Understanding the Cremation Oven: A Quick Look

When you search for "oven for cremation," you're likely looking for answers about what these specialized units are and how they work. Here's a quick overview:

- What it is: A cremation oven, also called a retort, is a high-temperature furnace.

- Its purpose: It's designed to reduce human or animal remains to bone fragments (cremated remains).

- How hot it gets: These ovens typically operate between 1400 and 1800 degrees Fahrenheit, with an optimal temperature often around 1650 degrees Fahrenheit.

The oven for cremation is a vital piece of equipment in the modern death care industry. It's a highly engineered, high-temperature chamber. Its main job is to transform a body into bone fragments through intense heat. This process is known as cremation.

These specialized ovens, sometimes called retorts, are built for precision and safety. They reduce organic matter efficiently and respectfully. Understanding how they work is key to appreciating the cremation process.

How a Cremation Oven Works: The Science of Heat

Have you ever wondered what truly happens inside an oven for cremation? It's more than just turning up the heat! At its heart, every cremation relies on incredibly precise thermal science. This isn't just about high temperatures; it’s about a carefully controlled environment that ensures a respectful and thorough process.

If you peeked at a digital control panel, you’d see some impressive numbers. The main cremation chamber typically operates between 1400 and 1800 degrees Fahrenheit. Many facilities, including those we partner with, aim for an optimal operating temperature of around 1650 degrees Fahrenheit. This specific heat range is essential for effectively reducing organic materials to bone fragments.

So, how do we get things so hot? Most modern cremation ovens use powerful burners fueled by either natural gas or propane. These burners don't just "burn" in the common sense. They create a process called oxidation. Think of it like a very efficient, controlled reaction where high temperatures and specific airflow work together. This causes the organic matter to gently vaporize, leaving behind only the skeletal structure.

A modern oven for cremation isn't a single big box. It's usually a clever two-chamber system. First, there's the primary combustion chamber. This is where the deceased, carefully placed in a combustible container, begins the process. It’s where the main change happens.

Then, there's the secondary combustion chamber, often called an afterburner. This chamber is located above or behind the primary one and often reaches even higher temperatures, sometimes between 1600-1800 degrees Fahrenheit. Its role is incredibly important for our environment. It ensures that any gases or tiny particles from the primary chamber are fully combusted. This means only clean, clear air is released, meeting strict environmental standards.

The entire journey, from loading to initial cool-down, is called the cremation cycle. How long does it take? Typically, a cycle lasts between 60 to 90 minutes. Some advanced models can finish in as little as 60 minutes, while others might take 75 to 90 minutes. A few things can influence this timing, such as the body mass (some ovens can accommodate cases up to 1000-1200 lbs!) and the type of container used. Our goal is always to balance efficiency with the utmost dignity and respect for the process.

The Anatomy of an Oven for Cremation

When you peek inside an oven for cremation, you're looking at something pretty remarkable. This isn't just a big metal box with a burner – it's a carefully engineered piece of equipment built to handle extreme conditions day after day.

The construction materials used in these ovens are nothing like what you'd find in your home furnace. We're talking about fire-resistant bricks and special masonry that can laugh in the face of temperatures that would melt copper. These high-alumina silicate firebricks are the real heroes here – they can handle heat well over 3,000 degrees Fahrenheit without breaking a sweat.

The interior of every oven for cremation gets lined with these specialized bricks, creating a protective barrier that contains all that intense heat. The bottom part, called the hearth, often features what's known as a hot hearth design. This isn't just fancy terminology – it means the floor of the oven is built from specially formulated materials that can take direct contact with the intense flames and heat.

But the engineering doesn't stop there. The whole structure sits on a robust steel frame that provides the backbone for all this heavy-duty construction. Think of it like the skeleton that holds everything together, made from thick steel that's been welded and reinforced to handle the weight and stress.

One of the most important design features is the wall thickness. These aren't thin walls – we're talking about 6-inch thick walls with a refractory lining that creates multiple layers of protection. This thickness serves several purposes: it keeps the incredible heat contained where it belongs, protects anyone working nearby, and helps the oven run more efficiently by preventing heat loss.

The chamber system is where the real magic of engineering shows. The primary chamber is where the deceased is respectfully placed, and it's designed to distribute heat evenly throughout the space. But there's also a secondary chamber – sometimes called an afterburner – that plays a crucial role in emissions control.

