Investing in Cremation Technology: What You Need to Know

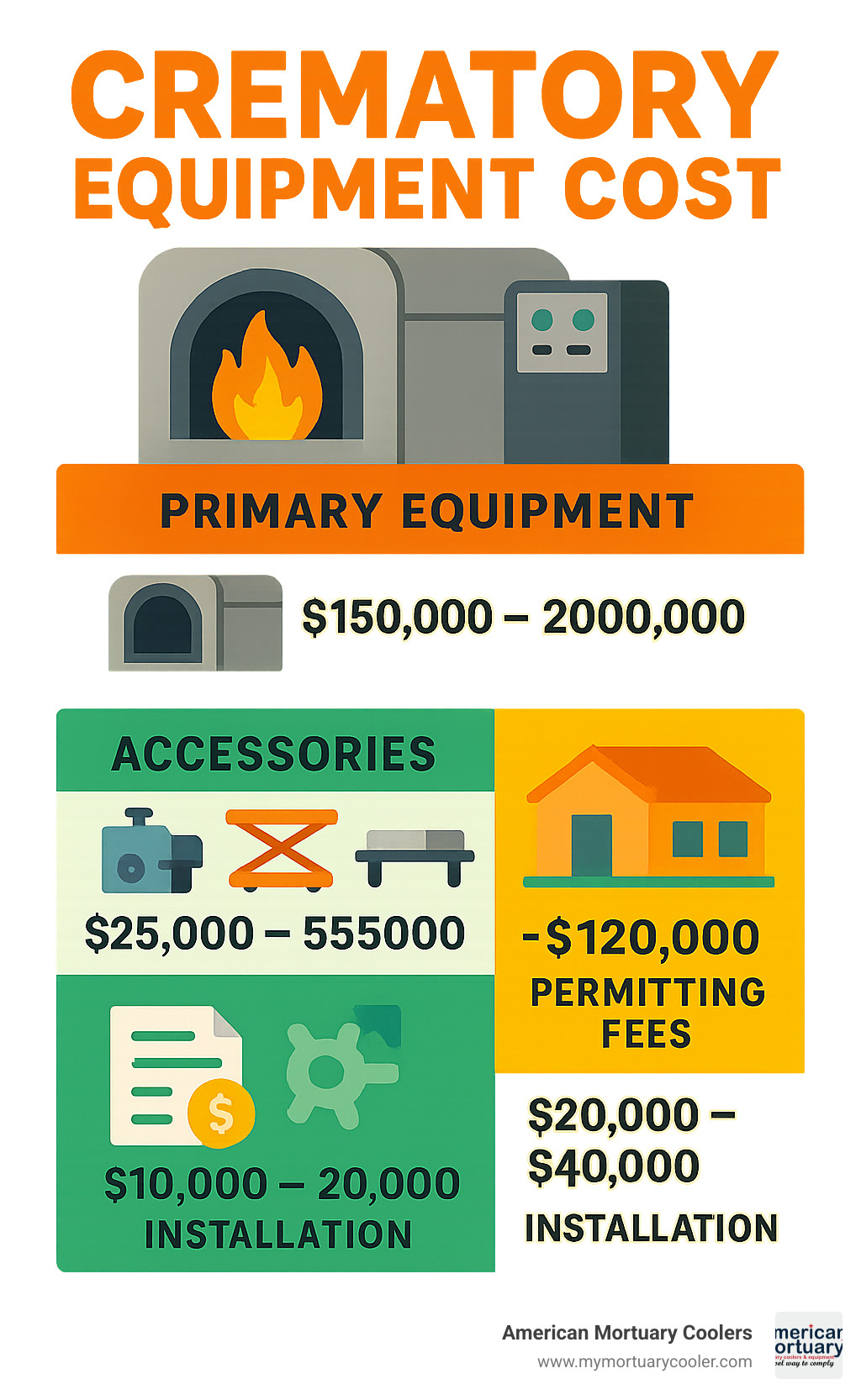

The average crematory equipment cost ranges from $150,000 to $500,000 for a complete installation, depending on equipment type, facility requirements, and location.

Quick Crematory Equipment Cost Breakdown:

- Human cremation retort (chamber): $150,000-$200,000

- Refurbished retort: $90,000-$140,000

- Processors: $2,500-$12,000

- Hydraulic lifts: $5,000-$7,000

- Autoloaders: $15,000-$35,000

- Building costs (1,200 sq ft): ~$120,000

- Total typical turnkey facility: $270,000-$500,000

Starting or upgrading a crematory operation represents a significant investment that requires careful planning and budgeting. The crematory equipment cost encompasses not just the cremation chamber itself, but also essential accessories, building requirements, permits, and installation expenses.

