The Science Behind Keeping Things Cold

What is the refrigeration system? A refrigeration system removes heat from an enclosed space to lower its temperature below the ambient environment. It works by circulating refrigerant through a cycle of compression, condensation, expansion, and evaporation.

Here's what you need to know:

- Definition: A closed-loop system that transfers heat from a cooler area to a warmer one

- Main components: Compressor, condenser, expansion valve, and evaporator

- Operating principle: Uses phase changes of refrigerant to absorb and release heat

- Common applications: Food preservation, air conditioning, medical storage, industrial processes

The refrigeration cycle is something we encounter daily but rarely think about. From your home refrigerator to hospital cold storage, this technology is fundamental to modern life. The process doesn't actually "create cold" — instead, it removes heat, similar to how water flows downhill.

As Benjamin Franklin once observed after experimenting with evaporative cooling: "From this experiment, one may see the possibility of freezing a man to death on a warm summer's day."

I'm Mortuary Cooler, a national-level supplier of mortuary cooling systems with extensive experience designing and optimizing refrigeration systems for funeral homes and medical facilities.

What is the refrigeration system terms explained:

What is the Refrigeration System? (Definition & Purpose)

What is the refrigeration system exactly? Think of it as nature's heat thief. Instead of creating cold (which isn't actually possible), refrigeration systems work by removing heat from an enclosed space and releasing it elsewhere.

The magic of refrigeration is all about heat transfer. In your home refrigerator, that carton of milk stays fresh because the system continuously pulls heat away from it.

Basic Definition of "What is the refrigeration system"

At its heart, a refrigeration system is an artificial cooling arrangement that uses a thermodynamic cycle to move heat from a cooler area to a warmer one. This goes against heat's natural tendency to flow from hot to cold—like trying to make water flow uphill!

To make this happen, the system needs energy input, typically electricity that powers a compressor. The compressor is like the heart of the system, keeping the refrigerant flowing through the cycle.

As ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers) puts it, refrigeration is "the science of providing and maintaining temperatures below that of the surrounding atmosphere."

Main Purpose in Homes, Industry & Healthcare

The refrigeration system plays critical roles in our daily lives:

In your kitchen, refrigeration keeps perishables below 40°F, slowing down bacteria growth. Those strawberries in your fridge? They'd last mere hours at room temperature but can stay fresh for days when properly cooled.

When summer heat becomes unbearable, your air conditioner (which is really just a specialized refrigeration system) creates a comfortable oasis by cooling and dehumidifying indoor air.

In hospitals and clinics, medical storage refrigeration literally saves lives. Vaccines, blood products, and biological samples all depend on precise temperature control.

Industrial processes often rely on cooling for proper operation. From plastic manufacturing to food processing, controlled cooling ensures consistent quality.

In our specialty area at American Mortuary Coolers, refrigeration serves a dignified purpose. Our mortuary refrigeration systems maintain the proper preservation of the deceased at temperatures between 35°F and 40°F, allowing funeral homes to provide families with the time they need for proper arrangements.

How Does a Refrigeration System Work? The Vapor-Compression Cycle

Ever wondered what's happening inside your fridge while it keeps your food fresh? The vapor-compression cycle is the unsung hero of modern cooling.

