Why Cooler Doors Are Critical for Temperature Control and Energy Savings

Cooler doors are specialized insulated barriers designed to seal walk-in refrigeration units while providing access for personnel and equipment. These doors serve as the primary defense against temperature loss, air infiltration, and energy waste in commercial cold storage applications.

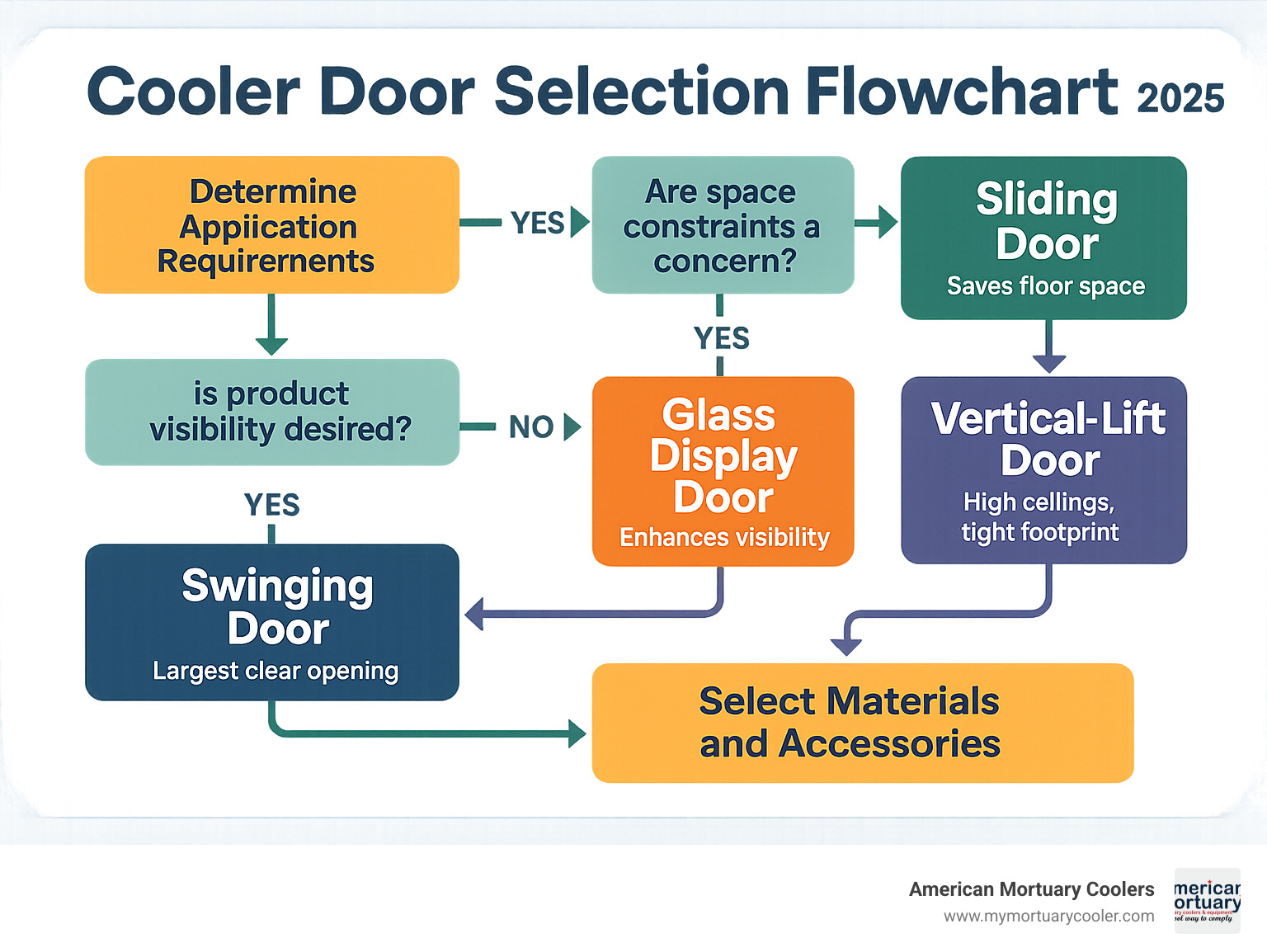

Key Types of Cooler Doors:

