The Essential Guide to Materials in Modern Construction and Manufacturing

What materials are used most commonly across industries today? Here's a quick overview:

| Material Type | Primary Applications | Key Properties |

|---|---|---|

| Concrete | Foundations, structures | High compression strength |

| Steel | Frameworks, infrastructure | High strength-to-weight ratio |

| Wood | Framing, finishes | Renewable, good insulation |

| Aluminum | Windows, lightweight structures | Corrosion resistant, recyclable |

| Plastics | Piping, insulation, components | Lightweight, versatile, moldable |

| Glass | Windows, facades | Transparency, thermal properties |

| Composites | Specialized applications | Customizable strength, lightweight |

| Stone/Brick | Facades, flooring | Durability, thermal mass |

What materials are used in construction and manufacturing depends largely on the specific application requirements, regional availability, and performance needs. The world today is built on these essential industrial materials that power infrastructure, technology, and daily life.

Material selection has evolved dramatically over the past century, with sustainability now joining strength and cost as primary considerations. Modern projects typically combine multiple materials to leverage each one's unique advantages while mitigating weaknesses.

For specialized applications like mortuary equipment, material choice becomes even more critical, requiring surfaces that are not only durable but also easy to clean, chemically resistant, and appropriate for the sensitive nature of the work.

I'm Mortuary Cooler, a national supplier of mortuary refrigeration equipment with extensive experience evaluating what materials are used for optimal performance in medical and funeral service applications. My expertise stems from years of working directly with manufacturers to select materials that balance durability, function, and value.

What materials are used terms to know:

What Materials Are Used: 2025 Snapshot

The materials landscape continues to evolve as we move through 2025, with both traditional and innovative materials playing crucial roles across industries. At American Mortuary Coolers, we keep a close eye on these developments to ensure our products incorporate the best materials for durability, functionality, and sustainability.

| Material | Global Usage Volume | CO₂ Footprint (tons/unit) | Primary Applications |

|---|---|---|---|

| Concrete | Highest (4.4B tons/year) | 0.9 | Foundations, structures, infrastructure |

| Steel | Very High (1.8B tons/year) | 1.85 | Frameworks, reinforcement, machinery |

| Wood | High (regional variation) | -1.0 (carbon negative) | Framing, finishes, furniture |

| Plastics | High (380M tons/year) | 2.5 | Components, insulation, packaging |

| Aluminum | Medium (64M tons/year) | 16.5 (primary); 0.6 (recycled) | Lightweight structures, electronics |

| Glass | Medium (regional variation) | 0.85 | Windows, containers, electronics |

| Composites | Growing (regional variation) | Varies by composition | Specialized applications, aerospace |

The materials we use today are increasingly selected not just for their physical properties but also for their environmental impact. This holistic approach represents a significant shift in how industries approach construction and manufacturing.

What materials are used most in construction?

Construction remains one of the largest consumers of raw materials globally. The following materials dominate the construction landscape in 2025:

Concrete: Still the foundation of modern construction, concrete's compressive strength makes it ideal for foundations and infrastructure. Modern formulations increasingly incorporate supplementary cementitious materials to reduce carbon footprint.

Steel: Used primarily for structural frameworks and reinforcement (rebar), steel's exceptional strength-to-weight ratio makes it indispensable for high-rise buildings and long-span structures.

Wood: Particularly in residential construction, wood framing remains popular due to its renewability and natural insulation properties. Engineered wood products like cross-laminated timber (CLT) are gaining traction for larger structures.

Glass: Modern building facades often feature extensive glazing to maximize natural light. Advanced glass technologies incorporate low-E coatings and improved insulation properties.

In our mortuary cooler manufacturing facilities across regions like Johnson City, TN, and Columbia, SC, we see these construction materials used in different proportions depending on regional building practices.

What materials are used most in manufacturing?

