Understanding Walk-In Cooler Sizing Essentials

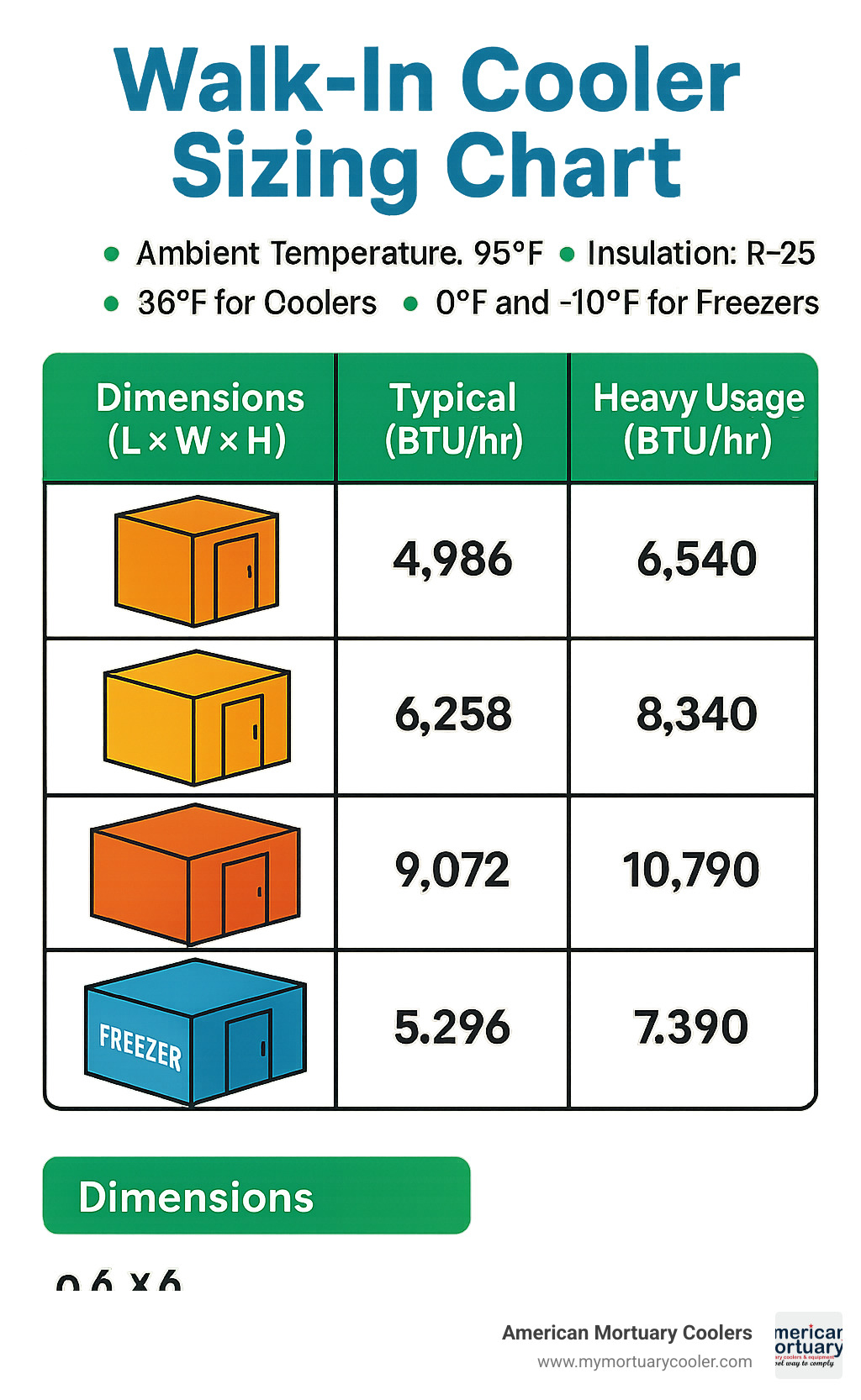

A walk in cooler sizing chart is a reference tool that helps determine the appropriate refrigeration capacity (BTU) needed for walk-in coolers of various dimensions. Here's a quick reference guide to standard walk-in cooler sizes and their typical BTU requirements:

| Walk-In Dimensions (L×W×H) | Typical Load (BTU/hr) | Heavy Usage Load (BTU/hr) |

|---|---|---|

| 6' × 6' × 8' | 4,986 | 6,540 |

| 8' × 8' × 8' | 6,258 | 8,340 |

| 10' × 10' × 8' | 9,072 | 10,790 |

| 6' × 8' × 8' (Freezer 0°F) | 5,296 | 7,390 |

Selecting the right size for your walk-in cooler is crucial for operational efficiency and product preservation. Whether you're installing a new unit or replacing an existing one, understanding how to interpret a walk in cooler sizing chart can save you from costly mistakes.

The consequences of improper sizing are significant. An undersized unit will run continuously, struggling to maintain temperature and potentially failing prematurely. Conversely, an oversized unit wastes energy and money while creating unnecessary temperature fluctuations.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral homes select properly sized walk-in coolers using walk in cooler sizing chart data to ensure optimal performance and reliability. My expertise comes from years of working with funeral directors to find solutions that balance space constraints, refrigeration needs, and budget considerations.

