Why Walk In Mortuary Refrigerators Are Essential for Modern Funeral Operations

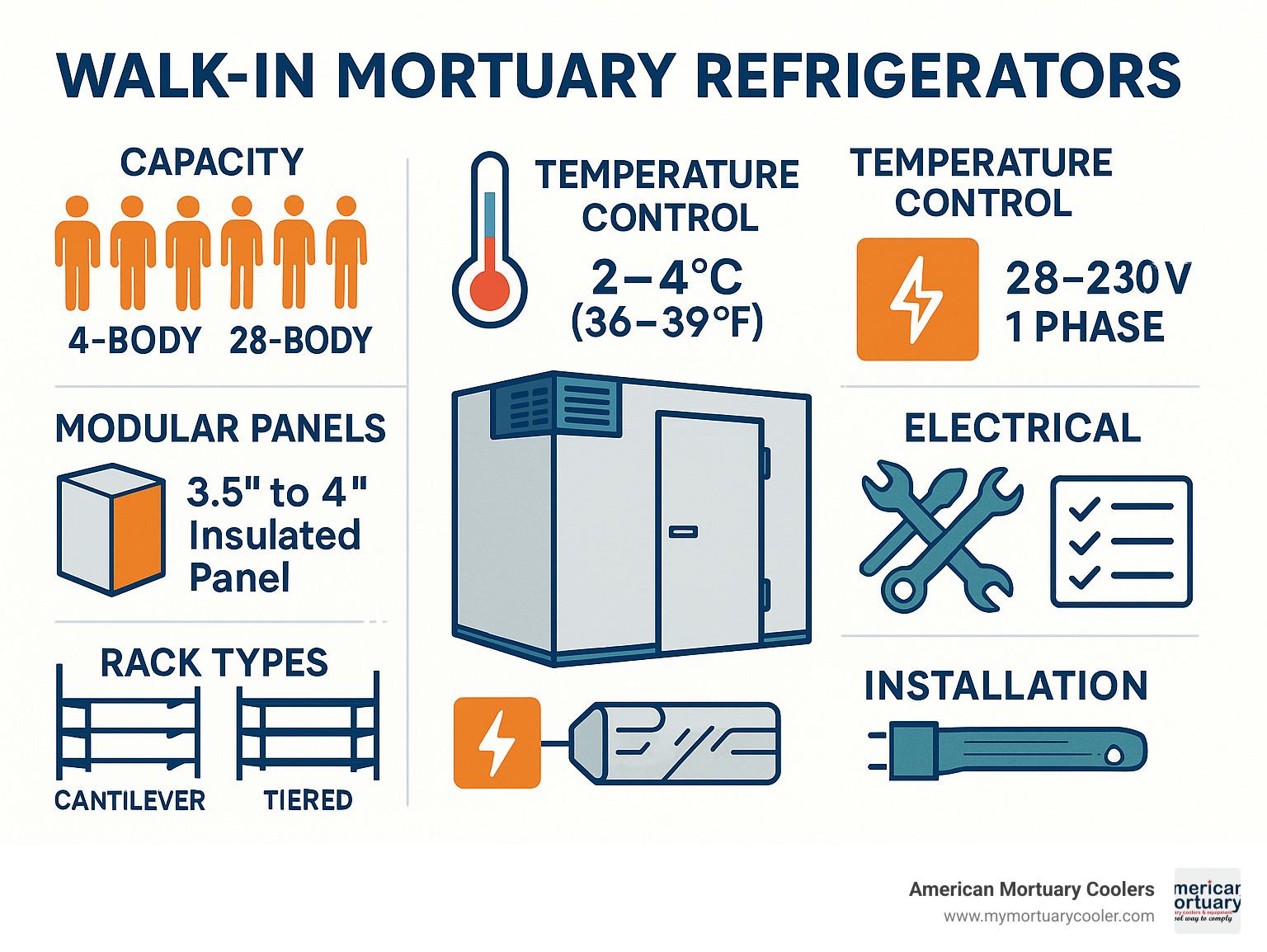

A walk in mortuary refrigerator is a temperature-controlled room designed to preserve human remains at 2-4°C (36-39°F), offering significantly more storage capacity and operational flexibility than traditional body boxes or cabinet-style coolers.

