The Remarkable History of Surgical Wire Saws

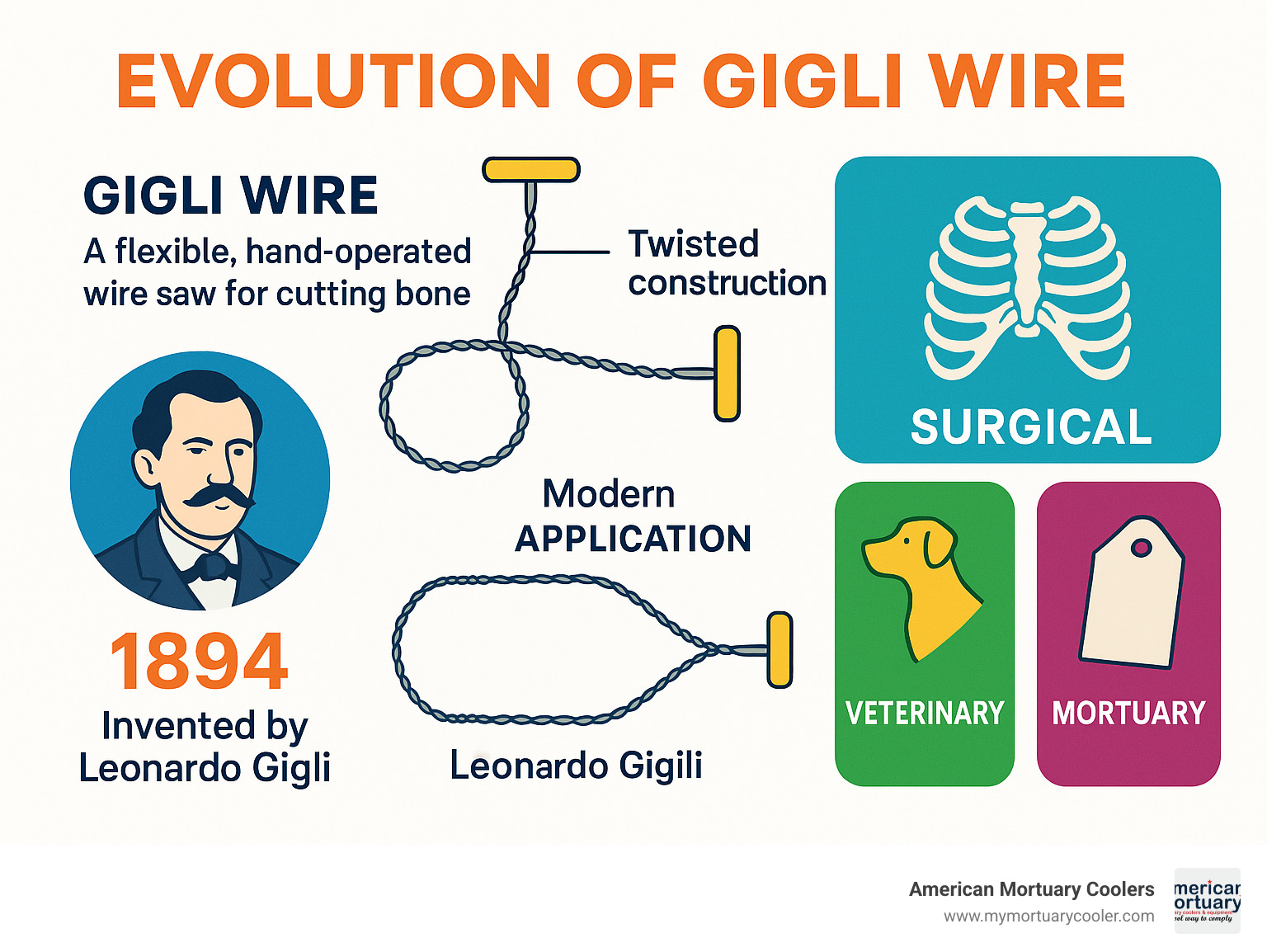

A gigli wire is a flexible twisted-wire saw used by surgeons, veterinarians, and mortuary professionals for precise bone cutting. This specialized cutting tool consists of multiple flexible wires twisted together to create serrated cutting edges.

What is a Gigli Wire?

- Definition: A flexible, hand-operated wire saw for cutting bone

- Inventor: Leonardo Gigli, Italian obstetrician (1894)

- Material: High-quality stainless steel (typically SS 316L or German steel)

- Common Lengths: 12", 20", 21", 30", and 50 cm

- Applications: Surgical amputations, craniotomies, veterinary procedures, mortuary dissection

- Operation: Requires handles at both ends with back-and-forth sawing motion

Despite the prevalence of modern power tools, the gigli wire remains valued for its precision, minimal heat generation, and effectiveness in confined spaces. Its simple but brilliant design was inspired when Leonardo Gigli observed a jagged knife at a country banquet, leading him to create what would become an essential surgical instrument that has endured for over 125 years.

I'm Mortuary Cooler, with extensive experience supplying pathology and mortuary equipment including specialized dissection tools like gigli wire for funeral homes across America. My work with mortuary professionals has given me unique insights into how these traditional instruments remain vital in modern practice.