- Swinging doors - Most common, provide largest clear opening for easy loading

- Sliding doors - Save floor space when swing clearance is limited

- Glass display doors - Improve product visibility while maintaining energy efficiency

- Vertical-lift doors - Ideal for high ceilings and tight floor footprints

Primary Benefits:

- Prevent warm air infiltration that increases compressor runtime

- Retrofit glass doors can save 68-80% on energy costs compared to open cases

- Maintain optimal temperatures (35°F-41°F for coolers, -10°F to 0°F for freezers)

- Meet DOE and EISA 2017 compliance standards for commercial refrigeration

The right cooler door choice depends on your space constraints, traffic patterns, product visibility needs, and energy efficiency goals. Poor door selection leads to temperature fluctuations, higher utility bills, and compromised product quality.

With over 30 years of experience in cold storage solutions, American Mortuary Coolers is a national-level mortuary cooler supplier specializing in cooler doors for funeral homes, medical facilities, and commercial applications. We've helped hundreds of facilities select the optimal door configuration to balance operational efficiency with long-term durability.

Quick cooler doors definitions:

Understanding Cooler Doors: Types and Applications

When shopping for cooler doors, you'll find options beyond basic hinged panels. Each door type serves different needs across industries - from convenience stores showcasing beverages to restaurants managing inventory, and mortuaries requiring specialized preservation solutions.

Modern cooler door technology offers versatility. Swinging doors remain the industry workhorse, while sliding doors solve space problems. Glass display doors transform hidden walk-in coolers into merchandising tools, and vertical-lift doors offer solutions for unique space constraints.

At American Mortuary Coolers, we've seen how different industries have vastly different door requirements. Florists need easy access to delicate arrangements, warehouses prioritize forklift traffic flow, convenience stores want maximum product visibility, and restaurants need doors handling constant opening during busy periods.

Mortuary applications require reliability and dignified operation. When we design cooler doors for funeral homes, we consider both temperature control and the sensitive environment, ensuring dependable performance.

Swinging vs. Sliding Door Basics

Swinging doors excel in clear opening size and ease of operation. They're ideal when you have adequate floor space for door swing and need maximum access width. Most swinging cooler doors include heavy-duty cam-lift hinges, magnetic gaskets, and self-closing mechanisms for automatic temperature integrity.

Swinging doors shine during busy periods - whether wheeling delivery carts or carrying multiple items, the wide-open doorway simplifies everything. Simple mechanics mean fewer potential problems over time.

Sliding doors excel when swing clearance is limited. With narrow aisles, nearby equipment, or limited floor space, sliding doors conserve precious floor space while providing good cooler access.

Manual vs. powered operation changes workflow dramatically. Manual sliding doors work for moderate traffic, but powered sliding doors with motion sensors suit high-traffic environments. Forklift traffic flows smoothly without operators stopping to manually open doors - efficiency that pays for itself quickly.

Glass Display Door Advantages

Glass display doors transform walk-in coolers from hidden storage into active sales tools. Product visibility alone can boost sales significantly, while modern glass technology maintains energy efficiency.

Today's glass doors feature Low-E glass with coatings maximizing visibility while minimizing heat transfer. Anti-fog technology keeps glass crystal clear in humid conditions, and heated frames prevent condensation around door edges.

Most glass cooler doors include seven-shelf systems attaching to door frames, creating stable display space. Perfect for convenience stores displaying beverages, restaurants showcasing desserts, or any business where presentation matters.

Low-E coatings and argon-filled panes create invisible barriers keeping cold air in while allowing perfect product visibility. Advanced glass doors often outperform solid doors in energy savings when factoring reduced opening frequency.

Vertical-Lift & Specialty Mortuary Cooler Doors

Vertical-lift doors solve seemingly impossible problems. With limited floor space but plenty of overhead clearance, these doors lift straight up. The space efficiency is remarkable - full cooler access without floor obstruction.

