The Heart of Your Walk-In Cooler: Understanding Compressors and Evaporators

Walk-in cooler compressor and evaporator systems are the critical components that make refrigeration possible in commercial and mortuary applications. For those looking for quick answers about these essential parts:

| Component | Function | Types | Typical Lifespan |

|---|---|---|---|

| Compressor | Pressurizes refrigerant gas, raising its temperature | Scroll, Reciprocating, Screw | 8-12 years |

| Evaporator | Absorbs heat from the cooler interior through refrigerant evaporation | Low-profile, Center-mount, Half-round | 10-15 years |

The compressor and evaporator work together in a continuous cycle to maintain precise temperatures inside your walk-in cooler. The compressor acts as the heart of the system, pumping refrigerant through the cycle, while the evaporator serves as the lungs, absorbing heat from inside the cooler.

A properly sized and matched walk-in cooler compressor and evaporator system ensures efficient operation, consistent temperature control, and extended equipment life. When these components work in harmony, they create the ideal environment for preserving sensitive contents while minimizing energy consumption.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience designing and optimizing walk-in cooler compressor and evaporator systems for funeral homes across America. My expertise helps funeral directors select reliable refrigeration systems that meet their specific preservation needs while ensuring long-term performance.

Easy walk-in cooler compressor and evaporator word list:

Understanding the Refrigeration Cycle & Core Components

Have you ever wondered how your walk-in cooler actually keeps things cold? It's not magic—though sometimes it seems that way! Let's break down the refrigeration cycle in simple terms that anyone can understand.

Here at American Mortuary Coolers, we've installed cooling systems everywhere from small-town funeral homes in our home state of Tennessee to large facilities in busy cities like Los Angeles and New York. One thing we've learned along the way: when our clients understand how their coolers work, they make smarter decisions about their equipment.

The science behind your walk-in cooler compressor and evaporator is beautifully simple. It all comes down to a basic principle of physics: when liquids evaporate, they absorb heat. Your refrigeration system cleverly exploits this natural phenomenon through a continuous cycle with four main parts working together.

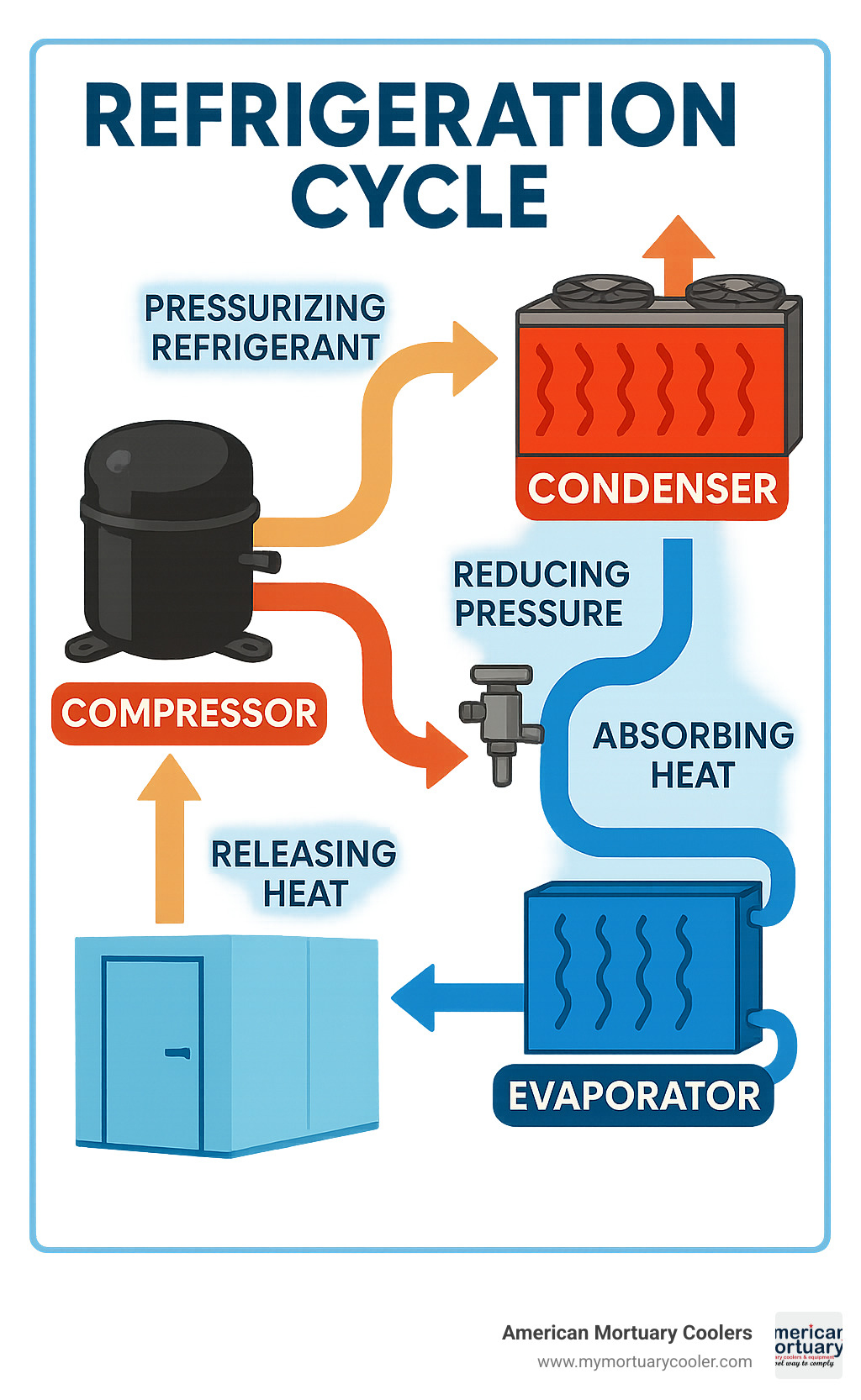

Step-By-Step Refrigeration Cycle

Think of the refrigeration cycle as a never-ending relay race, with the refrigerant as the baton being passed through four stages:

Compression starts the journey. Your compressor (think of it as the heart of the system) squeezes the refrigerant gas, which raises both its temperature and pressure. Picture squeezing a bicycle pump and feeling it get warm—same principle! This hot, pressurized gas then rushes to the condenser.