Similar topics to gigli wire:

Why This Guide Matters

In specialized surgical and mortuary instruments, complete and accurate information can be hard to find. This comprehensive guide aims to answer all your questions about gigli wire – from its fascinating history to its modern applications. Whether you're a medical professional, veterinarian, mortuary technician, or simply curious about specialized tools, this article provides the definitive resource on this remarkable instrument that has stood the test of time.

What Is a Gigli Wire?

The humble gigli wire has an interesting origin story, beginning in the field of obstetrics before quickly finding its way into various medical specialties. At its heart, this remarkable tool consists of several strands of high-quality stainless steel twisted together, creating a flexible saw with multiple cutting edges. This clever design allows it to slice through bone with impressive precision while remaining flexible enough to thread around anatomical structures.

You'll find that a gigli wire carries CE marking in many regions, classifying it as a proper medical device that meets strict health, safety, and environmental protection standards. Depending on who makes it and how it's meant to be used, these wires come as either single-use disposable items or as reusable instruments that can be properly sterilized between procedures. Veterinarians typically file these tools under orthopedic instruments in their equipment catalogs.

What really makes the gigli wire shine is its beautiful simplicity. Unlike modern powered bone saws that need electricity, compressed air, or batteries, this wire requires only human power and proper technique. This makes it particularly valuable in field conditions, emergency situations, or settings where power might be unavailable or unreliable.

As one surgical technician once told me with a smile, "When the power went out during a procedure, the gigli wire saved the day. Sometimes the oldest technology is the most reliable."

Sizes of Gigli Wire

Gigli wires don't come in a one-size-fits-all package. You'll find them in various lengths to suit different surgical needs:

The 12-inch (30 cm) version works beautifully for small bone procedures and tight spaces, while the 20-inch (50 cm) serves as the standard workhorse for most general procedures. Veterinarians often reach for the 21-inch (52 cm) wire, and when greater working distance is needed, the 30-inch (76 cm) version comes into play. European practitioners might be more familiar with the 50 cm measurement, and for specialized applications requiring extended reach, there's even a 70 cm option available.

Choosing the right length isn't just about preference—it depends on several practical factors: the circumference of the bone being cut, how deep you need to work, the amount of space available, and the specific technique being used.

While lengths vary considerably, you'll find the gauge (thickness) of gigli wire tends to be standardized. Most feature the same diameter and tooth pattern regardless of length, ensuring consistent cutting performance whether you're using a shorter or longer wire.