Manufacturing industries rely on a diverse range of materials that can be broadly categorized as follows:

-

Metals: Steel, aluminum, copper, and their alloys form the backbone of manufacturing. Each metal brings unique properties:

- Steel: Strength, durability, and relatively low cost

- Aluminum: Lightweight, corrosion-resistant, and highly recyclable

- Copper: Excellent electrical and thermal conductivity

Polymers: These versatile materials include thermoplastics, thermosets, and elastomers. Their ability to be molded into complex shapes makes them ideal for everything from packaging to precision components.

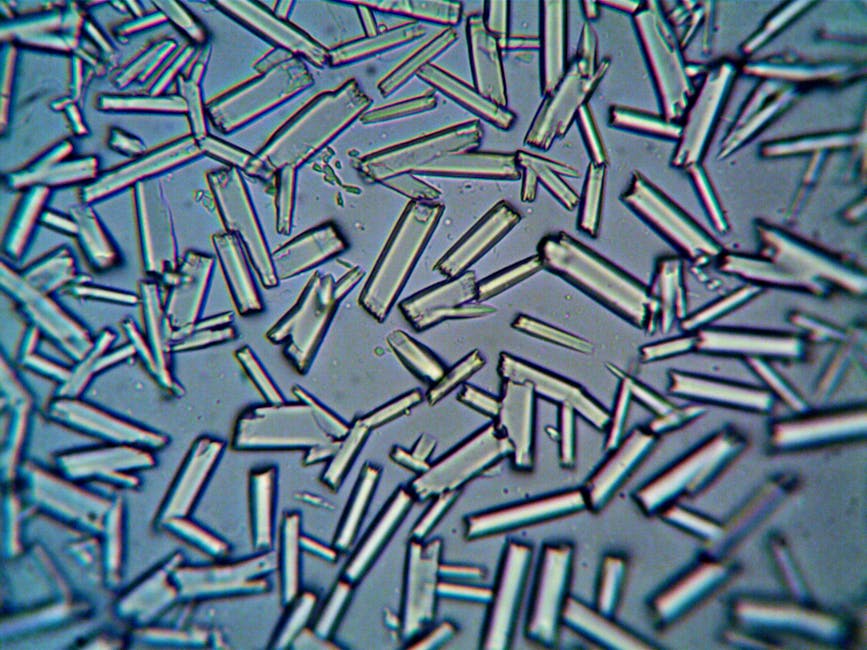

Ceramics: Known for hardness, heat resistance, and electrical insulation properties, ceramics find applications in electronics, medical devices, and cutting tools.

At our facilities in Dallas, TX, and Chicago, IL, we use many of these materials in our mortuary cooler production, carefully selecting each based on its performance characteristics.

Major Material Classes & Their 2025 Advantages

When considering what materials are used in modern applications, it helps to understand the major material families and what makes each one special. In 2025, each type of material brings unique benefits to the table.

Polymers

Today's polymers offer incredible flexibility in how they can be shaped and what properties they can have. They're lightweight (which saves energy during shipping), increasingly recyclable, and remarkably resistant to chemicals.

At American Mortuary Coolers, we carefully select polymers for components that need to withstand regular cleaning with strong disinfectants.

Metals

Metals give us that perfect balance of strength and flexibility, conduct heat and electricity wonderfully, and can be melted down and reused many times with minimal quality loss. With thousands of alloy options, we can fine-tune their properties for specific needs.

In our mortuary coolers, we rely on metals for structural integrity and long-term durability.

Ceramics

Today's advanced ceramics are engineering marvels. They're incredibly hard and resistant to wear, can handle extreme temperatures, don't react with most chemicals, and can insulate against electricity. Many are also compatible with the human body, making them perfect for medical applications.

Composites

By combining different materials, we can create something with properties neither material could achieve alone. Modern composites offer customizable performance, exceptional strength while remaining lightweight, and impressive resistance to rust and corrosion.

At American Mortuary Coolers, we strategically use composites in our premium models to improve durability while keeping weight manageable for easier installation.

