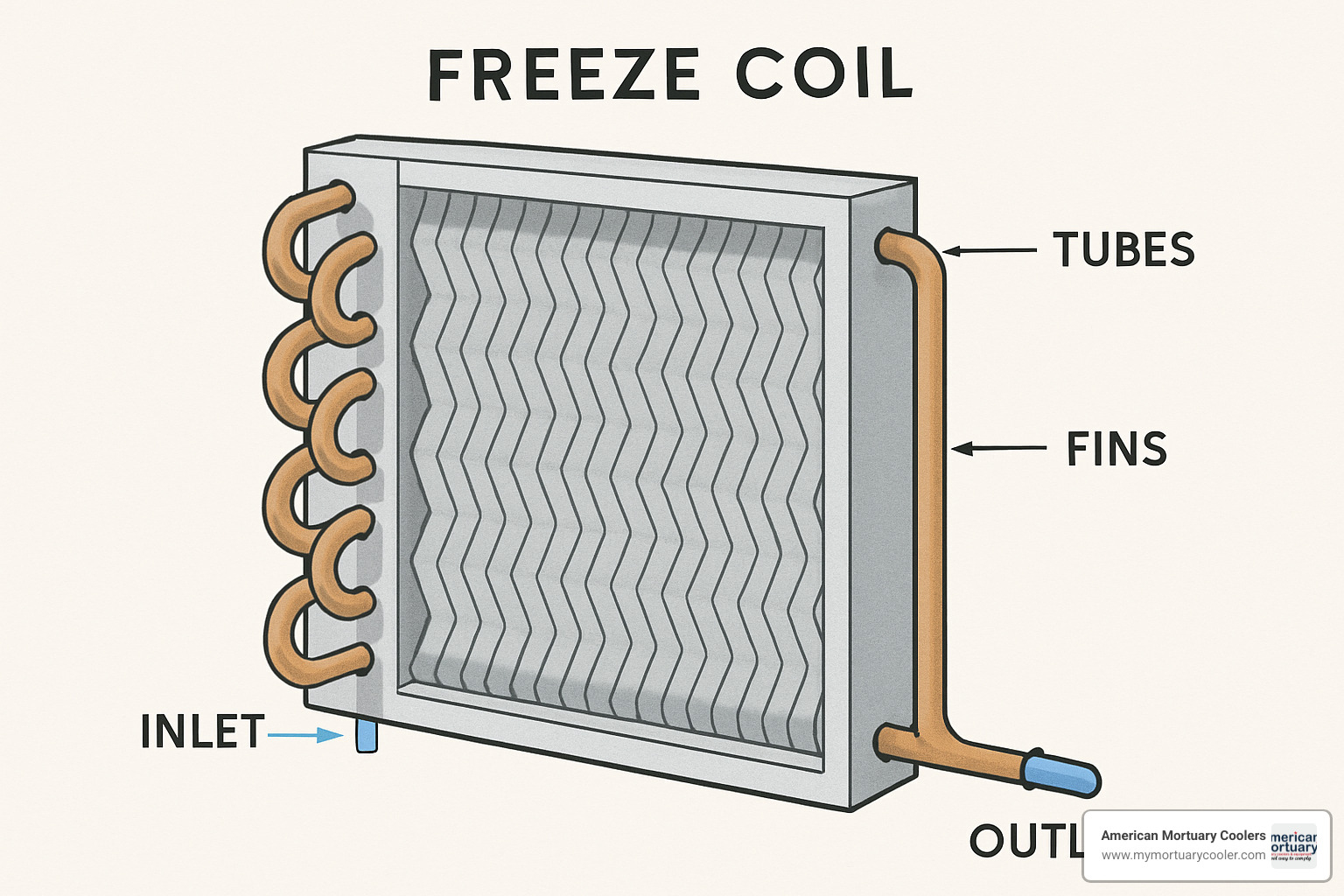

Fluid flows through a network of tubes surrounded by metal fins. When operating normally, this setup effectively heats or cools facility air. But when that fluid freezes, physics becomes your enemy. Water expands by about 9% when it turns to ice, creating crushing internal pressure that most coil tubes can't handle.

