Why Cellule Réfrigérante Morgue Selection Matters for Modern Funeral Operations

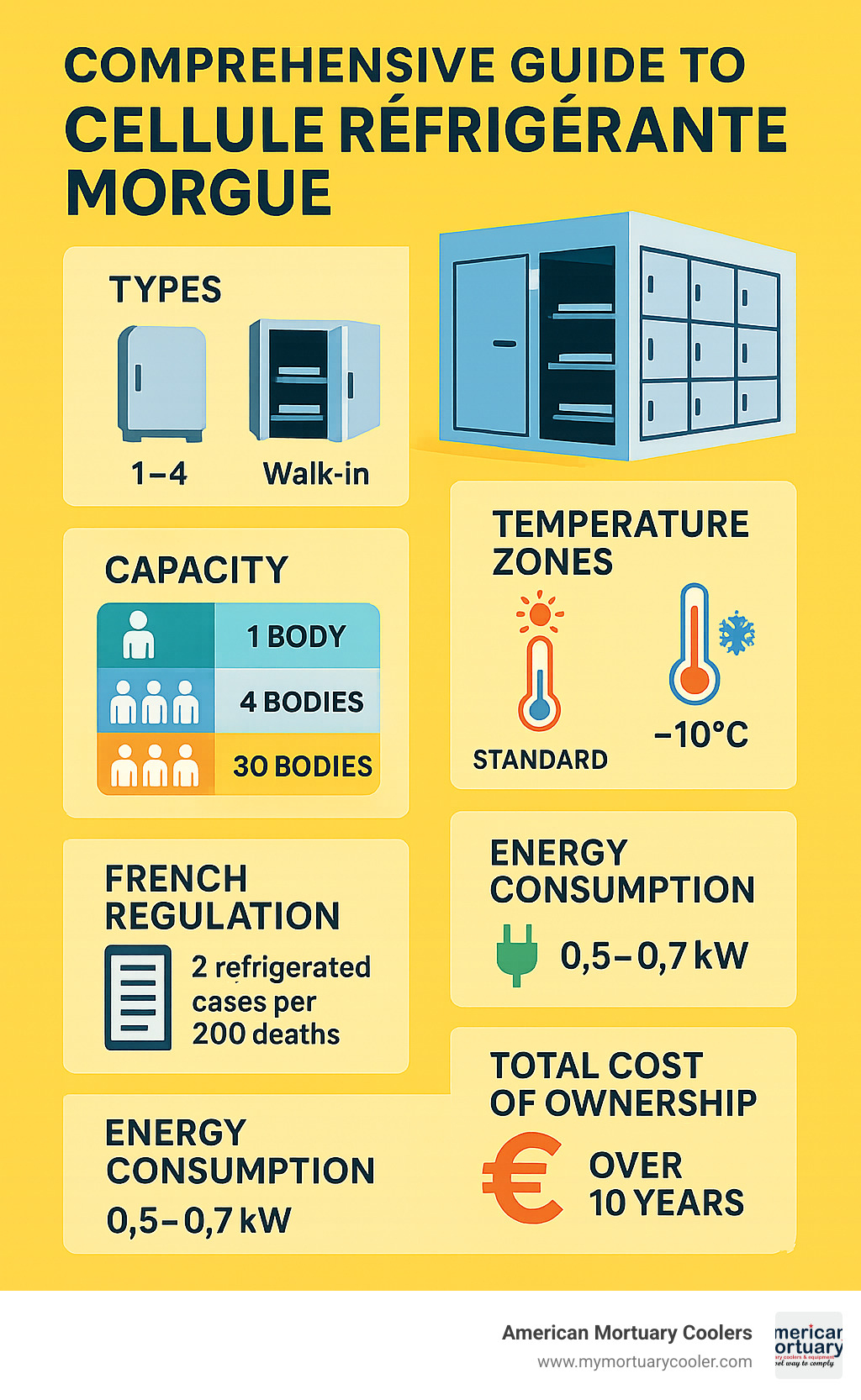

Cellule refrigerante morgue systems are specialized refrigeration units designed to preserve human remains at controlled temperatures, typically between 0°C to +5°C for standard preservation and down to -10°C for medico-legal cases. These essential mortuary cooling systems serve hospitals, funeral homes, and morgues by maintaining dignified storage conditions while complying with strict health regulations.

