Understanding What a Mortuary Chamber Is and Why It Matters

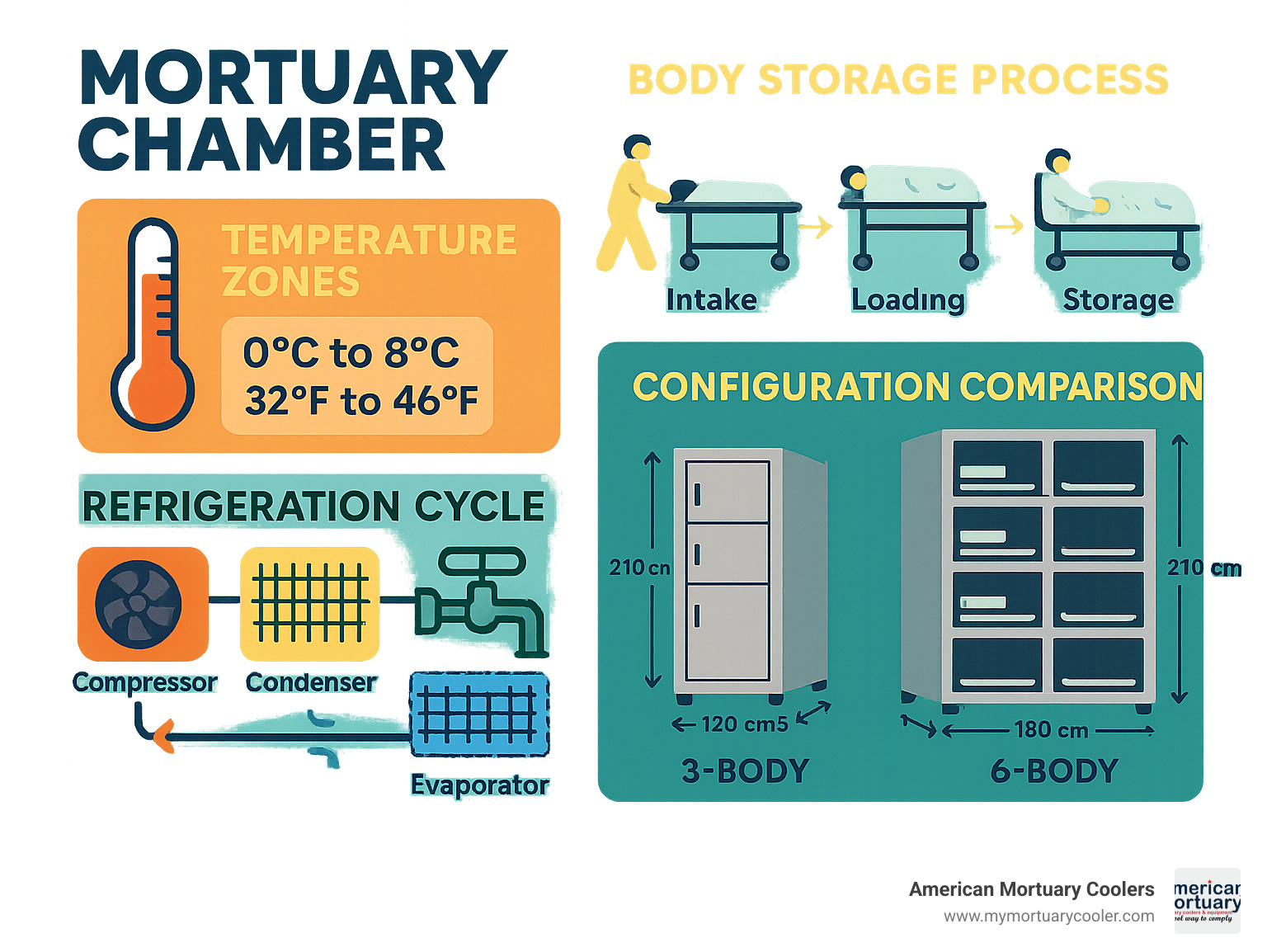

A mortuary-chamber is a refrigerated storage unit designed to preserve human remains at controlled temperatures, typically between 0°C to 8°C, providing funeral homes and healthcare facilities with the time needed for proper funeral arrangements and legal procedures.