During condensation, the hot refrigerant meets cooler outside air in the condenser. This causes it to release heat (that's the warm air you feel blowing from behind a refrigerator) and transform from a gas into a high-pressure liquid.

Next comes the expansion phase. The liquid refrigerant passes through an expansion valve, which works like a controlled bottleneck. As the refrigerant squeezes through, its pressure drops dramatically, causing it to partially flash into gas and become very cold—much like how spray deodorant feels freezing when it hits your skin.

Finally, evaporation occurs inside your cooler. The now-cold refrigerant flows through the evaporator coils, absorbing heat from the surrounding air like a sponge. As it soaks up this heat, it completely transforms back into a gas. Meanwhile, the air inside your cooler gets cooler and is circulated by fans to maintain even temperatures.

Then the cycle repeats—over and over again, keeping your walk-in at the perfect temperature.

Main Hardware Inside a Walk-In

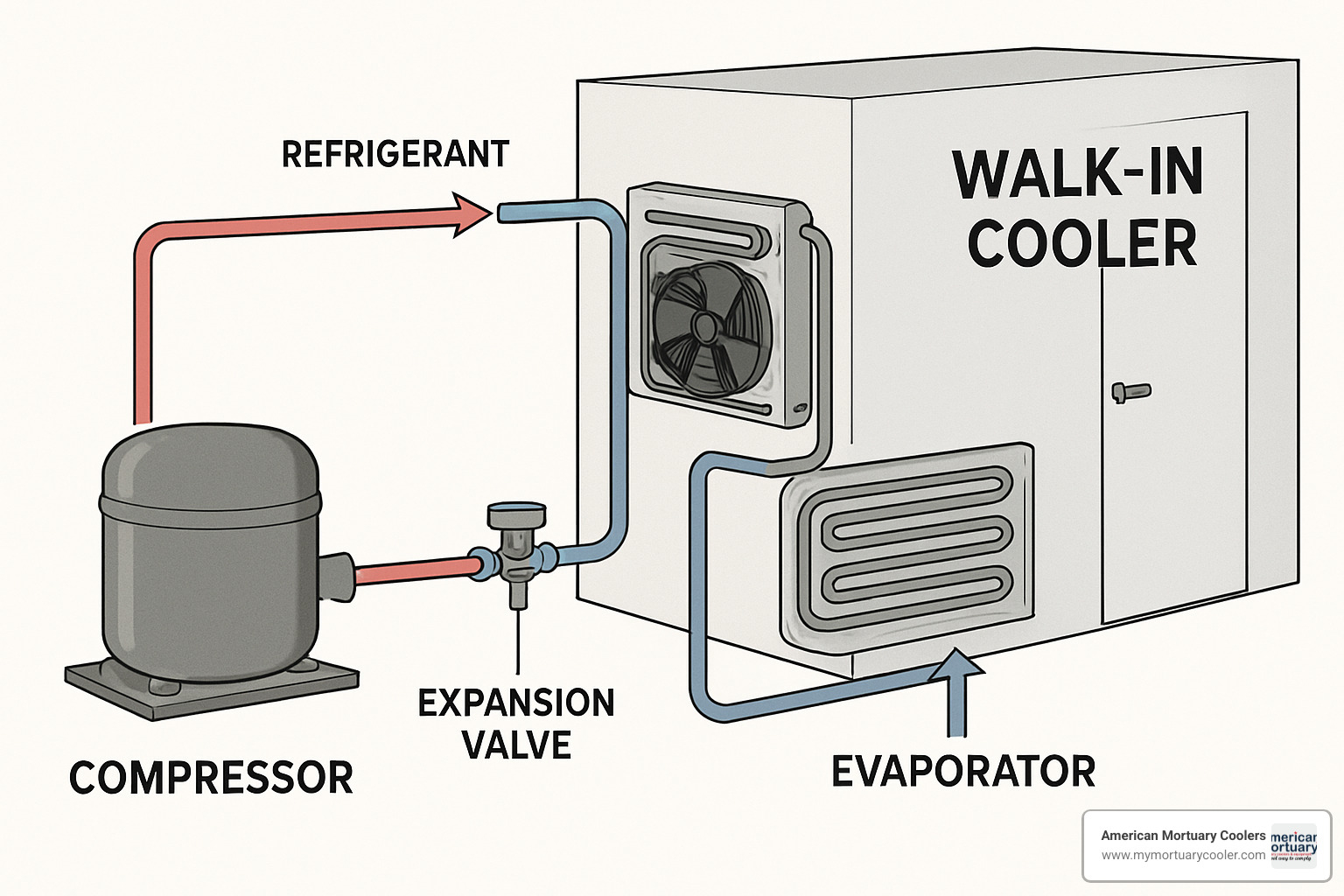

Your walk-in cooler compressor and evaporator system is just part of the story. The complete walk-in consists of several crucial elements working together:

The cabinet panels form the actual structure of your cooler. These aren't just simple walls—they're sophisticated sandwiches of metal with insulation in between. Think of them as the thermal fortress protecting your cooled space from the outside world.