For mortuary applications, door selection involves considerations beyond standard commercial requirements. Body storage demands doors maintaining precise temperatures while providing dignified, reliable access. Our specialized mortuary cooler doors meet strict compliance requirements while ensuring dependable operation.

Mortuary cooler doors incorporate reinforced construction for heavy-duty use, specialized gasket systems for superior sealing, and finishes maintaining professional appearance while resisting wear. These doors must perform flawlessly when families depend on you most.

Mortuary doors are built for longevity. While convenience stores might replace doors every decade, funeral homes need decades of reliable operation. We focus on heavy-duty construction, premium materials, and time-tested designs.

Key Features, Materials & Insulation Technology

When shopping for cooler doors, construction quality determines whether you get decades of reliable performance or maintenance headaches. Most walk-in cooler doors feature 4-inch thick insulation panels acting as thermal barriers between controlled environments and outside conditions.

Polyurethane foam remains the gold standard for cooler door insulation, achieving impressive R-32 ratings that exceed R-25 requirements for coolers and meet Energy Independence and Security Act standards. Polyurethane expands to fill every gap during manufacturing, creating seamless thermal barriers.

For high moisture or extreme conditions, extruded foam insulation offers superior performance, particularly valuable in car washes, food processing, or facilities with fluctuating humidity levels.

Door construction uses a sandwich approach - inner and outer metal skins with insulation core between. Outer skin options include stucco embossed galvanized steel for budget applications, painted surfaces for specific colors, and stainless steel for premium installations prioritizing hygiene and appearance.

At American Mortuary Coolers, we've seen how material choice affects long-term satisfaction. Funeral homes often prefer stainless steel finishes maintaining professional appearance after years of use, while budget-conscious facilities find galvanized steel performs well when properly maintained.

Essential hardware includes magnetic gaskets creating airtight seals, cam-lift hinges supporting heavy doors smoothly, and kick plates protecting door bottoms from damage.

How Cooler Doors Contribute to Energy Efficiency

Cooler doors prevent air infiltration forcing compressors to work overtime. Every time warm air enters your cooler, refrigeration systems work harder and longer to maintain temperature, driving up energy costs.

Installing retrofit glass doors on open refrigerated cases can save 68-80% on energy costs compared to open cases. Properly designed doors can cut refrigeration energy use by more than half by eliminating constant air exchange plaguing open display cases.

DOE and EISA 2017 compliance ensures modern cooler doors meet federal efficiency standards while often qualifying for utility rebates and tax incentives, improving return on investment.

Energy efficiency comes from creating multiple air leakage barriers. High-quality magnetic gaskets form primary seals, while double-sweep gaskets provide backup protection. Proper door alignment ensures consistent sealing around entire perimeters.

Scientific research on insulation performance provides detailed data on door configuration performance under various conditions.

Walk-In Cooler Glass Door Feature Set

Modern glass cooler doors perfectly marry form and function. Ultra-clear glass provides maximum product visibility while Low-E coatings reduce heat transfer without affecting clarity.

Argon-filled glass improves thermal performance by replacing regular air with denser, less conductive gas between panes, improving insulation without adding bulk or compromising visibility.

Heavy-duty shelving systems integrate directly with glass doors, typically providing seven shelves per door securing to frames for stability. High-output LED lighting illuminates products effectively while generating minimal heat.

Heated frames prevent condensation around door perimeters without heating glass itself, maintaining clear visibility while preventing ice formation in freezer applications using replaceable anti-condensate heat wire.

For upgrading existing installations, replacement walk-in cooler doors offer modern efficiency without complete system replacement.

Sizing, Customization, Installation & Maintenance

Getting the right fit for cooler doors requires understanding how proper sizing, customization, and installation work together for years of smooth operation.

Most cooler doors follow industry standards making planning easier. Common sizes include 30" x 80" for display applications, 36" x 80" for beer caves, and up to 60" wide for moving pallets and large equipment. Manual sliding systems can span up to 20 feet for warehouse forklift access.