Quick Overview: Mortuary Chamber Essentials

- Primary function: Slow decomposition through controlled refrigeration

- Standard temperature: 0°C to 8°C (32°F to 46°F)

- Common configurations: 3-body, 6-body, and modular systems up to 20 bodies

- Key features: Individual refrigeration systems, stainless steel construction, easy-clean trays

- Applications: Hospitals, funeral homes, forensic centers, disaster response

- Materials: Type 304 stainless steel with CFC-free polyurethane insulation

Modern mortuary chambers have evolved far beyond simple cold storage. Today's units feature independent refrigeration systems for each chamber, meaning if one compressor fails, the other chambers continue operating normally. This reliability is crucial for funeral directors who cannot afford equipment downtime.

The technology centers on precise temperature control - maintaining that critical 0°C to 8°C range that slows bacterial growth without freezing tissue. Some units offer freezing options down to -20°C for longer-term preservation needs.

From compact 3-body cabinets perfect for smaller funeral homes to large modular systems accommodating 20 or more bodies, these chambers come in configurations ranging from side-loading panels that assemble on-site to front-loading cabinets with individual doors and locking mechanisms.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral homes select the right mortuary-chamber solutions for their specific needs. My background includes working directly with funeral directors across the country to solve space constraints, capacity challenges, and equipment reliability issues.

Key mortuary-chamber vocabulary:

Understanding the Mortuary Chamber

When you step into funeral service, the mortuary-chamber represents far more than just refrigeration equipment. It's a guardian of dignity, providing families with precious time during their most difficult moments. These specialized units create a controlled environment where human remains are preserved with respect while funeral arrangements unfold at a pace that honors both the deceased and their loved ones.

