Understanding Chambers Refrigerators: Precision Cooling for Critical Applications

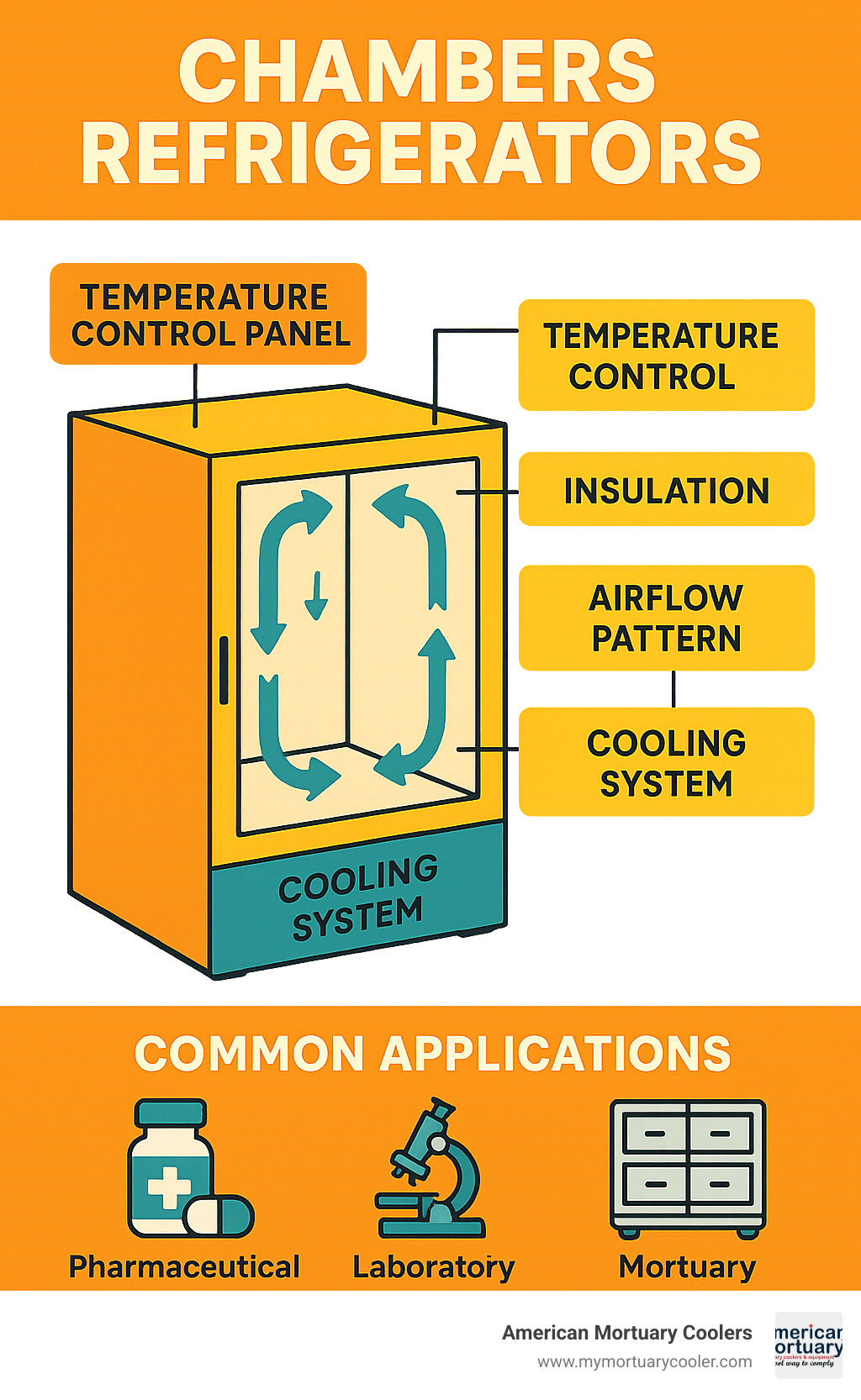

Chambers refrigerators are specialized cooling units designed for precise temperature control and stability, typically used in scientific, pharmaceutical, mortuary, and food service industries. Unlike standard refrigerators, they maintain extremely tight temperature tolerances and uniform conditions throughout the interior space.

| Key Features of Chambers Refrigerators | Primary Applications |

|---|---|

| ± 0.2°C temperature control accuracy | Pharmaceutical storage |

| Uniform cooling (± 1.0°C throughout) | Laboratory specimen preservation |

| Microprocessor-controlled environment | Mortuary and forensic facilities |

| Available as walk-in or reach-in units | Stability testing chambers |

| Optional humidity and light control | Wine and specialty food storage |

Chambers refrigerators stand apart from standard refrigeration through their precision engineering, which eliminates temperature fluctuations that could compromise sensitive materials. These specialized units use advanced airflow systems, superior insulation, and sophisticated control technology to maintain consistent temperatures – critical for applications where even minor temperature variations could have significant consequences.