Handling the Gigli Wire

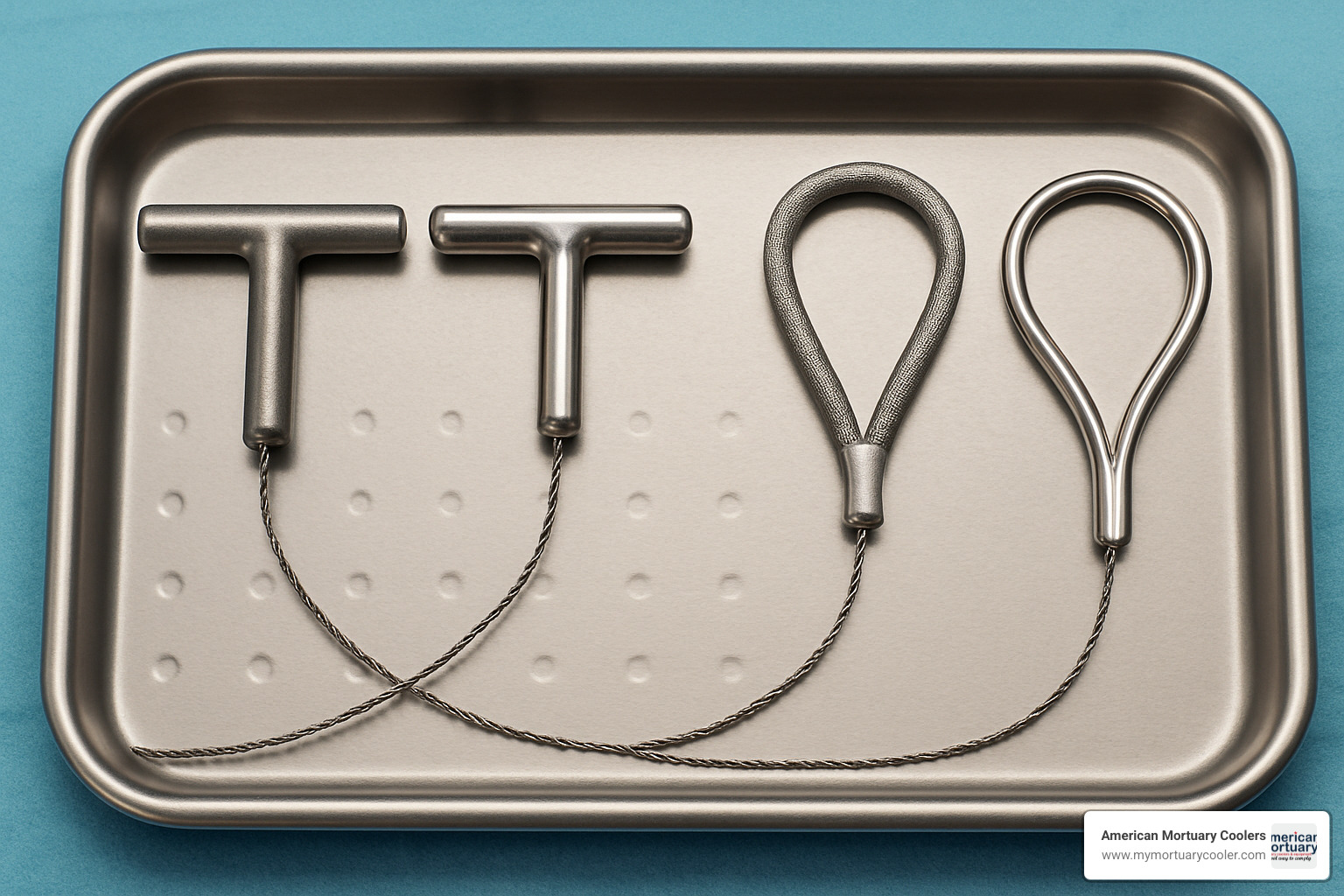

To use a gigli wire effectively, you'll need specialized handles, which come in several thoughtful designs:

Ring handles feature circular finger grips that allow for a secure hold, giving you precise control during delicate procedures. T-handles offer a T-shaped design that provides excellent leverage for controlled sawing motions. For simpler applications, loop handles provide a basic but effective design with a finger insertion loop.

Proper handling is straightforward but requires attention to detail. You'll want to attach the wire securely to the handles and use a smooth back-and-forth sawing motion at approximately 180 degrees. This motion allows the serrated edges to progressively cut through bone tissue on both the forward and backward strokes, making the process remarkably efficient.

Because of their reliability without power requirements, gigli wires have earned a permanent place in field surgical kits for emergency medicine, military applications, and disaster response teams. Their lightweight nature and minimal space requirements make them perfect companions in portable medical kits where every ounce and cubic inch matters.

The Inventor & Historical Background

Leonardo Gigli (1863-1908) wasn't just another Italian obstetrician—he was a true medical innovator whose 1894 invention changed surgery forever. Driven by compassion for mothers facing dangerous childbirth complications due to pelvic deformities, Gigli created a tool that would save countless lives throughout the next century.

The inspiration behind the gigli wire came from an unexpected moment. While enjoying a country banquet, Gigli noticed a jagged knife and had a flash of insight: what if a flexible wire could be designed with similar cutting teeth? This simple observation sparked the creation of the twisted wire saw that now bears his name.

Gigli initially designed his wire saw for a specific purpose—lateralized pubiotomy, a procedure to widen the maternal pelvis during difficult labor. His first prototype cleverly included a whalebone guide for precise placement. After successful testing in 1894, Professor Obalinski suggested wider applications, and the tool quickly found its way into other surgical fields.

"In spite of the recent introduction of craniotomes in neurosurgical practice, the simple but brilliant wire saw invented by Leonardo Gigli still holds an important place in neurosurgical instrumentation," notes historical records in the Journal of Neurosurgery.

Sadly, Gigli's brilliance wasn't always appreciated in his homeland. Historical accounts suggest his academic contributions were belittled in Italy, despite his invention gaining international acclaim. Today, the gigli wire stands as proof of his ingenuity—still in use more than 125 years after its creation.

The centennial celebration of the gigli wire in 1994 marked a century of continuous service in medicine. What began as an obstetric tool evolved organically into standard equipment found in pathology labs, operating theaters, and veterinary clinics worldwide.

Milestones in Use

The journey of the gigli wire through medical history reveals its remarkable versatility and staying power:

When first introduced in 1894, the wire saw revolutionized pubiotomy procedures. By 1897, neurosurgeons had adapted it for cranial flap preparation, appreciating its precision and control. The early 1900s saw its widespread adoption in amputation surgery, where its flexibility proved invaluable.

During the chaos of World War I and II, the gigli wire became a battlefield hero—included in military field surgical kits where its independence from power sources made it literally a lifesaver. A surgeon could perform critical amputations under the most challenging conditions with just this simple tool and skilled hands.

By the mid-20th century, mortuary professionals had standardized the use of gigli wire for cranial dissection during autopsies. The tool's precision allowed for clean calvarium removal while preserving delicate brain tissue for thorough examination.

The late 20th century brought veterinary applications, particularly in antler removal and orthopedic procedures for animals of all sizes. Even in our power-tool dominated 21st century, the humble gigli wire maintains its place in specialized surgical fields—a testament to perfect design meeting essential function.

As one veteran pathologist once remarked, "Some tools never need improving. The gigli wire is surgical perfection in its simplicity."

Construction, Materials & Types of Gigli Wire

When you hold a gigli wire in your hands, you're experiencing a marvel of medical engineering that's remained largely unchanged for over a century. These remarkable tools are crafted from premium stainless steel—typically SS 316L or German surgical steel—chosen specifically for properties that make them perfect for their demanding role.

The high-grade steel provides excellent corrosion resistance, crucial for tools that face repeated sterilization cycles in demanding medical environments. This material also delivers the perfect balance of strength and flexibility—strong enough to cut through bone while remaining flexible enough to be threaded around anatomical structures without breaking.