Step-by-Step Cycle Walk-Through

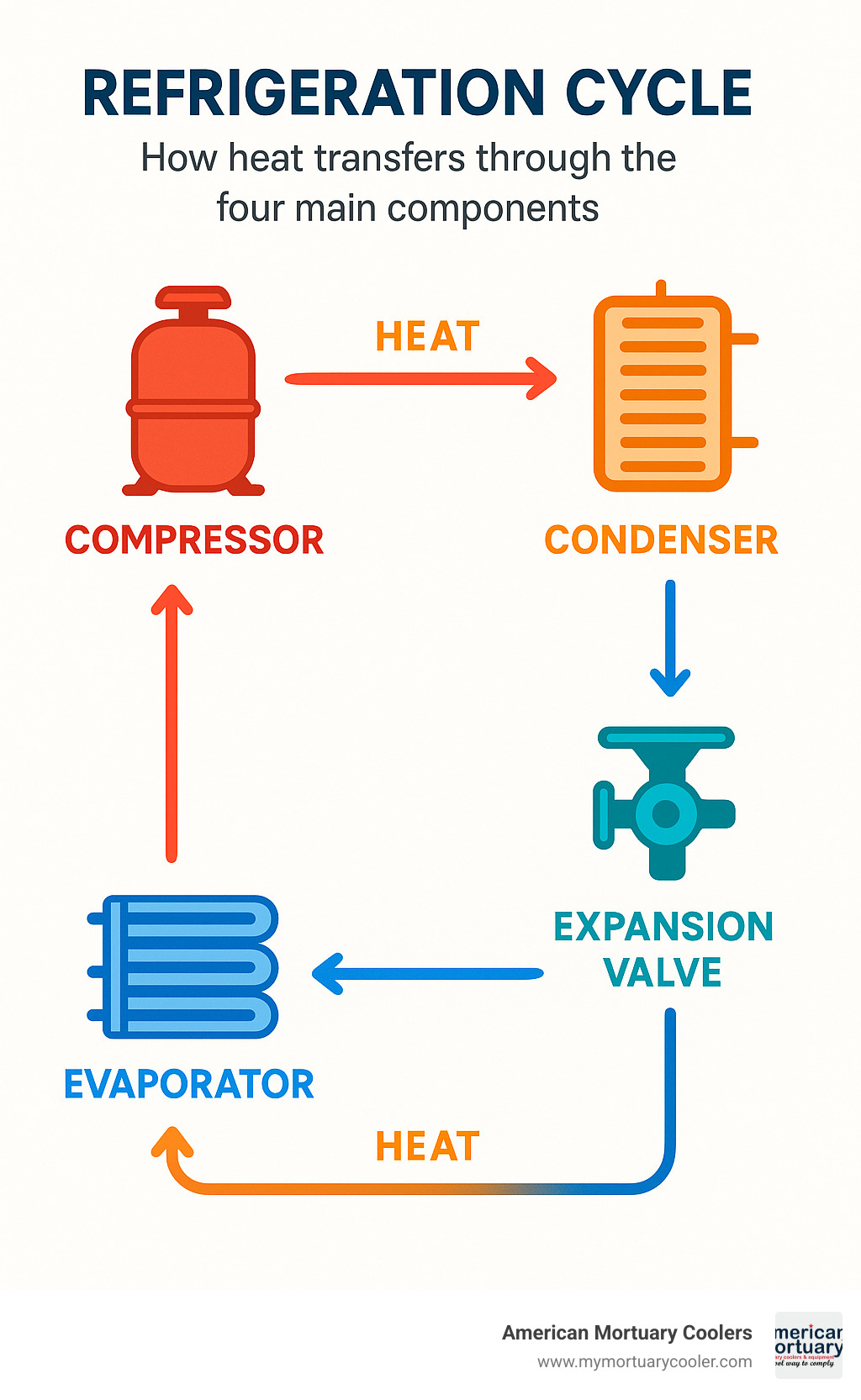

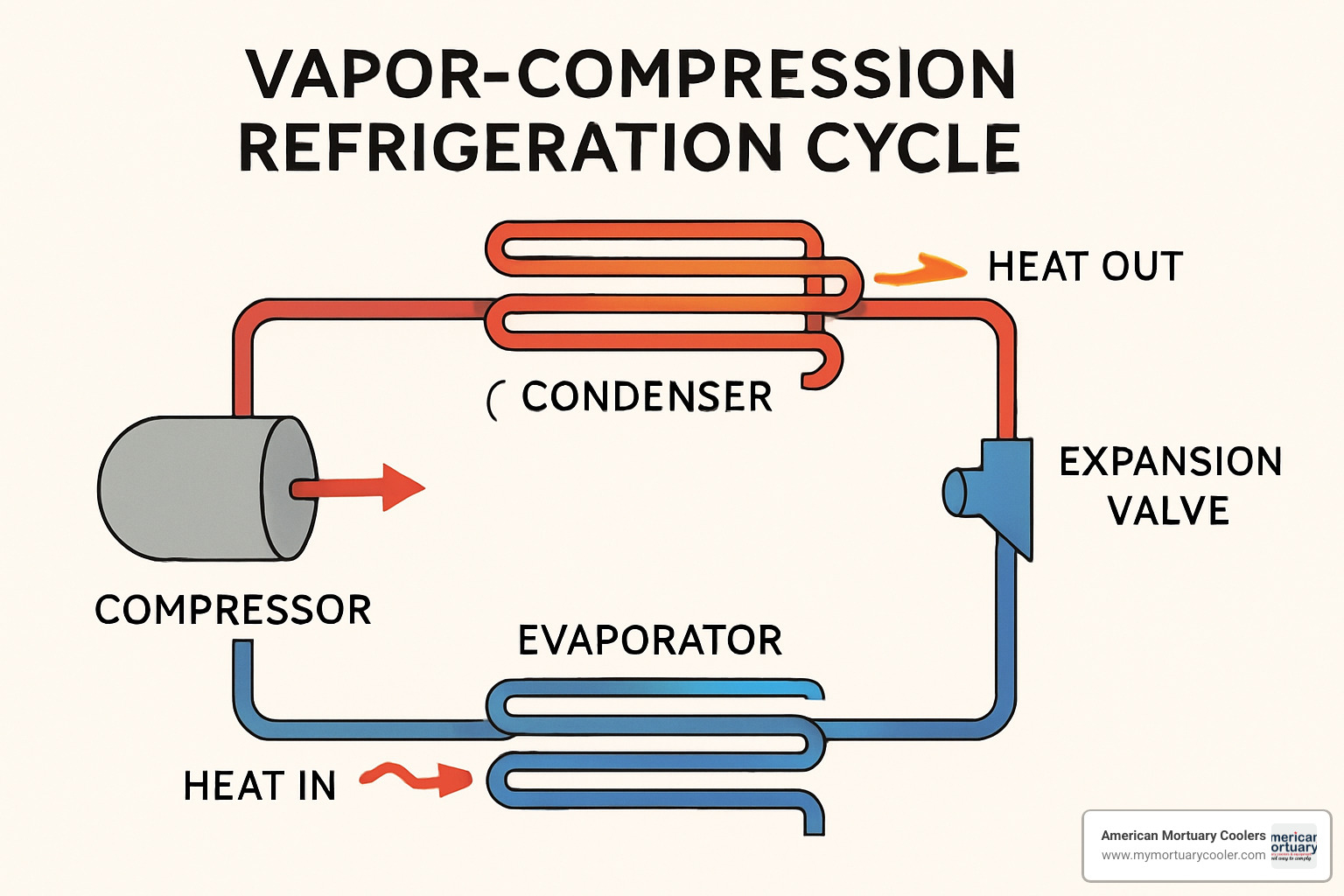

Think of the refrigeration cycle as a continuous journey your refrigerant takes through four distinct stages:

First, the compression stage kicks things off. The compressor sucks in cool, low-pressure refrigerant vapor and squeezes it tight. This compression works like a bicycle pump – as you compress air, it heats up. The same happens to our refrigerant, changing it into a hot, high-pressure gas.

Next comes condensation, where our hot refrigerant needs to cool down. In the condenser, the refrigerant releases its heat to the surrounding environment – that's why the back of your fridge feels warm! As it cools, the refrigerant transforms from a gas into a high-pressure liquid.

The third stop is the expansion device, where things get interesting. Our high-pressure liquid refrigerant suddenly passes through a tiny opening, creating a dramatic pressure drop. This is similar to what happens when you spray an aerosol can – it feels cold. Some refrigerant instantly "flashes" into vapor, cooling the remaining liquid significantly.

Finally, in the evaporation stage, our now-cold refrigerant enters the evaporator coils inside the refrigerated space. Here, it absorbs heat like a sponge soaking up water. This heat absorption is what creates the cooling effect you feel. As it warms up, the refrigerant completely evaporates back into a vapor and returns to the compressor to start its journey all over again.

Components in Detail

Let's take a closer look at the key players in this cooling symphony:

The compressor comes in several varieties. Reciprocating compressors use pistons and are workhorses in smaller systems. Scroll compressors, with their interlocking spiral design, offer excellent reliability for medium applications. For larger systems, robust screw compressors can handle industrial-scale cooling demands.