For mortuary applications specifically, chambers refrigerators provide the reliable cooling and dignified storage essential for deceased care, with specialized body box configurations available in 2, 3, or 4-body capacities to meet facility needs.

I'm Mortuary Cooler, a national-level supplier of mortuary refrigeration systems with extensive experience helping funeral homes select the right chambers refrigerators for their specific requirements. My team specializes in providing American-made cooling solutions that combine precision temperature control with practical, customizable designs.

Basic chambers refrigerators vocab:

Chambers Refrigerators 101: Definition & How They Differ

When you walk into a lab, pharmacy, or modern funeral home, you might notice refrigeration units that look a bit different from your kitchen fridge. These are chambers refrigerators – the precision instruments of the cooling world.

Think of the difference this way: if your home refrigerator is like a wristwatch, a chambers refrigerator is like a Swiss chronometer. They maintain astonishingly precise temperatures, typically within ±0.2°C at the sensor and ±1.0°C throughout the entire chamber.

"The difference between a standard refrigerator and a chambers refrigerator is like comparing a household thermometer to laboratory-grade equipment," says Scott Young from Lawrence Berkeley National Laboratory. "When you're storing materials worth thousands or even millions of dollars, that precision becomes non-negotiable."

What makes these units special is their brains – sophisticated microprocessor PID controllers that constantly adjust cooling output to maintain perfect conditions. Many use field-proven systems from companies like Fuji Electric, which have been reliably controlling temperatures in thousands of installations worldwide.

The construction is equally impressive. Chambers refrigerators feature professional-grade insulation panels (usually 60-100mm thick), precision-engineered airflow systems, multiple temperature probes, vapor-tight seals, and heavy-duty construction that often includes stainless steel. They're built to meet strict FDA cGMP standards that ordinary refrigerators simply can't achieve.

Whether you're looking at a compact reach-in unit for a small lab or a spacious walk-in chamber for a pharmaceutical facility, these refrigerators deliver something standard commercial units cannot: absolute reliability when it matters most.