The return bends—curved sections where tubes connect—are usually the first to fail. During manufacturing, these areas get stretched and thinned, making them weak links. When pressure builds from ice expansion, these spots burst first, often leaving you with flooding and expensive repairs.

Core Components and Thermodynamics

The tubes and headers handle normal operating pressures but aren't designed for extreme forces that frozen water creates. The fins won't burst like tubes, but ice formation blocks airflow, making the system work harder and accelerating freezing.

Return bends are the Achilles' heel—manufacturing stretches and thins metal in these curved sections, making them most likely to fail under pressure.

Modern protected coils include pressure relief valves or freeze plugs designed to fail in a controlled way, venting pressure before expensive coil tubes burst.

Once coil temperature hits 32°F, water starts forming ice crystals. Unlike most materials that shrink when cold, water expands with tremendous force, creating pressures reaching thousands of PSI in confined coil tubes.

Key Applications Beyond HVAC

Walk-in coolers and freezers use smart defrost cycles to prevent ice buildup, typically running defrost once or twice daily with fail-safe timers.

Industrial pipe freezing uses this principle intentionally, with technicians using liquid CO₂ at -109°F to freeze water in pipes for maintenance work.

Steam distribution systems use specially designed coils with inner distribution tubes to maintain even steam flow and eliminate cold spots that could freeze.

Why Coils Freeze & Common Beginner Mistakes

A properly maintained coil should never freeze under normal operating conditions. Yet frozen coils remain one of the most expensive problems in mortuary cooling systems.

When your system can't move enough air across the coil surface, temperatures drop below 32°F and ice forms. Low airflow is the biggest culprit, but low refrigerant charge, thermostat malfunctions, and defrost system failures all contribute.

Most freeze events trace back to three preventable beginner mistakes.

Freeze Coil Mistake #1: Ignoring Airflow Restrictions

The number one mistake? Treating air filters like they're optional. Dust and dirt act as insulation on the evaporator coil, restricting airflow and leading to freezing.

Dirty filters create back-pressure that reduces airflow across your freeze coil. Less airflow means less heat transfer, dropping coil temperatures below freezing. Change filters every 30-90 days, monthly in dusty environments.

Blocked return vents cause the same problem. A couch blocking a return vent starves the evaporator coil of airflow and leads to freezing. In mortuary settings, caskets, embalming equipment, or cleaning supplies can accidentally block critical air returns.

Fan motor problems complete this trio. When blower motors fail or run at reduced speed, coils don't get needed air movement, creating larger temperature differences that push surface temperatures below freezing.

Freeze Coil Mistake #2: Delaying Defrost or Maintenance

Walk-in freezers are typically designed to defrost once or twice a day, but many operators never adjust cycles based on actual conditions.

Defrost timer neglect is common. Factory settings assume average humidity and usage, but mortuary coolers often operate in higher humidity. In very humid locations with heavy usage, coils accumulate frost more rapidly, requiring extra defrost cycles.

Termination switch failures end defrost cycles when coil temperature reaches 60°F, but failures cause cycles that either waste energy running too long or end too early, leaving ice on coils.

Running an air conditioner with frozen coils may cause irreparable harm—ice buildup forces liquid refrigerant into compressors, causing damage requiring complete system replacement.

