Essential Guide to Knife Handle #3

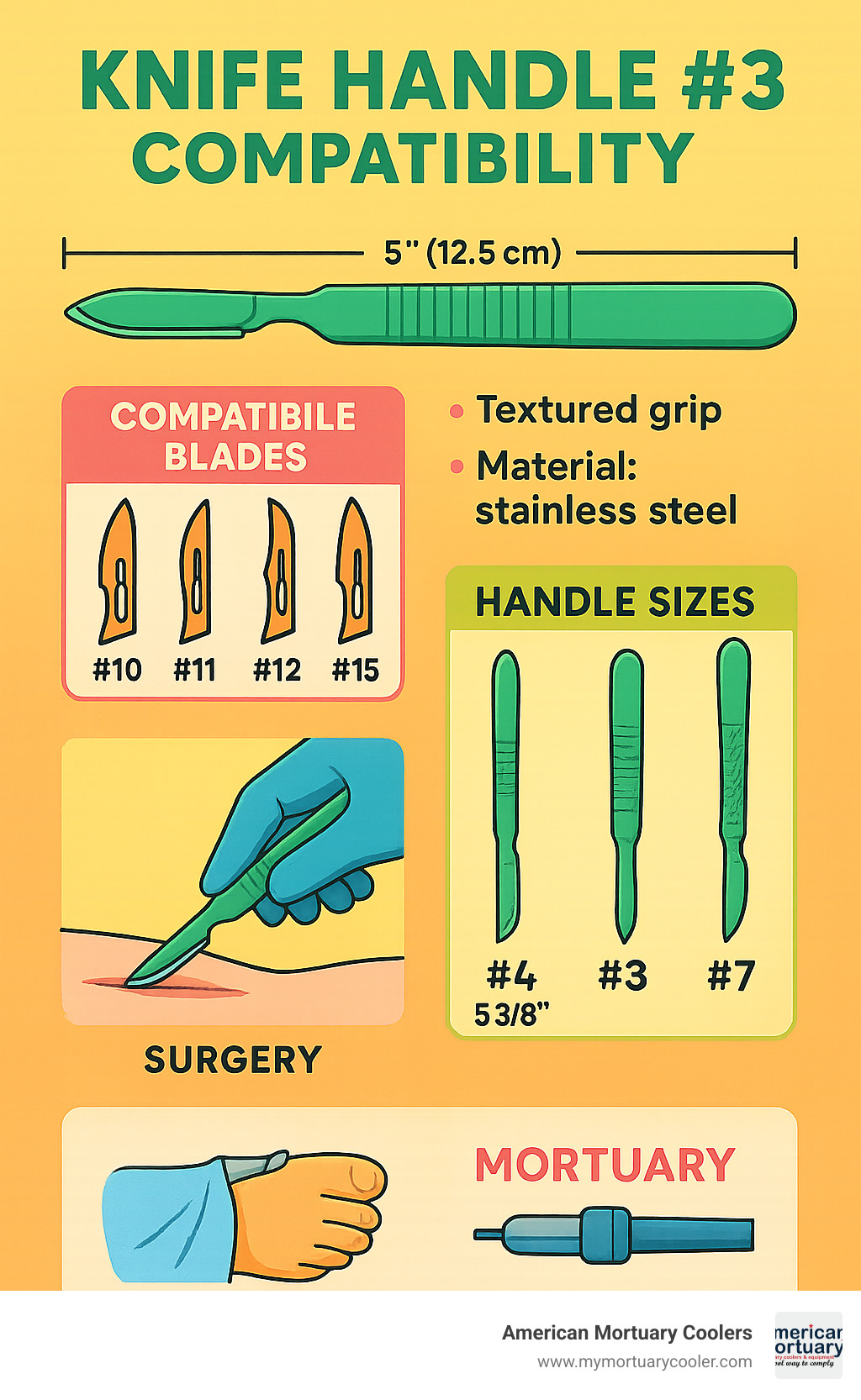

A knife handle #3 is a 5-inch (12.5 cm) surgical instrument handle designed to hold small, replaceable blades for precise cutting and dissection. This standard handle is compatible with Bard-Parker blade numbers 10, 11, 12, and 15.

| Knife Handle #3 Quick Reference | |

|---|---|

| Length | 5 inches (12.5 cm) |

| Compatible Blades | #10, #11, #12, #15 |

| Material | Surgical stainless steel |

| Price Range | $8.40 - $15 |

| Common Uses | Microdissection, fine surgery |

| Features | Textured grip, balanced weight |

The #3 handle represents the perfect balance between precision and control, making it the instrument of choice for procedures requiring detailed work. Unlike larger handles, the #3 is specifically designed for smaller blades with curved or pointed cutting edges, allowing for intricate tissue manipulation and fine incisions.