Metals: Steel & Aluminum

Steel and aluminum form the backbone of modern construction and manufacturing, including specialized equipment like our mortuary coolers.

Steel: The Backbone of Infrastructure

This remarkable metal offers an exceptional balance of strength and weight. Recent advances have given us:

- High-strength steels that do more with less material

- Formulations that resist rust and corrosion better than ever

- More efficient recycling that reduces environmental impact

For our mortuary coolers manufactured in Pittsburgh and elsewhere, stainless steel remains our go-to choice for interior surfaces. It resists corrosion beautifully, cleans up easily, and naturally fights microbial growth.

Aluminum: Lightweight Champion

Aluminum's combination of light weight, corrosion resistance, and recyclability makes it increasingly valuable in 2025:

- Alloys like 6061 (with added magnesium and silicon) provide excellent strength while remaining easy to work with

- Its natural resistance to corrosion means we often don't need protective coatings

- It can be recycled almost infinitely with minimal quality loss

The 6061 aluminum alloy deserves special mention. With a density of 2.70 g/cm³ and tensile strength between 124–290 MPa, it offers an ideal balance of strength and weight savings.

Concrete & Masonry

Concrete: The Foundation of Modern Construction

Concrete remains the world's most widely used building material, with good reason. More than 4.4 billion tons are produced annually, and its benefits are substantial:

- Best compressive strength for supporting heavy loads

- The ability to form virtually any shape

- Thermal mass that helps regulate temperature

The concrete industry has made impressive strides toward sustainability with new cement formulations that actually absorb CO₂ as they cure and geopolymer concretes that eliminate traditional cement entirely.

Masonry: Combining Tradition with Innovation

Brick and block construction offers unique advantages that have stood the test of time:

- Exceptional durability—many masonry structures have lasted centuries

- Natural temperature regulation through thermal mass

- Very low maintenance requirements over a building's life

Wood & Engineered Lumber

Traditional Lumber: The Original Renewable Resource

Solid wood offers numerous advantages:

- It actually removes carbon from the atmosphere as trees grow

- Provides excellent strength relative to its weight

- Naturally insulates against heat and cold

Engineered Wood Products: Expanding Capabilities

Engineered wood has transformed what's possible with timber:

- Cross-laminated timber (CLT) now enables wooden buildings that compete with concrete and steel

- Laminated veneer lumber (LVL) offers consistent properties and greater strength than natural wood

- Wood-plastic composites combine durability with reduced maintenance needs

Plastics & Advanced Polymers

The world of polymers has exploded with innovation in 2025, offering specialized materials with remarkable performance.

High-Performance Thermoplastics

Several advanced plastics stand out for specialized applications:

Ultra-high-molecular-weight polyethylene (UHMWPE) achieves incredible impact strength through its extremely long molecular chains. We use it for wear surfaces and high-strength components.

Polyether ether ketone (PEEK) handles extreme temperatures (up to 250°C) while remaining chemically stable and mechanically strong. This is perfect for demanding environments, including medical applications.

3D Printing Revolution

Polymer-based 3D printing has transformed how we create parts, allowing us to quickly test new designs without expensive tooling and create complex shapes that would be impossible to make traditionally.

Composites & Smart Materials

Fiber-Reinforced Composites

Fiber composites continue finding new applications:

Fiberglass combines glass fibers with polymers for excellent corrosion resistance and moderate strength.

Carbon fiber composites provide exceptional strength while remaining incredibly lightweight.

Emerging Smart Materials

The frontier of materials science in 2025 includes some truly remarkable innovations:

- Metamaterials with engineered structures that create properties not found in nature

- Shape-memory alloys and polymers that can return to a predetermined shape when activated

- Self-healing materials capable of automatically repairing damage

At American Mortuary Coolers, we're actively evaluating smart materials for future product generations, with particular interest in self-cleaning surfaces and antimicrobial properties.

Selecting the Right Material for Your Project

When clients ask us what materials are used for optimal performance, we emphasize that material selection is a multifaceted decision process that must balance numerous factors.

