Why Cooling Tables Remain Essential for Modern Funeral Homes

A cooling table for funeral home operations serves as the cornerstone of respectful body preservation, providing a controlled environment for deceased individuals before burial, cremation, or viewing services. These specialized tables maintain proper temperature and drainage to preserve dignity while supporting the funeral preparation process.

Quick Answer for Funeral Directors:

- Primary Function: Temporary body preservation using refrigeration or ice

- Key Features: Stainless steel construction, drainage systems, temperature control

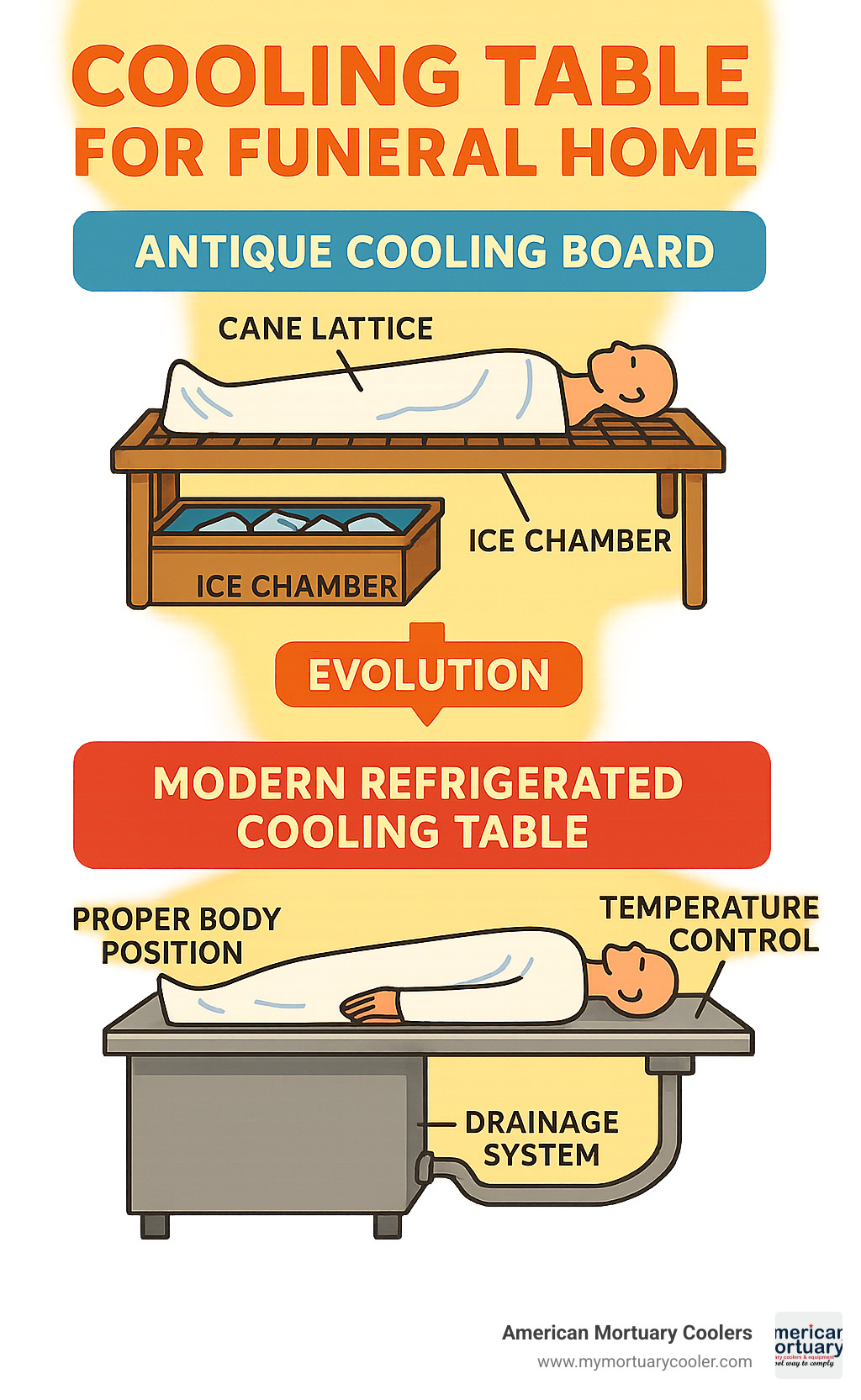