The magic of a gigli wire lies in its unique construction. Several strands of wire are twisted together in a precise pattern that creates serrated cutting edges along the entire length. This clever design allows the wire to cut effectively in both directions as the surgeon moves it back and forth. The specific twist pattern determines how aggressively the wire cuts—different patterns serve different surgical needs.

Today's market offers several variations of gigli wires to suit different needs. The standard twisted wire remains the workhorse for general bone cutting procedures. For more delicate work, surgeons might select a fine-tooth wire with smaller teeth that create more precise cuts. Budget-conscious facilities often opt for disposable wires that eliminate reprocessing needs, while others invest in higher-quality reusable wires designed to withstand multiple sterilization cycles.

Quality control is non-negotiable in gigli wire manufacturing. A wire that breaks during surgery isn't just an inconvenience—it's potentially dangerous. That's why premium wires undergo rigorous testing for tensile strength, cutting efficiency, and durability before they ever reach an operating room.

Gigli Wire vs. Powered Bone Saws

In an age of technological advancement, you might wonder why anyone would still use a hand-powered tool like a gigli wire. The answer becomes clear when comparing it to modern powered alternatives:

| Feature | Gigli Wire | Powered Oscillating Saw |

|---|---|---|

| Power Source | Manual | Electric/Battery/Pneumatic |

| Heat Generation | Minimal | Significant |

| Precision | High | Moderate |

| Speed | Slower | Faster |

| Cost | Low | High |

| Portability | Excellent | Limited |

| Noise Level | Low | High |

| Maintenance | Simple | Complex |

| Field Use | Ideal | Challenging |

| Learning Curve | Moderate | Steep |

While powered saws might win on speed, the gigli wire shines in situations where electricity isn't available or when working in field conditions. It's also wonderfully quiet compared to the high-pitched whine of powered alternatives—a small mercy in already stressful situations.