Quick Overview - Cellule Réfrigérante Morgue Essentials:

- Temperature Range: 0°C to +5°C (standard), -10°C (forensic)

- Capacity Options: 1-20 bodies (standard units), 30+ bodies (walk-in systems)

- Power Consumption: 0.5-0.7 kW for standard models

- Price Range: €5,000-€7,000 (1 body), €8,500-€13,500 (2 bodies)

- Materials: AISI 304 stainless steel, 75-100mm polyurethane insulation

- French Regulations: Minimum 2 refrigerated cases per 200 annual deaths

The mortuary refrigeration market has grown significantly, with facilities requiring reliable preservation solutions that meet both regulatory standards and operational demands. Modern units feature advanced insulation panels, digital temperature controls, and energy-efficient compressors.

I'm Mortuary Cooler, a national-level mortuary cooler supplier specializing in cellule refrigerante morgue systems across the United States. With extensive experience helping funeral homes and healthcare facilities select optimal refrigeration solutions, I understand the unique challenges of balancing quality, compliance, and budget constraints.

Cellule refrigerante morgue glossary:

Cellule Réfrigérante Morgue : fonctionnement et composants essentiels

A cellule refrigerante morgue operates on precision cooling principles similar to commercial refrigeration but engineered for strict temperature control and reliability. The compressor pressurizes refrigerant fluid (usually R-134a or R-407c), pushing it through the condenseur where it releases heat and becomes liquid. After passing through an expansion valve, it enters the évaporateur where it absorbs heat from the storage chamber.

Modern cellule refrigerante morgue systems feature isolation PU (polyurethane insulation) panels that are 75-100 mm thick with 35-45 kg/m³ density. This engineered insulation maintains precise temperature control while keeping energy costs reasonable at just 0.5-0.7 kW consumption.

Temperature precision is critical - standard preservation requires 0°C à +5°C, while forensic cases need -10°C capability. Systems automatically maintain these temperatures within ±1°C accuracy.

Principe de réfrigération d'une cellule réfrigérante morgue

The cooling process uses controlled échange thermique (heat exchange) where fluide frigorigène continuously circulates, pulling heat from the storage chamber through the evaporator. Humidité control prevents ice buildup through automatic dégivrage (defrost) systems, while coaxial blowers ensure even air circulation throughout the chamber.

Composants clés et matériaux à privilégier

Quality sandwich panels feature high-density polyurethane foam with thermal conductivity of 0.23 W/m²·K. Inox AISI 304 stainless steel provides durability for intensive cleaning and disinfection. Joints double étanchéité (double sealing) prevents temperature loss and reduces energy consumption. Alarmes température with audio/visual alerts ensure compliance and prevent equipment failure.

Door design includes heated frames preventing condensation, viewing windows, and heavy-duty hinges rated for thousands of cycles.

Capacités et formats : du 1 corps aux walk-in modulaires

When choosing a cellule refrigerante morgue, capacity planning is crucial. Standard cabinet-style units handle 1-20 bodies, while walk-in systems accommodate 30 or more. Roll-in versus front-loading configurations each serve different needs - roll-in systems ease body handling but require more floor space, while front-loading units are more space-efficient.

Modern systems feature modular design using prefabricated panels that make expansion straightforward and allow relocation if needed.

Cellule refrigerante morgue 1-2 corps : usages et limites

Single and double-body units are ideal for smaller funeral operations. 1-body units typically cost €5,000-€7,000 and plug into standard 230V outlets. Two-body units at €8,500-€13,500 offer better value with 2×1 stacked design maximizing storage in compact footprints.

Limitations include unsuitability for facilities handling more than 2-3 bodies weekly and challenges with unpredictable demand spikes.