Freeze Coil Mistake #3: Relying Only on Glycol

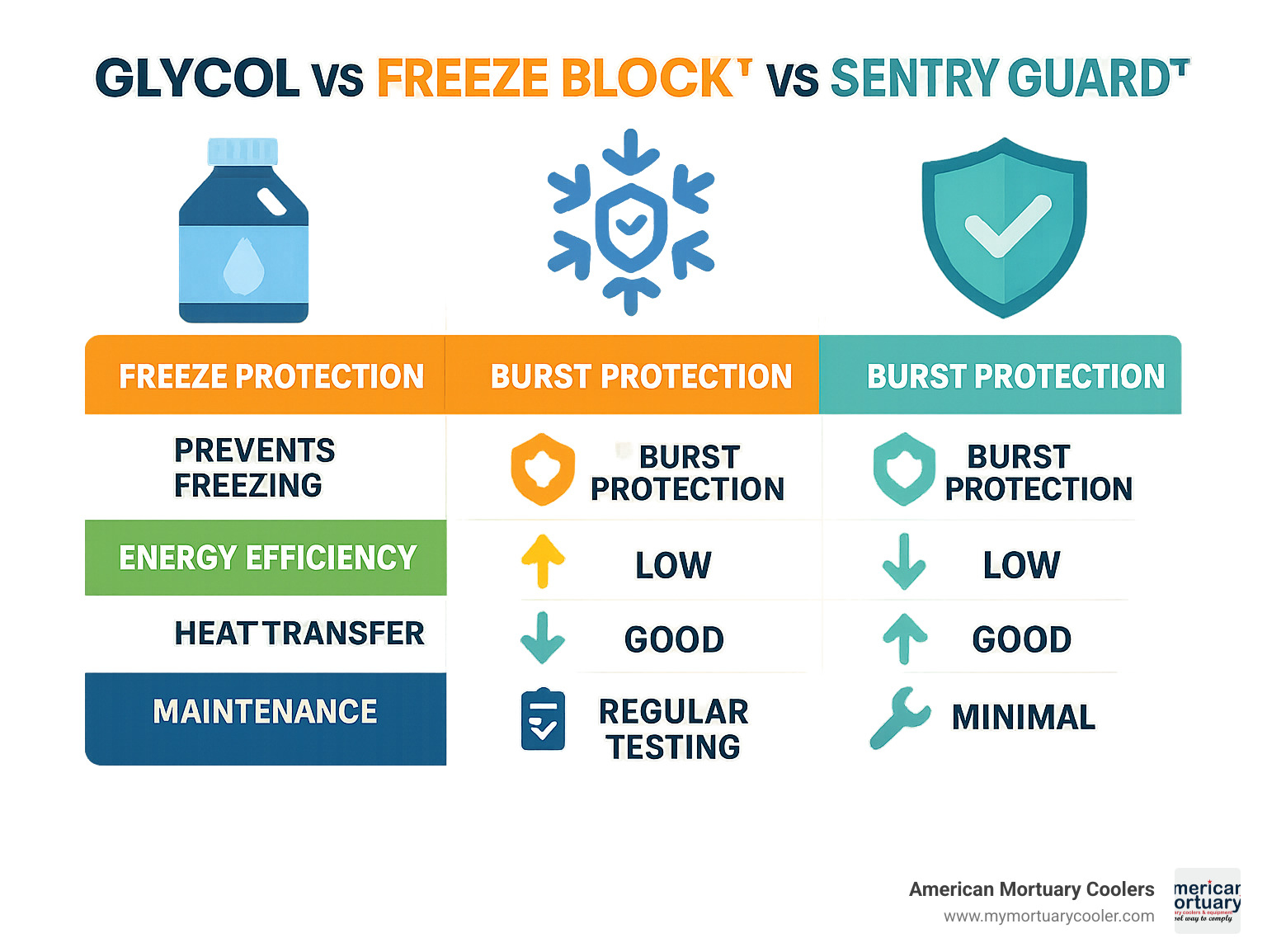

Many think adding glycol antifreeze solves freeze protection, but it creates problems often costing more than the protection it provides.

Traditional glycol-based freeze protection methods can lead to high energy consumption and maintenance costs due to glycol's thick viscosity and low heat transfer characteristics. Systems work harder to pump thicker fluid and transfer heat.

Glycol requires regular testing and replacement as it breaks down, potentially becoming corrosive to system components.

Freeze Protection Technologies & Products

Modern freeze coil protection technologies provide better reliability while improving system efficiency rather than hurting it. These solutions prevent damage without compromising performance.

How Freeze Block™ Coils Prevent Damage

Freeze Block™ systems have been climate room and wind tunnel tested to -74°F, far beyond anything your mortuary will experience.

The pressure-temperature valve system monitors both conditions simultaneously, sensing both pressure and temperature changes to automatically discharge water before coils freeze. When freezing conditions develop, the system discharges just enough water to prevent damage, then automatically reseats the valve when conditions normalize.

Freeze Block™ technology has been installed in thousands of HVAC systems across North America, including facilities like Ford Motor Company, GlaxoSmithKline, and The White House.