With cremation rates rising nationwide, understanding the full scope of this investment has become increasingly important for funeral home operators looking to expand their services. Today's modern crematory equipment combines advanced technology with efficiency features that can impact both your initial outlay and long-term operational costs.

Whether you're adding cremation capabilities to an existing funeral home or building a standalone facility, the equipment represents the cornerstone of your investment – but it's just one piece of a larger financial puzzle that includes building modifications, environmental permits, and ongoing operational expenses.

I'm Mortuary Cooler, a national supplier of mortuary refrigeration solutions with extensive experience advising funeral directors on crematory equipment cost and facility planning to ensure optimal investments that meet both regulatory requirements and budget constraints.

Important crematory equipment cost terms:

Understanding Crematory Equipment & Its Main Types

When you're stepping into cremation services, it helps to understand the variety of equipment that makes up a complete crematory system. Your crematory equipment cost will vary quite a bit depending on which components you select and their specifications.

The heart of any crematory is the cremation chamber, commonly called a retort. These specially designed high-temperature furnaces reach between 1,400-1,800 degrees Fahrenheit. But there's much more to a complete system than just the retort itself.

Think of a crematory like a kitchen – the oven (retort) is essential, but you also need counters, sinks, and tools to prepare a full meal. In cremation, you'll encounter equipment like retorts and chambers for the main cremation process, furnaces that power the heat system, and processors that handle the remains afterward. There are also lifts and autoloaders that help move the deceased safely into the chamber, coolers for temporary storage, and organizational racks for keeping everything in order.

Some facilities also invest in alternative technologies like aquamation units for water-based cremation, smaller kilns often used for pet cremation, or industrial incinerators adapted for cremation purposes.

As one funeral director from the Midwest told us, "I was shocked to find the retort was only about 60% of my total equipment investment. Those accessories and support equipment added up faster than I expected!"

Key Components of a Crematory Line

Understanding the main elements of a cremation system helps explain why the crematory equipment cost can be substantial. It's like buying a car – the engine is important, but so are the transmission, brakes, and electronics.

The primary chamber is where the body is placed for cremation. It's built with specialized materials designed to withstand extreme heat day after day. Working alongside it is the secondary chamber, also called the afterburner, which ensures complete combustion of gases and particles. This secondary chamber is crucial for reducing emissions and meeting environmental regulations.

Both chambers are lined with refractory material – specialized heat-resistant brick and cement that can withstand the intense temperatures. The quality of this refractory significantly impacts both your initial crematory equipment cost and your long-term maintenance expenses. Modern systems like the Quick Change Modular Hearth make repairs faster and reduce downtime.

Modern cremation systems are managed by PLC controls – essentially the computer brains that automate the cremation process. Today's units feature touchscreen interfaces and can adjust the entire process based on the weight of remains, taking the guesswork out of operation.

Finally, the emissions stack safely directs combustion gases away from your facility. Many modern units include opacity sensors to monitor emissions and ensure you're staying compliant with environmental regulations.

As Tom Krowl, Vice President of Marketing at Cremation Systems, explains: "Today's cremation equipment has evolved significantly. The PLC control systems can adjust the entire cremation cycle based on case weight, and remote diagnostics allow us to troubleshoot issues without even visiting the site."

Optional & Support Equipment

Beyond the core cremation unit, several accessories make your operation more efficient and comfortable to run. Each adds to your total crematory equipment cost, but they're worth considering:

After cremation, remains need to be processed into a consistent, fine powder using a processor. These range from basic manual units starting at $2,549 to sophisticated ventless processing stations that run about $11,794.

Hydraulic lifts help your staff load remains into the cremation chamber safely, reducing physical strain and improving workplace safety. A basic lift costs around $5,325, while models with specialized platforms run closer to $6,795.

Accurate weight measurement is crucial for proper cremation cycle programming, so a good scale with ramp (typically around $4,499.95) is a practical investment.

If you plan to offer witnessed cremations, a viewing window allows family members to observe the beginning of the process. This feature is increasingly popular with families seeking closure.

Proper ventilation is essential for operator safety and comfort. High-temperature vacuum systems ($1,749.95) help manage dust and particulates in your workspace.

After cremation, remains must cool before processing on a remains cooling rack (about $459.95), and a simple urn loader (starting at $149.95) helps transfer processed remains into urns without spillage.