- Evolution: From 1880s wooden cooling boards to modern refrigerated units

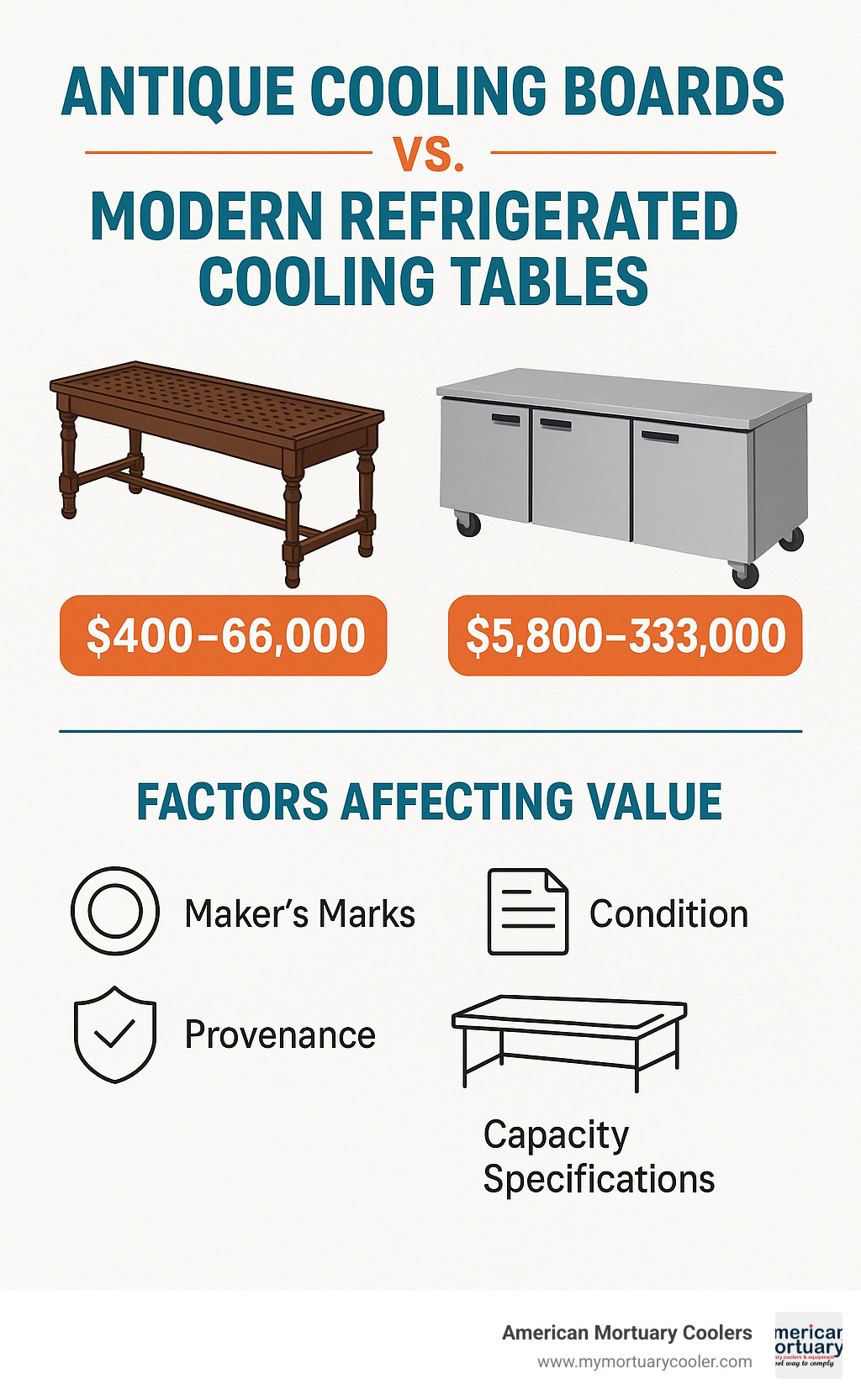

- Price Range: $400-$6,000 for antique boards; $5,800-$33,000 for modern systems

- Alternatives: Walk-in coolers, multi-tier storage racks, refrigeration pods

The journey from simple wooden cooling boards to today's sophisticated refrigerated systems tells a fascinating story of innovation driven by necessity. As one antique collector noted about their Victorian-era cooling board: "This piece of furniture may be one of the strangest objects that I have ever encountered, and definitely the strangest that I own."