All Cooney Freeze Block™ coils come with a minimum 30-month warranty against freeze damage, which can be extended to 48 months with the Smart Coil System.

Sentry Guard™ and Freeze Plugs: Pros & Cons

Sentry Guard™ uses patented burst proof coil design [that] guarantees against freeze damage through strategically placed pressure relief points—controlled weak spots that fail safely before expensive coils do.

Freeze-relief plugs are brazed onto return bends and headers where freeze damage typically starts. When internal pressure reaches dangerous levels, these plugs rupture to relieve pressure. Internal pressure relief built into coils [prevents] catastrophic freeze damage.

When plugs rupture, they discharge water until manually replaced. In tight mechanical rooms, locating and replacing them can cause lengthy downtime. Manufacturers offer expedited production [that] allows shipment in as little as 1 working day for replacement plugs.

Smart Freeze-Alert Add-Ons

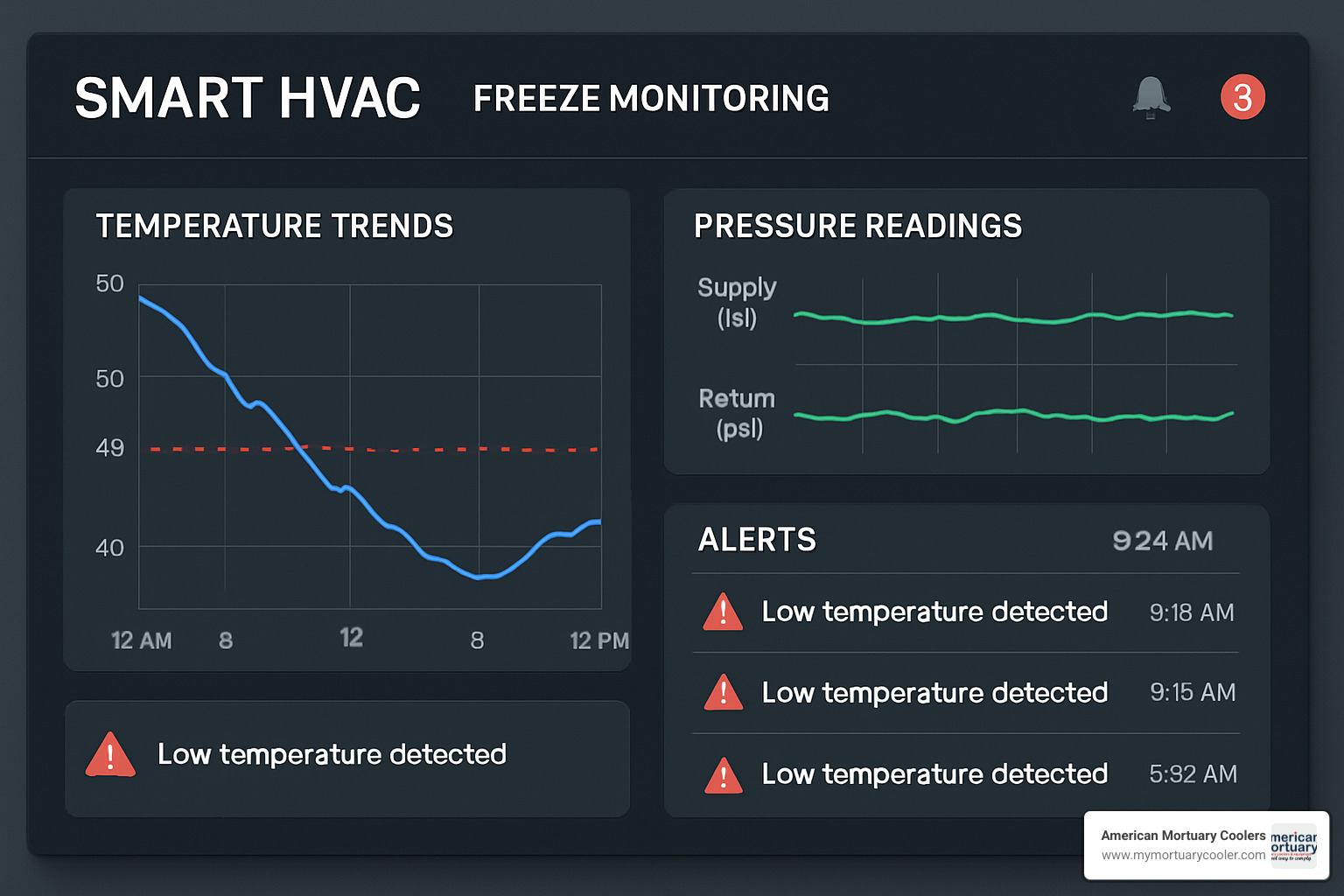

Modern IoT monitoring systems provide real-time temperature and pressure monitoring with early warning before damage occurs. Smart systems coordinate with HVAC controls, automatically adjusting operation when freeze conditions develop.

Predictive maintenance capabilities log freeze events and performance data, helping identify patterns indicating developing problems before they become expensive failures.

For more detailed information about evaporator freezing issues, check out the latest research on evaporator freezing. You can also verify AHRI certification for specific coil models at www.ahridirectory.com certification lookup.

Maintenance & Retrofit Best Practices

Proper maintenance procedures make the difference between quick fixes and costly disasters. Never rush a frozen coil repair. Technicians must fully thaw the evaporator coil before attempting any diagnostic procedure.

Safe thawing starts with patience. Switch your thermostat from 'Cool' to 'Off' and set the fan to 'On'. If needed, use a hair dryer on low-to-medium heat from six inches away. Never chip the ice—this can puncture coil tubes and cause refrigerant leaks.

Regular coil cleaning maintains heat transfer efficiency that prevents ice buildup. Use proper coil cleaners and angle coil-cleaning spray to avoid fin damage.

For specialized applications, CO2 pipe-freeze kits offer controlled freezing for maintenance work.

Can Freeze Protection Be Retrofitted to Existing Systems?

Retrofit is cost-prohibitive and complex due to brazing needs—order a direct-fit replacement coil instead. Adding Freeze Block™ or Sentry Guard™ technology requires extensive modification work with significant piping changes to accommodate new valve locations and connections.