At American Mortuary Coolers, we've noticed more facilities investing in automated, user-friendly support equipment. While this increases initial crematory equipment cost, it typically results in more efficient operations and lower labor costs in the long run – not to mention less physical strain on your staff.

Crematory Equipment Cost Breakdown

Understanding the detailed breakdown of crematory equipment cost is essential for proper budgeting. The price spectrum is wide, with significant differences between new and refurbished equipment, human and pet cremation units, and various required accessories.

Average Crematory Equipment Cost for a Human Retort

The cremation chamber (retort) represents the largest single expense when establishing a crematory. Think of it as the heart of your operation – and like any vital organ, it comes with a significant price tag.

Based on our industry experience and conversations with funeral directors across the country, a new human retort will typically set you back $150,000-$200,000 for the unit alone. Factor in installation and delivery costs of approximately $20,000-$30,000, and your total installed cost jumps to $170,000-$230,000.

Geography plays a surprising role in what you'll pay. A funeral director friend of ours in North Texas recently shared that Matthews Cremation quoted him approximately $350,000 for a complete system in 2022. This included the retort, installation, and all necessary accessories – definitely on the higher end of the spectrum, but not unusual for areas with stricter environmental regulations.

What drives these price variations? Several factors come into play. Units handling larger cases (750+ pounds) naturally cost more. If you want faster cremation cycles (60-90 minutes versus 2+ hours), expect to pay premium prices. Advanced features like touchscreen interfaces, remote diagnostics, improved pollution monitoring, and better energy efficiency all add to the bottom line – though they often pay for themselves in operational savings down the road.