Historical Timeline:

- 1880s-1940s: Wooden cooling boards with cane lattice and ice chambers

- 1930s-1950s: Transition to stainless steel embalming tables

- Modern Era: Refrigerated units, walk-in coolers, and modular storage systems

We're American Mortuary Coolers, a Tennessee-based specialist in crafting custom mortuary coolers and related equipment for the funeral industry. Our expertise in cooling table for funeral home equipment spans both historical preservation methods and cutting-edge refrigeration technology, helping funeral directors choose the right equipment for their specific needs across the contiguous 48 states.

Cooling Table for Funeral Home: Definition & Core Functions

At its heart, a cooling table for funeral home operations is a carefully engineered piece of equipment that preserves dignity while maintaining proper body temperature and drainage. It serves as the gentle guardian that keeps everything stable while families steer one of life's most difficult moments.

The main job of these tables is temporary preservation. We're talking about providing a safe, controlled environment for those crucial hours or days between death and the next steps—whether that's embalming, burial, or cremation. During this time, families are making arrangements, relatives are traveling, and funeral directors are coordinating countless details.

Embalming preparation becomes much more manageable with proper cooling equipment. The controlled temperature slows natural processes, giving morticians the time they need to work carefully and thoroughly.

When viewing arrangements need flexibility, cooling tables provide crucial viewing support. Maybe the casket delivery is delayed, or perhaps the family needs extra time to gather. These tables can temporarily serve as dignified display surfaces.

The drainage design handles fluids efficiently and hygienically, keeping the environment clean and respectful throughout the preservation process.

Temperature control ties everything together. Whether it's the simple physics of melting ice from decades past or today's precise digital systems, maintaining the right temperature is what makes everything else possible.

Anatomy of a Modern Cooling Table for Funeral Home

Today's cooling tables feature a stainless steel frame—typically made from 304-grade stainless steel that resists corrosion and cleans easily. This isn't just about durability; it's about maintaining sanitary conditions day after day.

The perforated deck represents a huge leap forward from those old solid wooden platforms. These carefully designed holes allow proper drainage while still providing even support.

Integral drains connect directly to your facility's plumbing, eliminating the old bucket-and-mop routine. The table surfaces are sloped just enough to guide fluids naturally toward the drainage points.

Modern casters transform these substantial pieces of equipment into surprisingly maneuverable tools. Industrial-grade wheels support significant weight while rolling smoothly across different floor surfaces.

Some models still feature foldable legs, echoing those innovative early 20th-century designs. Today's versions use hydraulic or mechanical systems that one person can operate.

Digital thermometers and precise temperature controls take the guesswork out of preservation. These systems maintain optimal conditions automatically and alert staff if anything goes off track.

For more detailed information about our comprehensive services, visit our funeral cooling tables guide.

How a Cooling Table Works

The science behind cooling tables is straightforward—it's all about moving heat away from where you don't want it. Conduction transfers heat directly from the body to the cooled table surface, while convection circulates cool air to maintain even temperatures.

Back in the ice block era (1880s through the 1940s), the process was beautifully simple. Large ice blocks went beneath perforated wooden platforms, creating natural cooling zones. As the ice melted, it absorbed heat from everything around it.

Modern refrigeration coils are like having a perfectly controlled ice block that never melts. These systems circulate refrigerant through coils built into or beneath the table surface.

Airflow patterns in contemporary designs ensure no hot spots develop. Strategic placement of cooling elements maintains consistent conditions across the entire table surface.

Timeline of Cooling Solutions: From Cooling Boards to High-Tech Tables

The evolution of cooling table for funeral home equipment reflects broader changes in American funeral practices, technology, and social customs. This journey from simple wooden boards to sophisticated refrigeration systems spans nearly 150 years of innovation.

Cooling boards emerged in the 1880s as a practical solution to body preservation challenges. These wooden platforms, often featuring cane lattice construction, represented the first systematic approach to controlled cooling.

B.F. Gleason became a prominent manufacturer during this era, holding patents from April 13, 1881, to September 7, 1886. Gleason's innovations included portable folding designs that allowed morticians to make house calls.

The 1918-19 Spanish Flu pandemic accelerated innovation in cooling table design. The overwhelming number of deaths required more efficient preservation methods, spurring development of improved portable systems.