Direct-fit replacements make more financial sense and provide fresh starts with full warranty coverage. Plan retrofit work during low-demand periods when backup cooling is available.

For detailed information about walk-in cooler systems and replacement considerations, check out our comprehensive guide: More info about walk-in cooler evaporators.

Routine Checks to Keep Your Freeze Coil Warranty Valid

Warranty coverage requires documented maintenance and proper operation.

Annual valve testing verifies that Freeze Block™ valves open at correct pressure and temperature thresholds, then reseat properly. For Sentry Guard™ systems, check that rupture plugs are properly installed and undamaged.

Event logging documents all freeze events, including conditions and corrective actions. This helps identify patterns and supports warranty claims.

Coating integrity inspection catches small problems before they become big ones. Address coating issues promptly—small touch-ups prevent complete coil replacements.

Selecting the Right Freeze Coil for Your Application

Choosing the right freeze coil protection means understanding your specific needs and matching them with appropriate technology. Key factors include water versus steam applications, row depth requirements, copper versus stainless steel construction, climate zone, required airflow CFM, and expected ROI.

Water coils are more common in mortuary applications, while steam coils require specialized distribution designs to prevent condensate accumulation in cold spots.

Row depth impacts performance and freeze risk. Four-row coils offer the best balance of efficiency and freeze protection for most mortuary cooling applications.

Copper tubes offer superior heat transfer and lower cost. Stainless steel provides better corrosion resistance in harsh climates or poor water quality conditions.

Climate zone considerations are crucial. Northern facilities need robust freeze protection, while southern facilities might prioritize efficiency but still need protection from unexpected cold snaps.

ROI calculations should include energy savings and avoided downtime costs. Traditional glycol-based freeze protection methods can lead to high energy consumption due to poor heat transfer properties.

Specifying a Freeze Coil for New Mortuary Coolers

New construction allows designing freeze protection from the ground up. Sizing formulas for mortuary applications must account for normal cooling loads plus additional capacity for freeze protection systems. We recommend oversizing by 15-20% for operational margin.

Humidity control requirements affect coil operating temperatures. Design systems with adequate margin—typically keeping coil surface temperatures at least 5°F above freezing during normal operation.