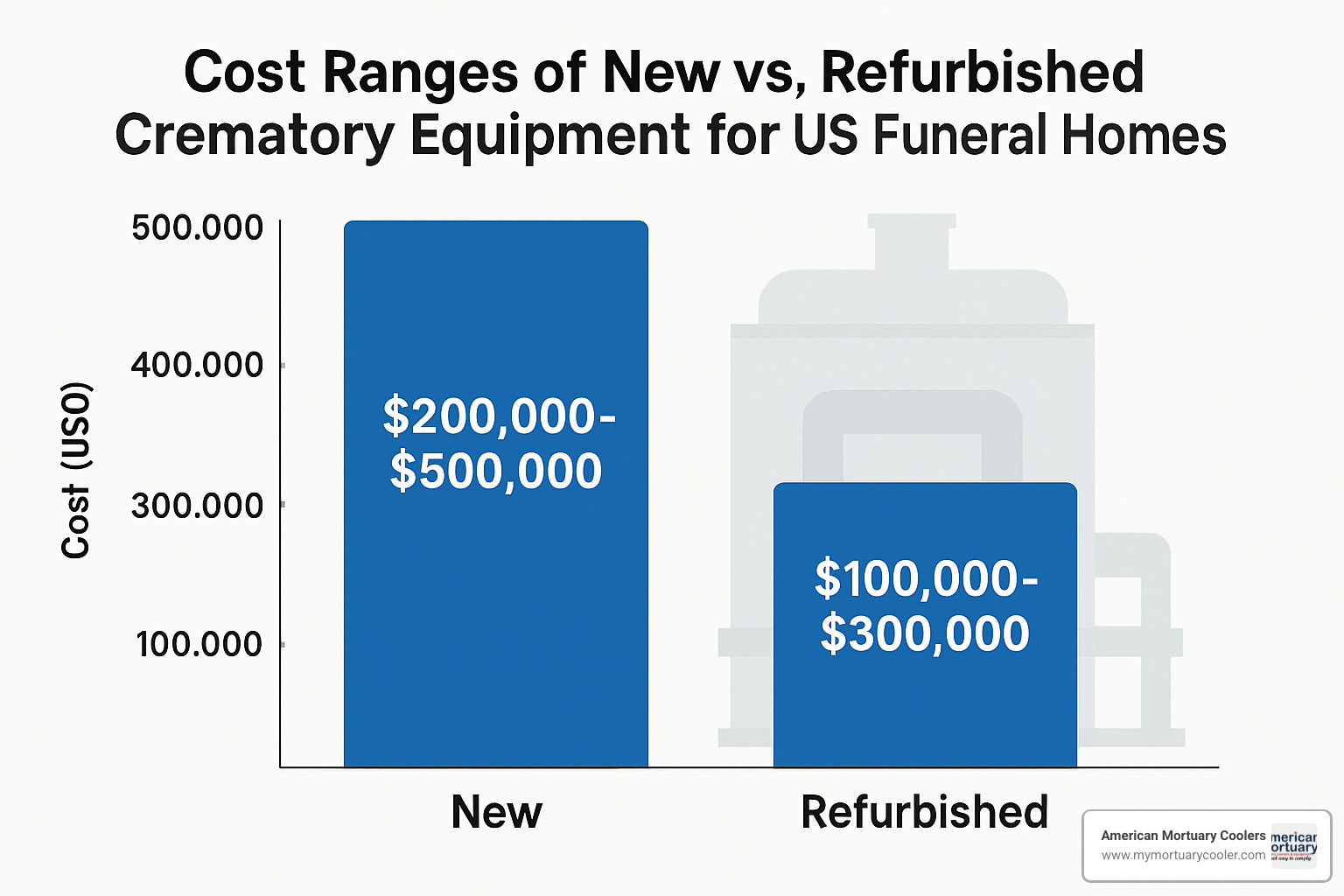

New vs Refurbished Crematory Equipment Cost Spectrum

Many funeral directors we work with at American Mortuary Coolers consider refurbished equipment to manage their crematory equipment cost without compromising quality. Refurbished units typically run about 40-60% of what you'd pay for new equipment while still delivering reliable performance.

| Equipment Type | New Cost Range | Refurbished Cost Range | Lifespan |

|---|---|---|---|

| Human Retort | $150K-$200K | $90K-$140K | 15-20 years |

| Pet Retort | $50K-$120K | $30K-$70K | 15-20 years |

| Processor | $2.5K-$12K | $1.5K-$7K | 8-10 years |

| Hydraulic Lift | $5K-$7K | $3K-$4.5K | 10-12 years |

| Autoloader | $15K-$35K | $9K-$20K | 10-15 years |

Choosing refurbished equipment offers significant capital savings – we're talking $60,000-$100,000 on a human retort alone. Plus, these units are often in stock and ready to ship, compared to the 14-20 week lead times typical for new units. Many manufacturers even offer trade-in programs where older models can be exchanged for fully refurbished systems with updated components.

A crematory operator in Chicago shared his experience with us: "We started with a refurbished unit to keep our initial investment manageable. Five years later, when our volume justified it, we upgraded to a new unit with all the latest features and sold our refurbished unit to a startup operation." This kind of equipment lifecycle is common in the industry.

Of course, refurbished equipment does come with some trade-offs. You'll typically get a shorter warranty period (usually 1 year versus 2-5 years for new), potentially higher maintenance costs down the road, and you might miss out on the very latest technological features.

Crematory Equipment Cost of Essential Accessories

The retort might be the star of the show, but a complete cremation system requires a supporting cast of accessories. These additional components can add $30,000-$60,000 to your total investment – a fact that catches many first-time buyers by surprise.

Processors range from $2,549 for a basic model to $11,794 for an advanced processing station with ventless operation. These machines transform cremated remains into the consistent, fine powder that families receive.

Hydraulic lifts ($5,325-$6,795) spare your staff's backs and improve safety when loading remains into the cremation chamber. The higher-end models feature specialized roller ball platforms that make transfers nearly effortless.

Autoloaders represent another significant expense, starting at $15,799 for a basic Auto Loader (AC-2) and going up to $35,304 for a premium Flex 180 Autoloader. These systems automate one of the most physically demanding aspects of cremation.

Other essential accessories include mortuary coolers (starting at $6,000 – a specialty we provide at American Mortuary Coolers), scales with ramps (approximately $4,499.95), remains cooling racks (around $459.95), and urn loaders ($149.95-$289).

One of our clients in the Southeast Region put it perfectly: "The right accessories made all the difference in our workflow. The hydraulic lift and processor were worth every penny in terms of staff efficiency and reduced physical strain." We couldn't agree more – while these accessories add to your initial crematory equipment cost, they typically pay dividends in operational efficiency.

For more detailed information on cremation equipment pricing, check out our article on Price Check: Navigating the World of Cremation Equipment Costs.

Full Crematory Project Budget & Influencing Factors

When planning a complete crematory installation, the crematory equipment cost is just one piece of a much larger financial puzzle. Think of it as buying a car – the sticker price doesn't include insurance, gas, maintenance, or the garage to keep it in!

From our years helping funeral homes across the country, we've seen that a typical turnkey crematory project ranges from $270,000 to $500,000. This total varies widely based on your location, existing facilities, and specific needs.

