Why Pickup Bed Ramps Are Essential for Safe Equipment Loading

A pickup bed ramp is a loading platform that creates an inclined pathway from the ground to your truck bed, allowing you to safely roll heavy equipment up instead of lifting it. Here's what you need to know:

Key Types:

- Folding ramps - Portable, store in toolbox (600-750 lb capacity)

- Tailgate replacement - Permanent mount, heavy-duty (1,500+ lb capacity)

- Slide-out systems - Built-in convenience, extends bed length

- Arched ramps - Prevents scraping on low-clearance equipment

Main Benefits:

- Eliminates heavy lifting and reduces injury risk

- No trailer needed - saves fuel and parking space

- Works year-round in all weather conditions

- Protects equipment from damage during loading

Whether you're hauling lawn mowers, ATVs, or specialized equipment, the right ramp makes loading safer and faster. Most users report immediate time savings and reduced back strain after switching from manual lifting or trailer systems.

As one lawn care professional noted in an online forum: "I save $100 per week in fuel by ditching the trailer and using pickup bed ramps instead."

I'm Mortuary Cooler, and through years of supplying mortuary equipment that requires careful handling and transport, I've seen how the right pickup bed ramp can make loading delicate stretchers and heavy coolers both safer and more efficient. This guide will help you choose the perfect ramp for your specific needs and budget.

Easy pickup bed ramp glossary:

Pickup Bed Ramp Essentials: Definition, Benefits & Trailer Comparison

What Is a Pickup Bed Ramp?

Think of a pickup bed ramp as your back's best friend. It's basically a sturdy bridge that connects the ground to your truck bed, creating a gentle slope instead of a vertical wall you need to heave equipment over.

The magic happens through weight transfer. Instead of your spine bearing the load of that heavy lawn mower or ATV, the ramp does all the work. You simply roll, push, or drive the equipment up the incline. It's the difference between deadlifting 200 pounds and pushing a shopping cart.

Most ramps work as incline aids that replace your tailgate or attach alongside it. The steeper the angle, the harder it is to push things up - which is why longer ramps make loading so much easier, even though they take up more storage space.

Why Choose a Ramp Over a Trailer?

After years of watching funeral professionals struggle with equipment transport, I've seen the trailer versus ramp debate play out countless times. Here's what usually tips the scales toward ramps:

Maneuverability becomes your superpower. Ever tried backing a trailer into a narrow cemetery driveway? With a ramp system, you keep all the nimbleness of your pickup truck. No more three-point turns in tight spaces or asking someone to guide you backward.

Cost efficiency hits your wallet immediately. One landscaper told me he saves over $5,000 yearly by ditching his trailer setup. No registration fees, no trailer insurance, no maintenance on trailer brakes and bearings. Plus, your fuel economy improves dramatically without that wind-catching box behind you.

Parking ease might seem minor until you're circling downtown looking for a spot that fits your truck and trailer. With a ramp, you park wherever your pickup fits. Period.

Core Benefits You'll Notice Day One

The time-saving aspect surprises most people. Loading equipment becomes a quick 30-second operation instead of wrestling with straps and lifting for five minutes. Modern folding ramps like the ReadyRamp deploy faster than you can walk around your truck.

Back injury reduction is where ramps really shine. In our industry, we've seen too many professionals end up with chronic pain from repeatedly lifting heavy mortuary equipment. A good pickup bed ramp eliminates about 90% of the heavy lifting involved in loading.