I'm Mortuary Cooler, a national-level supplier with extensive experience providing high-quality knife handle #3 instruments and other precision tools to funeral homes and mortuary facilities across the country. My background in mortuary equipment has given me unique insights into how the knife handle #3 is used in post-mortem care and preparation.

While companies like Integra Miltex, Sklar Instruments, and Medline offer similar products, American Mortuary Coolers specializes in providing these essential tools alongside our comprehensive mortuary solutions.

Quick knife handle #3 terms:

Understanding the Knife Handle #3

Let's explore the knife handle #3 - a tool that might seem simple at first glance but has quite a story to tell. This little workhorse has been a faithful companion in surgical suites, autopsy rooms, and mortuary settings for decades, barely changing its design because, well, why mess with perfection?

What Is a #3 Knife Handle?

The knife handle #3 is part of the Bard-Parker numbering system - basically the language that medical professionals speak when they need to grab the right tool quickly. Think of it as the Goldilocks of knife handles - not too big, not too small, but just right for detailed work.

When a surgeon, pathologist, or mortician reaches for a knife handle #3, they're choosing a tool specifically designed for precision. The numbering logic isn't random - it's based on what each handle does best. The #3 earned its designation because it hits the sweet spot for fine dissection work.

This handle shines in several settings:

It's the go-to for surgeons making delicate incisions where every millimeter matters. During autopsies, it helps pathologists reveal important details. Veterinarians rely on it for procedures on both large and small animals. Medical students learn their craft with it in anatomy labs. And in our world of mortuary services, it's essential for the careful preparation work that shows respect for the deceased.

The #3 handle's origins stretch back to the early 1900s, when medical professionals realized that standardized tools would help advance their practice. Little did they know their practical solution would become a staple across multiple fields for over a century!

Key Features of a Knife Handle #3

The standard knife handle #3 measures about 125 mm (5 inches) long - perfect for cradling in your palm while your fingers direct precise movements. It's like an extension of your hand when you need to work with ultimate control.

What makes this handle special? First, there's the balanced weight - typically around 8 grams. It's substantial enough to feel secure in your hand but light enough to use for hours without fatigue. The weight distribution is carefully engineered to rest naturally in your grip.

The compatibility slots at the tip are precision-engineered to securely lock blades in place. This clever design allows for quick blade changes when needed, without any wobbling or slipping during use.

Most quality #3 handles feature a textured grip with knurled patterns or grooves. This thoughtful detail prevents the handle from slipping, especially important when working with biological materials.

While American Mortuary Coolers provides high-quality knife handle #3 instruments, other suppliers in the market include Integra LifeSciences, Sklar Surgical Instruments, and Medline Industries. Each manufacturer offers slight variations in grip texture and weight balance, though all adhere to the standard dimensions that professionals expect.

Knife Handle #3 Blade Compatibility & Size Guide

What makes the knife handle #3 truly shine is its versatility. Understanding which blades work with this handle will help you choose the perfect combination for your specific needs.