Measuring Your Space & Why Size Matters

Getting the size right for your walk-in cooler isn't just about making it fit in your available space—it's the foundation of everything that follows. I've seen how proper sizing makes all the difference for funeral homes from Tennessee to California.

Think of your walk-in cooler as the heart of your preservation capabilities. When sized correctly, it works efficiently and reliably. When sized incorrectly... well, that's when the headaches begin.

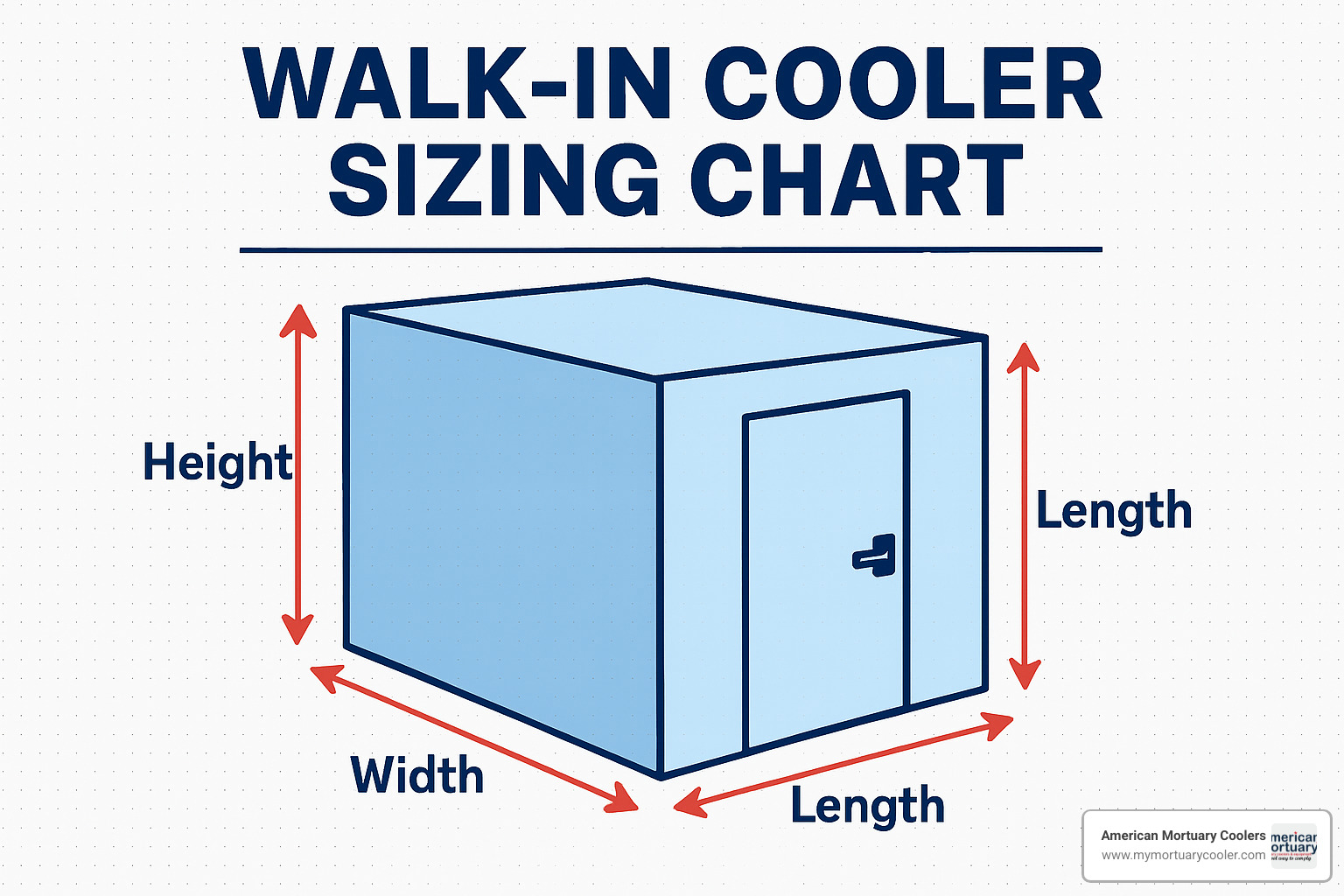

How to Measure Length, Width & Height

Let's start with the basics. Grab your tape measure and let's get accurate measurements—because every inch truly matters.

For your interior footprint, measure the exact floor space where your cooler will live. Be thorough and precise here. Standard walk-in coolers come in modular panels (typically 4' wide), so understanding your available space helps determine which standard size might work best.

When measuring ceiling height, standard walk-ins have an 8' ceiling, but we can customize if needed. Don't forget to look up—check for any pipes, ducts, or light fixtures that might create obstacles.

Your door swing needs special attention too. A typical door needs at least 36" of clearance to open properly. I always recommend thinking about the flow of your space—how will people and equipment move in and out?

"I always tell my clients to leave about 4-6 inches of clearance around their walk-in," says our technical team lead. "That little bit of breathing room improves air circulation dramatically and helps your system run more efficiently."

This small detail is something I've seen overlooked in our Midwest and Northeast regions, where space is often at a premium. Placing coolers flush against walls might save space, but it forces your cooling system to work harder—costing you more in the long run.