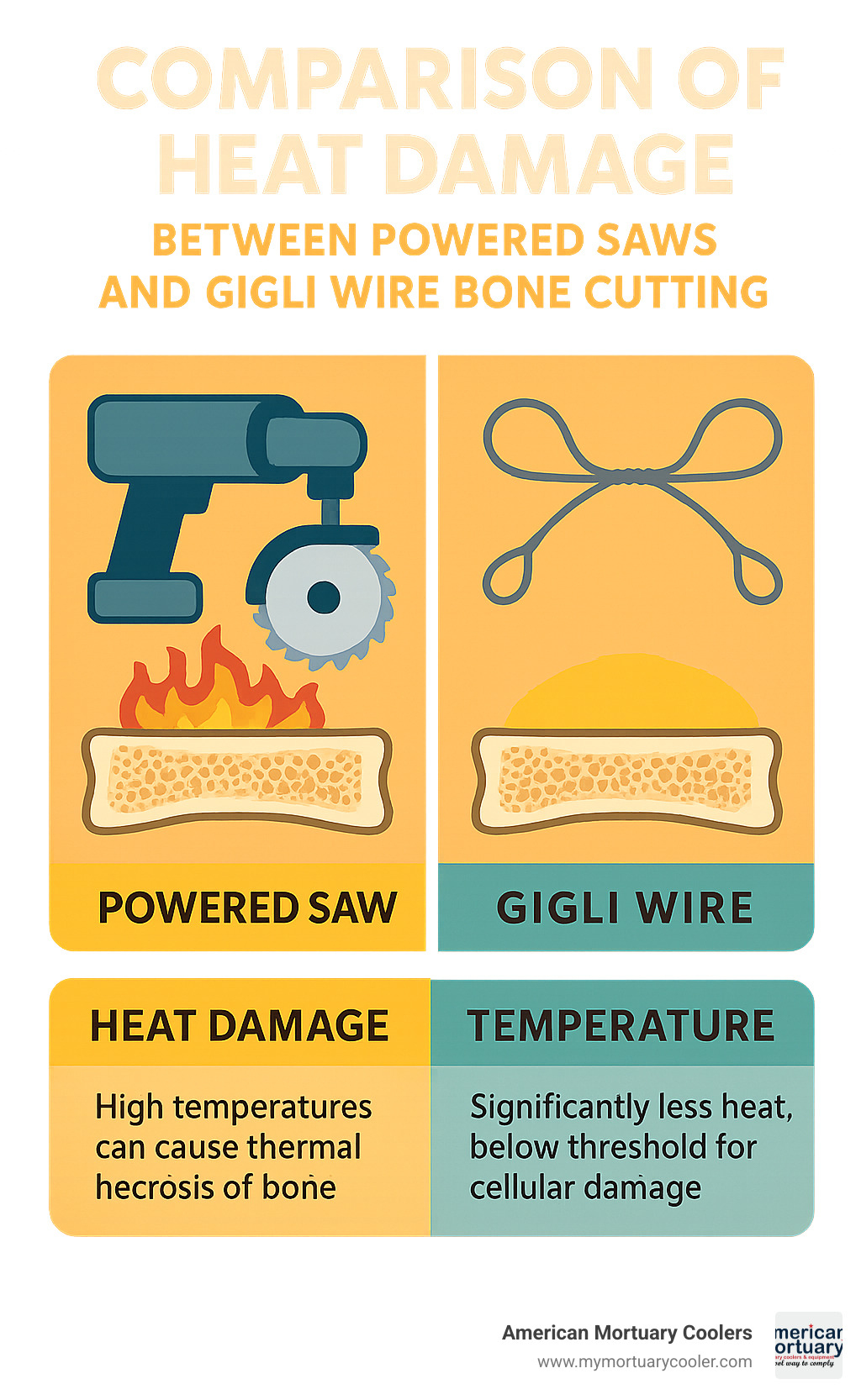

Perhaps most importantly, gigli wires generate minimal heat during use. This matters because the heat from powered saws can cause thermal necrosis in bone tissue, potentially complicating healing. The cooler cut from a gigli wire helps preserve tissue viability.

As one orthopedic surgeon told me during a recent equipment consultation, "For certain precision cuts, especially around delicate structures, I still reach for the gigli wire. Sometimes the older technology gives you better control and feel than the powered alternatives."

This perfect balance of simplicity, effectiveness, and gentle tissue interaction explains why this humble tool continues to earn its place in surgical trays, veterinary clinics, and mortuary settings worldwide—even in our age of technological marvels.

How a Gigli Wire Functions in Surgery & Veterinary Medicine

The humble gigli wire might seem like a simple tool, but its applications span across multiple medical fields with remarkable versatility. This flexible bone-cutting marvel continues to be an invaluable instrument in many specialized settings, proving that sometimes the most enduring medical tools are the least complicated.

In human surgery, the gigli wire shines in orthopedic amputations where clean, precise bone cuts are essential for optimal healing and prosthetic fitting. Neurosurgeons still reach for this tool during craniotomy procedures, appreciating its ability to create controlled access to the brain with minimal heat damage. In tight anatomical spaces where bulkier power tools simply won't fit, the gigli wire becomes the instrument of choice.

Veterinary medicine has acceptd the gigli wire for a fascinating range of applications. From trimming overgrown antlers, horns, and tusks to performing delicate canine TPLO (Tibial Plateau Leveling Osteotomy) surgery, veterinarians value its precision and portability. As one rural large animal vet told me, "When I'm out in a field with no electricity treating a farm animal, my gigli wire is worth its weight in gold."

In mortuary practice, the gigli wire has long been a standard tool for creating clean cranial cuts during autopsy procedures. Pathologists rely on its precision for sectioning bone specimens during detailed examinations, and forensic investigators appreciate its ability to create clean cuts that don't damage adjacent tissues. For more information about essential tools in autopsy procedures, you can explore the essential role of bone saws in autopsies.

What makes the gigli wire truly special is its unique ability to be threaded around structures and cut from within outward—something powered saws simply cannot do. This distinctive capability preserves surrounding tissues and provides access in situations where conventional approaches would be impossible.