The condenser is essentially a heat exchanger. Air-cooled condensers use metal fins and fans to dissipate heat. Water-cooled versions use flowing water to carry heat away. Plate heat exchangers stack thin plates together to maximize surface area for efficient heat transfer.

The expansion device might be small, but it's mighty important. Thermostatic expansion valves (TXVs) adjust refrigerant flow based on temperature needs, while electronic expansion valves (EEVs) offer digital precision.

The evaporator typically features finned coils that maximize surface area for absorbing heat. Air circulates across these fins, allowing the cold refrigerant inside to soak up warmth from the surrounding space.

Beyond Vapor Compression: Absorption, Adsorption & Emerging Tech

While vapor-compression dominates the cooling world, some fascinating alternatives exist:

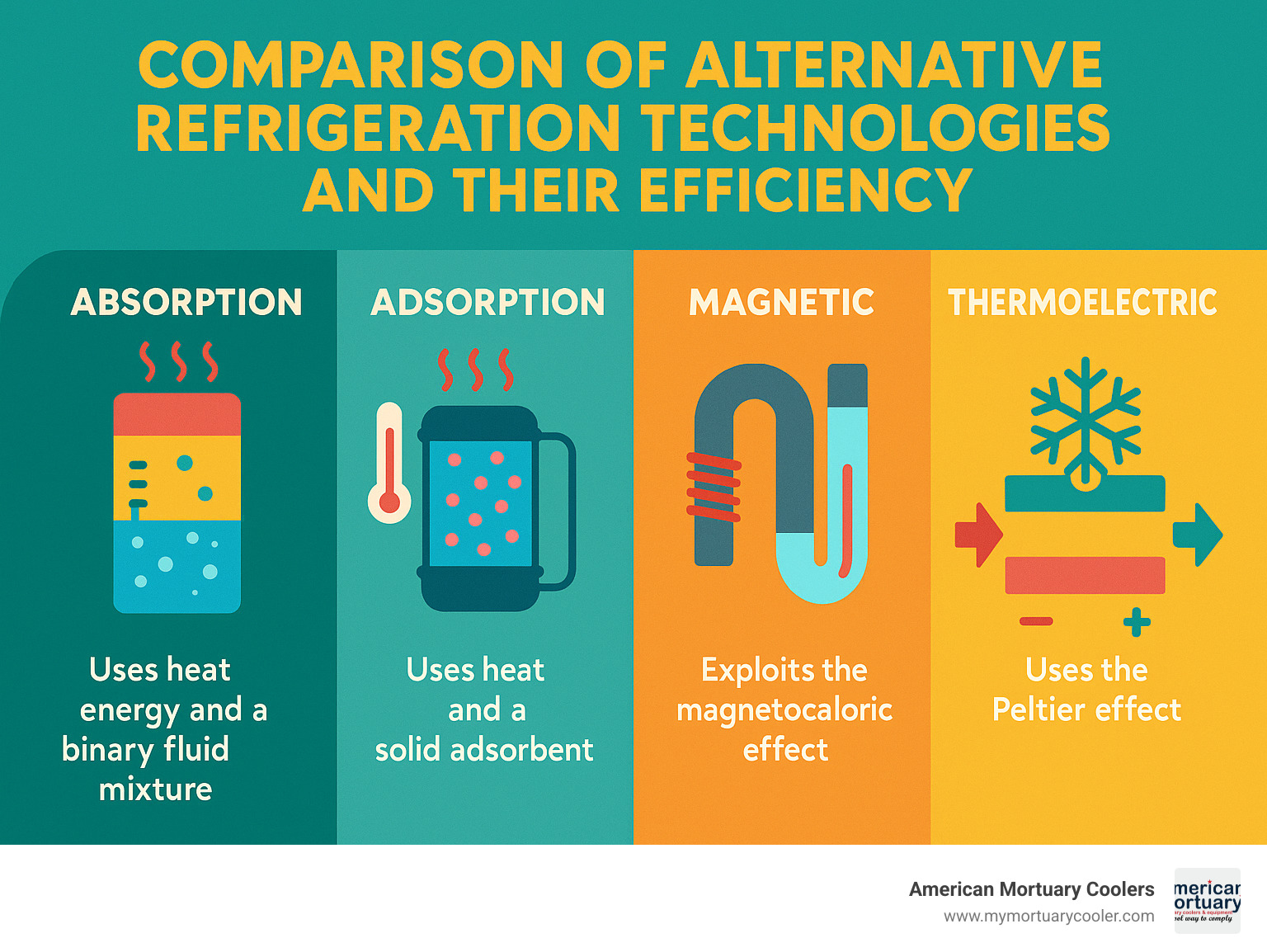

Absorption refrigeration replaces the mechanical compressor with a chemical process using heat energy and a fluid mixture (typically ammonia and water). These systems run quietly and can operate on various heat sources.