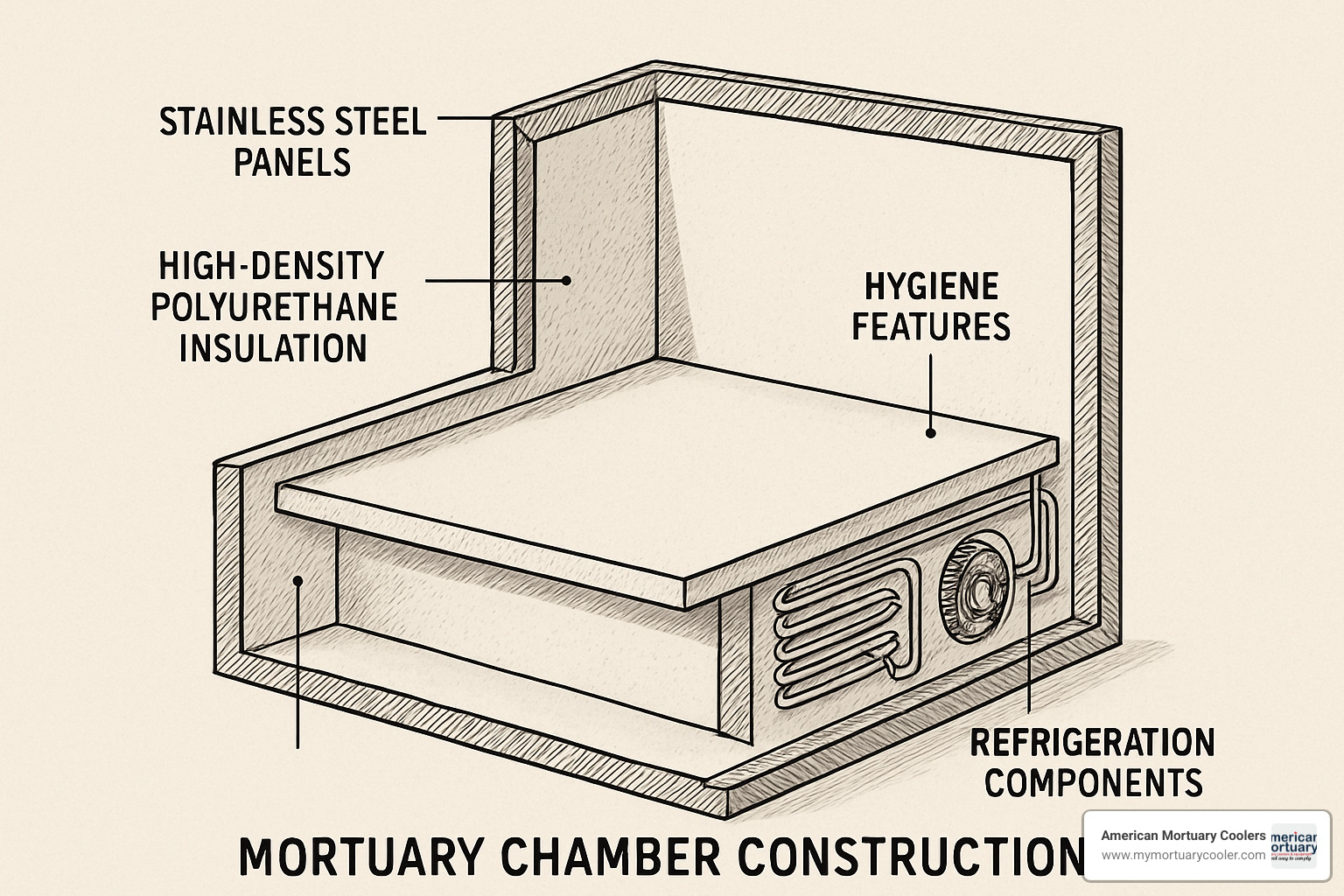

Think of a mortuary-chamber as a highly sophisticated refrigeration system designed specifically for this sacred purpose. Unlike your kitchen refrigerator, these units are engineered with medical-grade precision. They feature seamless stainless steel construction that prevents bacterial growth, specialized insulation that maintains consistent temperatures, and control systems that monitor conditions around the clock.

The capacity flexibility is remarkable - from compact 2-body units perfect for smaller funeral homes to expansive modular systems accommodating 20 bodies or more. The most popular configurations are 3-body and 6-body cabinets, which strike the perfect balance between capacity and space efficiency for most funeral operations.

What sets modern mortuary chambers apart is their independent refrigeration systems. Each chamber operates on its own compressor and temperature control. This means if one unit needs maintenance, the others keep working normally - a reliability feature that funeral directors absolutely depend on.

Primary Function & Temperature Science

The heart of mortuary preservation lies in understanding heat exchange and bacterial biology. Human bodies generate heat even after death, and bacteria thrive in warm environments. A mortuary-chamber solves this by continuously removing heat and maintaining that critical 0°C to 8°C temperature range where decomposition slows to a crawl.

This temperature sweet spot isn't arbitrary. It's cold enough to dramatically slow bacterial activity - we're talking about extending preservation time from days to weeks. But it's not so cold that tissue freezes, which would cause cellular damage and complicate funeral preparation.

For special circumstances, some units offer freezing options down to -20°C. This ultra-cold storage serves situations requiring long-term preservation, such as forensic cases or when families need extended time for arrangements.

Energy efficiency drives much of today's design innovation. Independent compressors for each chamber mean the system only works as hard as needed. If you're storing two bodies in a six-body cabinet, only those chambers actively refrigerate.

Mortuary-Chamber vs Historical Burial Chambers

The journey from ancient burial practices to modern mortuary chambers reveals humanity's evolving relationship with death and preservation. Ancient Egyptian burial chambers, as detailed in studies of Tombs in ancient Egypt, were architectural marvels focused on spiritual passage rather than physical preservation.

These elaborate underground complexes combined burial chambers with mortuary chapels, creating "houses of eternity" through religious ritual and favorable climate conditions. The preservation came from Egypt's dry environment and complex mummification processes, not temperature control.

Fast-forward to 1830s Scotland, where historical morthouses tackled a very different problem. These circular stone buildings housed coffins on rotating wheels with locks - an ingenious mechanical solution to prevent body-snatching.