The insulation is where we get serious about energy efficiency. At American Mortuary Coolers, we prefer extruded polystyrene because it maintains its insulating properties better over time. While industry standard is R-29 for coolers and R-32 for freezers (complying with the Energy Independence and Security Act), what matters is how that performance holds up over years of use. Our preferred insulation retains about 47% of its initial value throughout its lifetime, compared to only 19% for polyurethane—that's a significant difference in long-term performance!

Your cooler's controls are its brain, monitoring temperatures and managing the refrigeration cycle. These range from simple analog thermostats to sophisticated digital systems that can alert you to potential issues before they become problems.

Fans are the unsung heroes of your cooling system, working tirelessly in both the evaporator and condenser units to move air and ensure efficient heat transfer. Without proper airflow, even the best refrigeration components would struggle to maintain consistent temperatures.

The doors might seem straightforward, but they're engineered specifically to maintain the temperature barrier while allowing easy access. Many walk-ins also feature strip curtains or air curtains—simple additions that dramatically reduce temperature loss when the main door is opened.

Understanding these components isn't just academic—it helps you spot potential issues early, communicate effectively with service technicians, and make informed decisions when it's time to upgrade or replace your system.

Whether you're storing sensitive materials in a mortuary setting or preserving food in a commercial kitchen, the principles remain the same. The walk-in cooler compressor and evaporator system works tirelessly behind the scenes, moving heat from where you don't want it to where you don't mind it.

Walk-In Cooler Compressor and Evaporator Breakdown

Let's dive deeper into the dynamic duo that keeps your walk-in cooler running - the walk-in cooler compressor and evaporator. Think of them as the heart and lungs of your refrigeration system, each with a crucial role to play.

After installing hundreds of systems across America, from small funeral homes in rural Tennessee to large facilities in major metropolitan areas, we've seen how important it is to understand these components.

Walk-in cooler compressors and evaporators come in various sizes to match your specific needs. At American Mortuary Coolers, we offer systems ranging from modest 3/4 HP units perfect for small funeral homes all the way up to powerful 100 HP systems for industrial-scale applications. Finding the right match is crucial - it's not unlike finding the right dance partner who complements your every move.

Role of the Compressor in the Walk-In Cooler Compressor and Evaporator Pair

The compressor truly earns its nickname as the "heart" of your refrigeration system. Its main job? Pressurizing refrigerant gas to kick-start the entire cooling process.

When your compressor is humming along nicely, it's continuously drawing in low-pressure refrigerant gas and compressing it. This compression not only increases pressure but also raises the temperature - setting the stage for the heat transfer that makes refrigeration possible.