Consequences of Under- or Over-Sizing

Let me share what happens when sizing goes wrong—because I've seen both scenarios play out numerous times.

An undersized cooler creates a cascade of problems. Your compressor runs constantly, fighting a battle it can't win to maintain temperature. This leads to premature failure of equipment, higher energy bills, and most concerning for funeral homes—the risk of compromised preservation. Your cooler should provide peace of mind, not constant worry.

On the flip side, an oversized cooler wastes valuable floor space and your hard-earned money. The higher upfront cost is just the beginning—larger units consume more energy even when they're not operating at capacity. Plus, the frequent on/off cycling (called "short-cycling") wears out components faster and creates unnecessary temperature fluctuations.

A funeral director in Georgia shared this story with me: "We initially thought bigger was better and installed an oversized unit. Not only did it take up space we needed for other purposes, but the constant cycling on and off meant temperatures were never quite stable. When we switched to a properly sized American Mortuary Cooler, the difference was night and day—steady temperatures and lower energy bills."

As a general rule, one cubic foot of walk-in space can hold approximately 30 pounds of product when efficiently organized. For mortuary applications, though, we need to consider proper spacing for dignified arrangement and ease of access.

Federal regulations also play a role in your sizing decisions, particularly regarding clearance and accessibility. Getting this right from the start saves headaches down the road with inspections and compliance.

The walk in cooler sizing chart is your friend, but it's just the starting point. Your specific needs and space constraints are equally important in making the right choice for your facility.

The Ultimate Walk In Cooler Sizing Chart Explained

Let's explain those walk in cooler sizing charts you've been puzzling over. Think of these charts as your roadmap to refrigeration success—they connect the dots between your cooler's dimensions and the cooling power (measured in BTU/hr) needed to keep everything properly chilled.

Most charts you'll encounter are built around some standard assumptions: 4" of urethane insulation (that's R-25 value) and an ambient temperature of 95°F outside your cooler. This gives us a reliable starting point for calculations.

You'll typically see two columns of numbers on these charts:

- Typical Load: For everyday usage with normal door openings

- Heavy Load: For busy environments with frequent traffic, glass doors, or hot ambient conditions

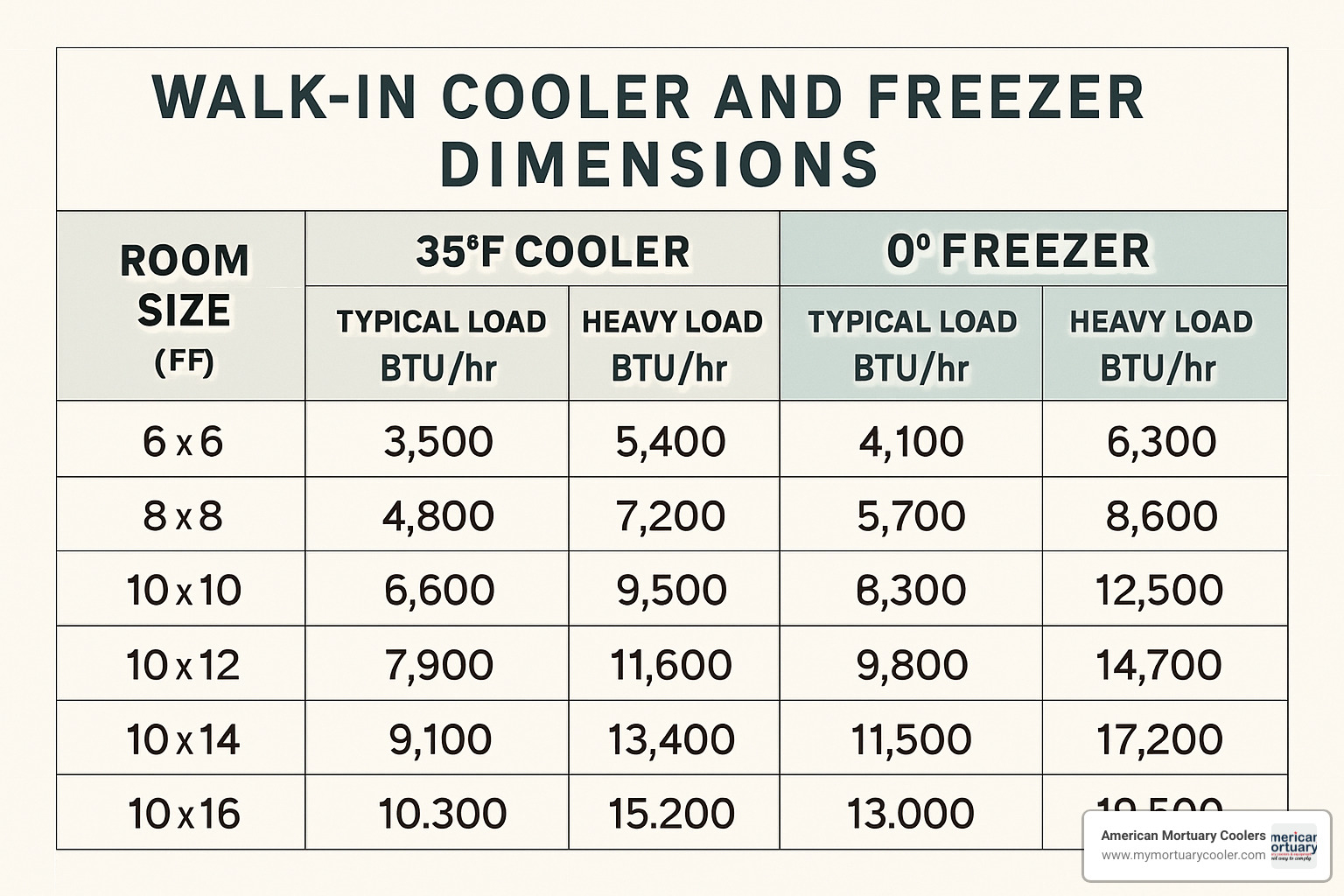

Here's a more comprehensive walk in cooler sizing chart showing what you'll need for coolers maintaining 35°F:

