Why Multi-Directional Systems Are Changing Modern Workplaces

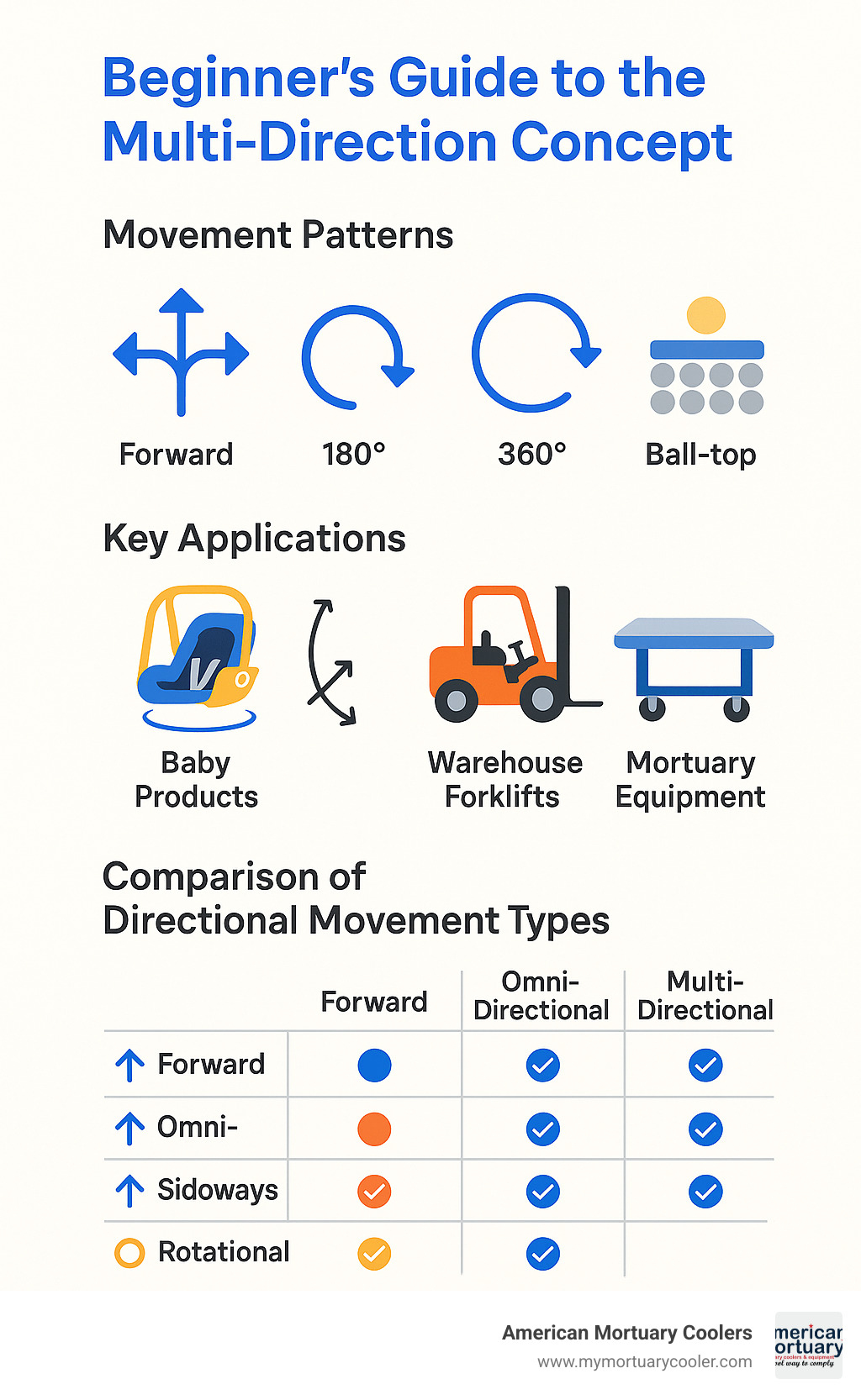

Multi direction- technology is rapidly changing how we think about movement, efficiency, and space utilization across industries. From baby swings that rotate 180° and move in three directions to forklifts that can travel sideways through narrow warehouse aisles, multi-directional systems offer unprecedented flexibility compared to traditional single-direction equipment.