How Chambers Refrigerators Maintain Temperature Uniformity

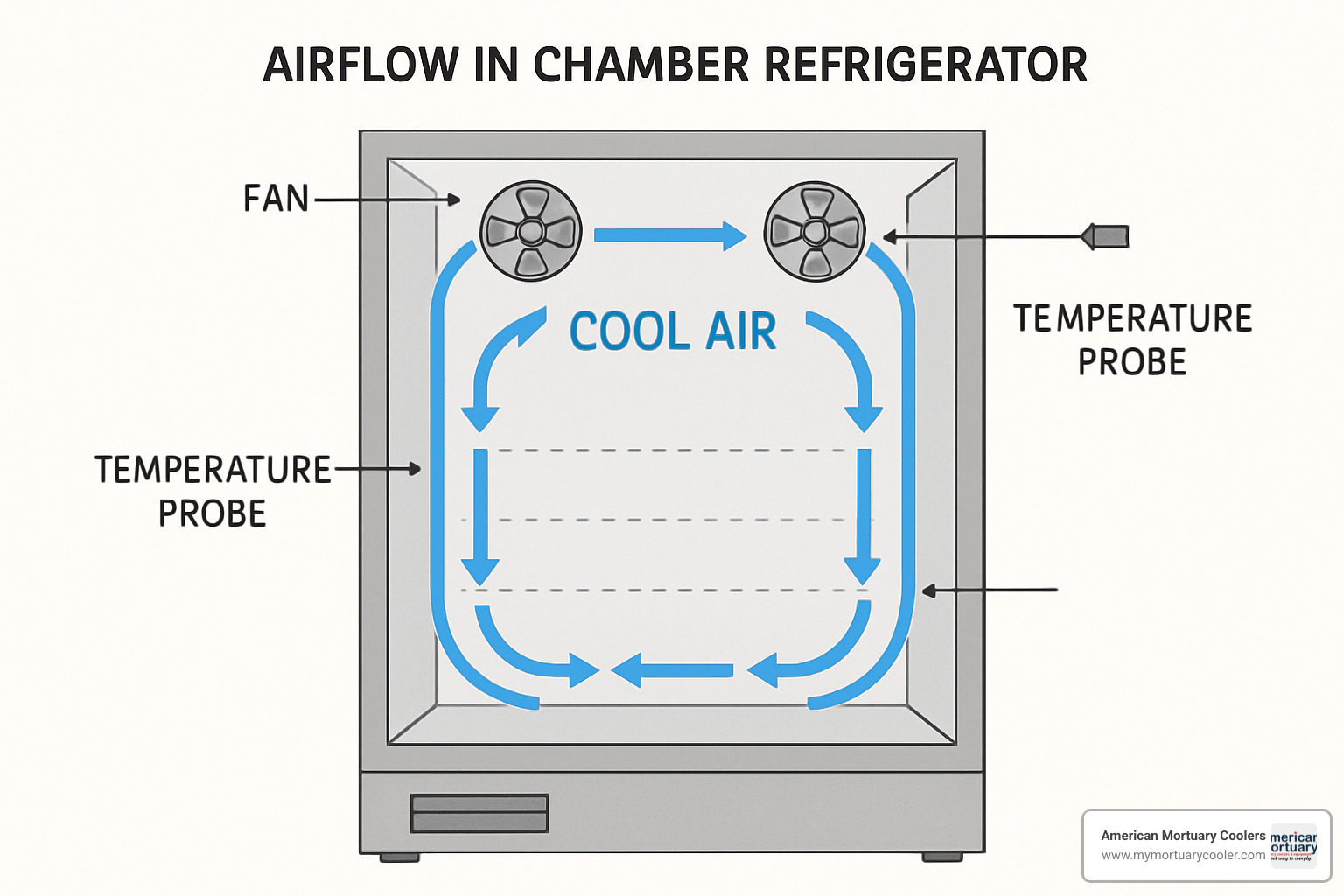

The magic of chambers refrigerators happens behind the scenes, where careful engineering eliminates temperature variations that could compromise sensitive materials.

Multi-point temperature probes act like vigilant sentinels throughout the chamber, constantly monitoring conditions at different locations. This network of electronic eyes ensures no corner of the unit strays from the target temperature.

Whisper-quiet DC fans create gentle, consistent airflow that prevents temperature stratification (where warm air rises and cold air sinks). Unlike the noisy AC fans in standard refrigerators, these specialized motors circulate air while generating minimal heat and vibration. As one manufacturer notes, "Quiet operation is achieved through the use of highly efficient DC fans" – something your staff will appreciate during long shifts.

The insulation in quality chambers refrigerators deserves special mention too. Most professional units use high-density polyurethane foam without wood components (which can absorb moisture and deteriorate). For mortuary applications, these panels are typically 4 inches thick, creating an exceptional thermal barrier against outside temperatures.

Behind the scenes, comprehensive data logging systems monitor and record conditions 24/7, providing documentation that can be essential for regulatory compliance. Many systems maintain records for years, creating an unbroken chain of evidence that materials remained within their required temperature parameters.

Benefits of Chambers Refrigerators for Sensitive Materials

The precision of chambers refrigerators delivers real-world benefits that matter across industries:

For vaccines, even brief temperature excursions can reduce potency. Chambers refrigerators maintain the exact 2°C to 8°C range needed to ensure these medications remain fully effective – a critical consideration when storing products that protect public health.

Pharmaceutical companies rely on these units for stability testing, determining how long medications remain effective under various conditions. These studies sometimes run for years, requiring the kind of unwavering temperature control that only specialized refrigeration can provide.

In laboratory settings, chambers refrigerators often include HEPA filtration and antimicrobial surfaces to prevent cross-contamination between samples – crucial for maintaining the integrity of diagnostic and forensic materials.

Security features provide peace of mind for high-value or sensitive contents. Electronic locks, access logs, and tamper-evident seals create a clear record of who accessed materials and when – essential for chain-of-custody requirements in forensic and pharmaceutical applications.

For funeral homes, these benefits translate to dignified, reliable preservation that gives families confidence during difficult times. At American Mortuary Coolers, we've seen how the right refrigeration solution makes a meaningful difference both for funeral directors and the families they serve.

Types & Industry Applications of Chambers Refrigerators

When you're exploring chambers refrigerators, you'll find they come in several flavors, each designed with specific industries and applications in mind. Let's take a friendly tour through these specialized cooling solutions and see which might be right for your needs.

Stability & Laboratory Units

If precision is your middle name, stability chambers are your new best friend. These are the cream of the crop when it comes to chambers refrigerators—the kind pharmaceutical companies trust with medications worth millions.

The Darwin ST series shines in this category with temperature ranges of 2°C to 15°C and remarkable control accuracy of ±0.2°C at the sensor. Throughout the entire chamber, you'll find ±1.0°C uniformity—something that makes FDA inspectors smile during audits.

"These aren't your kitchen refrigerators," as we like to tell our customers. "These units are where science meets reliability." With programmable alarms and optional data logging, these units keep your samples safe while documenting everything for your records.

Laboratory researchers particularly appreciate the visibility options—many lab models feature glass doors so you can see your samples without opening the door and disrupting the carefully maintained environment inside.

Walk-In & Modular Cold Rooms

When you need space to move around inside your chambers refrigerators, walk-in models are the way to go. These customizable cold environments can be custom to fit almost any space requirement.

Arctic Walk-ins can span up to an impressive 25-foot ceiling—perfect for large-scale operations. What I love about these systems is their flexibility. Since they're built with modular panels, you can expand them later if your needs grow, or even disassemble and relocate them if you move facilities.

These walk-ins serve diverse industries from pharmaceutical manufacturing to floral storage. I recently visited a craft brewery that used a walk-in chamber to store their hops at precise temperatures—the resulting beer was exceptional!