| Dimensions (L×W×H) | Typical Load (BTU/hr) | Heavy Load (BTU/hr) |

|---|---|---|

| 6' × 6' × 8' | 4,986 | 6,540 |

| 6' × 8' × 8' | 5,415 | 7,200 |

| 6' × 10' × 8' | 5,844 | 7,860 |

| 8' × 8' × 8' | 6,258 | 8,340 |

| 8' × 10' × 8' | 7,032 | 9,270 |

| 10' × 10' × 8' | 9,072 | 10,790 |

| 10' × 12' × 8' | 9,990 | 11,880 |

| 12' × 12' × 8' | 11,172 | 13,320 |

When it comes to freezers running at 0°F, you'll need substantially more cooling power:

| Dimensions (L×W×H) | Typical Load (BTU/hr) | Heavy Load (BTU/hr) |

|---|---|---|

| 6' × 6' × 8' | 4,859 | 6,380 |

| 6' × 8' × 8' | 5,296 | 7,390 |

| 8' × 10' × 8' | 6,864 | 9,060 |

| 10' × 10' × 8' | 7,980 | 10,310 |

Need more extensive calculations? The Heatcraft Quick BTUH Load Calculation Chart is the industry gold standard, covering rooms up to 40'×40'×8' and temperatures from a frosty -20°F up to 35°F.

Typical vs Heavy Usage Columns in a Walk In Cooler Sizing Chart

Choosing between "Typical" and "Heavy" load columns isn't just a guessing game—it's about matching your real-world conditions to the right specifications.

Go with the Typical Load when your cooler lives a relatively quiet life: door openings are occasional (fewer than 6 times hourly), it's installed in a climate-controlled area, has standard solid doors, and product loading happens at a steady, manageable pace.

Opt for the Heavy Load when your cooler faces more demanding conditions. Here at American Mortuary Coolers, we often recommend the heavy load calculations for funeral homes in our Southwest and Southeast service regions, where summer temperatures regularly climb above 90°F.

"I always tell our Tennessee clients to plan for the worst summer day, not the average," says our installation manager. "Those July heatwaves can push your equipment to the limit if you haven't sized properly."

Heavy load is also the way to go if your cooler has glass display doors, experiences frequent openings (more than 6 times hourly), sits in direct sunlight, or handles rapid product turnover. This might mean a 20-30% increase in BTU requirements, but that extra capacity provides crucial operational headroom.

Reading BTU Numbers on a Walk In Cooler Sizing Chart

Those BTU (British Thermal Unit) values aren't just random numbers—they represent how much heat your refrigeration system needs to remove every hour to maintain your desired temperature.

When I look at a walk in cooler sizing chart with a client, I explain that these calculations consider several key factors:

First, there's the base calculation that starts with your cooler's volume and the temperature difference you're trying to maintain. A larger space or a bigger temperature gap between inside and outside means more BTUs needed.

Second, good charts include a safety margin (typically around 10%) to account for real-world variables that inevitably crop up. It's like having an extra gallon of gas on a long road trip—you might not need it, but you'll be grateful if you do.

Finally, these values typically assume 16-18 hours of compressor run time daily. This isn't because the system can't run 24/7, but because it needs time for defrost cycles and recovery periods to maintain long-term reliability.

Let's put this in perspective: a 10'×10'×8' cooler maintaining 35°F under typical conditions needs about 9,072 BTU/hr of cooling power. This means your refrigeration system must remove that much heat every hour to keep everything properly chilled.

"Most folks don't realize that walk in cooler sizing charts are calculating four distinct heat sources," explains our technical director. "You've got heat transmission through walls, air infiltration when doors open, heat from the products themselves, and supplemental loads from lights and people. Understanding these components helps you determine if the chart's assumptions match your specific situation."

BTU Load Calculation & Usage Factors

While a walk in cooler sizing chart gives you a quick reference point, understanding what's actually happening behind those numbers can be incredibly helpful – especially if your situation isn't exactly "standard." Think of it as knowing not just what medicine to take, but why it works!

The basic refrigeration formula is pretty straightforward:

BTU/hr = Volume (cu. ft.) × 0.24 × Temperature Difference (°F)

Let me walk you through a real-world example: If you have a 1,000 cubic foot walk-in cooler, and the difference between your ambient temperature (95°F) and your desired holding temperature (35°F) is 60 degrees, your calculation would be: 1,000 × 0.24 × 42 = 10,080 BTU/hr

But here's where many folks go wrong – this simplified formula is just the starting point. At American Mortuary Coolers, we consider the complete picture, which includes:

Heat transmission through your cooler's walls, ceiling, and floor – basically anywhere the cold inside meets the warm outside.