Key Multi-Directional Applications:

- Baby Products: Swings with 3-directional movement and 180° rotation (Graco Simple Sway LX, Ingenuity AnyWay Sway)

- Material Handling: Forklifts combining counterbalance, side loader, and narrow aisle functions (Combilift C-Series: 2,500-25,000 kg capacity)

- Safety Equipment: Rolling ladders that turn in their own radius (450 lb capacity)

- Lifting Clamps: Dual-orientation devices for both horizontal and vertical lifting (1,000-10,160 kg capacity)

- Mortuary Equipment: Cadaver lifts with multi-directional ball tops for side and end loading

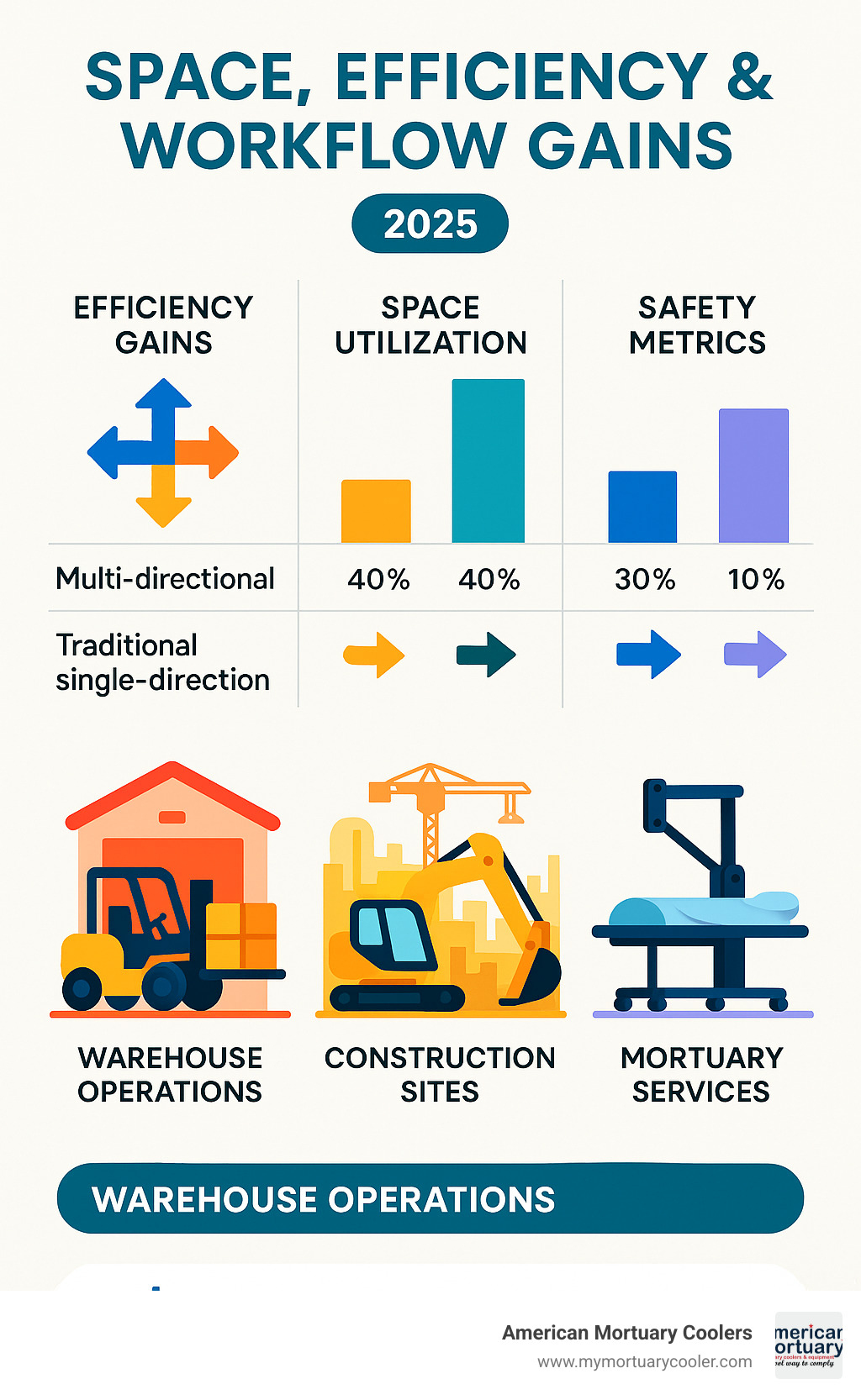

The concept of multi-directional movement dates back to 1897, according to Merriam-Webster's historical records. Today, these systems are solving real problems: warehouse operators report up to 40% storage increases when switching to multi-directional forklifts, while baby product manufacturers have found that multi-directional swings provide longer soothing periods for infants.