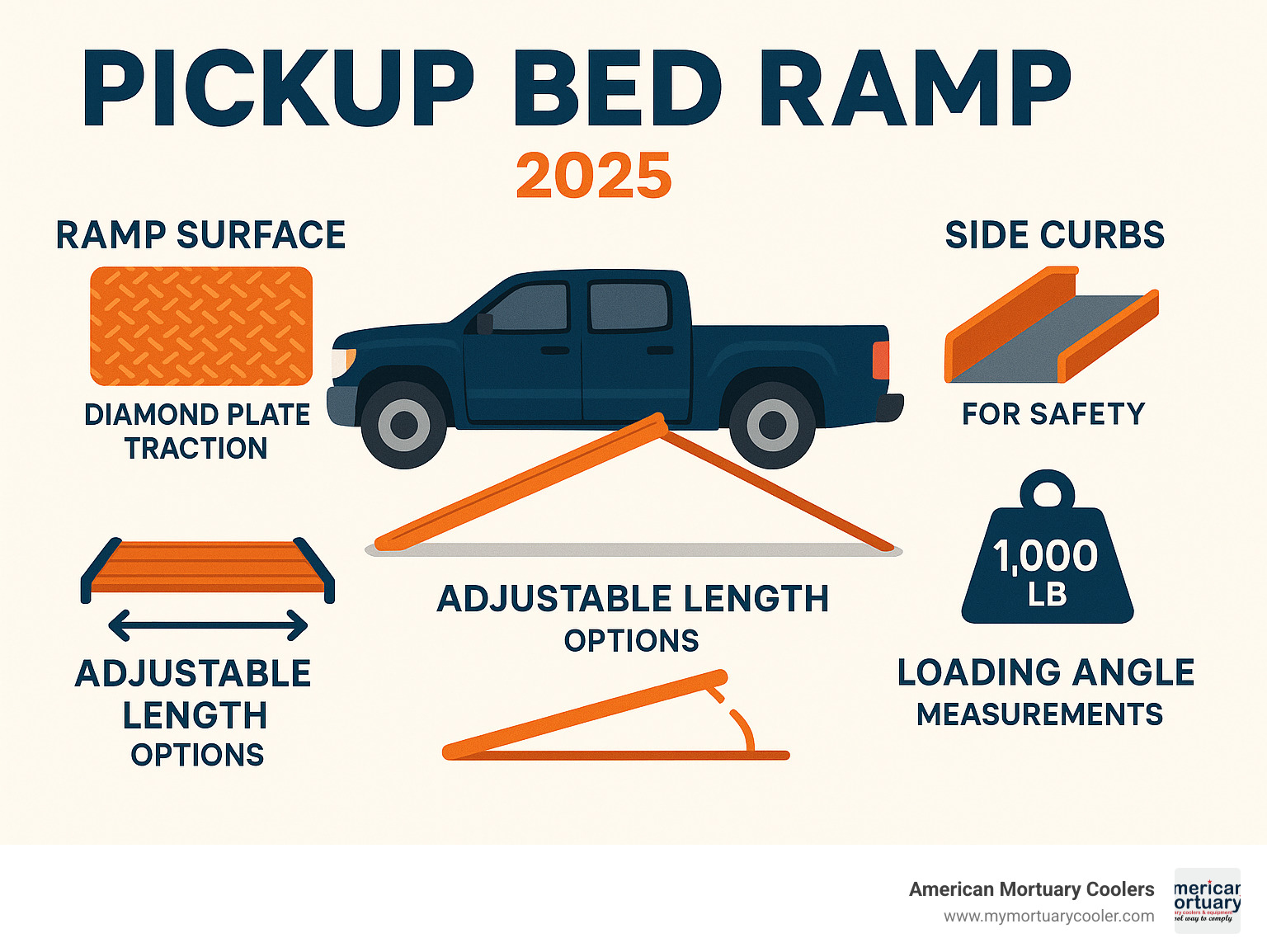

Year-round usability means your ramp works in January snow just as well as July heat. The diamond plate surface provides solid traction even when wet, unlike some trailer systems that become slippery hazards in bad weather.

Your payload protection improves too - no more dinged corners from muscling equipment over the tailgate edge. Everything rolls up smoothly without banging against metal.

Ramp Categories & Specialized Applications

The world of pickup bed ramps offers something for everyone, from weekend warriors loading motorcycles to professionals hauling heavy landscaping equipment daily. Understanding the different categories helps you choose the right tool for your specific needs.

Think of it this way: a folding ramp is like a good pocket knife - versatile and portable. A tailgate replacement system is more like a full workshop - powerful but permanent. And specialized ramps? They're the precision tools designed for specific jobs.

Folding & Tri-Fold Styles

Folding ramps are the workhorses of the ramp world, and for good reason. They strike that sweet spot between portability and functionality that most people need. Take the ReadyRamp, which handles a solid 600-pound capacity while folding compact enough to fit in many truck bed toolboxes.

What makes tri-fold designs so popular is their clever engineering. The ReadyRamp's dual-purpose design works as both a loading ramp and bed extender, giving you more bang for your buck. Made from 6061 T6 aluminum, it features a smart 4-degree hinge angle that helps vehicles with low ground clearance steer that tricky transition from ramp to bed without scraping their undercarriage.