The right material choice depends on a systematic evaluation of:

Performance Requirements: What specific properties are essential for the application?

Cost Considerations: Not just initial material costs, but lifecycle expenses including maintenance and disposal.

Lifecycle Analysis: How the material performs throughout its service life, including environmental impacts.

Regional Codes and Standards: Local building codes and regulatory requirements that may mandate specific materials.

Supply Chain Reliability: Availability of materials and potential supply disruptions that could affect project timelines.

At American Mortuary Coolers, our teams work closely with clients to steer these considerations. Our experience across multiple states gives us unique insight into regional variations in material availability and code requirements.

Key Factors When Asking "what materials are used?"

When determining what materials are used for a specific application, several critical factors must be evaluated:

Load Requirements and Structural Performance

- Static loads (constant weight or pressure)

- Dynamic loads (impact, vibration, or movement)

- Fatigue resistance for cyclic loading

Environmental Conditions

- Temperature ranges and thermal cycling

- Humidity and moisture exposure

- Chemical exposures including cleaning agents

- UV radiation and weathering

Aesthetic Considerations

- Surface finish and appearance

- Color options and consistency

- Texture and tactile qualities

Maintenance Requirements

- Cleaning protocols and compatibility

- Repair methods and difficulty

- Replacement frequency and cost

End-of-Life Considerations

- Recyclability or reuse potential

- Biodegradability for appropriate materials

- Disposal restrictions or hazardous material concerns

For mortuary equipment specifically, we place particular emphasis on:

- Chemical resistance to disinfectants and bodily fluids

- Smooth, non-porous surfaces that prevent bacterial harborage

- Durability under frequent cleaning protocols

Our experience manufacturing mortuary coolers across diverse regions from Atlanta, GA to Chicago, IL has taught us that material selection must be customized to both the application requirements and local conditions.

Emerging & Innovative Options for 2025

The materials landscape continues to evolve rapidly, with several innovative options gaining traction in 2025:

Bio-Concrete

This material incorporates living organisms to create self-healing properties:

- Bacteria embedded in concrete activate when cracks form

- Microorganisms produce calcium carbonate to seal cracks

- Reduces maintenance and extends service life

Recycled Plastic Lumber

Made from post-consumer plastic waste, this material offers:

- Weather resistance superior to wood

- No need for chemical treatments or preservatives

- Diverts plastic from landfills and oceans

Graphene-Improved Composites

The integration of graphene into various matrices provides:

- Dramatically improved strength and stiffness

- Improved electrical and thermal conductivity

- Reduced weight compared to traditional reinforcements

At American Mortuary Coolers, we're particularly interested in antimicrobial surfaces and self-cleaning materials that can improve hygiene and reduce maintenance of our mortuary equipment.

Frequently Asked Questions about What Materials Are Used

What materials are used to lower a project's carbon footprint?

When our clients ask about reducing environmental impact, we're excited to share the sustainable material options that are making a real difference in 2025.

Mass timber products like cross-laminated timber (CLT) are true climate heroes. Not only do trees absorb carbon dioxide as they grow, but that carbon remains locked away in the wood throughout a building's lifetime. Each cubic meter of wood can store around a ton of CO₂, making it actually carbon-negative when sourced from sustainable forests.

Low-carbon concrete has come a long way in recent years. By replacing portions of traditional Portland cement with supplementary cementitious materials like fly ash or slag, we can reduce the carbon footprint by 30-50%. One of our facilities in the Mountain West recently incorporated these mixes in their foundation work.

Recycled steel is another smart choice, producing about 75% less carbon emissions than virgin material. At American Mortuary Coolers, we prioritize recycled metals across our manufacturing processes.

Other standouts include bio-based insulation materials like hemp and cellulose that perform similarly to synthetic options with much lower embodied carbon.

What materials are used in high-temperature environments?

High-temperature applications present unique challenges that require specialized materials to ensure safety and longevity.