Your budget should account for everything from site prep ($5,000-$20,000) to the building itself (around $120,000 for a 1,200 sq ft structure). Don't forget utility connections ($10,000-$25,000), the cremation equipment ($150,000-$200,000 for a new human retort), and all those necessary accessories ($30,000-$60,000).

Then there are the less obvious costs – crane and rigging services ($5,000-$10,000), permits and zoning approvals ($5,000-$30,000), EPA compliance ($3,000-$15,000), labor for installation ($15,000-$30,000), and delivery charges ($5,000-$15,000).

As one of our equipment specialists often tells clients, "Your zip code can impact your bottom line significantly. Urban facilities with strict emissions standards might pay 20-30% more for permitting and compliance than their rural counterparts."

Construction & Facility Costs

The building that houses your crematory is a major investment that deserves careful consideration. Most of our clients find that prefabricated metal buildings offer the best value at approximately $100 per square foot. For a standard 1,200 square foot facility, that's about $120,000.

Don't forget to factor in the concrete slab foundation (roughly $24,000), interior walls and finishing (another $24,000), and bathroom and utility infrastructure (an additional $24,000). These costs add up quickly!

I recently spoke with a funeral director in Tennessee who shared, "We thought the retort would be our biggest expense, but the building modifications ended up being nearly as much. I wish someone had prepared us for that reality."

A well-designed crematory typically includes a welcoming reception or viewing area, a dedicated cremation chamber room, office space, bathroom facilities, storage areas, and often a walk-in cooler. At American Mortuary Coolers, we specialize in designing custom coolers that integrate seamlessly with your crematory layout.

Permitting, Zoning & Environmental Compliance

Navigating the regulatory landscape is often the most frustrating part of establishing a crematory – but it's absolutely essential to get right.

Most states require air quality permits before you can begin installation. You'll need to understand stack opacity rules (typically limiting visible emissions to 20%), local zoning ordinances that determine where crematories can operate, and standard building permits for any structural work.

This regulatory gauntlet typically takes 2-6 months to complete and costs between $5,000 and $30,000, depending on your location. It's not just about paying fees – it's about proving your facility will meet environmental standards.

One funeral director from Pittsburgh told me, "The permitting process was like learning a foreign language. Having our equipment vendor handle the environmental documentation saved us countless headaches and probably months of delays."

The good news? Many equipment manufacturers, including those we partner with at American Mortuary Coolers, will help guide you through permit preparation and submission. Their experience navigating these waters is invaluable.

Installation Timeline & Lead Times

Patience is definitely a virtue when establishing a new crematory. From the day you sign the contract to your first cremation, expect the process to take 4-6 months – sometimes longer.

After spending 1-2 weeks finalizing equipment specifications, you'll wait 14-20 weeks for your custom-built unit to be manufactured. Shipping adds another 1-2 weeks, depending on your location.

The actual on-site installation typically follows a three-day pattern:

- Day 1: Equipment delivery and placement

- Day 2: Utility connections and initial setup

- Day 3: Testing, training, and your first cremation

The key to staying on schedule is coordination. Your electrical contractor, gas company, construction team, and equipment installer all need to work in harmony. At American Mortuary Coolers, we help clients coordinate their crematory installation with our mortuary cooler installations to minimize disruption and create an optimally functioning facility.

As one manufacturer representative candidly told a client, "We don't compromise quality for speed." That's a philosophy we share at American Mortuary Coolers – doing it right matters more than doing it fast, especially with equipment you'll rely on for decades.

Operating & Ownership Considerations

When you invest in crematory equipment, the story doesn't end with the purchase. The true cost of ownership extends far beyond the initial crematory equipment cost – it's about understanding what it takes to keep your equipment running efficiently year after year.

Fuel Consumption and Efficiency

"I was shocked when I saw my first monthly gas bill," a crematory owner in Ohio once told me. "Nobody had prepared me for the ongoing fuel costs."

Modern cremation equipment varies dramatically in its efficiency, which directly impacts your bottom line. For natural gas units, smaller systems typically consume between 12.5-18 therms during a standard two-hour cremation (roughly 6.25-9 therms per hour). Larger, more industrial units burn through 18-28.5 therms in just 70-90 minutes.

If your facility runs on LPG instead, expect small units to use 10.5-16.5 gallons per 90-minute cremation, while larger units consume 15.5-25 gallons in the same timeframe.