What makes multi-directional systems special is their ability to move, function, or operate in more than one direction - typically combining forward, backward, sideways, and rotational movements in a single device. This versatility eliminates the need for multiple pieces of equipment and dramatically improves workflow efficiency.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with experience in multi direction- equipment solutions for funeral homes across America. My expertise includes designing and implementing multi-directional mortuary lifts and cooling systems that maximize space efficiency while meeting the unique operational needs of funeral service professionals.

Multi direction- terms to learn:

What Does Multi-Directional Mean?

Multi-directional simply means "able to move, function, or operate in more than one direction." It's not a new concept either - Scientific research on multidirectional definition shows this term has been around since 1897. What's fascinating is how this basic idea has evolved into sophisticated systems that are changing entire industries.

Think about it this way: traditional equipment forces you to work within its limitations. A regular forklift goes forward and backward. A standard ladder stays put. But multi direction- systems flip this relationship - they adapt to your needs instead of making you work around theirs.

In baby products, multi-directional might mean a swing that rocks side-to-side, bounces up and down, and rotates 180 degrees. For warehouses, it could be a forklift that combines three different machines into one - acting as a counterbalanced forklift, side loader, and narrow aisle truck all at once.

Everyday Uses of the Multi Direction- Idea

You're probably using multi-directional technology right now without realizing it. That robot vacuum quietly cleaning your floors? It uses multi direction- floating roller brushes with both rubber and bristles to tackle dirt from every angle. These smart devices steer around furniture, squeeze under beds, and reach corners that would leave traditional vacuums scratching their heads.

Audio enthusiasts have found something interesting about multidirectional speakers too. Instead of blasting sound in one direction like a megaphone, these speakers create what experts describe as "an unusually open and airy sound that is musically very pleasing."

Even your outdoor gear has gone multi-directional. Modern jackets feature multidirectional zippers that let you access pockets from different angles, plus hand-warming pockets positioned for comfort whether you're hiking uphill or setting up camp.

Industrial Interpretations of the Multi Direction- Term

In industrial settings, multi direction- becomes serious business. Take Combilift's multidirectional forklifts - these machines handle loads from 2,500 kg all the way up to 25,000 kg. But here's what makes them special: they're not just moving sideways for fun. They're solving real problems like narrow aisles, long loads, and the need to reduce equipment fleets.

Rolling ladders with all-directional capability can literally turn in their own radius. With six swivel casters and a 450-pound capacity, these ladders follow OSHA safety rules while eliminating the constant repositioning that wastes time and creates safety risks.

In our mortuary industry, we've seen how multidirectional ball tops on cadaver lifts make all the difference. These systems allow loading from both sides and ends, which is crucial when you're working in tight spaces typical of funeral homes. After working with locations from Johnson City, Tennessee to Los Angeles, I can tell you that this flexibility often determines whether a funeral home operates smoothly or struggles with constant logistical headaches.

Key Applications & Real-World Examples

When you look at how multi direction- systems work in the real world, it's amazing how they solve problems we didn't even realize we had. These aren't just fancy gadgets - they're practical solutions that make life easier, safer, and more efficient across completely different industries.

Take multi-directional lifting clamps, for example. These workhorses handle anywhere from 1,000 kg to 10,160 kg, but what makes them special is their two suspension holes. One hole is positioned perfectly for vertical lifting, while the other handles horizontal lifting tasks. It's like having two different tools in one, which means workers don't have to hunt around for the right equipment or risk using the wrong tool for the job.

Radio operators have been using multi direction- antenna systems for years to create eight distinct beam directions. Using a classic 4-square array with 90° phase hybrid technology, they can direct signals in multiple directions without having to physically move any equipment.

In our work at American Mortuary Coolers, we've seen how multi-directional ball tops transform funeral home operations. These systems handle the unique space challenges that funeral homes face while maintaining the dignity and safety that our industry absolutely requires.

How Multi Direction- Baby Swings Work

Baby swings might seem simple, but they're actually sophisticated examples of multi direction- engineering at work. The Graco Simple Sway LX with Multi-Direction Lounger shows how thoughtful design can make parenting a little easier. With 615 customer reviews and a 3.2 out of 5 rating, parents clearly appreciate what this swing offers.