This secondary chamber operates at even higher temperatures than the primary one. Any gases or particles that come from the primary chamber get drawn into this second space, where they're completely burned up. It's like having a second line of defense to make sure everything is handled cleanly and respectfully.

Every piece of this puzzle, from the interlocking bricks to the precise insulation placement, works together to create an oven for cremation that operates safely and efficiently while maintaining the dignity that families deserve during such an important time.

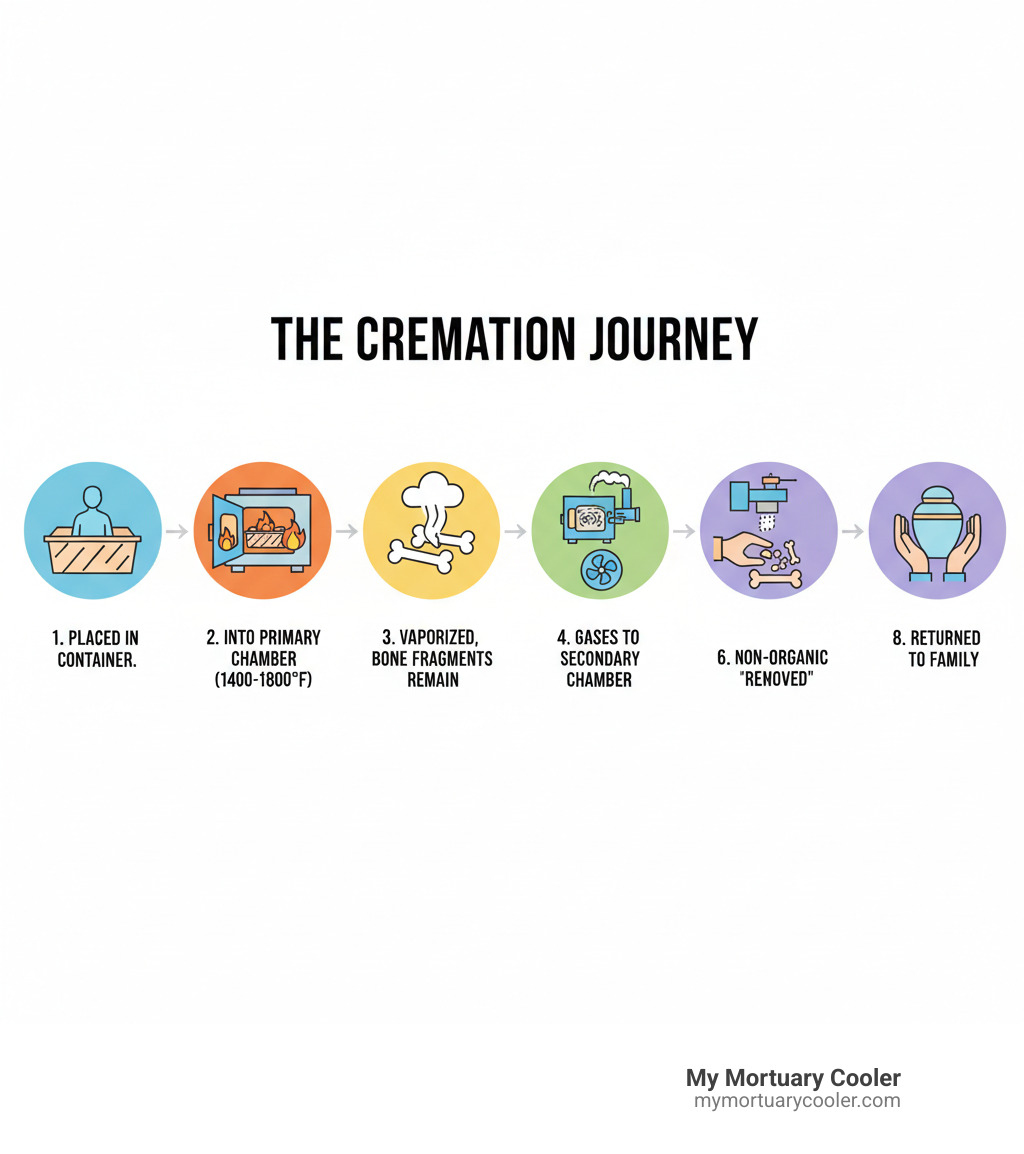

The Step-by-Step Cremation Process

The journey of a loved one through the cremation process is truly a testament to meticulous care and profound dignity. Every single step is carefully managed, guided by strict protocols and advanced equipment. It’s a thoughtful sequence designed to ensure the utmost respect, safety, and the accurate return of cremated remains to the family.