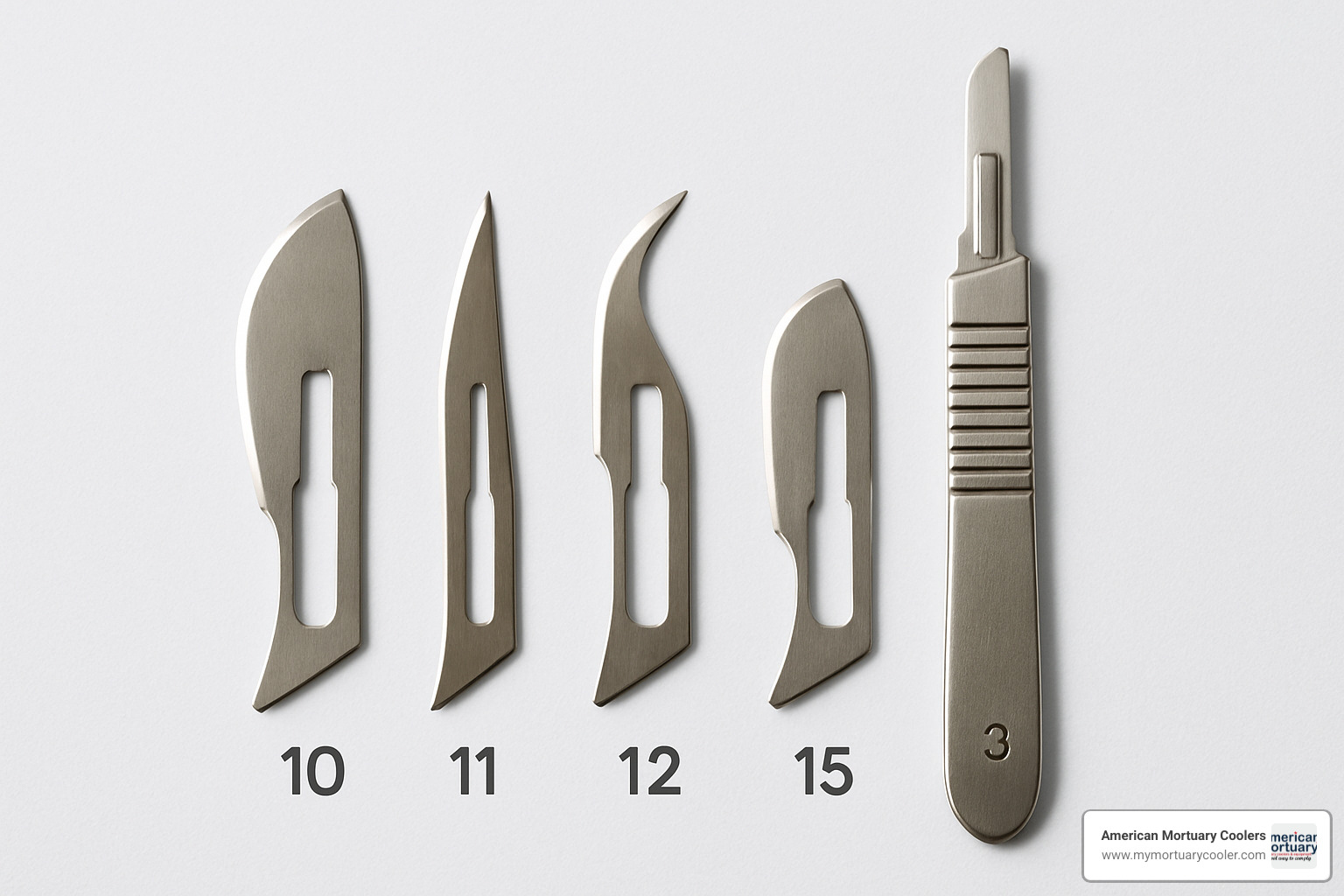

Your knife handle #3 accepts several blade types, each with its own special talents:

The #10 blade features a curved edge with a convex profile – perfect for longer, sweeping incisions. If you're making initial skin incisions during autopsies or surgical procedures, this blade is your go-to companion.

The #11 blade sports a triangular shape with a sharp point. Think of it as your precision instrument for delicate stab incisions and detailed work in tight spaces. Need to create a drainage point or access a tiny anatomical structure? The #11 has you covered.

The #12 blade offers a small, curved cutting edge that ends in a sharp point. It's like getting the #10 and #11 blades to have a baby! This versatile option handles a wide range of fine cutting tasks with ease.

The #15 blade gives you a compact version of the #10's curved edge. When extreme precision and delicate tissue dissection are on the menu, reach for this little wonder.

For specialized work, certain micro-surgical blades also fit the #3 handle, though these tend to show up only in highly specialized settings.