What makes this swing clever is how the multi-direction lounger lets babies face right, front, or left. This isn't just about variety - it's about keeping infants engaged longer by giving them different viewpoints. The convertible motion switches between side-to-side and head-to-toe swinging, which effectively doubles your soothing options when your little one gets fussy.

The Ingenuity AnyWay Sway Portable Swing takes things even further. It rotates 180° and moves in 3 directions while supporting babies from birth up to 20 pounds. The SlimFold design means you can actually take it with you, and with 19 built-in melodies and nature sounds, you've got plenty of audio options to complement all that multi-directional motion.

Warehouse & Construction Game-Changers

Industrial multi direction- equipment has completely changed how warehouses and construction sites operate. Combilift's multidirectional forklifts are perfect examples - they combine a counterbalanced forklift, side loader, and very narrow aisle truck all in one vehicle. With capacities from 2,500 kg to 25,000 kg, these machines handle serious work.

The Raymond 7310 4-D reach truck eliminates those awkward right-angle turns that eat up so much space. By adding lateral movement to standard forward and backward motion, it reduces aisle width requirements and can increase storage capacity by up to 40%. The Universal Stance design gives operators better visibility and comfort regardless of which direction they're traveling.

Cat's NRM20N2 and NRM25N2 series reach trucks achieve sideways movement by orienting both drive and load wheels laterally. The really smart part is how the automatic transitions between lateral and forward/backward motions happen with just a single button press - no stopping required.

Safety & Ergonomics on the Shop Floor

Safety becomes even more important when you're dealing with multi direction- equipment, but the good news is that these systems often improve safety rather than complicate it. The All Directional Rolling Ladder is a great example - it handles 450 pounds and can turn in its own radius, but it's actually safer than traditional alternatives.

These ladders use six swivel casters for full-radius movement, but they also include foot-pedal lockstep mechanisms and meet both OSHA and ANSI standards. The key insight is that multi-directional capability reduces how often workers need to reposition equipment, which actually decreases accident risk compared to repeatedly moving traditional ladders around.

Multi-directional lifting clamps address safety through smart redundancy. Having dedicated suspension holes for both vertical and horizontal lifting ensures operators use the correct attachment point for each orientation. This prevents the dangerous practice of trying to make single-orientation equipment work for jobs it wasn't designed for.

Engineering Principles, Benefits & Challenges

When you look under the hood of multi direction- systems, you'll find some pretty fascinating engineering. These aren't just regular machines with fancy wheels slapped on - they require a complete rethinking of how movement works.

The magic starts with 360° steering rotation paired with specialized wheel configurations. Multi-directional forklifts use all-wheel steering to shrink their turning radius dramatically, while their parallel traveling mode lets them slide sideways without changing orientation. It's like watching a crab walk, but with several tons of lifting capacity.

For lifting equipment, engineers use circular double cam lock systems that maintain ultra-strong clamping force no matter which direction you're working from. The real challenge here is making sure the clamp is just as safe and strong whether you're lifting vertically or horizontally - that takes some serious stress analysis and material science.

| System Type | Directions | Primary Benefit | Main Challenge |

|---|---|---|---|

| Uni-directional | 1 | Simple, reliable | Limited flexibility |

| Bi-directional | 2 | Moderate flexibility | Still requires repositioning |

| Multi-directional | 3+ | Maximum flexibility | Complex controls, higher cost |

Space, Efficiency & Workflow Gains

Here's where multi direction- systems really shine - they're absolute game-changers for space efficiency. Warehouse operators consistently report storage increases of up to 40% when they switch to multi-directional forklifts. That's not just a small improvement - that's the difference between needing a bigger facility or making your current space work harder.

The secret is in the aisles. Traditional forklifts need wide turning spaces at the end of each aisle, plus room to maneuver. Very narrow aisle (VNA) trucks with multi-directional capability can operate in spaces barely wider than the truck itself. They slide sideways into position, lift straight up, and slide back out. No wasted space for turning around.

Conveyor accumulation tables take this efficiency concept to production lines. These systems use bi-directional movement to create flexible buffer zones, continuously shifting products upstream or downstream using a last-in, first-out (LIFO) method.

Risks & Mitigation Strategies

Let's be honest - multi direction- systems do come with some unique challenges. The main concerns are operator training, load stability during direction changes, and increased maintenance complexity. But here's the thing: these challenges are manageable with the right approach.