The most popular man-door width is 33 inches, providing comfortable movement while maintaining structural integrity. French-style doors add appeal for customer-facing areas without sacrificing thermal performance.

Measuring & Selecting the Right Size

Accurate measurements prevent installation headaches and ensure proper sealing and operation. You need rough opening dimensions, clearance for door operation, and adequate vertical space.

For plug doors, 36" x 78" doors typically need 33.5" x 78" rough openings, while jamb frame installations require 37" x 80" openings. These extra inches account for frame thickness and installation clearance.

Door swing clearance becomes critical in tight spaces. Sliding doors eliminate swing concerns but need adequate wall space when fully open. All doors need clearance for operation and maintenance access.

Customization Options

Cooler doors come in standard sizes, but customization addresses specific needs. Options include specific colors, diamond-plate kick guards for heavy-duty use, windows for visibility, or logo etching for branding.

Standard sizes range from 30" x 78" up to 60" x 84", with custom doors available for larger openings when structure allows.

Finish options include food-grade appliance white for hygienic environments, stainless steel for premium applications, and various painted finishes matching facility aesthetics.

Installation & Accessories

Pre-hung frames simplify installation by providing complete door assemblies ready to mount. Hydraulic closers ensure doors close completely, preventing temperature loss from doors left ajar.

Kason hardware represents industry standards for commercial cooler doors, offering proven reliability and extensive parts availability. More info about hinges provides detailed hardware selection guidance.

Maintenance for Longevity

Regular maintenance keeps cooler doors performing efficiently. Monthly gasket inspections should check for tears, gaps, or magnetic seal loss allowing air infiltration.

Hinge lubrication prevents binding and extends hardware life, especially important in freezer applications where moisture causes corrosion. Use food-grade lubricants where contamination is a concern.

Seasonal checks before and after summer help catch problems before they become critical, as higher ambient temperatures stress refrigeration systems.

More info about door hardware covers comprehensive maintenance procedures.

Retrofitting Existing Doors

Plug door kits simplify replacement projects with complete assemblies designed for existing openings. Overlap doors with face case frames work for many walk-in brands when exact replacements aren't available.

Field measurements require precision for proper fit and performance. Professional measurement services eliminate risks while ensuring optimal results.

More info about replacement doors provides detailed replacement project guidance.

Compliance, Cost Considerations & Industry Use Cases

Understanding compliance requirements and cost structures helps make smart cooler doors decisions that won't break budgets or create regulatory issues.

DOE 2017 and EISA 2007 standards establish minimum energy efficiency requirements for commercial cooler doors. CSA certification ensures doors meet safety and performance standards, important for insurance and liability concerns.

Cooler doors typically range from $1,200 for basic swinging doors up to $7,700 for large electric sliding units. Most facilities find themselves in the $2,000-$4,000 range, depending on size, features, and customization.

Applications span industries: convenience stores rely on glass display doors for beverage merchandising, breweries need specialized beer cave configurations, mortuaries require doors balancing dignity with reliability, and floral shops need doors protecting delicate arrangements while allowing easy access.

Regulatory Standards

Certification labels prove compliance when inspectors arrive. DOE certification databases allow verification of product compliance and energy performance ratings.

Properly certified doors typically pass standard requirements without issues. Many jurisdictions offer rebates for high-efficiency installations, significantly improving project economics through reduced grid demand recognition.

Cost Ranges & ROI

Material choices create the biggest price variations. Basic steel construction keeps costs down, while stainless steel or specialty configurations command premium prices. Glass doors typically cost more than solid doors due to specialized glass and complex framing.

Manual versus powered systems create substantial cost differences. Powered systems need electrical connections and control systems but often provide better long-term value in high-traffic applications.