Deceased Preparation

Before any cremation can begin, careful preparation is absolutely essential. This starts with positive identification of the deceased. This step is paramount and usually involves several checks to make absolutely sure everything is accurate. It's about respecting the individual and ensuring there are no mix-ups.

Another important part of preparation involves medical devices. Things like pacemakers, which can unfortunately explode at high temperatures, or other battery-powered implants, must be carefully removed. It’s a safety measure for the staff and the equipment. Usually, jewelry and other personal items are also removed and returned to the family, unless they’ve specified otherwise.

Placement in a Cremation Container

Next, the deceased is always placed within a rigid, combustible container before entering the oven for cremation. This isn't just for practicality; it serves several vital purposes. It ensures dignified handling and placement, helps maintain sanitary conditions, and makes the transfer into the oven safe and smooth. These containers are often made from materials that burn away completely during the process, like fiberboard, unfinished wood, or heavy cardboard. They are specifically designed to be respectful and efficient.

Loading the Oven

With the deceased respectfully resting in their container, the next step is to gently load them into the primary chamber of the oven for cremation. Modern crematories use specialized equipment for this, often a mechanized charging door or a dedicated crematory charger. These robust chargers can gracefully handle cases weighing up to 1000 lbs. This mechanized approach ensures a smooth, dignified, and safe transfer into the high-temperature environment. The operator is always present, carefully monitoring the process to ensure perfect positioning within the chamber.

The Cremation Cycle

Once inside, the magic of the cremation cycle begins. The intense heat, typically humming between 1400 and 1800 degrees Fahrenheit, starts the reduction process. It's a fascinating change:

Vaporization of Organic Matter: The organic tissues of the body – muscles, organs, and fat – gently vaporize through a process of combustion and oxidation. They transform into gases and water vapor, which are then smartly directed to the secondary combustion chamber. This second chamber ensures these gases are fully processed before being released, keeping our environment clean.

What Happens to Non-Organic Implants: Now, what about those things that aren't organic? Items like surgical implants (think hip or knee replacements made of tough titanium or cobalt-chrome alloys), dental fillings, or even gold jewelry (if it wasn't removed beforehand) are made of materials that aren't consumed by the heat. They simply remain. These materials are unaffected by the extreme temperatures and will be carefully separated from the bone fragments later in the process.

Cool-Down and Retrieval

After the main cremation cycle gracefully concludes, the oven for cremation enters a cool-down period. Once the chamber has cooled down sufficiently for handling, the remaining bone fragments are very carefully swept from the hearth. This collection is done with immense care and precision, making sure that all recoverable remains are gathered. It's a delicate process to ensure nothing is missed.

Processing the Remains

The retrieved bone fragments are not quite the "ashes" families receive just yet. At this stage, they are still coarse and might contain some of those non-organic materials we mentioned. These fragments are then transferred to a specialized piece of equipment called a cremated remains processor (you might hear it called a pulverizer or cremulator). This clever machine gently reduces the bone fragments to a uniform, fine, granular consistency. Imagine something similar to coarse sand or crushed stone – that’s the texture. This processing step is usually quite quick, often taking about 30 seconds or even less. During this important stage, any remaining non-organic materials, like those surgical implants, are identified and carefully separated. The final, beautifully processed remains are then respectfully placed into a temporary urn or the family's chosen urn.

Every single one of these steps is performed with the utmost respect, precision, and strict adherence to industry best practices. It’s our way of ensuring a dignified and thoughtful conclusion to the physical presence of a loved one.