The reviews speak for themselves - Dirt Rider gave it a perfect 10/10 rating, and Motorcyclist called it "a must-have for any bike-hauling pickup-truck driver." When magazines that test equipment for a living get that excited, you know you're looking at something special.

Tailgate-Replacement & Slide-Out Systems

When you need serious capacity and don't mind a permanent installation, tailgate-replacement systems are where the magic happens. The HandiRamp M-200 doesn't mess around - it delivers a massive 1,500-pound capacity with a generous 52.5-inch usable width. At 165 pounds it's not something you'll be moving around, but it transforms your truck into a legitimate loading machine.

The LoadAll V3 takes a different approach with its clever slide-out design. It offers 1,300-pound capacity while completely disappearing into your truck bed when not in use. The system extends 44 inches beyond the tailgate to reduce that loading angle, making it much safer for low-clearance equipment like riding mowers.

Then there's the Ramp Rack system, which offers both pre-made and custom models that fit most pickup beds and work through all four seasons. Their motto "STOP PULLING A TRAILER" really captures what these integrated systems are all about - full-bed access without the hassle of towing.

Custom & Niche Ramps

Sometimes standard solutions just won't cut it, and that's where specialized ramps shine. Motorcycle ramps typically feature a narrow two-track design that matches your bike's wheelbase perfectly. Lawn mower ramps often use an arched profile to prevent those low-clearance mowers from getting hung up at the transition point.

For off-road enthusiasts, RTI testing ramps serve a completely different purpose - they're not for loading cargo but for testing suspension articulation. These 20-degree ramps have measurement markings every 5 inches to help calculate your vehicle's Ramp Travel Index score.

In our work at American Mortuary Coolers, we've seen funeral homes that need specialized solutions for loading stretchers and transport equipment. The principles stay the same - proper weight distribution, secure mounting, and appropriate capacity ratings - but the applications can get quite specific. More info about stretcher options if you're curious about professional transport equipment.

Whether you're hauling ATVs, UTVs, snowblowers, or landscaping gear, there's likely a ramp designed specifically for your needs. The key is matching the ramp's design to your equipment's characteristics and your usage patterns.

Buying Guide: Measurements, Capacity, Materials & Compatibility

Choosing the right pickup bed ramp isn't rocket science, but getting the measurements wrong can be frustrating and potentially dangerous. Let me walk you through the key factors that'll help you make the best choice for your truck and equipment.

How to Measure Your Truck Bed Correctly

Before you fall in love with any particular ramp, you need to know exactly what you're working with. Bed length is your starting point - measure from the inside of your tailgate to the back of the cab. Most trucks fall into three categories: 5.3 feet for short beds, 6.5 feet for standard beds, and 8 feet for long beds.

Tailgate height is equally important and often overlooked. With your tailgate down, measure from the ground straight up to the top edge. This measurement directly affects how long your ramp needs to be for safe loading angles.

If you plan to tow while your ramp is installed, you'll also need the bed-to-ball distance. Measure from behind your cab to your towing ball. Systems like the LoadAll V3 require this measurement for their custom fitting process, especially when you want to maintain towing capability.

Many manufacturers make this easier with detailed measuring guides. The Ramp Rack system, for example, provides step-by-step instructions to ensure you get the perfect custom fit. Taking a few extra minutes to measure correctly can save you weeks of waiting for exchanges.

Weight Capacity & Ramp Length Rules of Thumb

Weight capacity is where things get serious. Lightweight portable ramps like the ReadyRamp typically handle 600-750 pounds, which works great for lawn mowers, small ATVs, and most everyday equipment.

Heavy-duty steel ramps start at 1,000 pounds minimum, while heavy-duty aluminum options can surprise you - the HandiRamp M-200 reaches an impressive 1,500 pounds despite being aluminum. For professional and commercial applications, systems like the LoadAll V3 offer 1,300-1,500+ pound capacities.

The 4:1 rule is your friend for ramp length - for every foot of tailgate height, plan on at least four feet of ramp length. But this isn't set in stone. Your equipment's ground clearance and wheelbase can change everything.

Arched ramps solve the low-clearance problem that straight ramps can't handle. If you've ever watched a lawn mower get stuck at the transition point between ramp and bed, you'll appreciate how an arched design prevents that frustrating bottoming out.