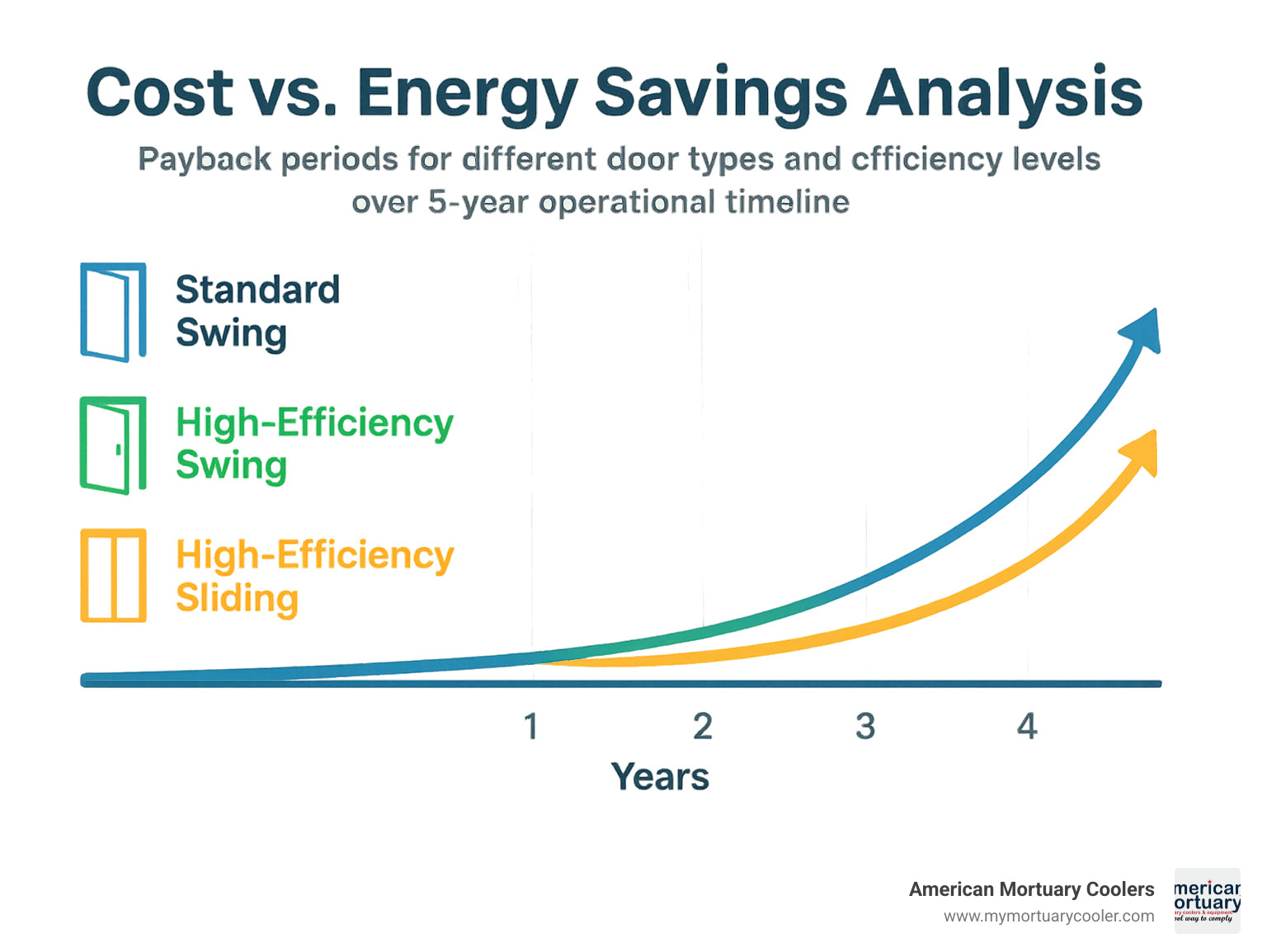

Return on investment for energy-efficient cooler doors typically occurs within 2-3 years through reduced energy costs. That 68-80% energy savings with retrofit glass doors makes compelling financial sense.

Technology Innovations

The cooler doors industry continues evolving with exciting innovations. Motion-activated LED lighting provides illumination only when needed, reducing energy consumption while ensuring product visibility.