Operator training becomes absolutely critical because these machines behave differently than anything most people have used before. The ability to move sideways can catch operators off guard, especially in tight spaces. Most manufacturers now require specific certification programs, and honestly, that's a good thing.

Load stability during direction changes requires careful attention to weight distribution and acceleration limits. The good news is that modern multi-directional forklifts use programmable performance profiles that can be adjusted based on operator experience and load characteristics.

The maintenance complexity is real - more moving parts means more things that can wear out. Additional hydraulic systems, complex electrical controls, and increased wear on steering components all need attention. But here's the trade-off: you're often replacing multiple pieces of single-direction equipment with one multi-directional machine, so the overall maintenance burden can actually decrease.

Selecting, Operating & Maintaining Multi-Directional Equipment

Finding the right multi direction- equipment isn't about choosing the fanciest option - it's about matching your real needs with the right capabilities. Think of it like buying a vehicle: you wouldn't choose a sports car for hauling construction materials, and you wouldn't pick a pickup truck for daily city commuting.

Load capacity should be your starting point. Multi direction- lifting clamps handle anywhere from 1,000 kg to 10,160 kg, while forklifts range from 2,500 kg to 25,000 kg. Here's the key insight: don't just think about your heaviest load. Consider the variety of loads you handle daily, because multi-directional systems often replace several single-purpose machines.

Power source decisions affect where and how you can use your equipment. Battery-powered options like the Ingenuity AnyWay Sway swing give you placement freedom but need charging infrastructure. Dual-power systems (AC adapter plus battery backup) offer the best flexibility, though they cost more upfront.

Certifications matter more than you might think, especially in regulated industries. Look for FDA, CE, and ISO 9001 certifications for medical equipment, plus OSHA and ANSI compliance for industrial applications. Our Mortuary Lifts: Enhancing Funeral Home Efficiency | American Mortuary equipment meets all relevant standards while delivering the multi direction- flexibility funeral homes actually need.

Checklist: Is a Multi Direction- Solution Right for You?

Deciding whether multi direction- equipment makes sense for your operation comes down to three key areas: floor space, budget reality, and workflow complexity.

Floor space constraints often provide the clearest justification. If your aisles are narrow enough that traditional equipment requires constant maneuvering, or if you're running out of storage space, multi-directional systems can deliver measurable improvements. Warehouse operators consistently report up to 40% storage increases when switching to multi-directional forklifts.

Budget considerations go beyond the initial purchase price. Yes, multi direction- equipment typically costs more upfront, but you might eliminate the need for multiple single-purpose machines. Factor in operator training costs and potentially higher maintenance complexity, but also consider the efficiency gains and space savings.

Workflow complexity reveals whether you'll actually use the multi-directional capabilities. Do you handle long loads that would benefit from sideways movement? Are your operators spending significant time repositioning equipment? Would the ability to approach work areas from multiple angles eliminate current bottlenecks?

Care & Upkeep Tips

Maintaining multi direction- equipment requires more attention than traditional single-direction machines, but the extra effort pays off in reliability and longevity. Think of it as caring for a more sophisticated tool - it needs more specific attention but delivers better results.

Lubrication becomes absolutely critical because multi-directional systems have more pivot points, additional hydraulic systems, and complex steering mechanisms. Follow the manufacturer's schedule exactly. The increased mechanical complexity means that skipped maintenance can cascade into expensive failures that could have been easily prevented.

Battery care for electric multi direction- equipment involves both main drive batteries and auxiliary systems. The Raymond 7310 4-D reach truck's ACR System extends battery life and reduces energy costs, but only with proper charging protocols and regular capacity testing.

Caster inspection takes on extra importance for equipment like all-directional rolling ladders. With six swivel casters enabling full-radius movement, any single caster failure compromises both mobility and safety. Check bearing condition, look for unusual wheel wear patterns, and test swivel mechanism operation regularly.

Software updates matter more than many operators realize. Modern multi direction- equipment incorporates sophisticated control systems, and updates often include safety improvements, efficiency optimizations, and new operational modes that can significantly improve performance.

Spare parts inventory should emphasize the unique components that enable multi-directional capability. Specialized casters, additional hydraulic valves, complex steering components, and control system modules often have longer lead times than standard parts.

Frequently Asked Questions about Multi-Directional Systems

What makes multi-directional movement superior to bi-directional?

The difference between multi direction- systems and bi-directional ones might seem subtle, but it's actually quite dramatic when you see them in action. Think of it this way: bi-directional equipment is like being able to walk forward and backward, while multi-directional systems let you walk, sidestep, and even dance.