Types, Safety, and Modern Advancements

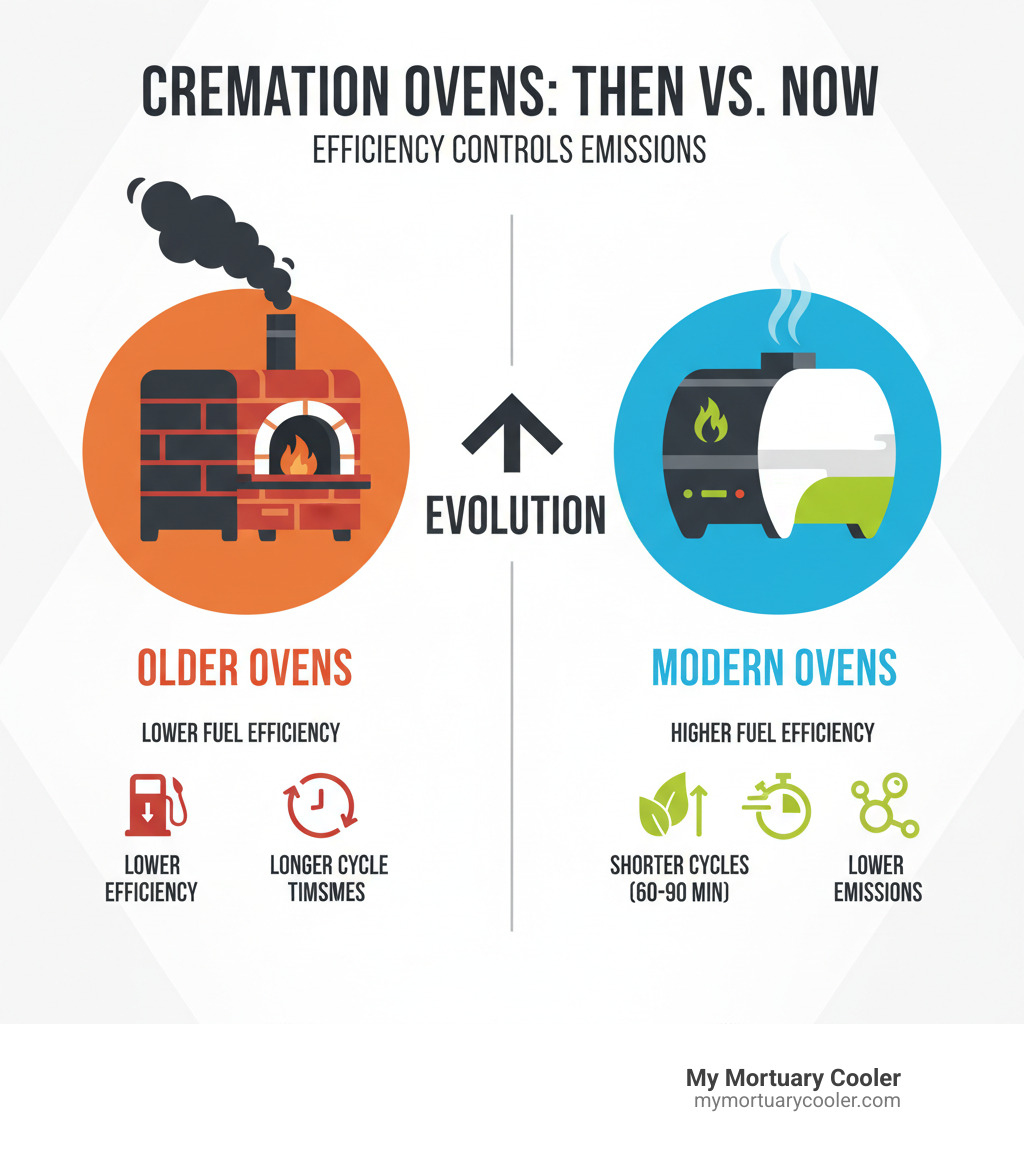

The oven for cremation industry has come a long way from its early days. What once were simple, manually-operated units have evolved into sophisticated machines that prioritize efficiency, safety, and environmental responsibility.