With thoughtful operation and newer, more efficient equipment, you can keep fuel costs as low as $13 per cremation – though this sweet spot varies depending on your location and current fuel prices. Many of our clients have found that investing in slightly more expensive, but more efficient units pays for itself surprisingly quickly.

Maintenance Requirements

The hearth of your cremation unit is like the heart of a person – it needs regular care to keep everything running smoothly. Most units require hearth replacement every 1,000-1,500 cremations, a significant maintenance milestone that should be budgeted for from day one.

Beyond the hearth, plan for:

- Annual burner inspections and adjustments

- Periodic control system updates and calibration

- Regular replacement of filters in processing equipment

One game-changing innovation worth considering is the Quick Change Modular Hearth system. Unlike traditional systems that might leave your operation down for days during repairs, these modern solutions allow for complete hearth replacement in just one day, with no curing time needed. For busy crematories, this difference can mean thousands in saved revenue.

Insurance Considerations

"Don't even think about skimping on insurance," advises a crematory operator from Florida who learned this lesson the hard way after a control system failure.

Specialized insurance for crematory operations typically adds $2,000-$5,000 to your annual expenses, but provides essential coverage for equipment replacement, business interruption, liability protection, and environmental damage. Given the specialized nature of cremation equipment and the potential for significant business disruption if something goes wrong, this is one area where cutting corners rarely makes sense.

Warranty & Service Support

Most new cremation equipment includes a standard 2-year parts warranty, with options to extend coverage to 3 years on select models or even 5 years through premium service contracts. Be aware that certain components, like motors, may have different terms (often around 18 months).

The service landscape has changed dramatically in recent years. Many manufacturers now offer remote diagnostic capabilities that can save you thousands in service calls. As one equipment provider explained to me, "Our Tek Marshal remote diagnostics allows our technicians to monitor your equipment, make adjustments, and troubleshoot issues without an on-site visit."

At American Mortuary Coolers, we've seen how comprehensive service support makes all the difference. When your equipment is down, every hour costs you money – the ability to quickly diagnose and resolve issues isn't just convenient, protecting your revenue stream.

Financing & Leasing Options

Given the substantial crematory equipment cost, it's no surprise that many funeral homes explore creative financing options rather than paying cash upfront.

Traditional bank loans typically offer 5-10 year terms with interest rates between 4-7%, while equipment leasing provides the advantage of predictable monthly payments and potential tax benefits. Many savvy business owners take advantage of Section 179 tax benefits, which may allow deduction of equipment costs in the first year rather than depreciating them over time.

"Many of our clients find that leasing crematory equipment provides better cash flow management and tax advantages compared to outright purchase," explains a financial advisor who specializes in funeral service businesses. "This is especially true when first entering the cremation market."

To simplify the process, many equipment manufacturers partner with financing companies to offer streamlined application processes. Some even provide a simple Financing application that can be completed online in minutes.

While monthly payments might be easier to manage than a large upfront investment, they add up over time. The right financing strategy balances immediate cash flow needs with long-term cost efficiency – something we help our clients steer every day at American Mortuary Coolers.

Choosing the Right Technology & Manufacturers

Selecting the appropriate cremation technology significantly impacts both initial crematory equipment cost and long-term operational expenses. The market offers several distinct approaches to cremation, each with different price points and characteristics.

Human vs Pet Cremation Equipment

When it comes to cremation equipment, size really does matter – and so does the price tag that comes with it.

Human cremation systems are built for larger capacities, typically handling 750+ pounds with robust construction designed for consistent, higher-volume use. These powerhouse units command a premium crematory equipment cost between $150,000 and $200,000. Models like the Classic-PRO can complete a cremation in 90 minutes with a 200 lb/hr processing rate and 800 lb capacity, while the speedier Classic-XCEL cuts that time to 60 minutes with double the processing rate and a 1,200 lb capacity.

On the pet side, the equipment is more compact but still mighty capable. These systems offer more versatile size options to match different business models, with capacities ranging from 300 to 1,200 pounds. The more modest footprint comes with a friendlier price point of $50,000 to $120,000. Popular models include the Sierra-300, which processes at 75 lb/hr with a 300 lb capacity, and the larger Sierra-750, handling 200 lb/hr with an 800 lb capacity.

The gap between human and pet equipment typically runs $30,000 or more for similar quality systems. I've seen this decision play out countless times with our clients at American Mortuary Coolers. Just last year, a pet crematory owner in Dallas told me, "We initially considered a smaller pet-specific unit to save on costs, but ultimately chose a human-rated system to accommodate larger pets and give us the option to expand our services in the future." That kind of flexibility can be worth the extra investment if your business plan might evolve over time.