Today's mortuary-chamber represents centuries of advancement in both engineering and decomposition science. Where ancient chambers relied on climate luck and elaborate chemical processes, modern units use precise refrigeration to achieve superior preservation with complete reliability.

Types & Configurations of Mortuary Chambers

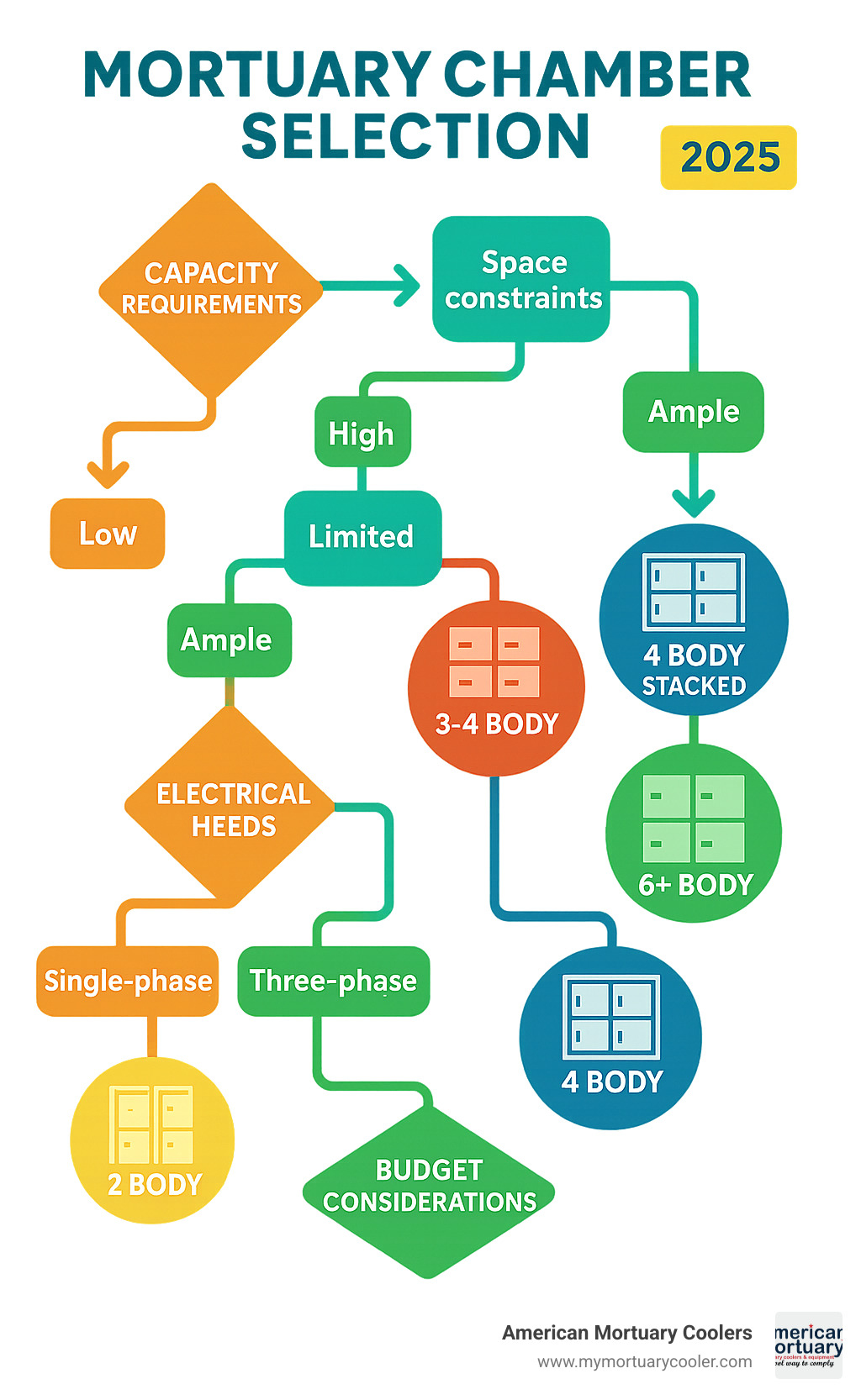

Choosing the right mortuary-chamber configuration is like selecting the perfect tool for your workshop - it needs to fit your space, handle your workload, and grow with your business. The good news is there's a solution for every situation, from cozy 2-body units that tuck into small prep rooms to impressive 20-body modular systems that serve major medical centers.