Air infiltration – every time that door opens, warm air rushes in (and we know how busy funeral homes can get during certain periods).

Product load – the cooling power needed to bring new items down to temperature.

Supplemental loads – all those extras like lights, people moving around inside, and equipment motors.

Each of these factors gets influenced by real-world conditions:

Your insulation quality makes a huge difference – most quality walk-ins use 4" urethane insulation with an R-value of 25, but variations exist.

Ambient conditions matter enormously – a cooler in Phoenix faces different challenges than one in Portland.

Door usage patterns directly impact your cooling needs – a high-traffic cooler needs more cooling power.

Starting temperatures of what goes into the cooler – warmer items require more energy to cool down.

Personnel traffic – each person working inside adds about 1,000 BTU/hr of heat (we're warm creatures!).

For those who want to get really precise, the Refrigeration Sizing Estimate tool can help you input these specific details for a more custom calculation.

At American Mortuary Coolers, we've developed specialized calculations specifically for mortuary applications, taking into account both the technical requirements and the dignified spacing needed in this sensitive industry.

Step-by-Step Example Calculation

Let's break down a detailed calculation for a 10'×10'×8' cooler that needs to maintain 35°F when it's 95°F outside:

Calculate volume: 10 × 10 × 8 = 800 cubic feet

-

Heat transmission load:

- Wall area: 2(10×8) + 2(10×8) = 320 sq. ft.

- Ceiling area: 10 × 10 = 100 sq. ft.

- Floor area: 10 × 10 = 100 sq. ft.

- Using U-factor of 0.04 (R-25 insulation):

- Walls: 320 × 0.04 × (95-35) = 768 BTU/hr

- Ceiling: 100 × 0.04 × (115-35) = 320 BTU/hr

- Floor: 100 × 0.04 × (75-35) = 160 BTU/hr

- Total transmission: 1,248 BTU/hr

-

Infiltration load (assuming moderate door usage):

- Air change factor: 2.5 changes per 24 hours

- Volume: 800 cubic feet

- Heat content difference: 2.5 BTU/cu. ft.

- 800 × 2.5 × 2.5 ÷ 24 = 208 BTU/hr

-

Product load (assuming 400 lbs of product cooled from 75°F to 35°F daily):

- Specific heat above freezing: 0.8 BTU/lb·°F

- 400 × 0.8 × (75-35) ÷ 24 = 533 BTU/hr

-

Supplemental loads:

- Lighting (2 watts/sq. ft.): 200 watts × 3.4 = 680 BTU/hr

- Personnel (1 person, 30 min/hr): 1,000 × 0.5 = 500 BTU/hr

- Total supplemental: 1,180 BTU/hr

Total load: 1,248 + 208 + 533 + 1,180 = 3,169 BTU/hr

Apply safety factor (10%): 3,169 × 1.1 = 3,486 BTU/hr

Adjust for run time (18 hours): 3,486 × 24/18 = 4,648 BTU/hr

You might notice this calculated value (4,648 BTU/hr) is lower than what you'd find on a standard walk in cooler sizing chart (which might show 9,072 BTU/hr). That's because our example uses fairly conservative estimates, while most professional charts include worst-case scenarios for all variables – they're trying to make sure you don't end up with an underpowered system.

Supplemental Loads You Shouldn't Forget

One thing I've learned from helping funeral homes across Tennessee and beyond is that there are several heat sources many people forget when sizing their coolers:

Electric defrost heaters can be significant heat contributors, especially in freezer applications. These are necessary for proper operation but do add to the overall load.

Glass door lighting might seem minor, but those display lights can add 25-40 watts per door – and that heat stays inside your cooler.

Equipment motors from evaporator fans to blowers all generate heat while operating. They're necessary for air circulation but contribute to the cooling load.

Material handling equipment like battery-powered pallet jacks or transport carts release heat while operating inside the cooler. Many funeral homes use specialized transport equipment that should be factored in.

Electronic equipment such as monitoring devices or digital thermostats add small but constant heat loads that accumulate over time.

"I remember installing a cooler for a client in Arizona," our lead technician often shares. "They didn't account for the extreme outdoor heat, and their unit struggled until we upgraded the system. In outdoor installations, especially in the Southwest, you might need to increase capacity by 15-20% to handle those 110°F summer days."

At American Mortuary Coolers, we account for these supplemental loads in our custom calculations. We believe in systems that perform flawlessly even during peak demand, providing the reliability and dignity that funeral services demand.

Avoiding Mistakes & Planning for Growth

I've seen it happen time and again across Tennessee to California - funeral homes invest in walk-in coolers only to find they've made sizing mistakes that cost them dearly. Let me share what we've learned at American Mortuary Coolers from helping hundreds of funeral directors avoid these common pitfalls.

The most frequent sizing mistake? Underestimating peak temperatures. Many funeral directors calculate based on average conditions, but your cooler needs to perform flawlessly during the hottest summer day when families are counting on you. In Memphis or Phoenix, this oversight can be particularly problematic.

Door traffic is another factor that's easy to misjudge. Each time that door swings open, warm air rushes in. One funeral home in Georgia called us after their new cooler couldn't maintain temperature simply because they hadn't accounted for their staff's frequent access patterns.