Cellule refrigerante morgue 3-4 corps et négative -10 °C

Mid-size units serve hospitals and established funeral homes well. Four-body configurations use 2×2 arrangements with dual door access for optimal workflow. Negative temperature capability to -10°C is essential for medico-legal cases, adding 15-20% to base price but providing necessary forensic compliance.

Grandes capacités & solutions walk-in

Walk-in systems offer comprehensive preservation facilities. 8-10 body systems serve mid-sized hospitals, 16-20 body configurations handle regional medical centers, and 24-30 body systems support major metropolitan operations.

Modular construction provides 10-year panel warranties with 2-4 day installation. Space requirements range from 200-250 square feet for 8-10 bodies up to 600-750 square feet for largest installations.

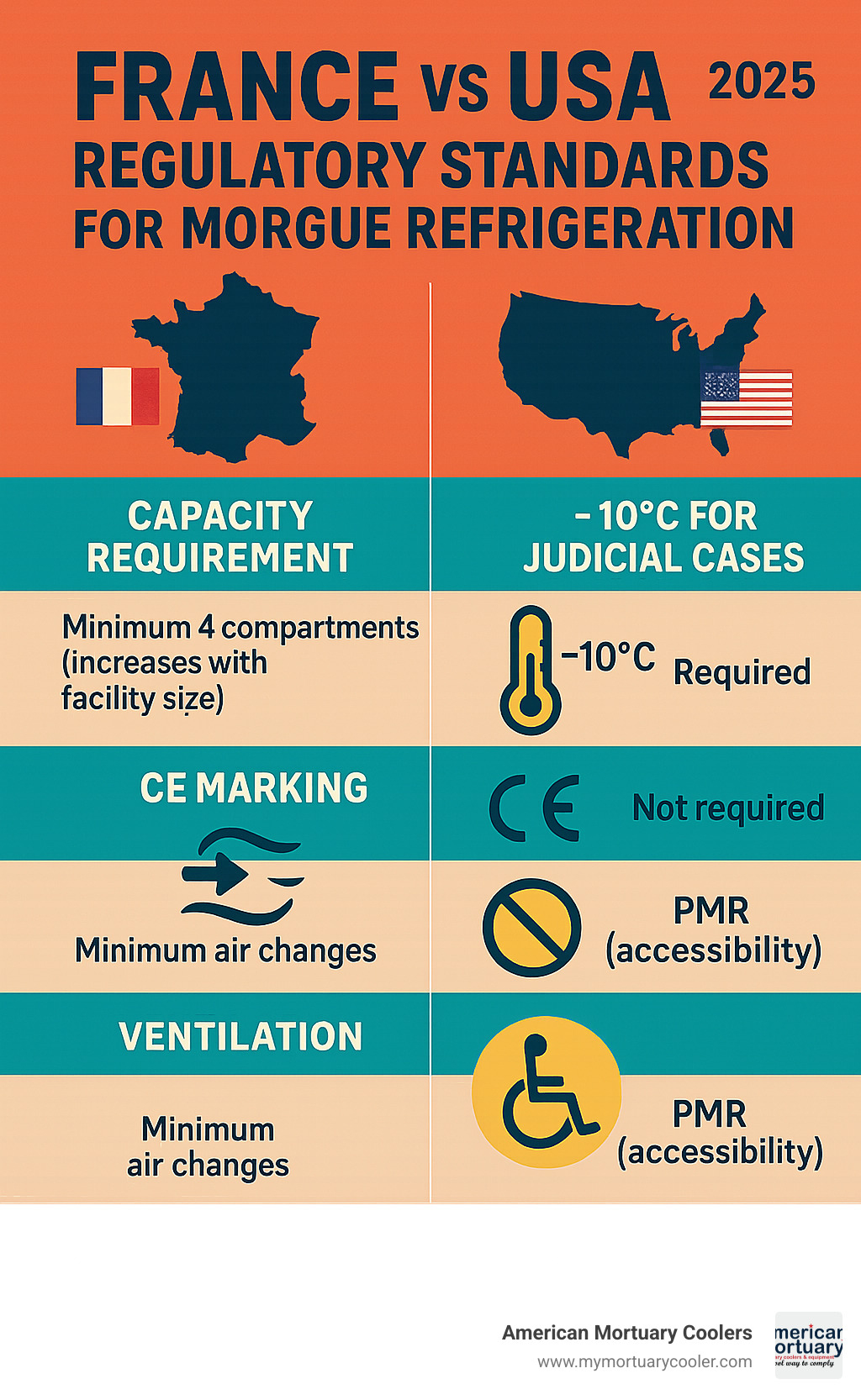

Normes, réglementation et installation en France & Europe

French funeral regulations require 2 refrigerated compartments for the first 200 annual deaths, plus 2 more for each additional 200 deaths. European standards mandate CE marking compliance, EN 60068 environmental testing, and HACCP principles for mortuary use.

The -10°C requirement for judicial cases is legally mandatory in France for facilities handling medico-legal cases. PMR accessibility requirements affect door heights, handle placement, and control positioning.

Étapes d'installation conforme

Site preparation requires adequate structural support, proper drainage, and sufficient clearance. Electrical supply varies - most small units use 230V single-phase, while larger systems need 400V three-phase supply with dedicated circuits.

Ventilation planning needs minimum clearances of 1-2 meters on condenser side. Commissioning takes 4-8 hours including refrigerant charging, temperature calibration, and alarm testing.

Maintenance & hygiène obligatoires

Annual maintenance includes compressor inspection, refrigerant level checks, and electrical connections. Stainless steel cleaning requires manufacturer-approved products to prevent surface damage. Temperature recording with continuous monitoring is often legally required.

Total cost of ownership over 10 years typically reaches 1.5-2 times initial purchase price including maintenance, electricity, and parts.

For detailed specifications, check out this comprehensive guide.