Knife Handle #3 vs #4 vs #7

Choosing between handle sizes can feel a bit like selecting the right golf club – each has its purpose! Here's how the knife handle #3 stacks up against its siblings:

| Feature | Handle #3 | Handle #4 | Handle #7 |

|---|---|---|---|

| Length | 5" (12.5 cm) | 5.5" (14 cm) | 6.25" (16 cm) |

| Compatible Blades | #10, #11, #12, #15 | #20, #21, #22, #23, #24, #25 | #10, #15 (different attachment) |

| Weight | Lightweight | Medium weight | Very lightweight |

| Primary Use | Fine dissection, precise work | General cutting, requiring more force | Ophthalmology, microsurgery |

| Grip Style | Standard | Larger diameter | Pencil-like |

| Best For | Detailed work requiring dexterity | Procedures requiring more leverage | Extremely delicate procedures |

The knife handle #3 hits that sweet spot between the ultra-fine #7 and the more substantial #4. It's like the "Goldilocks" of knife handles – not too big, not too small, just right for most applications.

Choosing the Right Knife Handle #3 for Your Procedure

At American Mortuary Coolers, we've helped professionals across Dallas, Chicago, and beyond find their perfect knife handle #3. Here's what we've learned about matching the handle to your specific needs:

For microdissection work, look for a lighter knife handle #3 with a finer grip pattern. The reduced weight gives you better control when performing detailed tasks.

When performing autopsy incisions, a standard stainless steel knife handle #3 with medium texturing provides that perfect balance of precision and durability.

Our veterinary clients often prefer handles with improved grip features. Animal tissues can present different resistance levels than human tissues.

For educational environments, we recommend durable, cost-effective stainless steel handles. These workhorses stand up to frequent use by students still developing their skills.

Want to learn more about specialized tools for mortuary settings? Our guide on cutting-edge mortuary tools dives deeper into the equipment that helps professionals perform their important work with precision and dignity.

Dimensions, Materials, and Ergonomic Design

Let's talk about what makes a knife handle #3 tick – because there's more to this little tool than meets the eye! When you hold one in your hand, you're actually holding the result of decades of refinement and thoughtful design.

A standard knife handle #3 measures about 13 cm (5.1 inches) long – just about the length of a standard pen. It weighs a feather-light 8 grams and has a comfortable diameter of 6-8 mm where you grip it. These dimensions aren't random – they're carefully calculated to give you precision control without making your hand tired, even during long procedures.

Material Options for Knife Handle #3

When it comes to what your knife handle #3 is made from, you've got some interesting choices:

The classic surgical grade stainless steel handle is reliable, durable, and ready for thousands of sterilization cycles without complaint. This is what most professionals reach for, and for good reason.

Some folks prefer to upgrade to premium German steel handles. These resist corrosion beautifully and still look pristine after years of service. Yes, they cost more, but many professionals find the investment worthwhile.

Titanium handles offer something special – they're incredibly strong yet lighter than their steel cousins. If you're doing delicate work where every gram matters, titanium might be your new best friend.

For situations where single-use tools make sense, polymer/plastic handles come into play. These medical-grade plastic options can still be autoclaved (contrary to what some believe), though they won't last through as many cycles as metal.

Some innovative handles feature silicone-improved grips over a metal core – giving you the best of both worlds with durability and comfort.

Competitors like Integra LifeSciences offer their Miltex line with proprietary grip patterns, while Sklar Surgical Instruments focuses on premium materials in their handles. Medline provides more budget-friendly options without sacrificing essential functionality.

For those looking for detailed specs on professional options, Knife Handle #3 - Novo Surgical offers excellent information.

Ergonomic Improvements

Modern knife handle #3 designs have come a long way in the comfort department. Today's handles feature knurled ribs that give you a secure grip even when wearing gloves or working with fluids – a common scenario in mortuary settings.

The thoughtful addition of anti-slip grooves helps guide your fingers to the right position and prevents rotation during procedures. Engineers have also carefully considered balance point engineering, placing the weight exactly where it gives you the most control.

Many handles now feature contoured profiles that simply feel better in your hand during longer procedures. And for busy facilities, color-coded handles can be a real time-saver when you need to quickly grab the right tool.

Applications, Advantages, and Safety Tips

The knife handle #3 is truly a jack-of-all-trades in the medical and mortuary world. During my years at American Mortuary Coolers, I've seen this versatile tool used in countless ways from New York to Los Angeles, in settings ranging from high-tech surgical suites to traditional funeral homes.