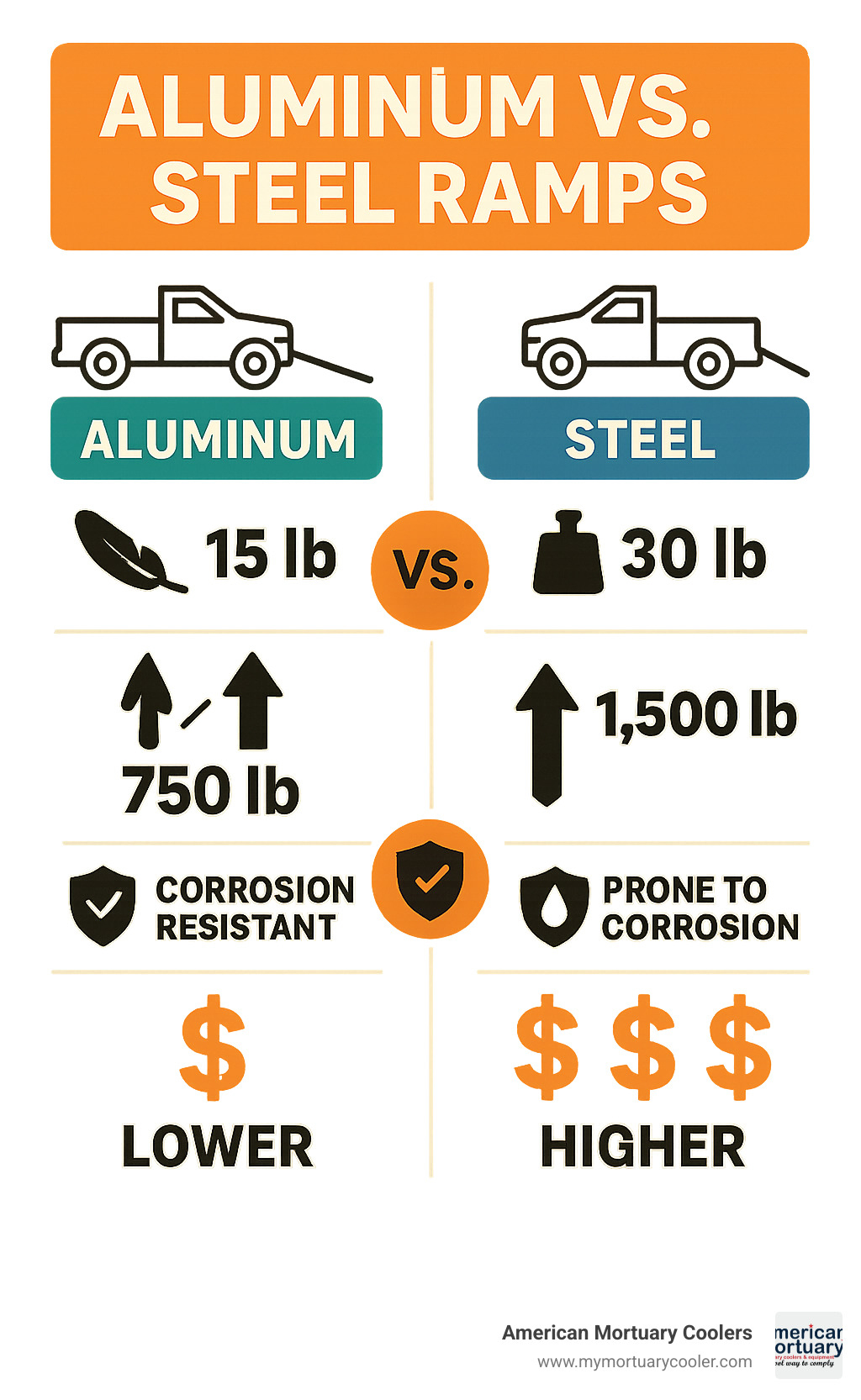

Material Choices & Durability Factors

6061 T6 aluminum has earned its reputation as the gold standard for portable ramps. The ReadyRamp uses this material because it delivers 600-pound capacity while staying light enough for one person to handle easily. The natural corrosion resistance means you won't be dealing with rust issues down the road.

Open-grate steel construction takes a different approach, like what you'll find in the HandiRamp M-200. It's heavier, sure, but it offers years of maintenance-free use. The open design lets debris fall through naturally and provides excellent drainage - no more hosing off stuck leaves and mud.

Diamond plate traction surfaces appear on virtually every quality ramp for good reason. Those raised diamond patterns provide grip while allowing debris to clear naturally. One thing to watch for though - too much surface texture can actually trip you up despite improving traction, so look for balanced designs that prioritize both grip and smooth movement.