The transition from wooden cooling boards to stainless steel embalming tables occurred primarily during the 1930s and 1940s. This shift coincided with the professionalization of funeral service and the movement from home-based funerals to funeral home facilities.

Walk-in coolers began appearing in larger funeral homes during the 1950s, offering expanded capacity and more precise temperature control.

Multi-tier storage racks emerged in the modern era as funeral homes sought to maximize capacity within limited space.

Recent innovations like CoolBot DIY cooling rooms demonstrate how technology continues to evolve. These systems allow funeral homes to create custom walk-in coolers using standard air conditioning units.

For historical context, you can learn more about the traditional cooling board evolution.

Key Milestones for the Cooling Table for Funeral Home

The Victorian parlor era (1880s-1900s) established the foundation for modern funeral cooling practices. Families used their formal parlors as temporary morgues, with cooling boards providing preservation until burial could be arranged.

The 1918 pandemic marked a turning point in cooling table technology and usage. The overwhelming mortality rate strained existing preservation methods, leading to rapid innovations in portable cooling systems.

The 1930s funeral home boom transformed cooling tables from home-use items to professional equipment. As funeral services moved from private homes to dedicated facilities, cooling table design evolved to meet commercial demands.

The 1950s stainless steel shift revolutionized sanitation and durability standards. Stainless steel construction became the industry standard, offering superior corrosion resistance and easier cleaning.

The 2000s brought modular rack systems that maximized storage efficiency. These multi-tier designs allowed funeral homes to accommodate fluctuating demand while maintaining precise temperature control.

Types & Designs Through the Years

Antique wooden cooling boards represent the earliest systematic approach to body preservation. These boards, typically constructed from oak or pine, featured simple but effective designs. Standard adult boards measured approximately 73¾ inches long by 19⅝ inches wide.

Cane lattice construction became popular for its superior drainage properties. Instead of drilled holes, these boards used woven cane panels that allowed fluids to drain while providing adequate support.

Child-sized cooling boards reflect the harsh realities of historical mortality rates. These smaller versions maintained the same design principles as adult boards but were proportioned for pediatric use.

Fold-out leg mechanisms represented a significant innovation in portability. This portability allowed funeral directors to provide professional services in private homes.

Modern hydraulic tables have transformed the physical demands of funeral work. These powered systems can raise, lower, and tilt cooling surfaces, reducing strain on funeral staff.

Refrigerated roll-in units combine the mobility of traditional cooling boards with modern temperature control. These self-contained systems can be moved between preparation areas as needed.

Choosing & Maintaining the Right Cooling Table

Selecting the appropriate cooling table for funeral home operations requires careful consideration of multiple factors including facility size, case volume, budget constraints, and regulatory requirements. We've helped funeral homes across our service areas steer these decisions based on their specific operational needs.

Ergonomic height considerations significantly impact daily operations. Tables should accommodate the average height of staff members while allowing for adjustment when possible. Fixed-height tables typically range from 32 to 36 inches.

Load capacity specifications must account for both typical and exceptional cases. Standard cooling tables support 300-500 pounds, but facilities serving diverse populations may require higher capacity units.

Material comparison reveals significant differences in durability, maintenance requirements, and cost. Stainless steel offers superior corrosion resistance and easy sanitization but requires higher initial investment.

Sanitation capabilities directly impact health compliance and operational efficiency. Look for seamless construction, rounded corners, and integrated drainage systems that facilitate thorough cleaning.

Mobility features improve operational flexibility. Lockable casters allow tables to be repositioned as needed while providing stability during use.

Energy consumption varies significantly between cooling methods. Ice-based systems require no electrical power but demand labor for ice management. Electric refrigeration systems consume power continuously but offer precise temperature control.

Warranty coverage reflects manufacturer confidence and provides protection against defects. Look for comprehensive warranties covering both mechanical components and refrigeration systems.

OSHA compliance ensures worker safety and reduces liability exposure. Cooling tables should meet relevant safety standards for electrical systems, mechanical components, and ergonomic design.

| Feature | Antique Cooling Boards | Modern Cooling Tables |

|---|---|---|

| Material | Oak/Pine Wood | 304-Grade Stainless Steel |

| Temperature Control | Ice Blocks | Electric Refrigeration |

| Mobility | Folding Legs | Lockable Casters |

| Drainage | Cane Lattice/Holes | Integrated Drain Systems |

| Capacity | Single Body | 1-12 Bodies |

| Price Range | $400-$6,000 | $5,800-$33,000 |

| Maintenance | Wood Care/Ice Management | Electrical/Mechanical Service |

Key Features Every Cooling Table for Funeral Home Should Include

Adjustable tilt capabilities provide crucial functionality for both drainage and preparation procedures. Slight elevation of the head or feet can improve fluid management while facilitating specific preparation techniques.