Benefits of Using Knife Handle #3 in Detail Work

What makes the knife handle #3 so special? It's all about balance and precision. When you're performing delicate work—whether that's preparing a loved one for viewing or conducting a medical procedure—this tool feels like a natural extension of your hand.

The lightweight, balanced design gives you exceptional control, which is absolutely crucial when working with delicate tissues. Your hands stay steady, even during longer procedures that might otherwise leave you with cramping fingers.

One of my favorite things about this tool is how quickly you can swap between different blade profiles. Need to switch from a #10 to a #15 for more detailed work? It takes just seconds, keeping your workflow smooth and efficient.

A quality knife handle #3 is an investment that pays for itself many times over. While the blades need regular replacement, the handle itself can serve faithfully for years when properly maintained.

The knife handle #3 particularly shines in fine tissue work where precision matters most. Embalmers rely on it for creating clean, easily concealed incisions. Ophthalmologists appreciate its delicate touch for work around the eyes. And in classroom settings, its standardized design gives students a consistent learning experience.

While we provide premium options at American Mortuary Coolers, competitors like Roboz Surgical and Fine Science Tools also offer quality handles with slightly different grip patterns. For those interested in professional-grade options, you might want to check out the Surgeon's Scalpel Handle, No. 3 which offers excellent quality for daily use.

Safety Considerations When Changing Blades

Let's talk safety, because even the most experienced professionals need a reminder sometimes. Changing blades on a knife handle #3 requires caution—those little blades are incredibly sharp!

Always wear cut-resistant gloves when handling blades. I can't stress this enough. I've seen too many unnecessary nicks and cuts from professionals who thought they were careful enough without proper protection.

Use a blade remover rather than your fingers—these simple tools make blade changes safer and easier. And please, always have a designated sharps container nearby for immediate disposal.

Many professionals find that using locking forceps to grip and position new blades gives them better control and keeps fingers safely away from sharp edges. And before you start any procedure, double-check that the new blade is firmly seated in the handle.

Common mistakes I've seen over the years include applying too much sideways pressure (which can snap blades), using handles with worn attachment mechanisms, trying to resharpen disposable blades (never a good idea!), and improper storage that allows blades to damage other instruments.

Cleaning, Maintenance, and Cost Considerations

Taking good care of your knife handle #3 isn't just about keeping it clean—it's about ensuring it serves you reliably for years to come. At American Mortuary Coolers, we've helped countless funeral homes maintain their precision tools, and we've learned a thing or two along the way.

Sterilization Protocols for Knife Handle #3

Your knife handle #3 deserves proper cleaning—think of it as a craftsman's tool that needs respect. For stainless steel handles, steam autoclaving works wonderfully, typically at 121°C for 30 minutes or 134°C for a quicker 3-4 minute cycle. Just remember to dry them thoroughly afterward—moisture is the enemy of fine steel instruments.

Can't use high heat? Ethylene oxide gas sterilization offers a gentler alternative, though you'll need patience for the longer processing times. Some of our clients in smaller facilities prefer cold soak chemical sterilants like glutaraldehyde or peracetic acid solutions.

The cleaning process is straightforward—remove the blade, rinse off visible material, give it a good ultrasonic bath with the right detergent, rinse thoroughly with distilled water, and dry completely before sterilization.

Don't forget those quality control checks! Take a moment regularly to inspect the blade attachment mechanism. Look for any signs of corrosion, pitting, or warping that might compromise how securely it holds blades.

If you've opted for polymer handles, double-check their autoclave compatibility—some can warp under high heat. For more maintenance wisdom, our guide on Metzenbaum Scissors care offers excellent crossover advice.