For steel ramps, powder coating and protective finishes aren't optional if you plan regular outdoor use. At American Mortuary Coolers, we've seen how Tennessee weather can affect unprotected metal over time. A good protective finish pays for itself by preventing rust and extending the ramp's working life.

The choice between aluminum and steel often comes down to your priorities: aluminum for portability and corrosion resistance, steel for maximum durability and capacity. Both materials can serve you well when properly designed and maintained.

Installation, Safety & Maintenance Best Practices

Getting your pickup bed ramp set up safely isn't rocket science, but it does require attention to detail. After years of helping funeral professionals transport delicate equipment, I've learned that the difference between a smooth operation and a costly accident often comes down to following basic safety protocols.

The key is developing good habits from day one. Whether you're loading a lawn mower or specialized mortuary equipment, the fundamentals remain the same - secure everything properly, take your time, and never skip the safety checks.

Step-by-Step Safe Loading Technique

Start with the straps before you even think about moving equipment. Your ramp needs to be rock-solid against the tailgate. The ReadyRamp's mounting system makes this quick, but don't rush it. A loose ramp is an accident waiting to happen.

Check your angle next. If you're looking up at a steep mountain of ramp, something's wrong. Reposition your truck or accept that you need a longer ramp for your setup. I've seen too many people try to make a short ramp work in situations where it simply isn't safe.

Use low gear whether you're driving equipment up or pushing manually. This isn't a race. Steady and controlled beats fast and reckless every single time. The extra few seconds you spend going slow could save you thousands in equipment damage.

Get a spotter for anything heavy or valuable. You can't see everything from the driver's seat or while pushing from behind. A second set of eyes prevents most loading accidents. Trust me on this one - pride comes before the fall, literally.

Tie everything down immediately once it's loaded. Don't drive around the block to test how well it sits. Secure your equipment before you move that truck an inch. It's amazing how many people remember this step only after their equipment has taken a scenic tour of the parking lot.

Ongoing Care to Extend Ramp Life

Keep it clean might sound obvious, but you'd be surprised how many people ignore this basic step. Mud, leaves, and ice turn even the best diamond plate surface into a slip-and-slide. A quick spray with the hose after each use saves headaches later.

Check those bolts periodically. Road vibration is sneaky - it gradually loosens hardware over time. A quick monthly check with a wrench prevents the kind of catastrophic failure that ruins your whole day.

Touch up scratches on steel ramps right away. Rust is like a bad habit - easy to ignore at first, but it spreads fast once it gets started. A little touch-up paint now beats replacing the whole ramp later.

Store smart during harsh weather. If you live somewhere with brutal winters, bringing portable ramps inside protects rubber components from freeze-thaw cycles. It's not always convenient, but it extends the life significantly.

Keep things moving smoothly with light lubrication on hinges and folding mechanisms. Don't overdo it - a little goes a long way, and too much just attracts dirt and debris.

Common Mistakes to Avoid

Overloading is the number one mistake I see. That weight rating isn't a suggestion - it's the law of physics. Remember to count fuel, attachments, and the operator's weight if they're riding the equipment up. Math doesn't lie, even when we want it to.

Going too steep with inadequate ramp length creates dangerous situations. Equipment can tip backward, lose traction, or get stuck at weird angles. The 4:1 rule exists for good reasons, and those reasons usually involve emergency room visits when ignored.

Skipping the security step seems to happen when people get comfortable with their routine. An unsecured pickup bed ramp can slip at the worst possible moment. Every single time you use it, secure it properly. No exceptions.

Playing hero with heavy equipment is tempting but dangerous. That HandiRamp M-200 weighs 165 pounds - it's definitely a two-person job. Asking for help isn't admitting weakness; it's showing wisdom. Your back will thank you for years to come.

Top Brands, Costs, FAQs & Next Steps

Brand Snapshot & Price Ranges

When it comes to pickup bed ramp options, you'll find choices ranging from budget-friendly portable models to professional-grade systems that cost more than some used cars. Let me walk you through what's actually available in today's market.

The ReadyRamp Compact sits at the affordable end at $229 for their 600-pound capacity model. What makes this ramp special is its dual-purpose design - it works as both a loading ramp and bed extender. With ratings consistently hitting 4.83 to 5.0 stars and compatibility with over 15 million trucks, it's become the go-to choice for many weekend warriors and small business owners.