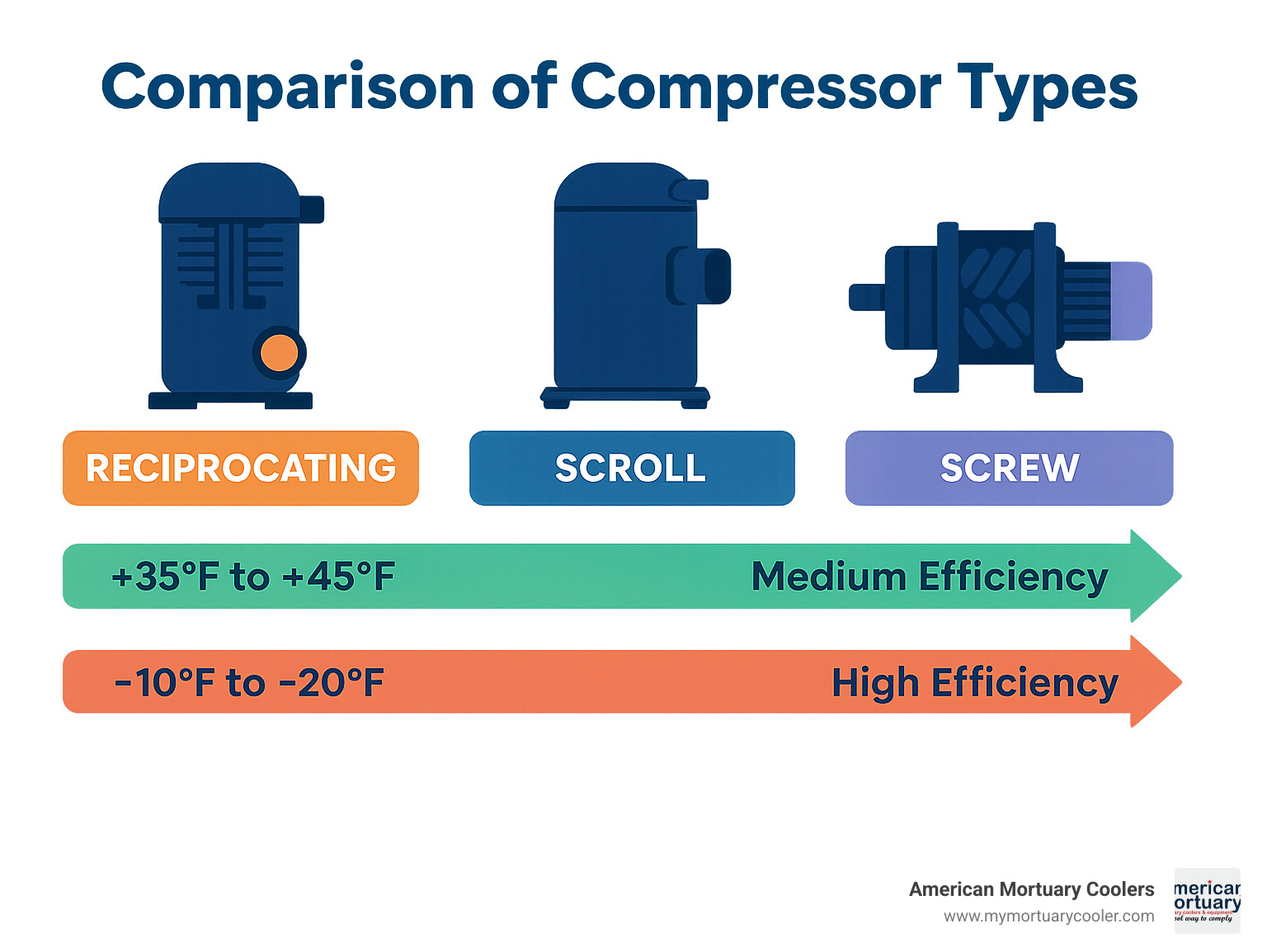

You've got options when it comes to compressor types. Scroll compressors have become increasingly popular because they're like the reliable, low-maintenance friend in your life - fewer moving parts means less that can go wrong, and they run more quietly too. Reciprocating (piston) compressors are the budget-friendly option, though they tend to be a bit noisier (think of that old refrigerator at your grandma's house). For larger operations, screw compressors offer excellent efficiency for continuous operation.

Compressors also come in different "shells" - fully hermetic compressors are completely sealed, making them ideal for locations where regular maintenance might be challenging. Semi-hermetic models allow access to internal components when repairs are needed, though they come with a higher price tag.

Don't forget about oil management! Just like your car's engine, compressors need proper lubrication. A well-designed system ensures oil returns to the compressor rather than wandering off through the system - something we pay careful attention to in every installation.

Role of the Evaporator in the Walk-In Cooler Compressor and Evaporator Pair

While the compressor works hard outside your cooler, the evaporator quietly does its job inside, absorbing heat like a sponge soaks up water.

The evaporator's coils are where the magic happens. As cold refrigerant flows through these coils, it absorbs heat from the surrounding air, causing the refrigerant to evaporate completely into a gas. The material matters here - most evaporators use copper tubes with aluminum fins because they transfer heat exceptionally well, like a good conductor leading an orchestra.

Fin spacing is another important consideration. In freezers, we use wider spacing to reduce frost buildup (think of how ice can form between the tines of a fork). For coolers, closer spacing works better for efficient heat transfer.

In humid environments like we often see in the South, regular defrosting is crucial. Ice buildup on evaporator coils acts like a blanket, insulating them and reducing efficiency. That's why proper defrost demand settings are so important for maintaining performance.

The evaporator's fans ensure air circulates evenly throughout your cooler, preventing those annoying hot spots that can compromise your temperature-sensitive contents.

How the Compressor and Evaporator Work Together

The walk-in cooler compressor and evaporator relationship is truly symbiotic - each depends on the other for proper function.

Think of the refrigerant as a messenger traveling between them. The compressor pumps this messenger through the system, while the evaporator is where the messenger picks up heat from inside your cooler.

Superheat is a term you might hear technicians mention - it refers to the temperature of the refrigerant gas as it leaves the evaporator. Having proper superheat ensures all refrigerant has evaporated before returning to the compressor. This is crucial because liquid refrigerant can damage your compressor - like water in your car's gas tank.

Suction pressure - the pressure of the refrigerant returning to the compressor - needs to be just right. Too high or too low can reduce efficiency and potentially damage your system.

The relationship between compressor and evaporator sizes is also critical. They need to be properly matched, like shoes that fit just right. An oversized compressor paired with an undersized evaporator creates an imbalance that leads to poor performance and potential damage.

In the mortuary industry, refrigeration requirements are unique and failure isn't an option. That's why we've created resources like our Compressor Conundrum: American Mortuary Coolers Has You Covered guide to help funeral directors steer compressor issues with confidence.

Understanding these components isn't just technical knowledge - it's peace of mind knowing that your walk-in cooler compressor and evaporator system is working harmoniously to maintain the perfect environment for your facility's needs.

Choosing the Right Compressor & Evaporator: Types, Sizing, Installation

Selecting the perfect walk-in cooler compressor and evaporator system isn't just about checking boxes—it's about finding the heart and lungs of a refrigeration system that will serve you faithfully for years to come. The right choice affects everything from your initial investment to those monthly energy bills that keep showing up in your mailbox.

When our team at American Mortuary Coolers designs cooling systems for funeral homes—whether it's a small family-owned business in rural Tennessee or a large facility in downtown Chicago—we don't just plug numbers into a formula. We get to know your specific needs, considering the unique challenges of your location, usage patterns, and future plans.

Walk-in coolers typically maintain temperatures between +35°F and +45°F (+1.67°C to +7.22°C), while freezers operate much colder at -18°C to -25°C. Getting this temperature range right is like finding Goldilocks' perfect bowl of porridge—not too hot, not too cold, but just right for your specific preservation needs.

Compressor Types & Mounting Options

Think of compressors as having different personalities, each with their own strengths and quirks:

Scroll Compressors are the quiet, reliable type we often recommend for mortuary applications. They're like that dependable friend who never lets you down—15-20% more efficient than their reciprocating cousins, with fewer moving parts to worry about. When a funeral home needs consistent, quiet operation day after day, scrolls are our go-to choice.

Reciprocating (Piston) Compressors are the traditional workhorses—a bit like an old pickup truck. They might not be as smooth or quiet as scrolls, but they're generally more affordable upfront and get the job done. For smaller walk-ins or when budget is a primary concern, these tried-and-true compressors still have a place.

Screw Compressors are the industrial powerhouses—you probably won't need one unless you're running a massive operation. They're designed for continuous heavy-duty use, making them overkill for most standard mortuary applications.