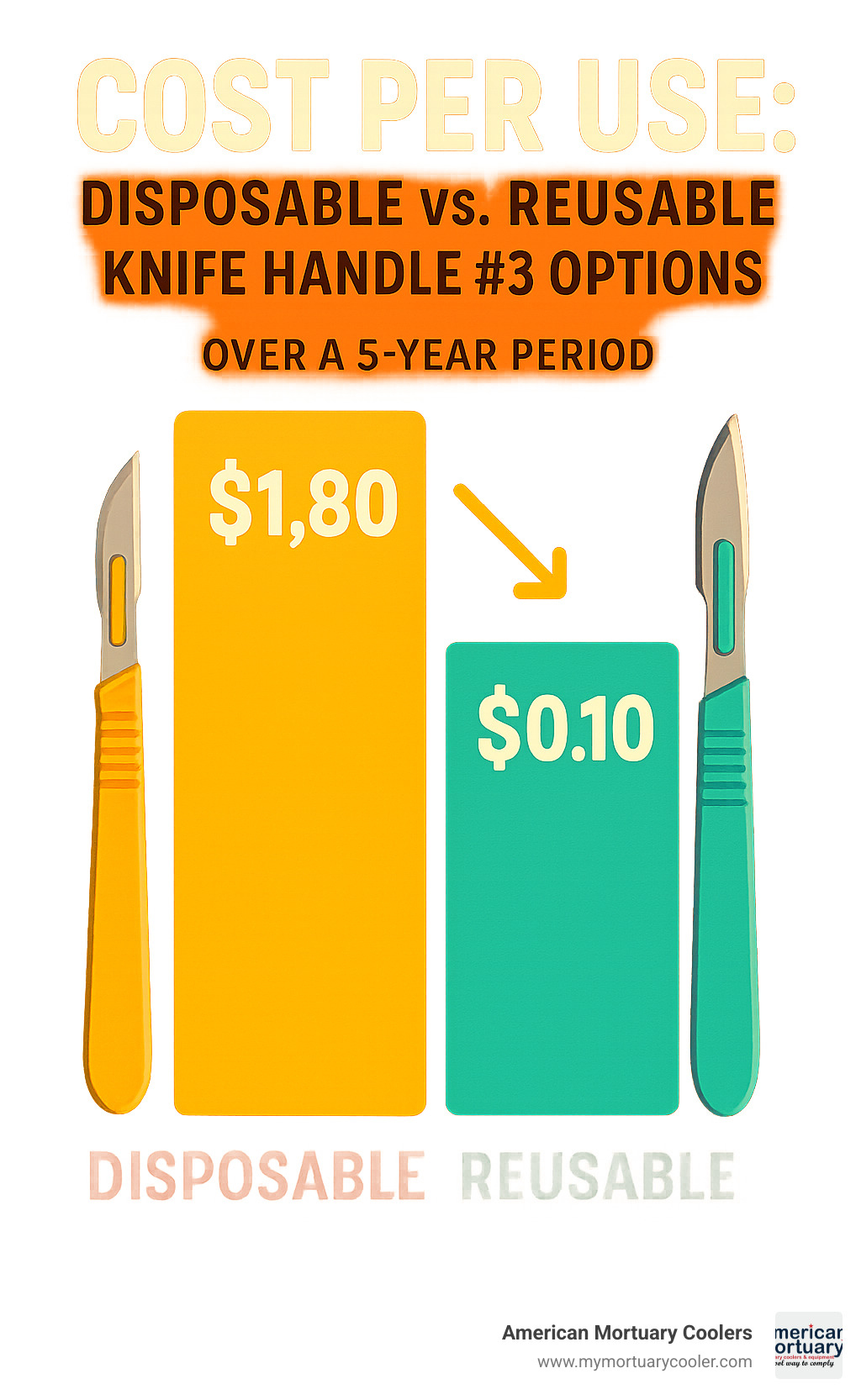

Budgeting for Knife Handle #3 Purchases

Let's talk dollars and sense. A single knife handle #3 typically runs between $8.40 and $15, but buying in bulk can save you 15-30% per unit. For busy funeral homes handling multiple cases weekly, that adds up quickly.

The reusable vs. disposable question comes down to your specific needs. Stainless steel handles cost more upfront but pay for themselves many times over with years of service. Disposable handles make more sense in teaching environments or where cross-contamination concerns outweigh cost considerations.

Don't overlook warranty coverage when comparing options. A good manufacturer stands behind their product, and at American Mortuary Coolers, we help our clients find suppliers with solid warranty policies.

When budgeting, think about the total cost of ownership—not just the price tag. Consider the handle's expected lifespan, ongoing sterilization costs, how often you'll need replacements, and even storage requirements.

Competitors like Integra LifeSciences offer premium handles at higher price points, while Medline provides more economical options. At American Mortuary Coolers, we position ourselves in the middle, offering professional-grade quality without the premium markup that some specialty surgical suppliers charge.