Most modern chambers use modular panel construction, which makes installation much easier, especially when you're working in tight spaces or basement locations where getting large equipment through doorways becomes a real headache.

The panels themselves are built tough, using either galvanized metal with food-certified white paint or premium stainless steel finishes. The insulation ranges from 60mm to 100mm thick - enough to keep temperatures stable while keeping energy costs reasonable.

3-Body & 6-Body Cabinets

The 3-body cabinet has earned its reputation as the workhorse of smaller funeral homes and hospital morgues. At roughly 2520 x 850 x 1850 mm, these units strike that perfect balance between capacity and space efficiency. They're like the pickup truck of mortuary equipment - versatile, reliable, and just the right size for most jobs.

For facilities needing more capacity without taking up much additional floor space, 6-body cabinets measure about 2520 x 1580 x 1850 mm. These units are particularly popular with hospitals that face unpredictable demand and funeral homes serving larger communities. Our Mortuary Coolers Wholesale Direct: Roll-In 3-Body Walk-In American Mortuary Coolers guide walks you through the specific advantages these compact units offer.

What makes both configurations special is their independent refrigeration systems. Each chamber operates separately, so if one compressor decides to take a break, the others keep working normally. This reliability is crucial when equipment downtime simply isn't an option.

Both sizes feature individual temperature controls with 0.1°C precision, stainless steel trays rated for 150kg each, and imported microprocessor controllers with clear, easy-to-read displays.

Front-Loading, Side-Loading & Modular Systems

Space constraints often determine whether you need front-loading or side-loading configurations. Front-loading cabinets work beautifully in traditional prep room layouts, with individual doors providing convenient access to each chamber. These units typically feature matte chrome closures with adjustable levers and security locks.

Side-loading modular systems shine when you're dealing with challenging spaces or unique building layouts. These systems arrive as panels for on-site assembly, making them perfect for basement installations or situations where moving large equipment becomes impossible.

The modular approach offers remarkable flexibility. The panels use self-supporting stainless steel structures that don't require cutting or drilling during assembly. The high-density CFC-free polyurethane insulation provides excellent thermal performance while meeting today's environmental standards.

Smart Mortuary-Chamber Modules & Surge Solutions

Modern facilities increasingly need the flexibility to handle unpredictable demand. Smart modular systems address this challenge with expandable configurations and mobile solutions that can adapt to changing circumstances.

ResponStor® temporary mortuary units provide surge capacity that deploys quickly during emergencies or unexpectedly busy periods. These units feature caster mobility for easy repositioning, standard 110V electrical connections, and capacity ranging from single-body portable boxes to multi-body walk-in units.

For disaster response and pandemic preparedness, trailer-mounted coolers offer mobile mortuary-chamber capacity that can be deployed wherever needed. These units maintain the same temperature control and hygiene standards as permanent installations while providing unprecedented flexibility.

Technical Specifications, Hygiene & Sustainability

When you're investing in a mortuary-chamber, you want to know it's built to last and designed with both safety and the environment in mind. Modern units represent decades of careful engineering, where every component serves a purpose in creating reliable, hygienic, and sustainable preservation solutions.

The foundation of quality construction starts with Type 304 stainless steel. This isn't just any steel - it's specifically chosen because it resists corrosion, cleans easily, and stands up to the high-humidity environments where these units operate. You'll find this material throughout the chamber, from interior surfaces to structural components.

Insulation makes all the difference in performance and energy costs. Today's mortuary-chamber units use 60-100mm thick polyurethane foam (PUF) with densities between 40-45 kg/m³. This CFC-free insulation gets injected under high pressure, creating a seamless thermal barrier that meets strict RoHS and REACH environmental standards.