The heavy-duty flooring options can even support forklift traffic, making these practical for busy commercial operations where efficiency matters as much as temperature control.

Mortuary & Forensic Coolers

At American Mortuary Coolers, we specialize in chambers refrigerators designed specifically for funeral homes and forensic facilities. Our mortuary coolers are built with both technical precision and the dignity of final care in mind.

Our most popular configurations include 2-body systems for smaller funeral homes, standard 3-tier body boxes (typically 7'8" × 3'1" × 5'6½"), and 4-body systems for higher-volume facilities. For medical examiners handling larger caseloads, we create custom-sized walk-in chambers that balance efficiency with respectful handling.

"We understand that this equipment serves a sacred purpose," as our founder often says. That's why we include features like heavy-duty stationary rack systems, vapor-proof LED lighting with exterior switches, and digital temperature displays with reliable alarm capabilities.

We take pride in our 100% American-made construction, using NSF and UL approved components throughout. You can learn more about these specialized units in our Detailed Guide to Mortuary Chamber: Purpose and Function.

Vintage & Retro Consumer Models

On a lighter note, the residential side of chambers refrigerators has developed quite a following among homeowners with an eye for distinctive style. While these units don't offer the scientific precision of their professional cousins, they bring unique character to home kitchens.

The Chambers Retro bottom-freezer models, with their 24-inch width and 12 cubic feet of capacity, fit perfectly in smaller kitchens while making a bold statement. The champagne and mint green finishes transport you straight back to the 1950s—but with modern energy efficiency.

As one delighted homeowner told us after installing their Chambers retro model: "It felt like a bit of a risk to buy this style of appliance, but I'm SO glad we took it! This fridge is exactly what our farmhouse kitchen needed."

Wine, Cheese & Cigar Cabinets

For the connoisseurs among us, specialized chambers refrigerators from companies like Chambrair offer climate control engineered specifically for life's finer pleasures.

These cabinets maintain constant temperatures over 24 hours with their TemperatureManagement© system, while UV protection systems prevent light damage to sensitive wines. The HygroControl© feature maintains optimal humidity levels that keep corks moist and cheeses at peak condition.

I particularly appreciate the VibraStop© technology that prevents vibration from disturbing sediment in fine wines. It's this attention to detail that makes these specialized units worth their premium price.

As Chambrair wisely notes: "One recognizes the connoisseur not by their wines, but by how they care for them!" Whether you're storing a vintage Bordeaux or artisanal cheese, these specialized chambers create the perfect environment for your treasures.

At American Mortuary Coolers, we understand that choosing the right chambers refrigerator is an important decision. That's why we're always available to help you steer the options and find the perfect solution for your specific needs. Whether you need more information about mortuary cold storage options or want to discuss a custom solution, we're just a phone call away.

Must-Have Features, Technologies & Customization Options

When shopping for chambers refrigerators, certain features truly separate the premium units from basic models. I've spent years helping funeral homes find the perfect refrigeration solution, and I can tell you that understanding these key technologies makes all the difference in making a smart purchase.

Temperature Control & Monitoring Systems

The heart and soul of any quality chambers refrigerator is its control system. The best units feature sophisticated PID controllers that continuously adjust cooling output to maintain perfect conditions. We recommend non-proprietary controllers like those from Fuji Electric because they offer both reliability and—just as importantly—serviceability years down the road.

Modern units now come with intuitive touchscreen interfaces that make operation simple while providing detailed status information at a glance. No more squinting at tiny LED displays or decoding cryptic error messages!

What really sets premium chambers refrigerators apart is multi-point monitoring. Rather than measuring temperature at just one location, quality units use multiple probes throughout the interior to ensure uniform conditions everywhere. This is crucial for mortuary applications where consistent cooling throughout the entire chamber matters.

Many of our clients particularly appreciate remote monitoring capabilities. These network-connected systems let you check conditions from your smartphone or computer, providing peace of mind and immediate alerts if anything goes outside acceptable ranges—even when you're away from the facility.

Alarm & Safety Features

Nobody wants that middle-of-the-night phone call about a refrigeration problem. Quality chambers refrigerators include comprehensive alarm systems that help prevent those scenarios:

Temperature excursion alarms provide both visual and audible alerts if conditions drift outside your set parameters. Door ajar alarms notify you if someone forgets to fully close the door—a common but easily preventable issue. Power failure alerts give immediate notification if electricity is interrupted, while backup power systems can automatically switch to battery or generator power during outages.

For funeral homes and medical facilities, security access controls have become increasingly important. Electronic locks with user-specific access codes not only restrict entry to authorized personnel but also create an activity log documenting exactly who accessed the unit and when.

As our friends at Darwin Chambers often note, these systems typically include "programmable high/low audible and visual alarms with remote alarm contacts," ensuring that responsible staff are immediately notified of any issues before they become problems.