Triple-pane argon-filled glass represents cutting-edge display door technology, providing superior insulation compared to standard double-pane configurations while maintaining excellent visibility.

Energy-free frames eliminate anti-condensate heater needs through advanced design and materials preventing condensation without electrical input, reducing operating costs while maintaining performance.

At American Mortuary Coolers, we're particularly excited about innovations improving reliability and reducing maintenance requirements for funeral home operations.

Frequently Asked Questions about Cooler Doors

What maintenance schedule keeps cooler doors performing at their best?

Consistent maintenance is key to long-lasting cooler doors. Monthly tasks include checking door gaskets for tears, gaps, or weak magnetic seals. Replace damaged gaskets immediately - waiting costs more in energy bills than gasket replacement.

Every three months, lubricate hinges with food-grade lubricant, especially important in freezer applications where moisture causes corrosion.

Twice yearly - before and after summer - schedule comprehensive checks including cleaning condenser coils, checking fan blades, and verifying door alignment hasn't shifted.

How do cooler doors meet DOE/EISA efficiency standards?

Modern cooler doors meet federal standards through impressive engineering. Foamed-in-place polyurethane insulation achieves R-32 ratings, significantly better than R-25 minimum requirements.

Advanced gasket systems create multiple air leakage barriers using magnetic gaskets combined with double-sweep gaskets sealing around entire door perimeters.

Products meeting these standards often qualify for utility rebates and tax incentives, helping offset costs while providing better performance.

Can I install cooler doors myself or should I hire a professional?

While simple plug door replacements might look straightforward, professional installation pays for itself. Proper alignment and sealing require specialized knowledge and tools most facilities don't have.

Complex installations like sliding doors or glass display systems absolutely require professional expertise involving electrical connections, control systems, and safety considerations.

Professional installers understand local codes and requirements varying by location and application, spotting potential problems before installation and ensuring proper integration with existing refrigeration systems.

Conclusion

Choosing the right cooler doors doesn't have to be overwhelming. The key is understanding what matters most for your specific situation - whether running a convenience store, managing a funeral home, or operating a warehouse facility.

The numbers tell a compelling story. Quality cooler doors, especially retrofit glass installations, offer potential energy savings of 68-80% compared to open cases. That's money back in your pocket, typically within 2-3 years.

Your decision comes down to key factors covered in this guide. Door type matters - swinging doors for maximum access, sliding doors for tight spaces, glass display doors for merchandising, or vertical-lift doors for unique layouts. Size and space constraints often make decisions, while insulation performance and energy efficiency ratings determine long-term operating costs.

Material choices affect both upfront costs and durability. Steel construction offers reliability at reasonable prices, while stainless steel provides premium performance. Glass doors cost more initially but often pay for themselves through improved sales and energy savings.

Compliance requirements aren't just regulatory problems - they're assurance you're getting efficient doors that may qualify for rebates or tax incentives.

Installation complexity varies dramatically. Simple plug door replacements might seem manageable, but professional installation ensures proper alignment, sealing, and long-term performance. Complex systems absolutely require professional expertise.

At American Mortuary Coolers, we've seen how the right cooler doors transform operations. Our custom solutions accommodate unique mortuary facility requirements, where reliability isn't just about energy savings - it's about maintaining dignity and professionalism during sensitive times.

We deliver custom cooler doors nationwide across the contiguous 48 states, working directly with funeral homes, medical facilities, and commercial operations needing specialized solutions. Our Tennessee-based team understands every facility has unique requirements, crafting solutions meeting specific needs.

Whether upgrading for better energy efficiency, expanding facilities, or replacing doors reaching end of service life, investing in quality cooler doors pays dividends for years. Reduced energy costs, improved temperature control, and reliable operation make the difference between facilities struggling with efficiency and those operating smoothly.

More info about preservation door choices provides additional guidance for funeral homes and medical facilities where preservation quality and operational reliability are critical.

The bottom line: quality cooler doors are investments, not expenses. Choose thoughtfully based on specific needs, install professionally for optimal performance, and maintain properly for years of reliable service. Your facility, energy bills, and peace of mind will thank you.