Pros & Cons: Retorts vs Aquamation vs Kilns

Today's cremation technology offers more options than ever before, and each comes with its own set of trade-offs.

Traditional retorts (what most people think of as cremation) represent the established standard. They're widely accepted by consumers and funeral professionals alike, completing the process in a relatively quick 60-180 minutes depending on the model and case size. However, they do produce higher emissions and consume more fuel than newer alternatives. The crematory equipment cost for these systems typically ranges from $150,000 to $200,000 for human-rated units.

Aquamation (alkaline hydrolysis) has gained traction as the "green" alternative. This water-based process uses significantly less energy and produces fewer emissions – a compelling selling point for environmentally conscious families. The trade-off? A longer process time of 6-12 hours and a steeper initial investment starting at $209,900 for a basic unit and climbing to $329,900 for advanced models (not including freight and hookups). There's also the matter of wastewater management to consider.

One funeral director who took the plunge with aquamation shared with me over coffee at a recent trade show, "The higher initial cost was offset by our ability to market ourselves as the only 'green' cremation provider in our area. We've seen a 15% premium on our aquamation services compared to traditional cremation." That premium can accelerate your return on investment considerably.

For those looking at more modest options, especially for pet cremation, kilns offer a smaller footprint and much lower initial cost ($5,000-$15,000). The downside is their limited capacity and longer cycle times, making them primarily suitable for lower-volume pet cremation operations.

For a deeper dive into water-based options, check out our comprehensive article on All About the Cost of Water Cremation: A Comprehensive Guide.

Leading Brands in the U.S. Market

The cremation equipment landscape features several trusted manufacturers, each with their own strengths and specialties.

Matthews Cremation stands as one of the industry giants, offering a comprehensive product line backed by global resources and extensive service networks. Their name recognition comes with premium pricing, but many operators find comfort in their established reputation.

Cremation Systems has built a loyal following with innovations like their CFS2300 human chamber featuring quick-change hearth technology and remote diagnostics – features that can significantly reduce downtime during maintenance.

For those looking toward European engineering, Facultatieve Technologies brings a strong focus on environmental performance and efficiency, often appealing to operators in regions with stricter emissions standards.

US Cremation Equipment offers a versatile lineup spanning both human and pet cremation systems with various capacities, providing options at different price points.

Therm-Tec has carved out a niche specializing in custom solutions and retrofitting existing equipment – a valuable option if you're looking to upgrade rather than replace.

Addfield, with over 40 years of experience from their UK base, has particular strength in the pet cremation market with systems designed specifically for that purpose.

At American Mortuary Coolers, we've developed relationships with multiple manufacturers because we've learned that the "best" equipment varies widely depending on each client's specific situation. While initial crematory equipment cost is certainly important, we help funeral professionals look beyond that number to consider local service availability, parts supply, and compatibility with existing systems – including our custom-designed coolers that complement any cremation setup.

The right equipment choice becomes much clearer when you consider your complete operational picture rather than focusing solely on the price tag. After all, the most affordable option isn't always the most economical in the long run.

Frequently Asked Questions about Crematory Equipment Cost

How much does it cost to build a turn-key crematory facility?

When funeral directors ask me about the total investment for a complete crematory facility, I typically share that they should expect to invest between $270,000 and $500,000. This isn't just for the equipment—it's everything you need to start operating.

The breakdown usually looks something like this: about $120,000 for a standard 1,200 square foot metal building, $150,000-$200,000 for a quality human cremation retort, $20,000-$30,000 for proper delivery and setup (including training), $30,000-$60,000 for essential accessories like processors and lifts, and $10,000-$45,000 for permits and compliance costs, which can vary dramatically depending on your location.

I remember chatting with a crematory owner in Chicago who shared some valuable wisdom: "Budget for at least 20% more than equipment quotes suggest. There are always unexpected costs in construction, permitting, and utility connections that weren't obvious at the outset." That extra cushion has saved many of our clients from stressful financial surprises during their projects.

What are the ongoing monthly operating expenses?

The crematory equipment cost is just your initial investment—the monthly operational expenses are what really determine your long-term profitability.

For fuel, expect to spend about $13-$30 per cremation, depending on your equipment's efficiency and local utility rates. Electricity typically runs $300-$600 monthly for a standard operation. Good maintenance practices will cost around $500-$1,000 per month when averaged over time (though some months might be higher if major repairs are needed). Insurance specifically for crematory operations usually falls between $200-$400 monthly.