Customization Options

One size definitely doesn't fit all when it comes to chambers refrigerators. The ability to tailor a unit to your specific needs dramatically improves its usefulness in your facility.

Shelving configurations can be customized from standard wire shelves to specialized racks designed specifically for mortuary trays. Interior finishes typically include stainless steel, aluminum, or specialized antimicrobial coatings that resist bacteria growth and simplify cleaning.

For exterior finishes, you're no longer limited to institutional white. Many of our clients choose stainless steel for its durability and professional appearance, while others select custom colors to match their facility's aesthetic. Door options include solid doors for maximum insulation or glass doors when visibility of contents is important.

Lighting systems have come a long way too. Modern LED systems provide even illumination while generating minimal heat and using a fraction of the electricity of older fluorescent systems.

At American Mortuary Coolers, we understand that every funeral home has unique requirements and space constraints. That's why we offer extensive customization options for our mortuary chambers, ensuring each unit perfectly matches your workflow and available space.

Positive vs Negative Temperature Chambers

Chambers refrigerators generally fall into two broad categories: positive and negative temperature units, each designed for specific applications:

| Feature | Positive Temperature Chambers | Negative Temperature Chambers |

|---|---|---|

| Temperature Range | 0°C to +5°C (32°F to 41°F) | -18°C to -20°C (0°F to -4°F) |

| Insulation Thickness | 60-80mm (2.4-3.1") | 100mm (4") minimum |

| Defrost Cycles | Less frequent | Regular automatic defrost required |

| Door Seals | Standard gaskets | Heated door frames to prevent freezing |

| Typical Applications | Fresh storage, pharmaceuticals, specimens | Frozen products, long-term storage |

| Energy Consumption | Lower | Higher |

As our colleagues at camarasfrigorificass.es explain, "Positive cold rooms operate at 0/+5°C; negative cold rooms at –18/–20°C," highlighting the fundamental difference between these systems. For mortuary applications, positive temperature units are typically what you'll need, operating in the 35-40°F range for optimal preservation.

Data Integrity & Compliance Tools

For regulated industries like healthcare and funeral services, data integrity features have become essential:

Modern chambers refrigerators often include 21 CFR Part 11 compliant logging that meets FDA requirements for data security and integrity. These systems maintain comprehensive audit trails of all activities, including temperature readings, door openings, and user access—creating an unbroken record that can be invaluable for both regulatory compliance and your own peace of mind.

Many of our clients appreciate cloud dashboards that allow monitoring multiple units across different locations from a single secure portal. For larger operations with multiple facilities, this capability streamlines management and ensures consistent standards.

Quality manufacturers also provide validation documentation—those IQ/OQ/PQ protocols that verify system performance and provide documentation for regulatory inspections. While paperwork isn't exciting, having these documents properly completed can save tremendous headaches during inspections.

Safety & Specialty Builds

Some applications require specialized safety features beyond standard refrigeration:

Explosion-proof designs are critical for storing flammable materials. These Class 1 Division 1 & 2 chambers include specialized electrical components and ventilation systems designed to prevent ignition hazards. Fire-rated panels provide additional protection by incorporating insulation with improved fire resistance.

For medical examiners handling potentially infectious materials, bio-containment features like negative pressure systems and specialized filtration help protect staff and the environment.

As we often tell our clients at American Mortuary Coolers, selecting the right features isn't about getting the most expensive unit—it's about finding the perfect match for your specific needs. That's why we take the time to understand exactly how you'll use your chambers refrigerator before recommending specific features and technologies.

Buying, Cost & Maintenance Guide

Investing in a chambers refrigerator is a significant decision that goes beyond just the initial purchase. Let's walk through everything you need to know to make a smart choice that serves you well for years to come.

Selecting the Right Size & Range

Finding that "just right" size starts with honest assessment of your needs – both today and tomorrow.

Think about your sample volume carefully. I always tell my customers to calculate their current storage requirements and then add about 20% for unexpected growth. Nothing's more frustrating than outgrowing your unit within a year of purchase!

Your growth projections matter tremendously. Is your funeral home expanding to serve more families? Are you adding new services? Most quality chambers refrigerators last 15-20 years, so consider where your business will be in 5, 10, and even 15 years.

Don't overlook your ambient conditions either. I visited a customer in Phoenix who installed their unit in a garage that reached 110°F in summer – their standard unit couldn't keep up! Higher ambient temperatures demand more powerful refrigeration systems, so be honest about your facility's environment.

As Darwin Chambers puts it: "We know you can't take risks with your research, so we don't take risks with quality." The same applies to mortuary care – you simply can't compromise on reliability.