Frequently Asked Questions about Knife Handle #3

Which blades fit a knife handle #3?

If you're new to working with a knife handle #3, you might be wondering exactly which blades you can use with it. The good news is that this is pretty straightforward!

Your knife handle #3 is designed to work specifically with Bard-Parker style blades #10, #11, #12, and #15. These blades have a special notch pattern that clicks securely into the slot at the end of your handle. Think of it like a perfect handshake between the blade and handle – when it's right, you'll know it.

One nice thing about these standardized blades is that they're universal across different manufacturers. So whether you pick up blades from one supplier or another, they'll fit your handle just fine as long as they follow the Bard-Parker standard.

One word of caution though – don't try to force larger blades (like #20 through #25) into your knife handle #3. These bigger blades are made for the larger #4 handle, and trying to make them fit can lead to a loose connection that might slip during use.

How long is a standard knife handle #3?

When you pick up a knife handle #3, you're holding a tool that's been refined over decades to hit the sweet spot between control and leverage. The standard length is exactly 5 inches (12.5 cm or 125 mm).

This might seem like a random measurement, but it's actually quite purposeful. The 5-inch length gives you enough reach to access what you need while still allowing for the precise control that delicate work demands. It's like Goldilocks – not too long, not too short, but just right.

Some manufacturers do offer slight variations, typically ranging from 4.75 to 5.25 inches, but the standard 5-inch version meets most professionals' needs perfectly. There's a reason this design has stood the test of time!

Can I autoclave a polymer knife handle #3?

This is probably one of the most common questions we get, and the answer is: it depends on the specific polymer used.

If you've invested in high-quality, medical-grade polymer handles, you're probably in luck. These premium handles are typically made from specially formulated materials designed to withstand standard autoclave cycles (121°C for 30 minutes). The manufacturer will usually clearly label these as "autoclavable" – that's your green light to proceed.

On the flip side, basic plastic handles generally don't play well with autoclaves. The intense heat can cause them to warp or melt, and in some cases, they might even release compounds you definitely don't want in your sterile environment.

Before you toss any polymer handle into your autoclave, take a moment to check the manufacturer's specifications. Look for temperature resistance ratings and recommended cycle counts – this information is your best guide.

If you find your polymer handles aren't autoclave-friendly, don't worry! Cold sterilization methods using approved chemical solutions work well as an alternative. At American Mortuary Coolers, we help funeral homes find the right knife handle #3 options that match their specific sterilization protocols.

Competitors like Integra Miltex and Sklar offer autoclavable polymer handles, though they typically come at a premium price point compared to standard options.

Conclusion

The knife handle #3 isn't just another tool in the drawer—it's the unsung hero of precision work in medical, surgical, and mortuary settings. This 5-inch wonder strikes that perfect sweet spot between delicate control and practical functionality that professionals have come to rely on day after day.

When you're making fine incisions or performing detailed dissections, having the right tool makes all the difference. That's something we understand deeply at American Mortuary Coolers. As we've worked with funeral homes from Nashville to New York, Chicago to Charleston, we've seen how quality instruments lift the level of care professionals can provide.

There's something reassuring about picking up a well-crafted knife handle #3—the balanced weight in your hand, the textured grip that stays secure even during the most delicate procedures. It's this attention to detail that matters when you're providing dignified, meticulous care for the deceased and their families.

While competitors like Integra LifeSciences, Sklar Instruments, and Medline Industries offer similar products, American Mortuary Coolers provides these essential tools as part of our comprehensive approach to mortuary equipment solutions. Our focus on the specific needs of funeral homes and mortuary professionals sets us apart from general medical suppliers.

For those looking to expand their professional toolkit beyond the basics, we invite you to explore our broader range of precision equipment. Our forensic refrigeration solutions complement these precision instruments, creating a complete ecosystem for professional mortuary care.

Whether you're setting up a new facility in Texas or upgrading equipment in your Pennsylvania funeral home, quality matters—especially with the tools you use every day. Our team is always here to help you select the right equipment for your specific needs, from knife handle #3 instruments to comprehensive storage solutions.

At American Mortuary Coolers, we're not just selling equipment; we're supporting professionals who provide essential, compassionate services during life's most difficult moments. That's a responsibility we take seriously, one custom cooler and precision instrument at a time.