OEM direct-fit options simplify installation and maintain warranty coverage. Most major mortuary cooler manufacturers offer factory-integrated freeze protection tested as complete systems.

For fundamental refrigeration principles that apply to mortuary cooling systems, review our Refrigeration System 101 guide.

Replacement Checklist for Existing HVAC Units

Dimensional verification goes beyond simple measurements. You need connection locations, orientations, and clearance requirements.

Connection types vary between manufacturers. Verify thread sizes, connection orientations, and valve locations before ordering.

Circuiting patterns affect performance and freeze protection effectiveness. Multi-circuit coils distribute refrigerant more evenly but require proper balancing.

Expedite programs are available when standard lead times would cause unacceptable downtime. Options include 2-day, 10-day, or 15-day expedite coil delivery.

Take detailed photos and measurements of existing installations, including all connections and surrounding equipment before ordering replacements.

Frequently Asked Questions about Freeze Coils

What are the signs of a frozen coil in an HVAC system?

The most obvious sign is when your AC is running but not cooling—the unit sounds like it's working, but your facility isn't getting proper temperature control.

You'll notice warm air coming from supply vents instead of cool air. This happens because frozen coils can't absorb heat properly.

Visible ice formation on the coil or refrigerant lines is a dead giveaway. Water puddles near the drain pan often appear as ice melts during off cycles.

Other warning signs include unusual noises, higher energy bills, and frequent cycling on and off.

How should a frozen coil be addressed or repaired?

Turn off the AC or heat pump immediately. Running the system with a frozen coil can cause compressor damage requiring complete system replacement.

Allow the coil to thaw completely before attempting diagnosis or repairs. Don't rush—chipping ice or using excessive heat can damage coils and create refrigerant leaks.

Identify what caused the freezing. Check air filters first, look for blocked vents, failing fan motors, or other airflow restrictions.

Address the underlying problem before restarting. Replace dirty filters, clean coils, and fix airflow issues. Call professionals for refrigerant problems or complex control issues.

Test the system thoroughly through several cycles to ensure normal operation has returned.

What maintenance is required for freeze protection coils?

Freeze Block™ coils require very little ongoing maintenance thanks to simple design with few moving parts.

Annual inspection and testing of protection valves is typically sufficient, checking that pressure-temperature sensors work correctly.

Sentry Guard™ systems need periodic inspection of replaceable freeze plugs and maintaining spare inventory for quick replacement.

General maintenance includes regular coil cleaning to maintain heat transfer efficiency and following manufacturer schedules for filter replacement.

Document everything for warranty coverage and troubleshooting future issues.

Conclusion

When families face their darkest hours, the last thing they should worry about is whether your mortuary cooler is working properly. Freeze coil damage doesn't just create expensive repair bills—it can shut down your entire operation at the worst possible moment.

Freeze damage can happen in minutes, but prevention takes just a few smart decisions. The most successful funeral directors we work with invest in proactive protection rather than reactive repairs. They maintain proper airflow through regular filter changes and have moved beyond outdated glycol solutions to modern freeze protection technologies that actually improve system performance.

Smart monitoring systems now catch problems before they cause damage. Whether you choose Freeze Block™ technology with its proven track record at facilities like The White House, or Sentry Guard™ systems with expedited replacement programs, the key is choosing protection that fits your specific needs and climate conditions.

At American Mortuary Coolers, we've built our reputation on understanding that reliability isn't just about equipment performance—it's about honoring the trust families place in you during their most vulnerable moments. Every custom mortuary cooler we deliver from our Tennessee facility reflects this understanding.

The technologies exist today to virtually eliminate freeze coil failures. Modern protection systems are more reliable, more efficient, and more cost-effective than ever before. The question isn't whether you can afford to invest in proper freeze protection—it's whether you can afford not to.

For additional guidance on maintaining optimal temperatures and avoiding common pitfalls, our team has compiled practical advice in Beginner Freezer Temperature Mistakes and How to Avoid Them.

Your community depends on you to be ready when tragedy strikes. Proper freeze coil protection ensures you always are, allowing you to focus on what matters most—serving families with the dignity, respect, and reliability they deserve during life's most difficult moments.