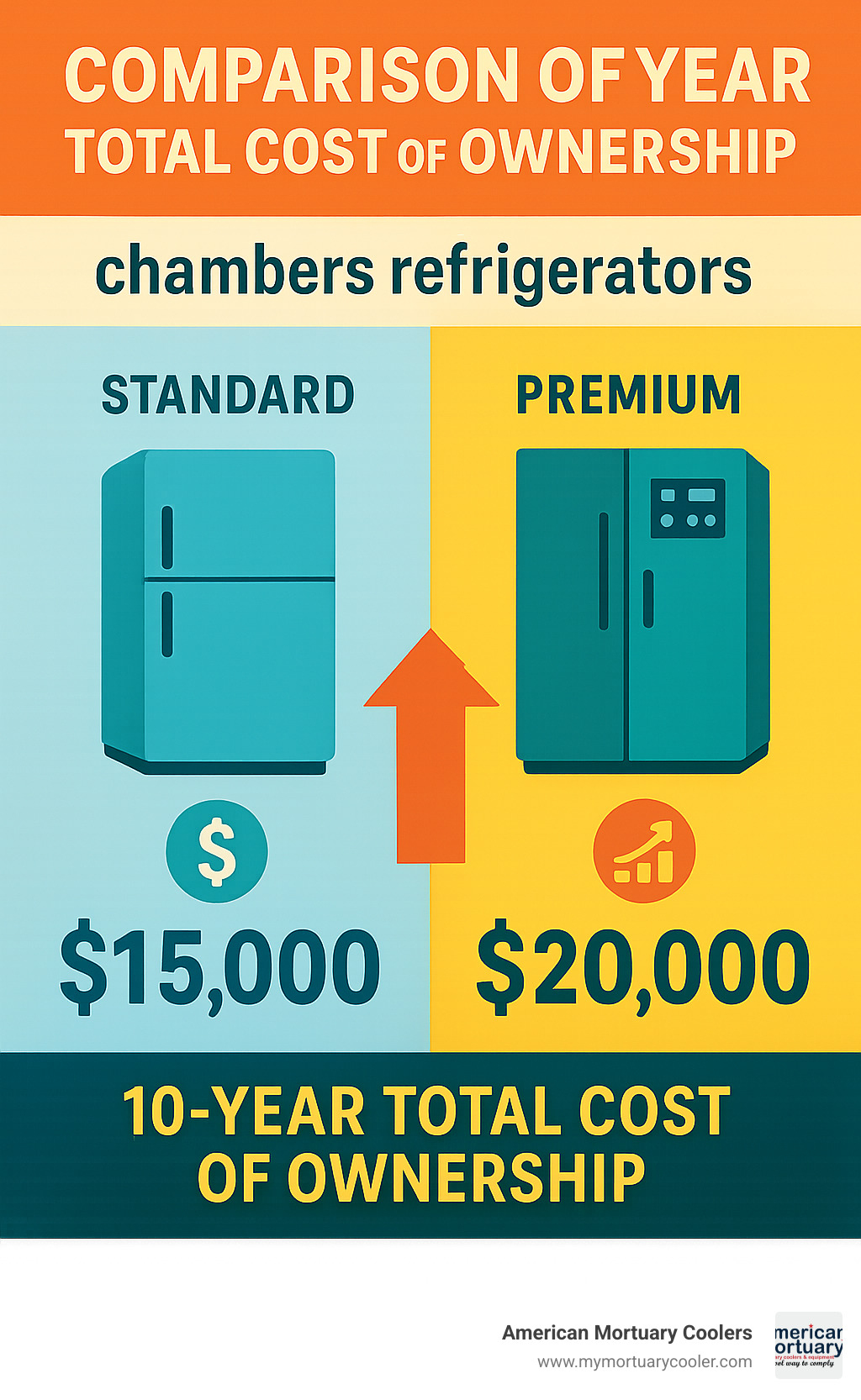

Budgeting: Upfront vs Lifecycle Cost

The sticker price is just the beginning of your investment story. Smart buyers look at the complete financial picture:

CAPEX vs OPEX considerations should guide your decision. While that initial capital expenditure might make you wince, operating expenses over the unit's lifetime often exceed the purchase price. A cheaper unit that guzzles electricity or needs frequent repairs will cost you much more in the long run.

Power consumption varies dramatically between models. I've seen energy-efficient units save funeral homes up to $600 annually in electricity costs compared to budget models. Those savings add up! Look for Energy Star rated units when available.

Don't forget to ask about rebates and incentives. Many utilities offer substantial rebates for energy-efficient refrigeration. We recently helped a customer in Tennessee secure a $1,200 rebate on their new mortuary cooler – a nice surprise that made the premium model much more affordable.

Always review the warranty coverage carefully. Quality matters here – premium units typically offer more comprehensive protection. At American Mortuary Coolers, we stand behind our products with robust warranty terms because we believe in building relationships, not just making sales.