Labor costs vary significantly based on your volume and staffing model, while supplies and consumables add roughly $5-$10 per cremation. For perspective, a medium-volume crematory performing about 50 cremations monthly might expect total operating expenses between $5,000-$8,000 per month, not including labor costs.

One thing I've noticed while helping clients at American Mortuary Coolers is that energy-efficient equipment often pays for itself through lower monthly operating costs, even if the initial crematory equipment cost is higher.

How long before a new cremator starts generating revenue?

Patience is definitely required when entering the cremation business. Most new operations follow a timeline that looks like this:

First comes planning and permitting, which typically takes 3-6 months (sometimes longer in areas with strict environmental regulations). Once approved, equipment manufacturing requires 14-20 weeks (3-5 months), as quality cremation equipment isn't mass-produced but built to order. Installation and training usually takes just 1-2 weeks, followed by regulatory final approval which can take another 1-4 weeks depending on your local authorities.

All told, most new crematories can expect a total timeline of 8-12 months from initial planning to first revenue. That's a significant period to carry costs without incoming revenue, which is why proper financing is so crucial.

To help manage cash flow, many funeral homes we work with at American Mortuary Coolers implement what I call a "stepping stone" approach:

They start by installing proper refrigeration (our specialty mortuary coolers) to support existing operations and reduce outsourcing costs. Then they add the cremation chamber and basic accessories once permits are approved. Finally, they gradually invest in automation and efficiency tools as their cremation volume increases and justifies the additional expense.

This phased implementation helps manage the significant crematory equipment cost while steadily building the cremation business toward profitability. It's a more sustainable approach for many funeral homes than trying to launch everything at once.

Conclusion

Navigating crematory equipment cost is like putting together a complex puzzle – each piece matters, and the complete picture reveals far more than just the price of a cremation chamber. Throughout this guide, we've walked through the various components that make up this investment, from the retort itself to the building that houses it, the accessories that support it, and the ongoing expenses that keep it running.

When funeral directors call us at American Mortuary Coolers, they're often surprised by the scope of what they're about to undertake. As one owner from Florida told me recently, "I thought I was buying a machine, but I ended up building a business within my business."

That's exactly right. Here's what you'll want to remember as you move forward:

First, be realistic about your total investment. A complete crematory facility typically requires $270,000-$500,000 – not just for equipment, but for the entire operational setup. I've seen too many funeral homes underbudget and then struggle to complete their projects.

Think beyond today's purchase price. The most affordable unit isn't always the most economical in the long run. Consider how fuel efficiency, maintenance requirements, and potential regulatory changes might impact your bottom line five or ten years from now. The crematory that costs $20,000 more upfront but saves $5,000 annually in operating costs pays for itself quickly.

Don't overlook financing options. Equipment leasing can preserve your capital while potentially offering tax advantages. Many of our clients find that monthly payments align better with their cash flow as they build their cremation volume.

Give yourself plenty of time for the regulatory process. The environmental permits and zoning approvals often take longer than expected – sometimes 3-6 months in stricter jurisdictions. This isn't something you can rush, no matter how eager you are to start operations.

Finally, don't skimp on accessories and support equipment. Items like hydraulic lifts and processors might seem like optional add-ons, but they dramatically improve your operational efficiency and staff safety. As one crematory manager told us, "The autoloader seemed expensive until I calculated the labor hours and worker's comp risk it eliminated."

At American Mortuary Coolers, we understand that crematory equipment represents just one part of your complete body care solution. Our custom mortuary refrigeration systems are designed to integrate seamlessly with your cremation operations, creating an efficient workflow from receipt to final disposition.

We've helped hundreds of funeral homes across the country design facilities that balance space efficiency with operational needs. With our direct delivery service spanning the contiguous 48 states and locations in key regions including Johnson City TN, Atlanta GA, and Chicago IL, we're positioned to support your crematory project no matter where you're located.

The cremation landscape continues to evolve with new technologies and changing consumer preferences. By understanding the complete crematory equipment cost picture and planning accordingly, you'll position your business for long-term success in this growing market segment.

For more information about how our mortuary coolers complement crematory operations, check out our article on American Mortuary Coolers: The Leading Supplier of Morgue Coolers, Funeral Home Coolers, and Forensic Refrigeration Solutions.

We're always just a phone call away when you're ready to discuss how refrigeration fits into your crematory plans. After all, proper body care begins long before the cremation process starts.