For serious commercial applications, the HandiRamp M-200 commands around $4,900, but you're getting a beast of a system. This 1,500-pound capacity ramp with its 52.5-inch usable width is built for daily professional use. At 165 pounds, it's definitely not portable, but it transforms your truck into a legitimate loading dock.

The LoadAll V3 splits the difference at $3,495 for their regular pricing. Their slide-out design is clever - it offers 1,300-pound capacity while completely retracting into your truck bed when not needed. This means you keep full bed functionality without sacrificing loading capability.

Ramp Rack Systems take a different approach with their integrated solutions. Their XTREME series and sport units vary in price based on customization, but they're designed around one core philosophy: eliminating the need for trailers entirely.

For the mechanically inclined, DIY builds using welded steel can run around $500 in materials. However, this assumes you have welding skills, equipment, and the time to engineer a safe design - not exactly a weekend project for most folks.

Cost of Ownership vs Alternatives

Here's where the numbers get interesting, and why so many professionals are making the switch from trailers to pickup bed ramps.

That lawn care professional I mentioned earlier wasn't exaggerating about saving $100 per week in fuel costs. When you add up $5,200 in annual fuel savings, most ramp systems literally pay for themselves in the first year. Even a premium HandiRamp M-200 makes financial sense for high-volume users.

Trailer maintenance becomes a thing of the past. No more replacing trailer tires every season, rebuilding wheel bearings, or dealing with trailer brake adjustments. These costs add up faster than most people realize.

Insurance considerations often favor ramps too. Many policies treat truck bed accessories differently than trailers, potentially saving you money on coverage. Plus, there's no separate registration or licensing requirements.

Resale value for quality ramps stays surprisingly strong. Unlike trailers that can sit and deteriorate, a well-maintained ramp often transfers to your next truck with minimal modification needed.

Frequently Asked Questions About Pickup Bed Ramps

How do I know what length ramp I need?

Start by measuring the vertical distance from ground to your truck bed, then multiply by 4. So if your tailgate sits 24 inches high, you'll want at least an 8-foot ramp. But here's the thing - this is just your starting point.

Your equipment's wheelbase matters too. A long zero-turn mower might need extra ramp length to prevent the middle from dragging, even if the basic math says a shorter ramp would work. When in doubt, go longer rather than shorter - a gentler angle is always safer.

Can I leave my ramp mounted while driving?

This depends entirely on which type you choose. Folding ramps like the ReadyRamp are designed to fold up and store right in your truck bed during transport. Tailgate-replacement systems like the HandiRamp M-200 fold up and lock securely in place for highway driving. Slide-out systems completely retract into the bed.

The key is following the manufacturer's transport instructions exactly. Each system has its own way of securing for road travel, and skipping these steps can be dangerous.

What's the difference between arched and straight ramps?

Arched ramps have a curved profile that solves a specific problem - they prevent low-clearance equipment from getting stuck at the transition point where ramp meets truck bed. If you're loading riding mowers, especially zero-turn models that sit low to the ground, an arched design is often essential.

Straight ramps work perfectly fine for equipment with adequate ground clearance and typically cost less than arched versions. ATVs, motorcycles, and walk-behind equipment usually do fine with straight ramps.

Conclusion & Call-to-Action

Choosing the right pickup bed ramp really comes down to honest assessment of your needs, budget, and how often you'll actually use it. Whether you're loading ATVs for weekend trips or need daily equipment transport for your business, there's a solution that will make your life easier and your back happier.

At American Mortuary Coolers, we've seen how the right equipment makes difficult jobs manageable. Just as we help funeral professionals across Tennessee, Georgia, Illinois, and beyond find mortuary solutions that work day after day, we believe in investing in tools that actually get used.

The best ramp is the one you'll use consistently. A $229 ReadyRamp that gets deployed every weekend beats a $5,000 system that stays stored because it's too complicated to set up. Start with accurate measurements, consider your real-world usage patterns, and choose something that slightly exceeds your current needs to allow for growth.

The investment pays dividends in reduced injury risk, time savings, and equipment protection. Plus, when you factor in potential fuel savings from ditching a trailer, many systems pay for themselves in the first year.

For those interested in professional transport equipment and how proper gear selection makes all the difference, check out our guide on body boards and gear.

Ready to make loading safer and easier? Check out the DiscountRamps product guide to explore your options and find the perfect pickup bed ramp for your specific needs.