Installation & Validation Checklist

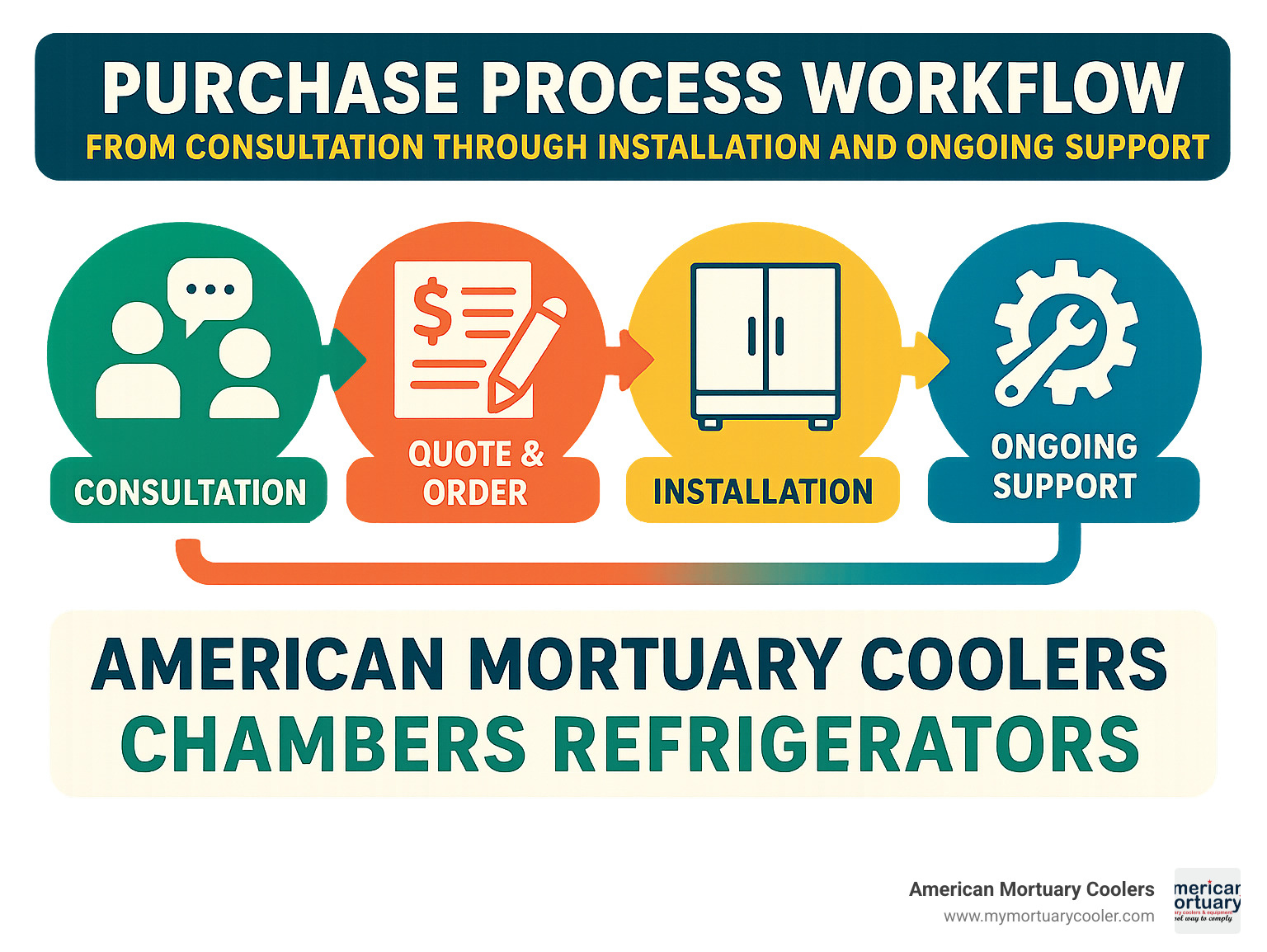

A smooth installation sets the stage for years of trouble-free operation. Let me share what we've learned from hundreds of installations:

Thorough site preparation prevents headaches later. Before your unit arrives, ensure you have adequate space (including clearance for ventilation), proper power supply, and easy access for delivery. I once saw a beautiful new mortuary cooler that couldn't make it through the facility's narrow doorway – an expensive lesson in measuring twice!

For facilities with regulatory requirements, formal IQ/OQ/PQ protocols (Installation Qualification, Operational Qualification, and Performance Qualification) might be necessary. We can guide you through this process to ensure compliance.

Consider backup power integration essential, not optional. Every mortuary cooler should connect to emergency power systems. A funeral director in Chicago told me how grateful he was for this feature during a three-day power outage after a severe storm – it saved his business from a potential disaster.

At American Mortuary Coolers, we work closely with facility managers from Johnson City to Los Angeles, ensuring smooth installations nationwide. We're not just dropping off equipment; we're making sure it works perfectly in your unique space.

Routine Maintenance & Troubleshooting

A little preventive care goes a long way toward ensuring your chambers refrigerator serves you reliably for decades.

Quarterly gasket inspection is something anyone can do. Run your hand along door seals feeling for cracks, tears or areas where the magnetic seal isn't quite right. This simple check can prevent temperature fluctuations and excessive energy use.