As for where to put these mechanical marvels, you've got options:

Remote Systems place the condensing unit (including the compressor) outside your building. This approach is typically gentler on your initial budget and prevents the unit from adding heat inside your facility. The catch? Installation labor might offset some of those initial savings.

Top-Mount Systems perch right on top of your walk-in cooler like a hat. These arrive ready to go—factory-assembled and pre-charged—which can save installation time. The downside? They take up valuable headroom and release heat inside your building.

Side-Mount Systems are perfect when you've got ceiling constraints but have some wiggle room on the sides. They work just like top-mounts but hang out on the wall instead of the ceiling.

Penthouse Systems might sound fancy (and their initial price tag might reinforce that impression), but they're incredibly practical. By placing the evaporator on the cooler roof with the condensing unit above it, they maximize your interior space. Over time, many of our clients find that the space savings justify the investment—especially in areas where square footage comes at a premium.

Evaporator Profiles, Defrost Methods, Mounting

Evaporators might not get as much attention as their compressor partners, but they're just as crucial to your system's success. Their design affects everything from space utilization to airflow patterns:

Low-Profile Evaporators are like minimalist furniture—they don't intrude much into your cooler space, leaving you maximum headroom for storage. If you're working with limited vertical clearance, these space-savers are worth considering.

Center-Mount Evaporators are all about balance, distributing cold air evenly throughout your cooler. Some models even offer gentler airflow for sensitive items—because sometimes a light breeze is better than a cold wind.

Half-Round Evaporators are the corner specialists, perfect for those oddly shaped or narrow walk-ins where space optimization is key.

When it comes to keeping these evaporators frost-free, you've got several defrost methods to choose from:

Air Defrost uses the room's ambient temperature during compressor off-cycles to naturally melt frost—simple and energy-efficient, but only suitable for medium-temperature coolers above 35°F.

Electric Defrost employs heating elements to melt frost on the coil. It's effective across all temperature ranges but does consume more energy—like using a hair dryer instead of letting something air-dry.

Hot Gas Defrost cleverly redirects hot refrigerant gas from the compressor to the evaporator coil. It's faster than electric defrost and more energy-efficient, making it ideal for freezers. It's like using the heat your system already generates instead of creating new heat.

Electric Warm Fluid Defrost and CO₂ Defrost offer specialized alternatives for specific situations, with the latter being particularly environmentally friendly.

If you're battling evaporator icing issues (a common headache in our industry), check out our practical guide on How to Fix an Iced Evaporator With These 5 Easy Changes.

As for mounting, most evaporators hang from the ceiling, but wall-mounting and (rarely) floor-mounting options exist for special circumstances.

Sizing a Walk-In Cooler Compressor and Evaporator

Sizing your walk-in cooler compressor and evaporator is a bit like buying shoes—too small and you'll be uncomfortable; too large and you'll trip over yourself. An undersized system will struggle to maintain proper temperatures, while an oversized one will short-cycle, wasting energy and wearing out components prematurely.

At American Mortuary Coolers, we don't guess—we calculate based on four key factors:

Box Load considers heat transfer through your cooler's walls, ceiling, and floor. It's affected by the size of your cooler, insulation quality, and the temperature difference between inside and outside. Think of it as your cooler's baseline energy need.

Product Pull-Down accounts for the cooling capacity needed to bring new items down to storage temperature. This is particularly important in mortuary applications, as bodies generate heat during the initial cooling phase—a factor many general refrigeration companies overlook.

Infiltration measures heat gain from air exchange when doors open. If your staff is constantly going in and out, this factor becomes increasingly important in your calculations.

Safety Factor is our way of future-proofing your investment. We typically add 10-15% capacity to account for unexpected loads or changing needs down the road.

For those who love the technical details, we follow industry standards outlined in the latest research on load sizing.

Don't forget about location! Ambient temperature significantly impacts system performance. Your cooling load can jump by 18-20% when outdoor temperatures climb from 80°F to 90°F, and up to 30% when they hit the century mark. That's why our Dallas and Los Angeles installations often require different specifications than those in cooler regions.

Choosing the right walk-in cooler compressor and evaporator system doesn't have to be overwhelming. With our decades of specialized experience in mortuary refrigeration, we'll guide you through the options to find the perfect match for your facility's specific needs—no engineering degree required.

Maintenance, Defrost Strategies & Troubleshooting

Let's face it - your walk-in cooler compressor and evaporator system is a lot like your car. It needs regular check-ups to keep running smoothly, and ignoring those little warning signs can lead to big headaches down the road. At American Mortuary Coolers, we've seen it all across our installations from Florida to Oregon, and we've learned that a little TLC goes a long way.

Preventive Maintenance Checklist

Think of maintenance as an investment, not an expense. A well-maintained system runs more efficiently, lasts longer, and is far less likely to fail when you need it most.

For your staff's monthly checks, focus on the basics: fan blades should be clean and spinning freely, door gaskets should form a tight seal with no tears, and condensate drain lines should flow freely without clogs. Keep an ear out for unusual noises (that grinding sound is never good news!) and verify your temperatures are holding steady.

Twice a year, it's worth bringing in a professional technician for a deeper dive. They'll clean those coils that collect dust and debris, check refrigerant levels (too much or too little can cause problems), and tighten any loose electrical connections that could cause shorts. They'll also calibrate your control settings, verify your compressor's operation, and make sure your expansion valve has proper superheat settings.

This might seem like overkill, but our experience shows that regular maintenance prevents up to 70% of unexpected failures. When you're preserving dignity in final arrangements, that reliability matters.

Common Failure Signs & Quick Diagnostics

Your cooling system often gives warning signs before major failures. Learning to spot these can save you thousands in emergency repairs and prevent those dreaded middle-of-the-night service calls.