The refrigeration systems have come a long way from older, environmentally harmful refrigerants. Modern units use R134a, R452A, and R290 - gases that cool effectively without damaging the environment. Each chamber typically gets its own independent compressor, so if one system needs service, the others keep running normally.

Here's how different preservation methods compare across time and technology:

| Feature | Mortuary Cabinets | Cold Rooms | Historical Burial Chambers |

|---|---|---|---|

| Temperature Control | 0°C to 8°C precise | Variable | None |

| Capacity | 2-20 bodies | Unlimited | 1-multiple |

| Mobility | Fixed/Mobile options | Fixed | Fixed |

| Preservation Method | Refrigeration | Refrigeration | Natural/Chemical |

| Hygiene Features | Seamless steel, removable trays | Drainage systems | None |

| Energy Source | Electrical | Electrical | None |

Understanding these technical details helps explain why modern mortuary-chamber systems cost more upfront but deliver better value through reliability and lower operating costs. You can learn more about specific specifications in The Complete Guide to Morgue Cooler Room Specifications, and see detailed options for 6-body mortuary cabinets that showcase these advanced features.

Temperature & Refrigeration Control

The heart of any mortuary-chamber is its temperature control system, and modern units offer precision that would have seemed impossible just a few decades ago. Microprocessor-based controllers now provide accuracy to 0.1°C, with clear digital displays that show current temperatures and allow easy adjustment of setpoints.

These smart systems do more than just maintain temperature. They include comprehensive alarm systems that alert you to temperature deviations, power failures, and maintenance needs before problems become emergencies. Advanced units offer data logging capabilities with multiple connectivity options - USB, WiFi, Ethernet, and even 3G - so you can monitor performance remotely.

Cloud monitoring capabilities mean facility managers can check system status from anywhere and receive instant alerts on their phones. This technology transforms maintenance from reactive to preventive, helping avoid costly breakdowns and ensuring consistent performance.

The refrigeration approach itself uses direct cooling rather than air circulation systems. This method extends compressor life while providing more consistent temperatures throughout the chamber - no hot spots or temperature variations that could compromise preservation.

Hygiene, Safety & Compliance

Hygiene isn't just important in mortuary applications - it's absolutely critical. Every design decision in a quality mortuary-chamber considers how to maintain the highest sanitation standards while making daily cleaning manageable for staff.

Seamless welded construction eliminates the cracks and crevices where bacteria love to hide. Rounded interior corners make thorough cleaning possible, while removable trays allow complete sanitization between uses. These aren't luxury features - they're essential for maintaining the dignity and safety that families deserve.

Gasketed doors provide airtight seals that prevent contamination while maintaining temperature stability. The gaskets themselves are designed for easy cleaning and replacement, ensuring long-term performance without compromise.

Safety features protect both the deceased and the living. Mechanical locks secure all doors, while internal lighting provides clear visibility during access. Anti-condensation systems prevent moisture buildup that could create slip hazards or promote bacterial growth.

OSHA guidelines and WHO recommendations shape every aspect of modern mortuary chamber design. This includes proper ventilation requirements, PPE protocols, and sanitation procedures that protect workers while maintaining public health standards.

Green Design & Future-Ready Refrigerants

Environmental responsibility has moved from nice-to-have to essential in modern mortuary-chamber design. The industry has acceptd low-GWP (Global Warming Potential) refrigerants that minimize environmental impact while delivering excellent cooling performance.

R290 (propane) and R452A represent the latest generation of eco-friendly refrigerants. These substances cool effectively without contributing to ozone depletion or global warming - a win for both performance and environmental stewardship.

Energy efficiency features make these units increasingly cost-effective to operate. High-R-value insulation minimizes heat transfer, while variable-speed compressors adjust automatically to cooling demand rather than running at full power constantly. LED lighting systems reduce power consumption compared to traditional lighting.

Some manufacturers now offer solar-ready condensing units that can integrate with renewable energy systems. Vacuum-insulated panels provide superior thermal performance in thinner profiles, reducing the overall footprint while improving efficiency.