Magnetic refrigeration harnesses the magnetocaloric effect – certain materials naturally change temperature when exposed to changing magnetic fields. This promising technology could eventually eliminate traditional refrigerants altogether.

Thermoelectric cooling uses the Peltier effect, where electricity flowing across two different materials creates a temperature difference. While less efficient than traditional methods, these solid-state systems have no moving parts.

For those interested in diving deeper into the science behind refrigeration, Britannica's research on refrigeration offers excellent technical insights.

Types of Refrigeration Systems & Real-World Applications

When it comes to keeping things cold, refrigeration systems come in all shapes and sizes. From the humble fridge in your kitchen to massive industrial cooling systems, the basic principles remain the same—but the applications and configurations vary widely.

Domestic & Commercial Compression Systems

What is the refrigeration system you'll encounter most often in daily life? In homes and businesses, direct expansion (DX) vapor-compression systems dominate the landscape. These systems directly use refrigerant to absorb heat from the space being cooled.

Your household refrigerator is a marvel of engineering simplicity—a self-contained unit with all components neatly packaged together. These units typically use capillary tubes as their expansion devices and hermetically sealed compressors.

Walk into any supermarket, and you're surrounded by commercial refrigeration at work. These systems might be self-contained units like beverage coolers, or more commonly, split systems where the condensing units are tucked away while the cooling happens right where it's needed.

For larger commercial spaces, packaged units offer a different approach. These all-in-one systems house every component in a single cabinet, typically installed on rooftops.

Industrial & Process Cooling

What is the refrigeration system best suited for industrial-scale cooling? The answer depends on what you're cooling and how cold you need it.

Chilled water systems take an indirect approach—rather than cooling air directly, they cool water that's then circulated to wherever cooling is needed. This approach offers tremendous flexibility for large buildings and manufacturing processes.

For food processing plants, cold storage warehouses, and ice rinks, ammonia refrigeration systems shine. Despite being toxic if leaked, ammonia's outstanding thermodynamic properties and zero global warming potential make it the refrigerant of choice for large industrial applications.

As environmental concerns grow, CO₂ transcritical systems are gaining popularity, especially in supermarket refrigeration. With a global warming potential (GWP) of just 1, carbon dioxide represents the future of environmentally responsible cooling.

In our specialty at American Mortuary Coolers, we focus on systems designed specifically for funeral homes and medical examiners. Our mortuary coolers prioritize unwavering reliability, stable temperatures between 35°F and 40°F, and whisper-quiet operation that maintains the dignity of the setting.

For funeral industry professionals, selecting the right refrigeration equipment isn't just about technical specifications—it's about ensuring respectful preservation and operational peace of mind.

Specialty Applications & Low-GWP Natural Systems

As regulations around refrigerants tighten, the industry is embracing natural refrigerants with lower environmental impacts:

CO₂ booster systems are increasingly common in supermarkets, cleverly handling both medium and low-temperature cooling needs in a single system using carbon dioxide.

For large industrial applications, ammonia/CO₂ cascade systems offer the best of both worlds—combining ammonia's exceptional efficiency with CO₂'s safety advantages in areas where people are present.

Smaller commercial applications are turning to hydrocarbon systems using refrigerants like R-290 (propane) or R-600a (isobutane). These natural refrigerants offer excellent cooling properties but require careful safety considerations due to their flammability.

Performance, Efficiency & Environmental Considerations

Refrigeration accounts for about 10% of all commercial building energy use in the U.S. Whether you're running a small funeral home or a large medical facility, understanding how to optimize your system can save money while reducing environmental impact.