Condenser cleaning is perhaps the most overlooked maintenance task. Every 3-6 months, turn off the unit and gently vacuum dust and debris from the condenser coils. This simple step can extend compressor life by years and reduce energy consumption by up to 25%.

Regular temperature verification using calibrated external thermometers provides peace of mind that your unit is performing as expected. For mortuary applications, this verification is particularly important for maintaining dignity in care.

Don't forget alarm testing – those safety features only help if they're working properly! Test all alarm functions quarterly by briefly creating alarm conditions (like holding a door open) to ensure the system responds appropriately.

For mortuary facilities specifically, we recommend scheduling comprehensive preventive maintenance quarterly. The modest cost of maintenance is insignificant compared to the value of reliability during sensitive periods of family care.

Frequently Asked Questions about Chambers Refrigerators

Q: What temperature accuracy can I expect from a quality chambers refrigerator?

A: Premium chambers refrigerators typically maintain ±0.2°C control at the sensor and ±1.0°C uniformity throughout the chamber. This precision exceeds FDA and ICH requirements for pharmaceutical storage and ensures optimal conditions for mortuary care.

Q: What regulatory standards do chambers refrigerators comply with?

A: Depending on the application, chambers refrigerators may comply with FDA, ICH, GMP, NSF, UL, and EISA 2007 standards. For mortuary applications specifically, NSF and UL approval are standard requirements that ensure safety and reliability.

Q: How long does customization typically take?

A: For standard customizations, expect 4-6 weeks from order to delivery. More extensive custom builds may require 8-12 weeks. At American Mortuary Coolers, we understand that sometimes you need equipment quickly, which is why we maintain some standard configurations in stock for expedited delivery when needed.

Q: What's the typical lifespan of a quality chambers refrigerator?

A: With proper maintenance, professional-grade chambers refrigerators typically provide 15-20 years of reliable service. The compressor is usually the first major component to require replacement, typically after 7-10 years of continuous operation. We've seen well-maintained units still performing flawlessly after more than two decades.

Q: Can chambers refrigerators be relocated if our facility changes?

A: Yes! Most professional chambers refrigerators are designed with potential relocation in mind. Modular walk-in units can be disassembled and reassembled at a new location, while reach-in units can simply be moved as complete systems. We recently helped a funeral home in Dallas relocate their entire cooling system to a new facility – the process was much smoother than they expected.

Looking for more information about mortuary refrigeration options? Check out our comprehensive guide to mortuary cold storage options for additional insights.

Conclusion

Chambers refrigerators represent the gold standard in precision cooling technology, delivering exceptional temperature stability for applications where consistency isn't just preferred—it's absolutely essential. I've seen how these specialized systems provide the peace of mind that comes with knowing sensitive materials are being stored under optimal conditions, whether they're preserving vital pharmaceuticals, supporting groundbreaking research, or providing dignified care for the deceased.

Throughout my years working with funeral homes and medical facilities, I've come to appreciate what truly matters when it comes to specialized refrigeration. The remarkable ±0.2°C control accuracy and ±1.0°C uniformity that quality chambers refrigerators deliver simply can't be matched by standard commercial units. This precision isn't just impressive on paper—it translates to real-world reliability when it matters most.

What I love about these systems is how they're thoughtfully engineered for specific industry needs. Whether it's a stability chamber carefully maintaining conditions for pharmaceutical testing or a mortuary body box designed with both functionality and dignity in mind, there's a perfect solution for every specialized application.

When helping clients choose the right system, I always emphasize looking beyond the sticker price. Yes, the initial investment matters, but the true value comes from the reliability, energy efficiency, and appropriate sizing for your specific needs. A properly sized, energy-efficient unit often pays for itself many times over during its 15-20 year lifespan.

Speaking of lifespan, I can't stress enough how critical regular maintenance is. Those quarterly check-ups might seem like a hassle, but they're absolutely worth it. Simple tasks like inspecting door gaskets, cleaning condenser coils, and testing alarm systems can mean the difference between a unit that runs flawlessly for decades and one that fails prematurely—potentially at the worst possible moment.

One of the things that excites me most about working with chambers refrigerators is the customization possibilities. There's something satisfying about tailoring a solution to fit perfectly within a client's workspace and workflow. The right customizations don't just look better—they make daily operations smoother and more efficient.

Here at American Mortuary Coolers, we've built our reputation on understanding the unique needs of funeral homes and medical examiner facilities. Our Tennessee-based team takes pride in creating custom mortuary refrigeration solutions that combine precision cooling with practical, dignified designs. We deliver directly to all 48 contiguous states, ensuring that no matter where you're located, we can provide the perfect chambers refrigerator for your specific requirements.

Whether you're replacing an aging unit that's seen better days or equipping a brand-new facility, I'd love to show you how our custom morgue coolers meet every spec. Our team serves the entire country from our regional offices, bringing our expertise right to your doorstep. After all, when it comes to something as important as mortuary refrigeration, you deserve a solution that's as reliable as it is respectful.