Short cycling is when your compressor turns on and off frequently, like someone with a nervous habit. This isn't just annoying – it's hard on your equipment and wastes energy. It usually points to refrigerant issues, a dirty condenser coil, control problems, or an oversized system working too hard for the space.

If your system is drawing high amperage, something's making your equipment work harder than it should. This could be failing compressor bearings, excessive pressure in the system, voltage problems, or too much refrigerant circulating through the lines.

When you see ice building up on your evaporator like in the image above, your defrost system might be failing, someone's leaving the door open too long, humidity is getting in, or your cabinet has air leaks. This ice acts like a blanket, preventing your evaporator from doing its job properly.

A compressor that's overheating will eventually shut down on thermal overload. Check if your condenser fan is running, look for refrigerant restrictions, and listen for unusual noises – a whistling sound often means trouble brewing inside.

If temperatures inside your cooler are warmer than they should be, first check the basics: Are the evaporator fans running? Is the evaporator coated in ice? Is there enough refrigerant in the system? Are door seals letting warm air sneak in?

The simplest explanation is often the right one. Before assuming you need a new compressor (a costly repair), check for dirty coils or refrigerant issues – these fixable problems are frequently the real culprits.

Defrost Options Explained

Frost on your evaporator is like cholesterol in your arteries – a little might not hurt, but let it build up and you've got problems. Different defrost methods work better in different situations:

Air defrost is the no-frills option that works well for medium-temperature coolers (above 35°F). It simply uses room temperature air during compressor off-cycles to melt any frost. It's energy-efficient but won't cut it for freezers or humid environments.

Electric defrost uses heating elements to melt frost from the coil – like the defrost feature in your home freezer. It's reliable and works in all temperatures, but it's slower and uses more electricity than other methods.

Hot gas defrost is like recycling – it redirects hot gas from your compressor to melt ice on the evaporator. It's fast and energy-efficient but requires more complex installation and additional components.

Electric warm fluid and CO₂ defrost systems are specialty options for specific applications. They offer benefits like environmental friendliness and efficiency but come with higher costs and complexity.

How often should you defrost? It depends. Medium-temperature coolers typically need 2-4 defrost cycles daily, while freezers might need 3-6 cycles. Modern systems often use demand defrost, which is like having a smart thermostat – it only runs defrost cycles when actually needed, not on a rigid schedule.

At American Mortuary Coolers, we customize defrost strategies for each installation. A cooler in humid Miami needs different settings than one in arid Arizona, and we account for these regional differences in every system we install.