Step-by-Step Surgical Technique With Gigli Wire

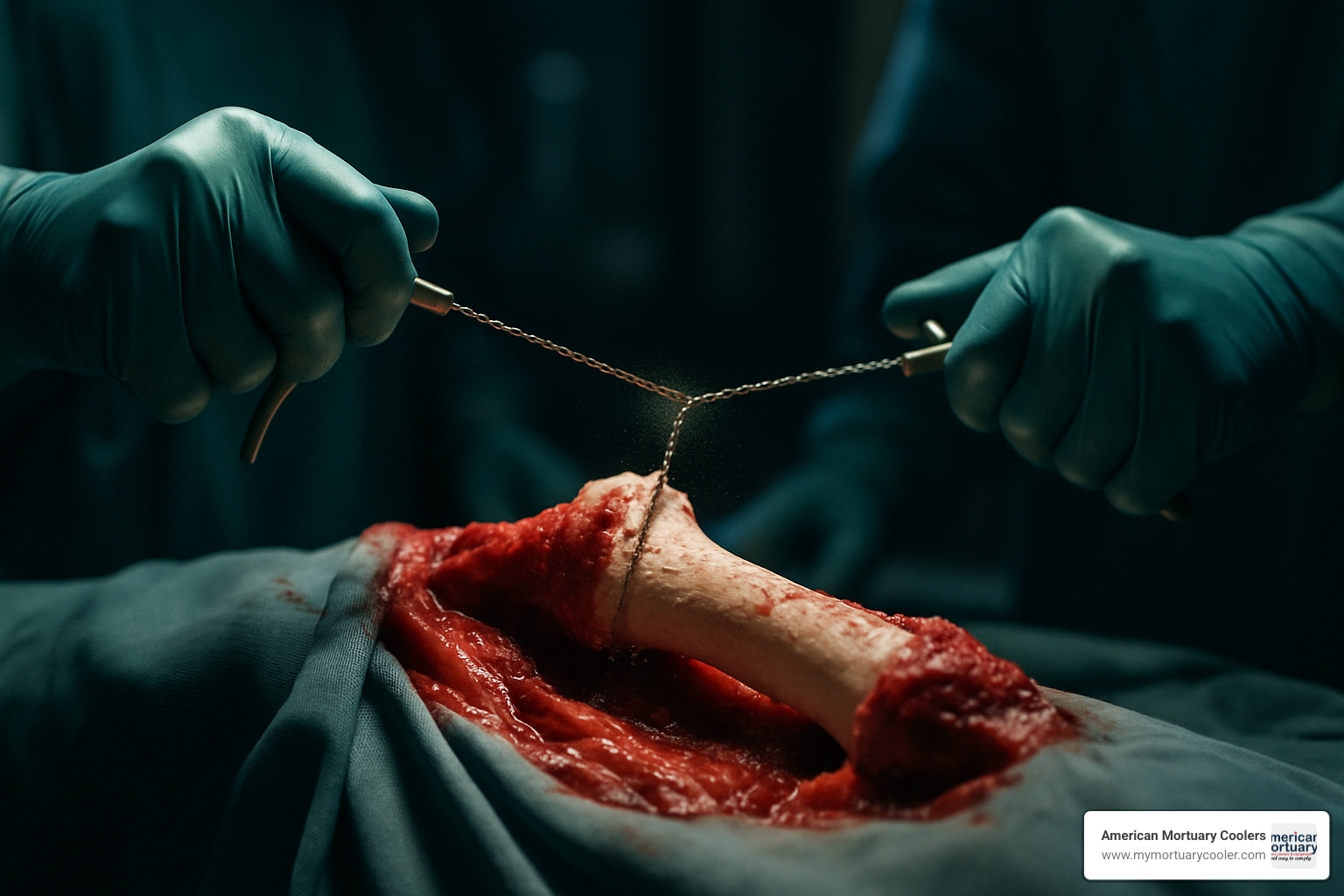

Using a gigli wire effectively requires careful technique and attention to detail. The process begins with proper preparation—ensuring the wire and handles are properly sterilized and securely assembled. After creating appropriate soft tissue access to the bone, the surgeon must carefully thread the wire around the target area, often using a specialized guide instrument.

In craniotomy procedures, small burr holes are first drilled to allow passage of the wire beneath the skull. Once properly positioned, handles are securely attached to both ends of the wire with a locking mechanism that prevents slippage during use.

The actual cutting technique involves a smooth, rhythmic back-and-forth sawing motion at roughly 180 degrees. This motion allows the wire's serrated edges to progressively cut through bone tissue with surprising efficiency. Many surgeons apply irrigation during cutting to wash away bone debris and minimize heat generation.

"The key is maintaining consistent tension without forcing the wire," explains a veteran orthopedic surgeon. "Let the serrations do the work—pushing too hard just increases the risk of breakage."

Once cutting is complete, the bone section can be removed, and any wire fragments must be carefully retrieved if breakage has occurred. Finally, the wire is either properly disposed of (if single-use) or prepared for sterilization (if reusable).

Advantages & Disadvantages

The gigli wire offers compelling benefits that explain its longevity in medical practice. Its extreme lightweight portability makes it ideal for field use, while the minimal heat generation during cutting prevents thermal damage to surrounding tissues. Compared to powered alternatives, the gigli wire is remarkably affordable and never needs charging or maintenance.

Many practitioners appreciate the excellent tactile feedback the wire provides—you can literally feel the different densities of bone as you cut. The ability to thread the wire around structures for inside-out cutting remains best by any power tool. Veterinarians particularly value its silent operation, which reduces stress in animal patients.

However, the gigli wire isn't without drawbacks. The manual effort required can be fatiguing during lengthy procedures, and cutting speed is notably slower than with powered alternatives. There's always a risk of wire fraying or breaking during use, and mastering proper technique involves a learning curve. Single-use versions create disposal waste, and complex geometric cuts can be challenging to execute precisely.

As one surgical technician put it, "It's not about which tool is better—it's about choosing the right tool for each specific situation. Sometimes that's the gigli wire, sometimes it's a power saw."

Safety Considerations & Risks

Working with a gigli wire requires specific safety awareness. The serrated edges that cut bone so effectively can just as easily slice through surgical gloves, creating a risk of sharps injury. Many practitioners adopt double-gloving or use specialized protective gloves when handling these wires.

Wire breakage represents another significant concern. Excessive force or improper technique can cause the wire to snap during use, potentially leaving fragments that must be carefully retrieved to prevent them from becoming dangerous foreign bodies.

For facilities using reusable wires, proper sterilization between cases is absolutely essential to prevent cross-contamination. The wire's multiple twisted strands can harbor biological material if not thoroughly cleaned.

Protecting surrounding soft tissues during cutting requires careful technique and appropriate retraction. The gigli wire should generally be avoided in cases of active infection, compromised vascularity, or known material sensitivity.

Research published in the Journal of Neurosurgery confirms that with proper technique, these risks can be minimized: "When properly employed with appropriate guides and controlled tension, the gigli wire provides safe and effective bone cutting with minimal complications." For more information about craniotomy techniques, see this scientific research on craniotomy technique.

Sterilization, Maintenance & Storage

Taking proper care of your gigli wire isn't just about making it last longer—it's essential for patient safety and successful procedures. Whether you're in a hospital setting or a mortuary, these flexible bone-cutting tools need special attention.