Take warehouse operations, for example. Bi-directional forklifts still need those wide turning areas at the end of each aisle - they're basically doing a lot of back-and-forth maneuvering to get positioned right. But multi direction- forklifts? They just slide sideways through narrow aisles like they own the place. That's how warehouses are seeing up to 40% more storage capacity in the same footprint.

The baby swing comparison really drives this home. A simple bi-directional swing goes back and forth, which is nice for a while. But babies get bored, as any parent knows. Multi-directional swings like the Graco Simple Sway LX can switch between side-to-side, front-to-back, and even rotate 180°. When one motion stops working, you've got backup options.

Are multi-directional devices harder to maintain?

Here's the honest answer: multi direction- equipment does have more moving parts, but that doesn't necessarily mean more problems. It's like comparing a smartphone to an old flip phone - yes, there's more complexity, but you're also getting capabilities that replace multiple other devices.

The maintenance reality is actually pretty manageable. Companies like Combilift and Raymond design their multi-directional systems with real-world maintenance in mind. They know that if their equipment is constantly breaking down, nobody's going to buy it. So they build in accessibility and use proven components wherever possible.

What changes is the type of maintenance knowledge you need. Your team will need to understand hydraulic systems, electronic controls, and more sophisticated mechanical components. But here's the thing - instead of maintaining three different pieces of equipment (which is what many operations replace with one multi-directional unit), you're maintaining one more capable system.

The key is not trying to wing it. Follow the manufacturer's maintenance schedules, keep the right spare parts on hand, and invest in proper training. Do that, and multi-directional equipment tends to be quite reliable.

How do I train staff to use multi-directional equipment safely?

Training for multi direction- equipment is definitely different from traditional single-direction machines, but it's not rocket science. The key is building confidence gradually rather than throwing people into the deep end.

Start with the basics while the equipment is stationary. Let your operators get comfortable with how the controls work before they start moving around. It's amazing how much confusion you can avoid by spending 15 minutes just explaining which button does what.

The Raymond 7310 and similar equipment often come with programmable performance profiles, which are perfect for training. You can limit the speed and complexity during the learning phase, then gradually open up the full capabilities as operators get comfortable.

Practice the weird stuff that only happens with multi-directional movement. Traditional forklift operators know how to back up and turn around, but sideways movement? That's a whole different sight line and stability consideration.

Most manufacturers offer specific certification programs for their multi-directional equipment, and honestly, they're worth the investment. These programs cover the unique safety considerations and operational techniques that you just don't encounter with traditional equipment.

Conclusion

The journey of multi direction- technology from a simple 1897 dictionary entry to today's sophisticated systems tells a remarkable story of human ingenuity. We've watched these innovations transform everything from how we soothe our babies to how we move massive loads through crowded warehouses.

What strikes me most about this evolution is how multi direction- solutions consistently reveal possibilities we didn't know existed. When Combilift created forklifts that could move sideways, they didn't just add a new movement - they opened up 40% more storage space in existing warehouses. When baby swing manufacturers added rotation and multiple motion patterns, they didn't just create variety - they extended the effective soothing time that helps exhausted parents.

The future looks even more promising. Eight-direction antenna systems are already changing how we think about communications, while AI-guided forklifts will soon combine multi-directional movement with smart navigation. These aren't just incremental improvements - they're stepping stones toward completely reimagined workflows.

At American Mortuary Coolers, we've seen this change across funeral homes from our Tennessee base to installations in California and everywhere between. Our multi-directional ball top cadaver lifts demonstrate something important: this technology isn't just about efficiency - it's about dignity, respect, and making difficult work more manageable for the professionals who serve grieving families.

The real breakthrough happens when you stop thinking about moving in more directions and start thinking about approaching challenges from new angles entirely. Whether you're designing a nursery, optimizing a warehouse, or planning a funeral home layout, multi direction- capability often reveals solutions that single-direction thinking simply can't see.

For funeral service professionals reading this, I encourage you to think beyond individual pieces of equipment. Our custom mortuary coolers work beautifully with multi-directional lifts and transport systems, creating integrated solutions that respect both your operational needs and the families you serve.

Ready to explore what multi direction- solutions might mean for your funeral home? More info about custom mortuary solutions - we're here to help you steer the possibilities and find equipment that combines proven reliability with innovative capability custom to your specific needs.