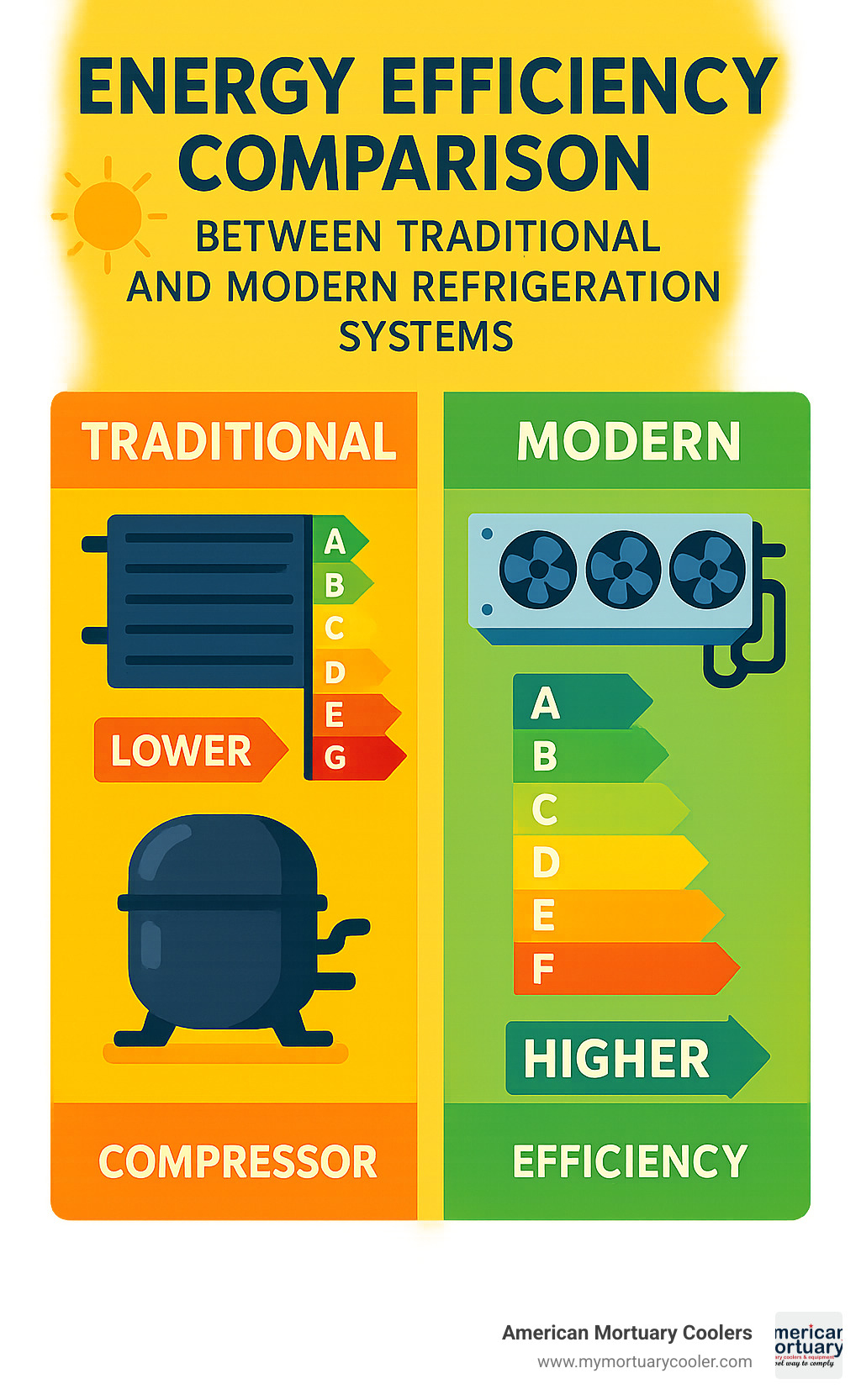

Energy Efficiency & Emerging Technologies

Let's talk about saving money while saving the planet. As energy bills keep climbing and environmental regulations tighten, the efficiency of your walk-in cooler compressor and evaporator system matters more than ever. Here at American Mortuary Coolers, we're passionate about helping funeral homes across America—from the humid Southeast to the dry Southwest—reduce their energy footprint without sacrificing performance.

The Energy Independence and Security Act (EISA) has been a game-changer, requiring high-efficiency motors in all new commercial walk-ins. But that's just the beginning of what's possible in refrigeration efficiency.

Remember when refrigeration systems were energy hogs that made your electric meter spin like a carnival ride? Those days are thankfully behind us. Today's walk-in cooler compressor and evaporator systems can be remarkably efficient, using a combination of smart technology and improved components.

High-efficiency motors have transformed the industry, cutting energy use by 15-20% compared to their predecessors. They're not just better for your utility bill—they run cooler and last longer too. It's like upgrading from a gas-guzzling truck to a hybrid; the savings add up month after month.

When we install systems with variable-speed fans, our clients are often amazed at the difference. Instead of blasting at full power all day, these intelligent fans adjust their speed based on actual cooling needs. This simple change can slash fan energy consumption by up to 40% while actually improving temperature stability. It's like having a smart assistant that only works as hard as needed.

The refrigerant revolution is also well underway. Traditional refrigerants like R-404A are being phased out due to their high global warming potential. Newer alternatives like R-448A and R-449A deliver similar cooling performance with a much smaller environmental footprint. Many of our newer systems are designed with these greener refrigerants in mind.

Electronic expansion valves might sound technical, but their benefit is simple: they're much smarter than old mechanical valves. By precisely adjusting refrigerant flow in real-time, they improve system efficiency by 10-15% and maintain more consistent temperatures. Think of them as the difference between a dimmer switch and a regular on/off light switch—much more precise control.

The brains of modern cooling systems have gotten a major upgrade too. Smart controls can optimize everything from defrost cycles to fan operation based on actual conditions rather than rigid schedules. We've seen these systems cut energy use by 15-30% in real-world applications. They're particularly valuable in funeral homes where cooling demands can vary widely throughout the week.

For our clients who accept technology, IoT monitoring has been a revelation. Internet-connected sensors track system performance, send alerts when something needs attention, and provide valuable data for ongoing optimization. One funeral director told me it was like having a 24/7 refrigeration technician on staff, minus the salary.

Some of our more innovative installations include heat recovery systems that capture the warmth rejected by the condenser and repurpose it for water heating or space heating. It's a beautiful bit of efficiency—using the "waste" heat from cooling to reduce heating costs elsewhere in the building.

The future looks even more exciting. We're keeping our eyes on several emerging technologies:

Transcritical CO₂ systems use carbon dioxide as a refrigerant, offering excellent environmental benefits. Magnetic refrigeration technologies are developing rapidly, potentially eliminating traditional refrigerants entirely. Predictive analytics can spot potential failures before they happen, and phase-change materials help stabilize temperatures while reducing compressor cycling.

When we sit down with funeral directors to discuss upgrades or new installations, we recommend focusing on efficiency features with the quickest payback. For most of our clients, the winning combination includes high-efficiency motors, smart controls, and properly sized systems matched to their specific needs.

The bottom line? A more efficient walk-in cooler compressor and evaporator system isn't just good for the environment—it's good for your bottom line too. And in the funeral business, where every dollar counts, that matters a whole lot.

Frequently Asked Questions about Walk-In Cooler Compressors and Evaporators

I've spent years helping funeral directors across America with their refrigeration questions. From busy urban facilities in New York to small-town funeral homes in Tennessee, the same questions about walk-in cooler compressor and evaporator systems come up time and again. Let me share some straight answers to what you're probably wondering too.

What is the lifespan of a walk-in cooler compressor and evaporator?

"How long will this thing last?" is usually the first question folks ask me when I'm installing a new system.

The truth is, with proper care, a quality compressor should serve you faithfully for 8-12 years, while evaporators often keep going for 10-15 years or even longer. I've seen systems in our Pittsburgh and Chicago locations still running smoothly well past their "expiration date" because their owners took maintenance seriously.

What really determines longevity? First, regular professional service makes an enormous difference - it's like getting oil changes for your car. Second, how you use the system matters - steady, consistent operation is easier on components than constant starting and stopping. Third, proper initial installation prevents premature wear and tear - a correctly sized system experiences less stress. And finally, your facility's environment plays a role - extreme heat or corrosive conditions can shorten equipment life.

How often should defrost cycles run in a medium-temperature cooler?

For standard medium-temperature walk-ins (35°F to 45°F), you'll typically want defrost cycles 2-4 times daily, with each cycle lasting about 15-30 minutes. But there's no one-size-fits-all answer here.

If your facility is in humid Miami, you'll need more frequent defrost cycles than a similar cooler in dry Phoenix. Likewise, a busy cooler with the door opening constantly needs more defrosting than one that's rarely accessed. Even what you're storing matters - items with high moisture content can increase humidity levels inside.