Key Metrics & How to Measure Them

When evaluating refrigeration systems, several important measurements tell the story of performance:

Cooling capacity tells us how much heat your system can remove per hour, measured in BTU/hr, tons of refrigeration, or kilowatts. Think of this as your system's muscle – how much cooling power it can flex when needed.

Coefficient of Performance (CoP) is like your car's miles-per-gallon rating – it shows the ratio of cooling provided to energy consumed. The higher this number, the more efficient your system. Most modern systems should achieve a CoP between 2 and 7.

Superheat and subcooling are crucial indicators of system health. Proper superheat ensures only vapor enters your compressor (liquid can cause damage), while good subcooling ensures maximum liquid refrigerant reaches the expansion device for optimal cooling.

Measuring these values doesn't require an engineering degree. Temperature sensors at key points in your system provide valuable data. Pressure gauges on high and low sides help calculate superheat and subcooling.

Strategies to Boost Efficiency & Cut Emissions

Simple changes can make dramatic differences in system performance:

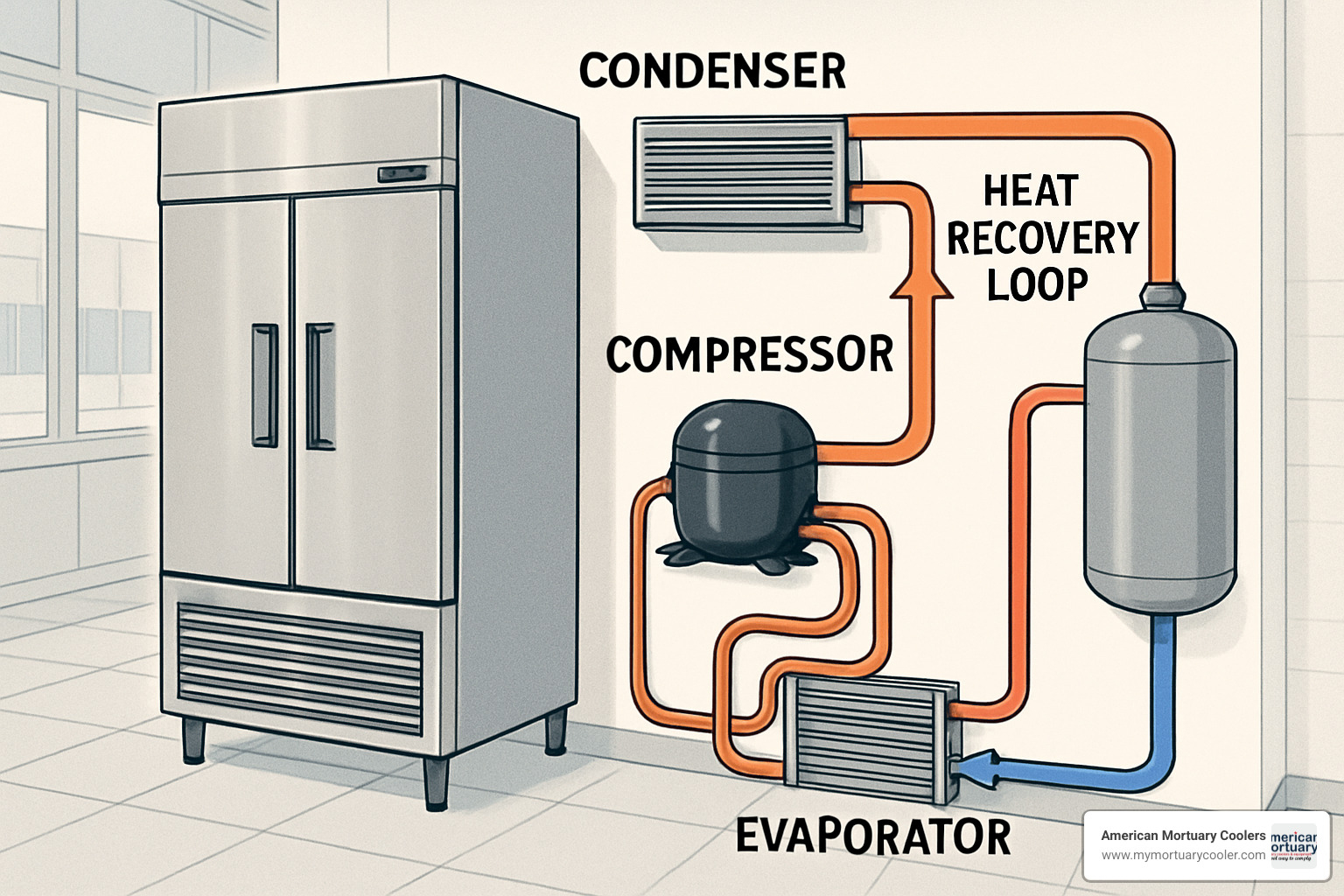

Heat reclamation is like getting a two-for-one special. Instead of wasting the heat rejected by your condenser, capture it for water heating or space heating. Funeral homes can reduce water heating costs by 30% with this approach.

Variable Frequency Drives (VFDs) allow your compressors and fans to operate at just the speed needed, rather than constantly turning on and off. This technology can reduce energy consumption by 20-50%.

Regular coil cleaning is perhaps the simplest yet most overlooked maintenance task. Dirty condenser or evaporator coils can slash efficiency by up to 90%! Quarterly cleaning ensures optimal performance.

Improved insulation of both the refrigerated space and refrigerant lines minimizes unwanted heat gain. This is especially important for mortuary coolers where temperature stability is critical.

Low-GWP refrigerants reduce environmental impact significantly. Natural refrigerants like CO₂, ammonia, and hydrocarbons offer excellent alternatives with minimal environmental impact.

At American Mortuary Coolers, we've incorporated these efficiency strategies in our designs. Our newest mortuary cooler models use heat recovery to pre-heat water, cutting overall energy costs while maintaining perfect preservation conditions.

For those interested in exploring more environmentally friendly refrigeration solutions, the Green Cooling Initiative offers excellent resources on sustainable cooling technologies.

Installation, Maintenance & Best Practices