Lockable casters represent essential mobility features for most installations. These heavy-duty wheels should support the table's full load capacity while providing smooth movement across various floor surfaces.

Sealed weld construction eliminates potential contamination points and simplifies cleaning procedures. All joints should be fully welded and ground smooth to prevent bacterial accumulation.

Removable trays improve cleaning efficiency and provide flexibility for different case requirements. These trays should fit securely during use but remove easily for thorough sanitization.

Built-in sinks integrate hand-washing capabilities directly into the cooling table design. These features improve workflow efficiency while supporting proper hygiene protocols.

For additional insights on optimizing your prep room setup, explore our guide on prep room tables that make mortuary work easier.

Daily Operation & Maintenance

Cleaning protocols form the foundation of safe cooling table operation. Begin each day with visual inspection of all surfaces, drainage systems, and mechanical components.

EPA-approved disinfectants specifically designed for mortuary use provide the most effective sanitization. These products eliminate pathogens while being compatible with stainless steel and other table materials.

Hinge lubrication prevents mechanical failures and extends equipment life. Use food-grade lubricants on any moving parts that might contact body fluids.

Gasket inspection ensures proper sealing in refrigerated units. Check door seals, drainage gaskets, and any other rubber components for cracks, tears, or hardening.

Compressor checks on refrigerated units should include monitoring operating temperatures, listening for unusual noises, and verifying proper cycling.

Record keeping documents maintenance activities and helps identify patterns that might indicate developing problems. Maintain logs of cleaning activities, temperature readings, and any maintenance performed.

Legal & Ethical Considerations

State codes governing funeral home operations often include specific requirements for body preservation equipment. These regulations may specify temperature ranges, construction materials, or sanitation procedures.

CDC guidelines provide federal-level recommendations for mortuary operations, including cooling table use and maintenance. These guidelines address infection control, worker safety, and public health protection.

Respectful display considerations apply when cooling tables serve viewing functions. The dignity of the deceased must be maintained throughout all preservation activities.

Liability issues can arise from equipment failures, improper maintenance, or inadequate temperature control. Comprehensive insurance coverage and documented maintenance procedures provide protection against potential claims.

Provenance documentation for antique cooling tables affects both legal ownership and collector value. Clear title documentation prevents ownership disputes while detailed history can significantly increase value.

For scientific context on preservation standards, reference established embalming research and standards.

Value, Culture & Alternatives

The market for antique cooling boards reflects both collector interest and historical significance. Authentic boards typically sell for $400-$1,000, with exceptional examples reaching up to $6,000. These valuations depend on several key factors.

Maker identification significantly impacts value. B.F. Gleason boards, identifiable by patent dates and maker's marks, command premium prices due to their historical importance and quality construction.

Condition assessment requires expertise in both woodworking and funeral equipment history. Original hardware, intact cane lattice, and functional folding mechanisms increase value substantially.

Provenance documentation adds significant value when boards can be connected to specific funeral homes, historical events, or notable individuals. Benjamin B. French's account of witnessing Lincoln's remains on a cooling board demonstrates how historical connections can transform utilitarian objects into priceless artifacts.

Cultural references in blues music have immortalized cooling boards in American folk tradition. Son House's lyrics describing a lover on a cooling board reflect how these objects became embedded in cultural consciousness.

The Appalachian tradition of using barns as winter morgues illustrates regional adaptations of cooling board technology. When frozen ground prevented burial, families would place deceased relatives on cooling boards in unheated barns.

Respectful repurposing of antique cooling boards requires sensitivity to their original function. Many collectors display boards as historical artifacts rather than converting them to other uses.

Console table conversions represent the most common repurposing approach. The flat surface and interesting construction details make cooling boards attractive furniture pieces.

Museum displays provide ideal settings for cooling board preservation and education. These controlled environments protect the artifacts while allowing public appreciation of funeral history.