For those who use reusable gigli wires, the sterilization process is straightforward but must be followed carefully. Autoclaving at 134°C is the gold standard, effectively eliminating all potential pathogens. After a procedure, an ultrasonic cleaning bath works wonders for removing those tiny bone particles that can get trapped between the twisted wire strands. Many facilities also implement regular passivation processes—chemical treatments that help prevent rust and corrosion on these stainless steel instruments.

"I always tell my staff to inspect every wire before use," shares one mortuary director. "A quick visual check for fraying or damage takes seconds but can prevent frustrating breakages during procedures."

Single-use gigli wires have their own set of considerations. Always dispose of these in proper sharps containers—these wires are surprisingly sharp and can easily cause injuries if mishandled. Before opening a new wire, check that the sterile packaging is intact, and as part of good practice, document lot numbers for tracking purposes in case of recalls.

Don't forget about those handles! The gigli wire is only as good as its handles, so regular inspection of locking mechanisms is crucial. A drop of medical-grade lubricant on moving parts (following manufacturer guidelines) can make all the difference in smooth operation. Always double-check that the wire is securely attached to the handles before beginning any procedure—a loose connection can lead to slippage at the worst possible moment.

When it comes to storage, think gentle curves rather than sharp bends. Gigli wires should be stored in a way that prevents kinking or damage to those delicate cutting edges. Many of our clients use specialized instrument trays with dedicated slots or compartments that keep these tools safe between uses.

Reprocessing Workflow

For facilities that reuse gigli wires, we recommend following a consistent reprocessing workflow. Start with a pre-rinse immediately after use—cold water is best for removing gross contaminants without setting proteins into the metal. Next comes the enzymatic soak, which breaks down organic material that might be invisible to the naked eye.

The ultrasonic cleaning step is particularly important for gigli wires because of their twisted construction. Those tiny spaces between wire strands can harbor debris that manual cleaning might miss. After cleaning, take time for a careful inspection under good lighting—looking for any signs of damage, fraying, or remaining contamination.

Proper packaging in appropriate sterilization pouches or trays comes next, followed by autoclaving according to the manufacturer's specifications. Store these delicate instruments in clean, dry conditions until their next use. Many facilities find that keeping a log tracking processing cycles and usage helps with quality control and longevity tracking.

"We've found that proper maintenance significantly extends the lifespan of these instruments," notes one of our specialists at American Mortuary Coolers. "When cared for correctly, a quality gigli wire can be surprisingly economical over time despite the initial investment."

For more detailed information about caring for mortuary tools of all types, check out our More info about tool care resource page.

Gigli Wire in Modern Practice & Pop Culture

The humble gigli wire may have been eclipsed by high-speed power tools in many operating rooms, but this resilient instrument still has a special place in modern medicine. Like a trusted old friend, it continues to show up exactly when needed.

In today's medical landscape, the gigli wire maintains several important roles. Surgeons still reach for it when they need exceptionally precise cuts that power saws might handle too aggressively. The wire's gentle touch and minimal heat generation make it perfect for these delicate situations.

When disaster strikes or in military field operations, you'll find the gigli wire packed in emergency medical kits. Its independence from electricity makes it invaluable when power isn't available – a reminder that sometimes the simplest tools are also the most reliable.

Veterinarians particularly appreciate the gigli wire for specialized procedures. From trimming antlers to performing orthopedic surgeries on our four-legged friends, its quiet operation and precision make it especially suitable for animal patients who might be startled by the noise of power tools.

In mortuary and pathology settings, the gigli wire remains a trusted companion for specific dissection tasks. When precision matters more than speed, many professionals still prefer this traditional tool over its modern counterparts.

Medical schools also use the gigli wire as a teaching tool. Before introducing students to powered instruments, instructors often have them master the fundamental principles of bone-cutting with this manual device – building skills and appreciation for surgical technique from the ground up.

Interestingly, the gigli wire has carved out a place in popular culture too. Horror film enthusiasts might recognize it from the 2023 movie "Saw X," where its distinctive appearance and bone-cutting capability made for a particularly memorable prop. This cinematic moment introduced many people outside the medical field to this specialized tool for the first time.

"Few medical instruments invented in the 19th century remain in active use today," noted one medical historian I spoke with recently. "The gigli wire stands as a testament to design that perfectly matches function." This neat simplicity explains its remarkable 125-year staying power in a field where technology evolves at breakneck speed.

Future Innovations

Even after more than a century, innovation continues with the gigli wire. Researchers are developing specialized coatings to reduce friction and improve cutting efficiency, while manufacturers are creating more ergonomic handles to reduce operator fatigue during lengthy procedures.

Some forward-thinking companies are even experimenting with hybrid systems – powered tensioners that maintain the wire's flexibility while reducing manual effort. Meanwhile, metallurgists are researching alternative alloys that could provide improved durability and cutting performance.

These ongoing improvements suggest that the gigli wire will continue finding its way into specialized corners of medical and mortuary practice for years to come. Like many classic designs, it proves that sometimes the best solutions aren't always the newest ones.

Frequently Asked Questions about Gigli Wire

What procedures still rely on a gigli wire today?

Even in our high-tech medical world, the humble gigli wire continues to play a vital role in several important procedures. It's like that reliable old tool in your grandfather's workshop that modern gadgets just can't quite replace.