Even the best refrigeration system won't perform well if it's poorly installed or neglected. Proper setup and regular maintenance make all the difference between a system that hums along for years and one that leaves you in the cold.

Routine Checklist for Reliable Operation

A simple quarterly maintenance routine can prevent most common problems and extend your system's lifespan significantly.

Clean those coils! This is perhaps the single most important maintenance task. Dirty condenser or evaporator coils force your system to work much harder than necessary, potentially increasing energy consumption by up to 90%.

Check refrigerant charge levels regularly. Too much or too little refrigerant doesn't just hurt efficiency—it can damage expensive components. Watch for unusual frost patterns, abnormal operating pressures, or cooling that doesn't seem right.

Monitor superheat and subcooling values to ensure proper system operation. Typically, you want superheat values between 8-12°F at the evaporator outlet and subcooling between 10-15°F at the condenser outlet.

Inspect door gaskets and seals for damage or wear. It's amazing how much warm, humid air can sneak through even a small gap, creating unnecessary cooling load and potential frost buildup.

Verify proper defrost cycles for systems operating below freezing. Ice-covered evaporator coils can't efficiently transfer heat.

Don't forget to check fan operation, electrical connections, drain lines, and oil levels as part of your regular maintenance routine.

Troubleshooting Common Issues

Even well-maintained systems occasionally develop problems. Knowing what to look for can save you time, money, and frustration.

Frost buildup on evaporator coils is one of the most common issues. Usually, this stems from air infiltration through damaged door seals, inadequate defrost cycles, or restricted airflow. Sometimes it points to a faulty expansion valve or low refrigerant charge.

Short cycling—when your system turns on and off frequently—often indicates an oversized system, improper thermostat settings, or refrigerant charge issues. This rapid cycling wastes energy and shortens component lifespan, particularly the compressor.

High head pressure problems typically result from dirty condenser coils, inadequate airflow, or refrigerant overcharge. Left unchecked, excessive pressure can trigger safety shutdowns or damage your compressor.

Unusual noises should never be ignored. That rattling, banging, or squealing is your system's way of crying for help. Address these sounds promptly before they lead to complete system failure.

For more comprehensive information about walk-in cooler features and maintenance, we've put together a detailed Complete Guide to Walk-In Cooler Features and Prices that covers everything from initial selection to long-term care.

Frequently Asked Questions about Refrigeration Systems

What refrigerant is best for my application?