These green technologies aren't just good for the environment - they save money on operating costs while future-proofing your investment against changing regulations and energy prices.

Applications & Buying Considerations

The beauty of modern mortuary-chamber systems lies in their versatility. Whether you're running a small family funeral home in rural Tennessee or managing a busy hospital morgue in downtown Chicago, there's a solution that fits your specific needs and space constraints.

When we talk with funeral directors and facility managers across the country, capacity planning always comes up as the biggest challenge. You need enough space for your daily operations, but what happens during flu season or unexpected circumstances? Our experience working with facilities from Atlanta to Los Angeles has taught us that most places benefit from having 25-50% more capacity than their average daily needs.

Mortuary-Chamber Use in Healthcare & Forensics

Hospitals have some of the most demanding requirements when it comes to mortuary equipment. Emergency departments need systems that work reliably around the clock, while pathology labs require precise temperature control for tissue preservation. These facilities can't afford downtime - when a mortuary-chamber fails in a hospital setting, it creates immediate problems.

That's why healthcare facilities often choose systems with independent refrigeration for each chamber. If one compressor goes down, the other chambers keep running normally.

Forensic applications add another layer of complexity. Chain-of-custody requirements mean better security systems and documentation capabilities. Some forensic facilities need sub-freezing temperatures down to -20°C for long-term preservation during extended investigations. Our Inside Morgue Cold Storage Systems: What You Should Know guide covers these specialized requirements in detail.

Autopsy suites often benefit from walk-in cooler configurations rather than cabinet-style units. These provide easier access with gurneys and enough space for multiple cases during complex investigations.

Funeral Homes, Disaster Response & Mobile Set-Ups

Funeral homes have a completely different set of priorities compared to hospitals. Quiet operation matters more when families are visiting nearby. Premium finishes and professional appearance become important factors. Most funeral homes need smaller-capacity units, but they still want the flexibility to handle busy periods.

The modular approach really shines here. You can start with a 3-body cabinet and add modules later if your business grows. It's much more cost-effective than buying a larger system upfront and paying to cool empty chambers.

Disaster response is where mobile mortuary units prove their worth. Whether it's trailer-mounted coolers or portable body boxes, these systems provide critical surge capacity when communities need it most. They maintain the same temperature control and hygiene standards as permanent installations while offering the flexibility to deploy anywhere.

Selecting the Right Unit: Capacity, Compliance & Service

Choosing the right mortuary-chamber system isn't just about picking a size from a catalog. Site measurements need to account for more than just the unit dimensions - you need adequate ventilation, proper electrical service, and space for maintenance access.

Electrical requirements can be a real gotcha if you don't plan ahead. Smaller units typically run on single-phase 220V service, but larger systems may need three-phase power. Getting this wrong means costly electrical work later.

The most important factors we help clients consider include current and projected capacity needs, available space and access constraints, electrical service capacity, local code compliance requirements, and ongoing maintenance requirements. Don't forget about operating costs - more efficient units cost more upfront but save money over time.

Expandability deserves special mention. Your needs today might not match your needs in five years. Modular systems that can grow with your business often make more financial sense than trying to predict exactly what you'll need down the road.

Frequently Asked Questions about Mortuary-Chamber

When funeral directors and healthcare administrators are considering mortuary-chamber systems, they often have the same core questions. Let me address the most common concerns I hear from facilities across the country.

How cold does a mortuary chamber need to be?

The sweet spot for most mortuary-chamber operations is 1°C to 5°C (34°F to 41°F). This temperature range strikes the perfect balance - cold enough to dramatically slow decomposition, but not so cold that it causes cellular damage from freezing.

Many modern units offer a broader operating range from 0°C to 8°C, giving facilities flexibility to adjust based on their specific needs. The science is straightforward: every degree of cooling slows bacterial activity, but each degree also increases your energy costs.

For special circumstances like extended forensic investigations or when embalming isn't possible, some units offer freezing capability down to -20°C (-4°F). However, this is typically reserved for unusual situations rather than standard operations.