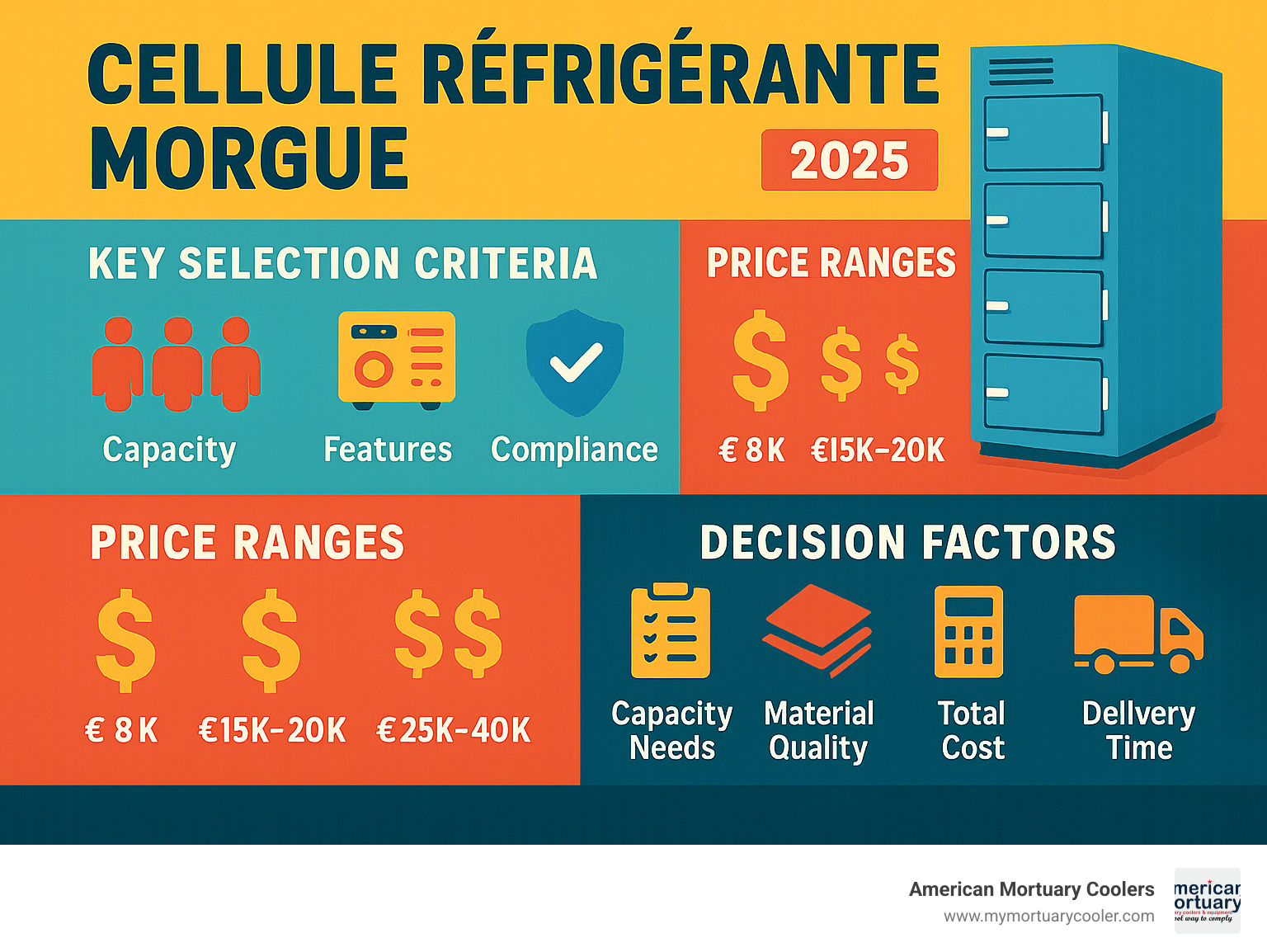

Choisir sa cellule : critères, options et budget optimisé

Choosing the right cellule refrigerante morgue starts with honest capacity planning. Take your busiest month, add 30%, then add two more bodies for unexpected demand.

Insulation thickness between 75mm and 100mm affects long-term electricity costs. AISI 304 stainless steel versus painted steel impacts cleaning ease and longevity. Smart options like temperature alarms, adjustable stretchers, LED lighting, and caster wheels typically add 10-15% to base price but save time daily.

Delivery timing ranges from 2-3 weeks for stock units to 8-12 weeks for custom configurations. Total cost of ownership over 10 years runs 1.5-2 times initial purchase price including electricity (€500-1,200 annually) and maintenance (€800-1,500 per year).

Checklist d'achat express

Essential checks include external dimensions fitting your space, door clearances for stretcher access, and electrical requirements. Security features like temperature alarms, locking mechanisms, and emergency releases are essential. Warranty coverage should include 10-year panel warranties and 1-year compressor coverage with local service availability.

Standard vs personnalisé : avantages / inconvénients

Standard units solve 90% of needs, ship in 2-3 weeks, cost 15-30% less, and offer proven reliability with readily available parts. Custom configurations work for space constraints or specialized requirements but cost 15-30% more, take 8-12 weeks delivery, and may have limited resale value.

Start by evaluating standard units with optional accessories before considering custom solutions.

Prix, coûts cachés et meilleures sources d'approvisionnement

Current pricing shows 1-body units at €5,000-€7,000 in France ($4,500-$6,000 USA), 2-body configurations at €8,500-€13,500 in France ($6,095-$7,696 USA), and walk-in systems starting at €20,000+ in France ($15,000+ USA). Used equipment offers 40-60% savings but requires careful inspection.

Hidden costs include delivery/installation (€1,500-€3,000), electrical work (€500-€1,500), site preparation (€1,000-€5,000), and annual maintenance contracts (€800-€1,500).

For detailed pricing breakdown, check: How Much Does a Cellule Réfrigérante Morgue Cost? Prices Revealed.

Facteurs influençant le prix

Panel thickness (100mm costs 15-25% more than 75mm), brand reputation, refrigeration capabilities (negative temperature adds 20-30%), connected technology (adds 10-15%), and delivery distance all impact final pricing.

Où acheter et comparer les offres

Sourcing options include local suppliers (hands-on support), trade shows (comparison opportunities), B2B platforms (price comparison), used equipment markets (significant savings), and direct manufacturers like American Mortuary Coolers (custom solutions with comprehensive support).