"My biggest regret was not planning for our growth," a funeral director in Nashville told me recently. "We added another location and suddenly our cooler was constantly at capacity. If I'd known better, I would have sized up from the beginning."

Insulation quality matters tremendously too. Not all R-25 rated materials perform equally over time. We've seen extruded polystyrene maintain about 47% of its R-value long-term, while some foam-in-place polyurethane options retain only 19%. That difference translates directly to your energy bills and cooling performance.

And please, don't forget the floor insulation – especially for freezers! Concrete floors without proper insulation create significant heat transfer that your system will fight constantly.

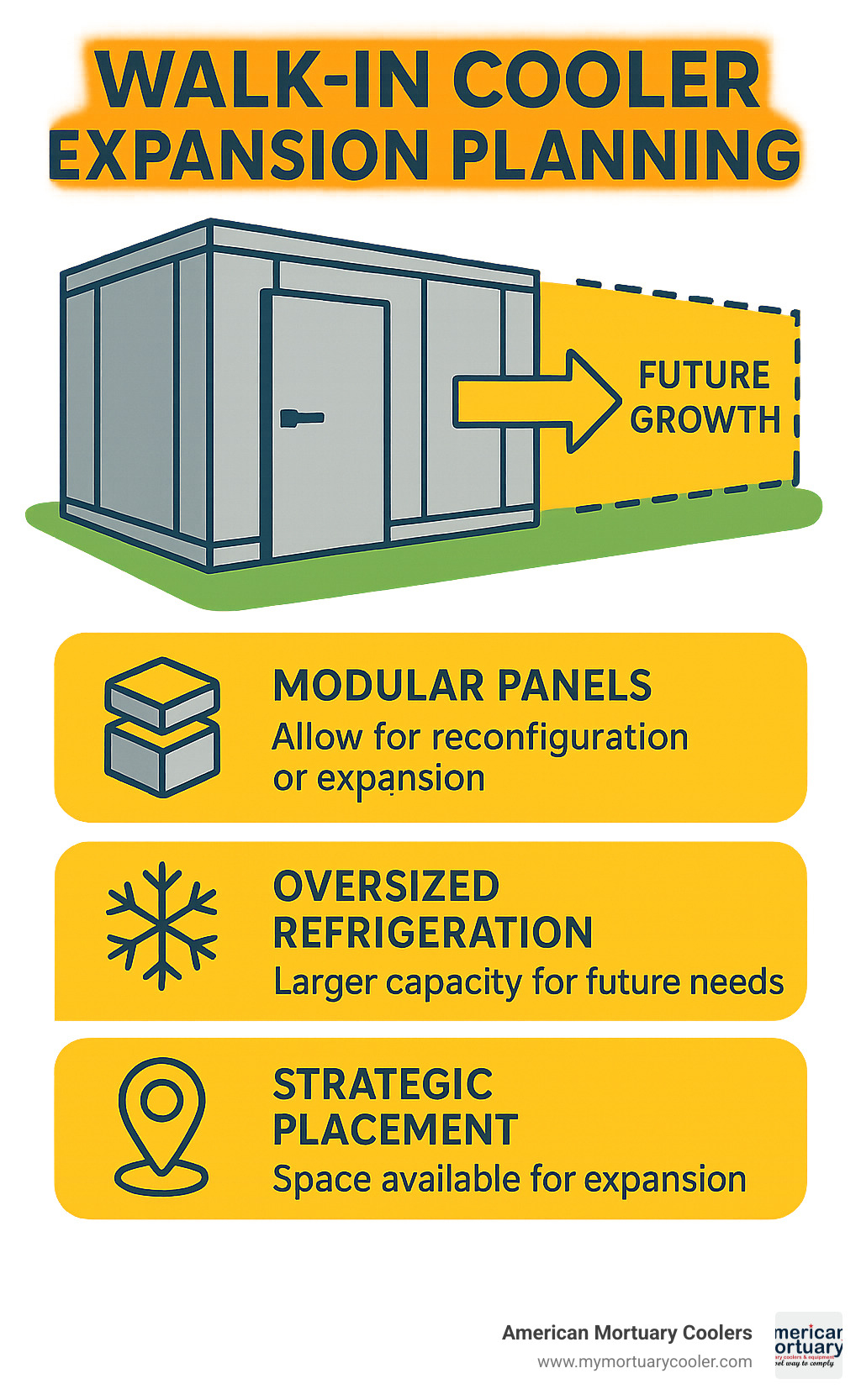

When thinking about future growth (which I strongly recommend), consider a modular design approach. Our panels at American Mortuary Coolers can be reconfigured or expanded later, giving you flexibility as your needs change. Some funeral homes opt for slightly oversized refrigeration capacity from the start – a smart investment that allows for future expansion without replacing the entire system.

Strategic placement within your facility matters too. We helped a funeral home in St. Louis position their walk-in with an exterior wall adjacency, making future expansion much simpler when the time came three years later.

For specialized applications beyond standard walk-ins, you might find helpful information in our complete guide to roll-in and walk-in mortuary coolers, which details options specifically designed for funeral service needs.