The differences between older and modern cremation ovens are striking. Where older units struggled with fuel efficiency and required longer cycle times, today's models complete cremations in just 60 to 90 minutes while using significantly less fuel. The control systems have transformed from basic manual operations to sophisticated automated PLC (Programmable Logic Controller) systems with touchscreens and even remote diagnostic capabilities.

| Feature | Older Cremation Ovens | Modern Cremation Ovens |

|---|---|---|

| Efficiency | Lower fuel efficiency, longer cycle times | Higher fuel efficiency, shorter cycle times (60-90 min) |

| Controls | Manual or electromechanical systems, less precise | Automated PLC (Programmable Logic Controller) controls, touchscreens, remote diagnostics |

| Emissions | Less sophisticated pollution control, potential for visible emissions | Advanced secondary chambers, opacity sensors, EPA compliance, near-zero visible emissions |

| Safety | Basic safety interlocks | UL listed, redundant controls, advanced flame safeguards, emergency shut-offs |

| Maintenance | More downtime for refractory repairs | Modular hearths for faster repairs, predictive maintenance |

Perhaps the most impressive advancement lies in emissions control. While older units sometimes produced visible smoke or odors, modern cremation ovens achieve near-zero visible emissions through advanced secondary chambers and precise combustion control.

Safety features in today's oven for cremation are comprehensive and reassuring. Automated PLC controls manage every aspect of the cremation cycle, from temperature regulation to airflow patterns, virtually eliminating human error. Opacity sensors continuously monitor exhaust clarity, automatically adjusting operations if emissions approach regulatory limits.

UL listing has become standard for quality units, meaning they've passed rigorous safety testing by Underwriters Laboratories. Emergency shut-off systems are strategically placed for immediate access, while advanced flame safeguard systems use ultraviolet scanning to monitor all burners continuously.

Environmental compliance drives much of the modern design philosophy. Today's cremation ovens must meet or exceed EPA compliance standards, which they achieve through multiple sophisticated systems. Advanced pollution control chambers ensure complete combustion of all gases and particulates. Efficient filtration systems provide an additional layer of emission control before any gases reach the atmosphere.

The precision of modern combustion control is remarkable. By carefully managing oxygen levels and fuel delivery, these systems achieve complete combustion while minimizing harmful byproducts. This isn't just good for the environment—it's also more efficient and cost-effective for operators.

For those seeking deeper technical knowledge about these remarkable machines, All About Cremation Ovens provides comprehensive insights into their operation and components.

Human vs. Animal oven for cremation

While the basic principles remain the same, an oven for cremation designed for humans differs significantly from those built for animals. These differences reflect the unique needs and regulations surrounding each type of service.

Size differences are the most obvious distinction. Human cremation ovens are built to accommodate adult bodies, including larger cases that can exceed 1000 pounds. Animal cremators, however, span a much wider range—from compact units for small pets to massive systems capable of handling horses or livestock.

Capacity variations reflect different service models. Human cremators focus on individual, private cremations, ensuring complete separation of remains. Animal cremators offer more flexibility, with single-chamber systems for individual pets and multi-chamber designs that allow several pets to be cremated simultaneously while maintaining complete separation.

The multi-chamber approach is particularly innovative for pet services. These systems let facilities perform multiple individual cremations at once, improving efficiency while preserving the privacy that grieving pet owners expect.

You'll find animal cremators serving diverse facilities: veterinary clinics use them for compassionate aftercare services, humane societies and animal control facilities rely on them for ethical disposal, pet cemeteries offer them as memorial services, and even livestock farmers use larger units for responsible animal care.

The choice between human and animal cremation systems depends entirely on the intended use and the specific needs of each facility.

Maintenance for an oven for cremation

A well-maintained oven for cremation is essential for safe, efficient operation. Like any sophisticated piece of equipment, these units require consistent care to perform at their best.

Regular inspections form the foundation of good maintenance. Daily or weekly visual checks help operators spot potential issues early. This includes examining the interior for refractory wear, monitoring burner performance, and reviewing control panel readings. Catching problems early prevents costly repairs and unexpected downtime.

Refractory repair and replacement represents the most significant maintenance challenge. The firebricks and masonry lining endure extreme heat cycles that gradually cause wear. Modern innovations like modular hearth systems have revolutionized this process, allowing complete hearth replacement in as little as one day compared to traditional methods that required weeks of curing time.

Burner maintenance keeps the heart of the system running smoothly. Regular cleaning and calibration ensure efficient fuel consumption and consistent temperatures. Neglected burners lead to longer cremation times and higher operating costs—problems that proper maintenance easily prevents.