Key Features of Walk In Mortuary Refrigerators:

- Capacity: Store 4 to 100+ bodies depending on size and rack configuration

- Temperature Range: Maintain 2-4°C (36-39°F) to prevent decomposition

- Modular Design: 3.5" to 4" thick insulated panels for easy assembly and expansion

- Applications: Hospitals, funeral homes, disaster response, pathology labs

- Customization: Adjustable racks, bariatric storage, multiple door configurations

Walk in mortuary refrigerators have become the preferred solution for facilities handling multiple remains simultaneously. The modular panel construction allows facilities to start small and expand as needed. Modern units feature antimicrobial finishes, digital temperature controllers, and audio/visual alarms for precise monitoring and compliance.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral directors select and install walk in mortuary refrigerator systems across the United States.

Simple walk in mortuary refrigerator glossary:

What Is a Walk In Mortuary Refrigerator & How It Differs From Body Boxes

A walk in mortuary refrigerator is essentially a custom-built cold room designed specifically for storing human remains. Instead of opening individual compartments, your staff can walk into a temperature-controlled room where everything is organized and accessible.

The fundamental difference between walk-in systems and traditional body boxes comes down to scale and accessibility. Body boxes typically store 2-6 bodies in individual compartments, while walk in mortuary refrigerators can accommodate anywhere from 4 to over 100 bodies depending on configuration.

Walk in mortuary refrigerators use modular construction - built using insulated panels that can be assembled, disassembled, and relocated as needs change. This scalability makes them ideal for hospitals, large funeral homes, disaster response situations, and pathology labs.

Why a walk in mortuary refrigerator matters in modern facilities

The body-handling workflow benefits become obvious when considering how funeral home staff actually work with remains. Instead of bending and reaching into individual compartments, staff can walk into the cooler with proper lifting equipment, dramatically reducing injury risk.

Staff safety is crucial - traditional body boxes often cause workers to strain their backs maneuvering remains in tight spaces. Walk-in units allow multiple staff members to work simultaneously and accommodate bariatric storage much more easily.

| Feature | Body Box | Cabinet Style | Walk-In Refrigerator |

|---|---|---|---|

| Capacity | 2-6 bodies | 6-15 bodies | 4-100+ bodies |

| Staff Access | External only | External only | Internal access |

| Mobility | High (on wheels) | Low | Modular/relocatable |

| Cost | $6,000-$12,000 | $15,000-$30,000 | $20,000-$100,000+ |

| Best For | Small operations | Medium facilities | High-volume facilities |

Key components that set a walk in mortuary refrigerator apart

The construction uses modular panels that lock together with cam-lock mechanisms. Insulated panels are 3.5 to 4-inch thick with high R-value insulation and contain no wood to prevent moisture absorption and bacterial growth.

Floor systems include specialized flooring with NSF-approved cove base construction for seamless transitions and easy cleaning. Every walk-in unit includes OSHA-compliant internal release handles for safety.

Sizing, Capacity & Customization Options

Choosing the right size for your walk in mortuary refrigerator needs to fit your current needs while leaving room to grow. Most facilities start with a 10' x 12' walk in mortuary refrigerator that comfortably handles 15-20 bodies with standard racking.

The modular panel system offers flexibility - 3.5" to 4" thick insulated panels can be configured to fit almost any space. We've built everything from compact 8' x 10' units to massive custom installations storing over 100 bodies.

Capacity planning comes down to understanding your workflow. We usually recommend planning for 150-200% of your normal caseload to avoid getting caught short. Bariatric storage is increasingly important, requiring reinforced shelving and wider door openings.

Customization options include roll-in carts for easier transfers, multiple door styles for optimized traffic flow, and proper vapor-proof LED fixtures with external switches.

For detailed sizing comparisons, see our More info about cooler sizes guide.

Choosing racks for your walk in mortuary refrigerator

Cantilever racks are the most popular choice - wall-mounted systems that extend into the cooler space without floor supports, giving maximum flexibility with adjustable shelving.