I'm particularly fond of modern demand defrost systems, which are smart enough to initiate defrost cycles only when actually needed. They monitor temperature differences across the coil or use other sensors to determine when frost is building up. This approach saves energy and ensures your system runs at peak performance - a win-win in my book.

Can I upgrade to a scroll compressor without changing the evaporator?

"Can I just swap out the compressor for a better one?" This question comes up often when folks are looking to improve efficiency without a complete overhaul.

In many cases, yes, you can upgrade to a scroll compressor while keeping your existing evaporator - but there are important considerations. The new scroll compressor must be capacity-matched to your evaporator. Both components need to use the same refrigerant. The oil types must be compatible (scroll compressors often use different oils than reciprocating models). And your control systems might need adjustments to work properly with the new compressor.

Before making this change, I always recommend getting a professional assessment. At American Mortuary Coolers, we evaluate existing systems to ensure any upgrades maintain proper system balance. An improperly matched system can lead to headaches like poor temperature control and premature failure - problems I'd rather help you avoid!

What's the difference between air defrost and electric defrost?

This question often comes from clients trying to understand their defrost options, especially when upgrading.

Air defrost is the simpler approach - it uses ambient air during compressor off-cycles to melt frost naturally. It's more energy-efficient since no additional heating elements are needed, but it's only effective in medium-temperature applications (above 35°F). The process is slower, typically taking 30-45 minutes, but requires no additional components.

Electric defrost, on the other hand, uses heating elements to actively melt frost. It works in all temperature ranges (including freezers), melts frost faster (usually 15-30 minutes), but consumes more energy and requires additional components like heaters and controls.

For most funeral homes with coolers operating above 35°F in moderate humidity conditions, I typically recommend air defrost for its simplicity and energy savings. But if you're running a freezer or dealing with high humidity, electric or hot gas defrost becomes necessary.

How do I know if my walk-in cooler compressor is failing?

Your compressor usually gives warning signs before it fails completely. Think of these as your refrigeration system crying for help!

Listen for unusual noises like grinding, knocking, or squealing - these often precede failure. Watch for frequent cycling where the compressor runs briefly then shuts off repeatedly. Feel the discharge line - if it's unusually hot, that's concerning. Look for oil leaks around the compressor itself. Monitor your electric bill for spikes that might indicate high amperage draw. Pay attention if your cooler struggles to maintain proper temperature despite running constantly. Be concerned if you're resetting circuit breakers frequently or if the compressor keeps shutting down from overheating.

If you notice any of these symptoms, please don't wait - call a professional immediately. Early intervention can sometimes save the compressor or at least prevent collateral damage to other system components. I've seen too many small problems become expensive disasters because someone hoped the issue would resolve itself.

At American Mortuary Coolers, we believe preventive maintenance is always more affordable than emergency repairs - especially when you're responsible for maintaining dignity in death care services.

Conclusion

Understanding the intricacies of walk-in cooler compressor and evaporator systems isn't just technical knowledge—it's essential wisdom for anyone responsible for commercial refrigeration, especially in specialized fields like mortuary services. Throughout this guide, we've walked together through the fundamentals, component options, maintenance approaches, and exciting new technologies that keep these critical systems running smoothly.

Here at American Mortuary Coolers, we've spent years getting our hands dirty designing, installing, and servicing custom mortuary refrigeration systems across the country. From our home base in Johnson City, TN, we've traveled to the far corners of America—from the humid Southeast to the arid Southwest, from the frigid Northeast to the temperate Pacific. Along the way, we've encountered just about every configuration and challenge a walk-in cooler can throw at us.

What have we learned from all this experience? A few critical lessons stand out:

First and foremost, system harmony matters enormously. Your compressor and evaporator need to work together like dance partners, perfectly matched in capacity and compatible in refrigerant types. When one component outpaces the other, the whole system suffers.

We've also seen time and again that proper sizing makes all the difference. An undersized system will struggle constantly, never quite reaching the temperatures you need. Meanwhile, an oversized system wastes energy and money through constant short cycling—like driving with one foot on the gas and one on the brake.

Nothing preserves performance like regular, thoughtful maintenance. The walk-in coolers that have served our clients for decades beyond their expected lifespan all share one thing in common: owners who invested in consistent professional service. It's much like healthcare—preventive checkups are always less costly than emergency surgery.

In today's energy-conscious world, efficiency improvements offer immediate returns. Modern technologies like scroll compressors, variable-speed fans, and intelligent control systems aren't just good for the planet—they're good for your bottom line, often paying for themselves through reduced energy bills.

We've also learned that your defrost strategy dramatically impacts performance. The right approach for your specific application ensures optimal efficiency and rock-solid temperature stability—critical for mortuary applications where precise temperatures are non-negotiable.

Perhaps most importantly, early intervention prevents disasters. Learning to recognize the warning signs of component issues allows for timely repairs before small problems cascade into catastrophic failures.

When you're selecting or upgrading a walk-in cooler system, we strongly recommend consulting with specialists who truly understand your unique requirements. At American Mortuary Coolers, we take pride in providing durable, custom solutions with direct delivery across the lower 48 states.

Our specialized knowledge in mortuary refrigeration ensures that funeral homes receive systems that maintain precise temperatures, operate reliably day after day, and meet all regulatory requirements without exception. For deeper insights into our specialized cooling solutions, please visit our comprehensive resource on mortuary coolers.

A thoughtfully designed and properly maintained walk-in cooler compressor and evaporator system does more than just preserve your valuable contents—it minimizes energy consumption, reduces operating costs, and provides peace of mind. By applying the knowledge we've shared in this guide, you can make confident decisions that lead to better performance, longer equipment life, and a healthier bottom line for years to come.