In surgical settings, gigli wires remain the go-to choice for certain amputations, especially when surgeons need clean bone cuts with minimal heat damage or when working in challenging field conditions. Many neurosurgeons still prefer them for creating cranial flaps during brain surgeries, appreciating the precise control that simply can't be matched by powered alternatives.

Veterinarians particularly treasure these versatile tools. From performing delicate TPLO (tibial plateau leveling osteotomy) procedures on our canine companions to the gentle removal of antlers and horns from larger animals, the gigli wire offers effectiveness with minimal distress to the animal patients.

In the quiet halls of pathology departments, medical examiners and pathologists consistently reach for gigli wires during autopsy procedures, particularly for those precise cranial cuts that require a steady hand and reliable tool.

Perhaps most importantly, many operating rooms worldwide keep gigli wires on standby as essential backup tools. When power fails or specialized equipment isn't available, this simple device can quite literally be a lifesaver.

Can a gigli wire be reused safely?

The question of reusing a gigli wire isn't as straightforward as you might think – it's a bit like asking if you can reuse a good kitchen knife after a thorough cleaning.

The answer depends on several important factors. First, check what the manufacturer says – some gigli wires come clearly labeled as single-use only, while others are specifically designed to withstand multiple uses. The quality matters tremendously here; higher-grade stainless steel wires can handle repeated sterilization cycles without compromising their integrity.

Proper reprocessing is absolutely critical. This isn't just a quick rinse and wipe – proper cleaning, meticulous inspection, and thorough sterilization following established protocols are essential steps. Many medical facilities have developed specific policies about reusing cutting instruments like gigli wires, and these guidelines should always be followed.

Before each use, a careful visual inspection is non-negotiable. Any signs of fraying, corrosion, or damage mean it's time to retire that wire. Many facilities wisely keep detailed records of sterilization cycles and usage history to maintain quality control.

Most experts agree that while properly reprocessed gigli wires can be safely reused a limited number of times, you need to carefully weigh the potential risks against the cost savings. After all, the last place you want a tool to fail is during a critical medical procedure.

How does gigli wire cutting compare to oscillating saw heat damage?

One of the most compelling advantages of the gigli wire is how cool it keeps things – literally. This difference in heat generation compared to powered alternatives has real-world implications for patient outcomes.

When an oscillating saw cuts through bone, it can generate temperatures exceeding 100°C at the cutting surface – hot enough to cause thermal necrosis (cell death) in the surrounding bone tissue. This damage can extend 3mm or more from the cut edge, potentially compromising healing in procedures where bone regrowth is essential.

The gigli wire, by contrast, keeps its cool. Its manual operation generates significantly less heat, typically keeping temperatures below the threshold where cellular damage occurs. This preserves the viability of cells right at the cut edge, creating much better conditions for healing.

"When I'm performing a procedure where bone healing is critical, I'll often choose the gigli wire specifically to minimize thermal damage, even though it takes a bit longer," one orthopedic surgeon shared with me. "The biological benefit outweighs the time consideration."

Research increasingly suggests that in certain procedures, this reduced thermal damage may contribute to better healing outcomes and fewer complications. It's a perfect example of how sometimes older technology offers benefits that newer, faster alternatives simply can't match.

Conclusion

The gigli wire stands as a remarkable example of medical innovation that has stood the test of time. From its humble origins in 19th-century obstetrics to its continued use in modern surgical, veterinary, and mortuary applications, this simple yet brilliant tool demonstrates that sometimes the most enduring solutions are also the most neat.

While powered alternatives have replaced the gigli wire in many settings, its unique advantages ensure it maintains a place in specialized applications. The minimal heat generation during cutting, precision in confined spaces, and complete independence from power sources make it invaluable in certain scenarios. When the electricity fails or when working in remote locations, this humble wire saw continues to deliver reliable results.

The ongoing innovation in wire materials and handle designs suggests this tool will continue to evolve. From improved ergonomics to specialized coatings that reduce friction, manufacturers continue to refine this century-old design to meet modern needs.

At American Mortuary Coolers, we've seen how reliable, precision instruments make all the difference in mortuary and pathology settings. As we provide custom morgue coolers and related equipment to funeral homes across the contiguous 48 states, we recognize that quality tools like the gigli wire remain essential components of professional practice. Our commitment to durability and custom solutions extends to all aspects of mortuary operations, from refrigeration to the specialized instruments that professionals rely on daily.

Whether you're a medical professional seeking to understand traditional surgical tools, a veterinarian exploring options for orthopedic procedures, or a mortuary professional looking to optimize your toolkit, the gigli wire represents a fascinating intersection of historical ingenuity and modern utility. Its continued relevance reminds us that sometimes, the best solutions are those that have already withstood the test of time.

The next time you encounter this unassuming twisted wire with its distinctive handles, take a moment to appreciate the brilliance of Leonardo Gigli's invention and how it continues to serve healthcare professionals more than 125 years after its creation. In a world of rapidly advancing medical technology, there's something reassuring about tools that remain relevant through generations of practice.

For more information about mortuary equipment and custom solutions for your facility, visit our page on morgue coolers and solutions.