Refractory ceramics are the workhorses of extreme heat environments, withstanding temperatures above 1600°C (2900°F). These remarkable materials form the critical linings of industrial furnaces and kilns where other materials would simply melt away.

For components that need to maintain strength while resisting corrosion at high temperatures, high-temperature alloys like Inconel (nickel-chromium-based) perform beautifully up to about 1000°C (1800°F).

Technical ceramics such as silicon carbide offer another solution, particularly when thermal shock resistance is needed alongside temperature stability. Their ability to handle rapid temperature changes without cracking makes them invaluable in certain applications.

For more moderate high-temperature needs, specialty glasses like borosilicate handle temperatures up to 500°C (930°F), while high-performance polymers such as PEEK and polyimides push the boundaries of what plastics can do.

What materials are used for hygienic surfaces like mortuary equipment?

When it comes to mortuary equipment, hygiene isn't just important—it's absolutely essential. This is an area where material selection directly impacts safety, dignity, and peace of mind.

Stainless steel remains the gold standard for good reason. Particularly grades 304 and 316, which contain chromium and nickel that form a self-healing passive layer on the surface. This remarkable material resists corrosion from bodily fluids and harsh disinfectants while providing a non-porous surface that bacteria can't penetrate. We use stainless steel extensively in our mortuary coolers for these very reasons.

Solid surface materials like Corian® offer another excellent option. Their seamless, non-porous construction eliminates the joints and crevices where bacteria might hide. These acrylic polymer and alumina trihydrate surfaces maintain their appearance even after years of intensive cleaning and disinfection.

An exciting development we've incorporated in some of our premium models is antimicrobial copper alloys. These EPA-registered materials actively kill bacteria on contact, with effectiveness lasting the lifetime of the product.

At American Mortuary Coolers, our mortuary equipment manufactured in Dallas, TX and other facilities strategically combines these materials—stainless steel for primary contact surfaces and antimicrobial materials in high-touch areas—to create equipment that meets the highest standards of hygiene and durability.

Conclusion

When it comes to what materials are used in today's construction and manufacturing world, there's no simple answer. As we've seen throughout this guide, choosing the right materials in 2025 means juggling performance needs, budget constraints, sustainability goals, and local factors.

Looking ahead, several important trends are shaping how we select materials:

The push for sustainability is driving remarkable innovation across industries. We're seeing exciting developments in bio-based alternatives, increased use of recycled content, and growing adoption of circular economy principles. These approaches aren't just good for the planet—they're increasingly good for business too.

We've also learned that durability truly pays off in the long run. While high-performance materials might cost more upfront, they often deliver better value over time through reduced maintenance and longer service life. This "lifecycle thinking" is becoming standard practice for forward-thinking companies.

Hybrid material solutions are becoming increasingly common as designers get more sophisticated about combining materials strategically. By pairing materials with complementary properties, we can create solutions that maximize strengths while minimizing weaknesses.

At American Mortuary Coolers, we understand that material selection directly impacts how well our products perform. Our experience manufacturing across diverse regions—from our Tennessee headquarters to facilities in New York, Chicago, and Los Angeles—gives us unique insight into optimizing material choices for specific needs and locations.

We carefully customize our mortuary equipment with materials specifically chosen for funeral service environments:

Corrosion-resistant surfaces stand up to frequent disinfection without degrading. Thermally efficient insulation ensures reliable temperature control in all conditions. Durable structural components provide decades of dependable service. And hygienic materials support proper infection control—something that's absolutely essential in mortuary settings.

By applying our deep understanding of what materials are used for optimal performance in mortuary applications, we create products that deliver exceptional value throughout their entire lifecycle. And with our direct delivery service across all 48 contiguous states, funeral professionals nationwide can benefit from our material expertise.

For more information about our mortuary coolers and how our thoughtful material selections improve their performance and longevity, reach out to our team today. We're committed to providing durable, custom solutions that truly meet the unique needs of the funeral industry.