Focus on total cost of ownership rather than initial price, considering warranty coverage, service availability, and long-term parts support.

For additional context, visit Wikipedia – Morgue.

Frequently Asked Questions about Cellule Réfrigérante Morgue

When you're considering a cellule refrigerante morgue for your facility, certain questions come up again and again. I've helped hundreds of funeral homes and hospitals steer these decisions, so let me share the answers to the most common concerns.

Peut-on transformer une cellule positive en négative ?

This is one of the trickiest questions I get. While it's technically possible to convert a positive temperature cellule refrigerante morgue to handle negative temperatures, it's rarely the smart financial choice.

Converting an existing unit means you'll need a more powerful compressor system - that's already 40-60% of what you paid for the original unit. Then you'll need improved insulation (adding another 20-30mm of thickness), plus an automatic defrost system and upgraded electrical supply to handle the higher power requirements.

When you add it all up, you're looking at spending 40-60% of what a brand-new negative-temperature unit would cost. At that point, you're better off investing in a new system that's designed from the ground up for negative temperatures. You'll get better reliability, full warranty coverage, and peace of mind knowing everything works together perfectly.

Faut-il une alimentation électrique spécifique ?

Here's some good news - most standard cellule refrigerante morgue units are surprisingly easy to plug in. The majority operate on 230V single-phase power (16A) without any special electrical work needed. That means they can connect to your existing electrical system in most cases.

However, if you're looking at larger units or ones with negative temperature capability, you might need 400V three-phase power supply. These bigger systems also require dedicated electrical circuits with proper disconnects and professional installation to meet electrical codes.

If your facility handles critical cases, you might also want backup power compatibility - something to keep in mind during the planning phase. The research confirms that "most units function on 230V monophasé standard (16A) without special installation," which makes life much easier for most facilities.

Quelle est la durée moyenne de livraison ?

Delivery timing is crucial when you're dealing with mortuary equipment - you can't exactly put operations on hold indefinitely. Here's what you can typically expect for cellule refrigerante morgue delivery:

Stock units that match standard configurations usually ship within 2-3 weeks. These are your bread-and-butter models that manufacturers keep ready to go.

Standard manufacturing with common options takes 4-6 weeks. This covers most situations where you need specific features but nothing too exotic.

Custom solutions require 8-12 weeks for specialized requirements. If you need something truly unique for your space or workflow, this is where the timeline extends.

Once your unit arrives, plan for an additional 1-2 days for professional installation. This includes setup, testing, and making sure everything meets local codes.

If you're in an emergency situation, rush delivery might be available, but expect to pay a 15-25% premium. The best approach? Plan ahead whenever possible. It saves money and ensures you get exactly what you need without the stress of tight deadlines.

At American Mortuary Coolers, we understand that timing matters in this industry. That's why we work hard to provide realistic delivery estimates and keep you updated throughout the process.

Conclusion

Choosing the right cellule refrigerante morgue becomes clearer when you understand your specific needs. These systems efficiently preserve human remains while consuming just 0.5-0.7 kW of power, maintaining precise temperatures from 0°C to +5°C for standard preservation or -10°C for forensic applications.

Successful installations require capacity planning with 20-30% buffer for unexpected demand, quality materials like AISI 304 stainless steel and high-density polyurethane insulation, regulatory compliance (French facilities need 2 cases per 200 annual deaths), and proper delivery planning (2-12 weeks depending on customization).

At American Mortuary Coolers, we've built our reputation on understanding that every facility has unique challenges. Based in Tennessee with delivery across all 48 contiguous states, we provide custom solutions custom to your space, budget, and operational needs.

Our Tennessee-based team combines manufacturing expertise with genuine understanding of funeral directors' and hospital administrators' daily challenges. We provide comprehensive guidance through selection, ensure regulatory compliance, and offer ongoing support for reliable long-term operation.

Ready to discuss your mortuary refrigeration needs? Our experts help you steer the selection process without sales pressure, finding solutions that make sense for your facility, budget, and peace of mind.

For additional information: More info about our body fridges.