Choosing the right refrigerant depends on what you're cooling, where you're located, and what matters most to you.

If you're running a medium-temperature system, R-134a might still be your go-to choice. It's been reliable for years, but with a Global Warming Potential (GWP) of 1,430, it's gradually being phased out.

Many modern air conditioners use R-410A, but with its hefty GWP of 2,088, it's also on the regulatory chopping block. For those looking ahead, R-32 is gaining popularity with its lower GWP of 675.

Nature-friendly options are making a comeback. R-290 (propane) offers excellent cooling performance with a tiny GWP of just 3, though its flammability requires careful system design. Meanwhile, R-744 (CO₂) is non-flammable and non-toxic with a GWP of just 1, but operates at higher pressures.

For industrial settings, R-717 (ammonia) remains the efficiency champion with zero GWP, though its toxicity means it's best for facilities with trained operators.

At American Mortuary Coolers, we typically recommend systems using R-134a, R-404A, or R-290 for mortuary applications, depending on specific needs and local regulations.

How often should coils be cleaned for maximum efficiency?

At minimum, condenser coils need cleaning every three months, but that's just a starting point.

The environment plays a huge role in determining cleaning frequency. Units near busy roads, in kitchen areas, or in locations with high pollen counts need more frequent cleaning.

Your usage patterns matter too. A system that runs constantly will collect dirt faster than one that cycles on and off.

A dirty condenser coil can spike energy consumption by up to 90% while reducing cooling capacity. It's like trying to breathe through a straw—everything works harder for less result.

Evaporator coils typically need cleaning once or twice yearly. When in doubt, a quick visual inspection can tell you a lot—visible dirt means it's cleaning time.

What is a ton of refrigeration and why does it matter?

What is the refrigeration system capacity measured in "tons"? A ton of refrigeration equals the cooling power needed to freeze 2,000 pounds (one ton) of water at 32°F into ice in 24 hours.

In practical terms, this translates to:

- 12,000 BTU per hour

- 3.517 kilowatts

- 200 BTU per minute

Understanding tonnage isn't just refrigeration trivia—it directly impacts your system's performance and costs.

Proper system sizing ensures you have adequate cooling capacity without wasting energy on an oversized unit. It's like buying shoes—too small and they'll never work properly, too large and you've wasted money while creating new problems.

For our mortuary coolers, we typically recommend approximately 1 ton of refrigeration capacity per 3-4 body storage capacity, though we consider factors like ambient temperature, insulation quality, and usage patterns when designing systems.

Conclusion

What is the refrigeration system if not one of humanity's most brilliant innovations? This technology has quietly revolutionized our lives in countless ways. From keeping our food fresh to making summer heat bearable, from safeguarding medicines to enabling crucial industrial processes, refrigeration has fundamentally transformed how we live.

As we look toward tomorrow, several exciting developments are reshaping refrigeration technology:

The environmental awakening has pushed sustainability to the forefront. Manufacturers are developing systems using refrigerants with lower global warming potential while boosting energy efficiency.

Our increasingly connected world has brought refrigeration into the digital age. Smart controls now allow adjustments from your smartphone, while sophisticated monitoring systems can predict problems before they occur.

Natural refrigerants are making a dramatic comeback. CO₂, ammonia, and hydrocarbons are replacing synthetic chemicals as regulations tighten.

Heat recovery systems are becoming standard rather than optional. Modern designs capture and repurpose heat, turning what was once an energy drain into an asset.

Meanwhile, advances in compressor technology have enabled remarkable miniaturization. Systems that once required substantial space can now fit into surprisingly compact footprints.

Here at American Mortuary Coolers, we keep our finger on the pulse of these innovations while maintaining our focus on the unique needs of funeral professionals. Our custom-crafted mortuary coolers are proudly built in Tennessee, with convenient delivery available throughout the contiguous 48 states. We understand that in the funeral industry, reliability isn't just a nice feature—it's absolutely essential for maintaining dignity and respect.

For those wanting to learn more about our specialized products and services, I encourage you to explore our resources on mortuary coolers.

Whether you manage a funeral home, work in a medical examiner's office, or operate another facility requiring specialized cooling, understanding refrigeration fundamentals helps you make smarter decisions about equipment selection, maintenance, and operation.