When to Use a Detailed Load Calculation or Call an Expert

While a walk in cooler sizing chart works well for standard situations, certain circumstances call for deeper analysis or professional help:

If your walk-in exceeds 12 feet in any dimension, standard charts may not apply accurately. Similarly, installations in extreme environments (like our Arizona customers facing 110°F+ summers) require specialized calculations.

Specialized storage needs also warrant expert consultation. A recent client storing specialized embalming chemicals needed precise temperature control beyond what standard charts could accommodate.

High-density storage situations are another red flag. While typical calculations assume about 30 pounds per cubic foot, some facilities need much higher capacity. Multiple temperature zones or partitioned areas also complicate the math significantly.

"I wish I'd called for help sooner," admitted a funeral director from Johnson City who tried to size his own system. "The money I thought I was saving disappeared quickly when my undersized unit couldn't keep up during our busy season."

At American Mortuary Coolers, our team is ready to perform detailed calculations custom to your specific conditions – whether you're in the humid Southeast or dry Southwest. We've learned that proper sizing isn't just about equipment; it's about giving you peace of mind when families entrust their loved ones to your care.

Frequently Asked Questions About Walk-In Cooler Sizing

What size walk-in cooler do I need for 1,000 lb of product?

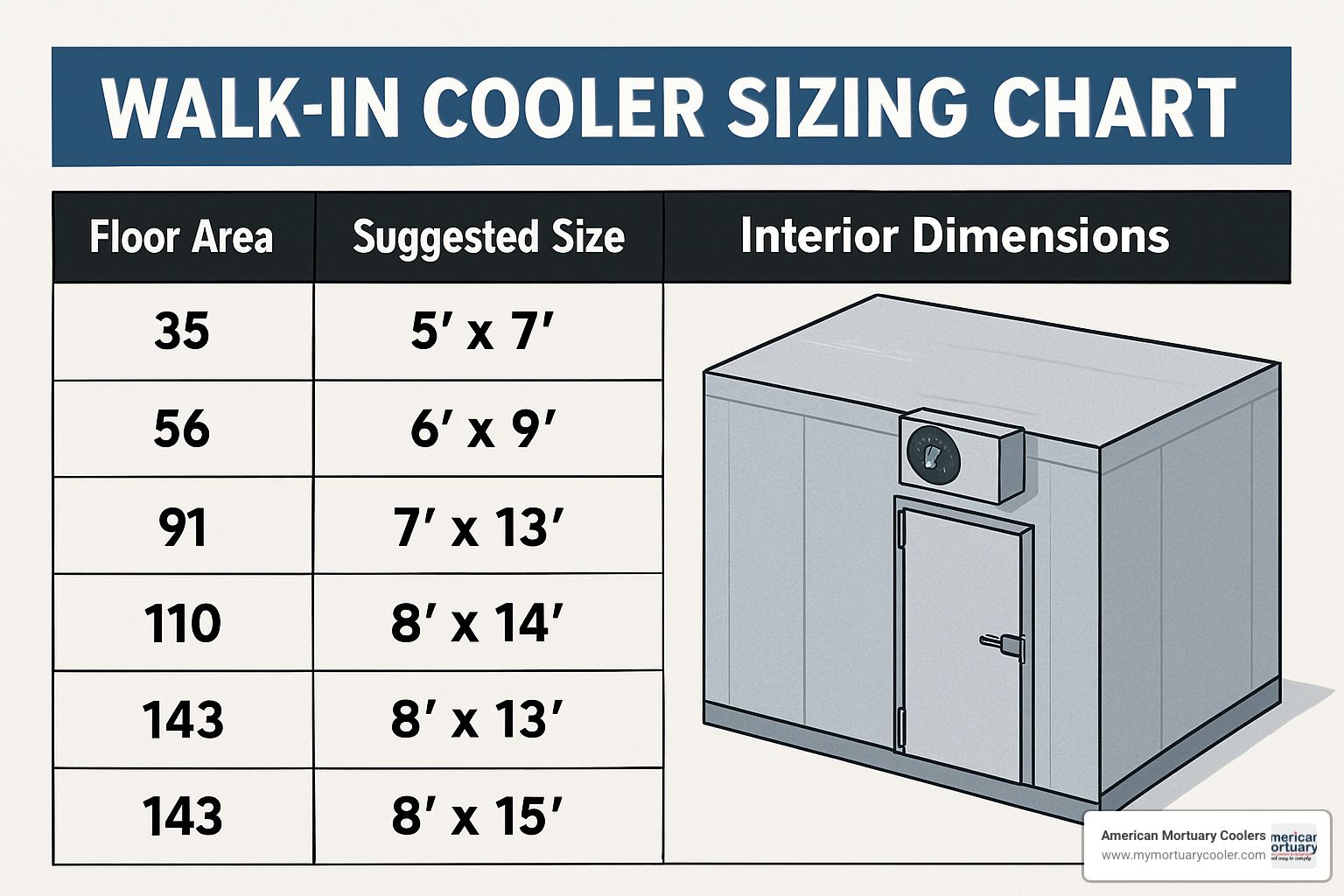

I get this question a lot when talking with funeral directors across the country. The simple answer is that the industry standard suggests about 30 pounds of product per cubic foot of usable space. So for 1,000 pounds, you'd need roughly 33-35 cubic feet of storage.

But here's the thing – in the funeral industry, we need to think differently.