Adherence to industry standards isn't just good practice—it's often legally required. Organizations like the Cremation Association of North America (CANA) and the National Funeral Directors Association (NFDA) provide essential guidelines for crematory operation and maintenance. Regular preventative maintenance inspections help facilities stay compliant with air quality regulations while ensuring optimal performance.

Proper maintenance extends equipment life, protects personnel safety, minimizes environmental impact, and upholds the dignity that families expect from the cremation process. It's an investment that pays dividends in reliability and peace of mind.

Frequently Asked Questions about Cremation Ovens

When families are considering cremation, they often have thoughtful questions about how the process actually works. As professionals who work with this equipment daily, we understand these concerns and want to provide honest, clear answers about the oven for cremation.

How hot does a cremation oven actually get?

The temperatures inside an oven for cremation are truly remarkable. When we tell people that the primary chamber reaches between 1400 and 1800 degrees Fahrenheit, they're often amazed. To help put this in perspective, that's hot enough to melt copper and is similar to the temperature you'd find in molten lava.

Most facilities aim for an optimal temperature around 1650 degrees Fahrenheit in the primary chamber. This ensures the process is both complete and efficient. But here's something many people don't realize: the secondary chamber actually runs even hotter, typically between 1600 and 1800 degrees Fahrenheit. This incredible heat is what makes modern cremation so clean and environmentally responsible, ensuring that any remaining particles are completely eliminated.

What are "ashes" made of?

This might surprise you, but what families receive aren't actually "ashes" in the traditional sense. The term is widely used and understood, but it's not technically accurate.

When the intense heat of the oven for cremation does its work, it vaporizes all the soft tissues and organic matter. What remains are the bones, which are incredibly durable and don't break down at these temperatures. After the cremation cycle is complete, these bone fragments are carefully collected.

The fragments are then processed in a specialized machine that reduces them to a uniform, fine consistency. The result has a texture similar to coarse sand or small pebbles. So when we say "cremated remains" or "ashes," we're really talking about processed bone fragments that have been transformed into this recognizable form.

What happens to things like dental fillings or surgical implants?

This is one of the most practical questions families ask, and it shows how thoughtful people are about the entire process. The simple answer is that non-combustible materials don't disappear during cremation.

Items made from metals and other durable materials remain completely intact after the cremation cycle. Dental fillings made of gold or silver survive the process unchanged. Surgical implants like hip replacements, knee joints, or titanium rods used in medical procedures are unaffected by even the highest temperatures in the cremation oven.

After the cooling period, these materials are carefully separated from the bone fragments during the collection process. Most reputable facilities, including those we work with, handle these materials ethically. They're often recycled through specialized programs, with the proceeds frequently donated to charitable organizations. It's a respectful way to give these materials a meaningful second purpose while maintaining the integrity of the cremated remains that are returned to families.

This careful attention to every detail is part of what makes modern cremation such a dignified and thorough process.

Conclusion

We’ve traveled together through the amazing world of the oven for cremation. It's been quite a journey, hasn't it? We've seen its clever design, learned about its super-hot temperatures, and understood all the careful steps involved. What truly stands out is that this isn't just any furnace. It's a highly engineered piece of equipment. It plays a central role in a process that is always handled with dignity and respect.

Think about it: the precise temperature controls, from 1400 to 1800 degrees Fahrenheit, keep everything just right. And the clever multi-chamber design ensures that we meet all environmental rules. Every part of a modern oven for cremation is built for efficiency, safety, and reverence. We've explored how it's made from special fire-resistant materials. We've seen how the cremation cycle gently turns organic matter into bone fragments. And we've learned about the strict rules that make sure every step is handled with the greatest care.

For places like funeral homes, crematories, and even veterinary practices, having professional and compliant equipment is super important. It's more than just needing the right tools for the job. It's a promise to the families they serve. It means keeping staff safe, being kind to our environment, and always treating the deceased with the highest level of dignity.

Here at My Mortuary Cooler, we're proud to be America's trusted experts in mortuary refrigeration. We also provide top-notch U.S. cremation equipment. We truly get how vital this equipment is for your daily work. That’s why we're dedicated to offering solutions that are fast, follow all OSHA rules, and are truly professional-grade. If you'd like a deeper look into all the essential tools for today's funeral services, we warmly invite you to explore our full guide: The Ultimate Guide to Mortuary Equipment.