Alternatives to a Cooling Table in Contemporary Practice

Walk-in mortuary coolers represent the most comprehensive alternative to traditional cooling tables. These room-sized refrigeration systems can accommodate multiple bodies while providing morticians with comfortable working environments. Prices range from approximately $6,000 for basic 2-body units to over $30,000 for large multi-body installations.

Our experience across regions shows that walk-in coolers work particularly well for high-volume facilities or those serving large geographic areas. The 8'×12' CoolBot cooler can accommodate up to 25 bodies for approximately $5,000.

Multi-tier storage racks maximize capacity within limited floor space. These systems, ranging from 2-tier to 5-tier configurations, cost between $955 and $2,464 depending on capacity and features.

Body storage boards provide basic cooling functionality without integrated refrigeration. These boards, priced from $141 to several hundred dollars, work with existing cooling systems or ice-based preservation methods.

Refrigeration pods offer modular cooling solutions that can be combined as needed. These self-contained units provide precise temperature control for individual bodies while allowing flexible configuration.

For comprehensive guidance on selecting the right cooling solution, visit our ultimate guide to choosing cooling tables.

Frequently Asked Questions about Cooling Tables for Funeral Homes

What's the typical price range for modern cooling tables? Modern refrigerated cooling tables range from $5,800 for basic single-body units to over $33,000 for sophisticated multi-body systems with telescoping slide rails.

How can I identify an authentic antique cooling board? Look for maker's marks, patent dates (particularly B.F. Gleason patents from 1881-1886), and period-appropriate construction techniques. Authentic boards typically feature oak or pine construction with cane lattice or drilled drainage holes.

How often should cooling tables be cleaned and maintained? Daily cleaning after each use is essential, with deep sanitization using EPA-approved disinfectants. Weekly maintenance should include hinge lubrication and gasket inspection.

Is it legal to own and display antique cooling boards? Yes, there are no federal restrictions on owning antique cooling boards. Ensure clear title when purchasing and consider displaying with respect for the item's original function.

What are the installation requirements for modern refrigerated cooling tables? Most modern units plug into standard 110V outlets, eliminating the need for special electrical installation. Ensure adequate ventilation around compressor units and verify that floor surfaces can support the loaded weight.

Conclusion & Next Steps

The journey from Victorian-era wooden cooling boards to today's sophisticated refrigerated systems tells a remarkable story of innovation rooted in compassion. Whether you're drawn to the historical significance of antique cooling boards or need a modern cooling table for funeral home operations, this evolution reflects our industry's unwavering commitment to dignity and respectful care.

We've walked alongside funeral directors for years, helping them steer these choices with both practical wisdom and deep respect for tradition. From our Tennessee workshop, we've seen how the right cooling equipment transforms not just operations, but the entire experience of serving families during their most vulnerable moments.

The beauty of modern cooling tables lies in their ability to honor the past while embracing the future. Today's systems maintain the same fundamental mission as those century-old wooden boards - preserving dignity while providing precious time for proper arrangements. The difference? Precision that our predecessors could only dream of, efficiency that respects both your time and your budget, and reliability that ensures you're always ready to serve.

Our reach extends across the contiguous 48 states because we understand that every community deserves access to quality equipment. Whether you're managing a busy urban facility or serving a close-knit rural community, we design cooling solutions that fit your unique space, operational flow, and budget realities.

The investment in proper cooling equipment pays for itself through improved workflow, seamless regulatory compliance, and most importantly, the peace of mind that comes from knowing you can provide families with the respectful care they deserve. Modern systems eliminate the labor-intensive demands of historical ice-based cooling while delivering temperature control that ensures optimal preservation every single time.

For funeral directors ready to improve their cooling capabilities or those planning new facilities, we offer more than just equipment - we provide partnership. Our team combines deep knowledge of historical preservation methods with cutting-edge refrigeration expertise, helping you choose solutions that serve your community while honoring the respectful traditions that define our profession.

The future of funeral service lies in this thoughtful balance between respectful traditions and modern technology. Every cooling table we build carries forward the legacy of those early wooden boards while incorporating innovations that make your work more efficient and effective.

Ready to explore how modern cooling solutions can transform your funeral home operations? Visit our comprehensive resource center at mymortuarycooler.com to find how we can help you provide the dignified care families deserve while streamlining your daily operations. Our team is standing by to design custom solutions that honor both the rich traditions of funeral service and the practical realities of modern operations.