For mortuary applications, dignity requires more space. We typically recommend a lower density of about 15-20 pounds per cubic foot. This means for 1,000 pounds, you're looking at 50-67 cubic feet of actual storage space.

Remember though, not all of your walk-in is usable storage! When I visit funeral homes in Tennessee or California, I often explain that shelving, racks, and the space needed to move around all reduce your actual storage capacity. As a rule of thumb:

A standard 6'×6'×8' walk-in gives you about 288 cubic feet total, but only about 50-60% of that is actually usable for storage. For 1,000 pounds with proper spacing for dignified arrangement, I typically recommend either a 6'×8'×8' or 8'×8'×8' unit for most funeral homes.

Every situation is unique though – give us a call at American Mortuary Coolers and we can help determine the perfect size based on your specific needs and space constraints.

How does insulation thickness change the sizing chart numbers?

This is where the science gets interesting! The insulation in your walk-in cooler dramatically affects how hard your refrigeration system needs to work. Most walk in cooler sizing charts are based on 4" of urethane insulation with an R-value of 25.

If you increase that insulation from 4" to 6", you can reduce your heat transmission load by about 30-35%. That's a significant energy savings! On the flip side, using lower-quality insulation (say R-20 instead of R-25) can increase your cooling load by 20-25%.

Here's a real-world example: A standard 10'×10'×8' cooler maintaining 35°F with 4" urethane insulation typically needs about 9,072 BTU/hr under normal conditions. Upgrade to 6" insulation (R-38), and that requirement drops to around 6,800 BTU/hr. That's not just initial savings on equipment – it's lower electric bills month after month.

One thing many folks don't realize is that insulation ages. Over time, extruded polystyrene retains about 47% of its initial R-value, while foam-in-place polyurethane might retain only 19%. That's why at American Mortuary Coolers, we insist on using high-quality insulation materials in every unit we build, whether it's headed to a hot climate in Texas or a cooler region in the Northeast.

Does outdoor installation always require extra BTUs?

Yes, absolutely. When we install walk-in coolers outdoors, they simply need more cooling power than the same-sized indoor unit. There are several reasons for this:

First, outdoor units face much higher temperatures, especially in summer. While your funeral home might be a comfortable 75°F inside, that same unit outdoors could be battling 105°F or higher in many parts of the country.

Second, don't underestimate the power of sunshine! Direct sunlight can dramatically increase surface temperatures on your cooler walls and roof, sometimes by 20-30 degrees above the actual air temperature.

Third, weather exposure affects performance. Rain, snow, and wind can compromise insulation efficiency and increase air infiltration over time.

For our outdoor installations, we typically recommend increasing your calculated BTU capacity by 20-30%. We also strongly suggest adding a rain roof for protection, and in colder regions, including a winter kit with crankcase heaters and head pressure controls to ensure year-round reliability.

I've seen this when installing units in places like Arizona versus Minnesota – the requirements are dramatically different. That's why at American Mortuary Coolers, we design our outdoor units with these regional factors in mind. Our experience serving funeral homes across all climate zones helps us provide equipment that performs reliably regardless of whether you're dealing with Northeast winters or Southwest summers.

Conclusion & Next Steps

After diving deep into walk in cooler sizing charts, you're now equipped with the knowledge to make informed decisions about your refrigeration needs. Proper sizing isn't just about numbers on a chart—it's about creating a system that works efficiently while meeting your specific requirements.

Throughout our years of serving funeral homes across America, we've learned that getting the sizing right from the start saves headaches (and dollars) down the road. When you measure carefully, account for your unique usage patterns, and think about future growth, you're setting yourself up for success.

Let's recap what matters most:

Your measurements need to be spot-on. There's no substitute for taking the time to measure your space accurately—it's the foundation everything else builds upon.

Your usage patterns make a big difference. If your staff will be constantly opening that cooler door or you're planning to install glass doors, you'll need that extra cooling capacity the "heavy usage" column provides.

All heat sources count. From the products you're storing to the people working in the space, even seemingly small heat contributors add up quickly.

Growth deserves thought now, not later. The most cost-effective approach is finding that sweet spot between your current needs and where you might be in a few years.

Expert advice matters for complex situations. When your application falls outside standard parameters, it's time to call in the professionals.

Here at American Mortuary Coolers, we understand that for funeral homes, refrigeration isn't just about maintaining temperature—it's about providing dignified care with absolute reliability. From our home base in Tennessee, we've helped funeral directors across all 48 contiguous states find the perfect cooling solution for their unique spaces and needs.

Our approach is different because we specialize in the funeral industry. We know that standard commercial coolers often don't address the specific requirements of mortuary applications. That's why we've developed modular designs that can be customized to fit your available space while meeting the unique demands of funeral service.

The walk in cooler sizing chart is an excellent starting point, but your specific situation might benefit from our personalized touch. We're happy to walk you through the sizing process, helping you balance immediate requirements with long-term planning. Our direct delivery service means you'll get exactly what you need, precisely when you need it—whether you're in New York, Texas, California, or anywhere in between.

Ready to find the perfect walk-in cooler for your funeral home? Let's combine what you've learned about sizing with our industry expertise. Reach out for a consultation, and we'll help you determine the optimal size and configuration that provides both the performance you need and the peace of mind you deserve.

For more information about our comprehensive mortuary cooler solutions, visit your one-stop shop for mortuary coolers.