Energy efficiency plays a bigger role in temperature selection than many people realize. Running your chambers at 3°C instead of 1°C can reduce energy consumption by 15-20% while still providing excellent preservation. It's about finding what works best for your specific situation.

What maintenance does a mortuary chamber require?

Keeping your mortuary-chamber running smoothly isn't complicated, but it does require consistency. Think of it like maintaining a high-end commercial kitchen - regular attention prevents major problems down the road.

Daily maintenance is mostly about vigilance. Check your temperature displays, make sure door seals are intact, and sanitize interior surfaces with approved disinfectants. These simple steps take just a few minutes but prevent most operational issues.

Quarterly maintenance gets more involved. You'll want to clean condenser coils (dusty coils can reduce efficiency by 30%), inspect door gaskets for wear, and verify temperature calibration. Most facilities can handle these tasks with basic training, though some prefer professional service.

Annual professional service is where the real technical work happens. This includes complete refrigeration system inspection, compressor performance testing, electrical connection checks, and control system calibration. Professional technicians also document everything for warranty and regulatory compliance.

The investment in proper maintenance pays dividends. Well-maintained units last 15-20 years or more, while neglected systems often fail within 5-7 years. Plus, regular maintenance keeps your warranty valid and ensures regulatory compliance.

Can mortuary chambers be expanded later?

Absolutely, and this is one of the biggest advantages of modern modular panel construction. Most facilities start with their immediate needs and expand as their business grows - it's a smart approach that manages cash flow while planning for the future.

Adding chambers is straightforward with modular systems. New panels and doors integrate seamlessly with existing installations, though you'll want professional installation to ensure proper sealing and refrigeration integration. The modular approach means you're not locked into your original configuration.

Scalable compressor systems make refrigeration expansion equally flexible. Many modern systems use individual compressors for each chamber, so adding capacity is simply a matter of installing new refrigeration units. No need to replace your entire system.

The key is planning ahead during initial installation. Ensuring adequate electrical service capacity, proper ventilation design, and sufficient space for additional equipment can save thousands of dollars in future expansion costs. We always recommend discussing future growth plans during initial consultations.

Smart facilities often install electrical and structural capacity for 50% more chambers than they initially need. The incremental cost is minimal during construction, but retrofitting later can be expensive and disruptive to operations.

Conclusion

Choosing the right mortuary-chamber isn't just about buying equipment - it's about investing in your facility's ability to serve families with dignity during their most difficult moments. These sophisticated systems have come a long way from simple cold storage, evolving into intelligent preservation solutions that balance engineering excellence with environmental responsibility.

Whether you need a compact 3-body unit for a smaller funeral home or a large modular system that can handle unexpected surge capacity, today's mortuary chambers deliver the reliability that funeral service professionals depend on. The independent refrigeration systems, precise temperature control, and modular expandability mean your investment will serve your facility well for decades to come.

At American Mortuary Coolers, we've learned something important from our work across Tennessee and throughout the contiguous 48 states: every facility has its own unique story and specific needs. What works perfectly for a busy hospital morgue in Atlanta might not be the right fit for a family funeral home in rural Tennessee. That's why we focus on custom design solutions rather than one-size-fits-all approaches.

The technical specifications matter, of course - the stainless steel construction, the environmental compliance, the energy efficiency. But what really matters is having equipment you can count on when families are counting on you. When you're dealing with the sensitive nature of death care, equipment failure simply isn't an option.

Our experience has shown us that the best mortuary chamber investments happen when facilities think beyond just their current needs. Planning for future expansion, considering surge capacity requirements, and choosing systems that can grow with your business - these decisions pay dividends for years to come.

Whether you're planning a new facility, expanding existing capacity, or replacing aging equipment that's seen better days, we're here to help you steer the technical specifications, regulatory requirements, and practical considerations that ensure your investment delivers reliable service.

For more detailed information about specific configurations and custom solutions that might work for your facility, visit our More info about custom mortuary chambers resource center. We're always happy to discuss how the right mortuary-chamber system can support your commitment to dignified death care.