Tiered rack systems work when you need maximum capacity in a smaller footprint. Multi-level configurations with telescopic designs and nylon rollers offer 2-, 3-, or 4-tier options.

Load ratings matter - standard racks handle 350 pounds per shelf, but bariatric cases need 500+ pound rated systems. Roll-in cart systems wheel directly in and out of the cooler, reducing staff strain.

Capacity planning: matching cooler footprint to caseload

That standard 10' x 12' configuration handles most medium-sized operations, but consider surge capacity for disasters or peak periods. The modular add-on capability means you can extend length or width by adding panels as needs evolve.

Critical Features, Materials & Temperature Control

Building a quality walk in mortuary refrigerator requires getting every detail right. We use Stainless Steel Grade 304 for all interior surfaces - it won't corrode, cleans easily, and meets NSF standards.

Antimicrobial finishes with SmartProtec® coatings actively fight bacterial growth. Polyurethane foam insulation creates a thermal barrier maintaining the critical 2-4°C range without overworking your compressor.

Digital controllers and data loggers track 30-day temperature history, send audio-visual alarms, and can connect to WiFi for remote monitoring. Some units include RS-485 communication ports for building management integration.

For technical specifications, check our The Complete Guide to Walk-In Mortuary Refrigerator Specifications.

Why a walk in mortuary refrigerator needs precise temperature & humidity

The 2-4°C range represents careful balance - below 2°C risks cellular damage affecting autopsy results, above 4°C accelerates bacterial growth and decomposition.

Humidity control prevents condensation problems and tissue dehydration. Redundancy through backup compressors or comprehensive alarm systems is essential.

Insulation, doors & flooring: building for hygiene and durability

No-wood Performance Panel Systems (PPS) are essential - wood absorbs moisture and harbors bacteria. Mortuary-grade panels use all-metal construction with high-density foam cores.

NSF-certified doors include magnetic gaskets, self-actuating closures, internal release mechanisms, and corrosion-resistant cam locks. Cove base flooring creates seamless curved transitions eliminating corners where debris accumulates.

Monitoring & alarm tech for compliance

EISA 2007 compliance requires DOE-certified panels tested per ASTM E84. OSHA safety requirements cover internal release handles and proper ventilation. Remote alert systems distinguish between door openings and equipment failures, reducing false alarms.

More information available through Scientific research on refrigeration alarms.

Installation, Energy Efficiency & Regulatory Compliance

Setting up a walk in mortuary refrigerator requires proper planning. Site preparation includes a level concrete floor that can handle the weight, and floor drains are highly recommended.

Electrical service requirements depend on cooler size - smaller units use standard 115V single-phase power, while larger installations need 208-230V service. Licensed electrical work ensures proper grounding and code compliance.

Ventilation is required for condensing units and some local codes require mechanical ventilation for walk-in coolers.

CoolBot retrofit systems offer an alternative, converting existing rooms into functional mortuary coolers for around $5,000 using window air conditioners with specialized controllers.

See our Walk-In Request Help Sheet for detailed specifications.

Energy consumption benefits from eco-friendly refrigerants like R-448A that provide excellent cooling performance while meeting environmental regulations.

Step-by-step install checklist

Floor leveling comes first - within 1/4 inch across the entire footprint. Panel assembly starts with corner pieces using the cam-lock system. Joint sealing happens during assembly with appropriate gaskets. Door installation and commissioning wraps up with testing all safety systems.

Most installations complete in one to two days with panels shipping "knocked down" to save freight costs.

Cutting operating costs without losing cold

High R-value insulation can cut cooling costs by 30-50% compared to standard insulation. LED lighting systems use 75% less energy than fluorescent lights and generate less heat. Variable speed condensers reduce energy consumption by 20-30% while extending equipment life.

Maintenance, Cost & Emerging Technology Trends

Taking care of your walk in mortuary refrigerator is straightforward but thorough. Use hospital-grade disinfectants on stainless steel surfaces designed to handle aggressive cleaning chemicals.

Door gaskets are the most common failure point - monthly inspection can catch wear before it affects temperature control. Quality systems offer comprehensive protection: one year parts and labor on refrigeration, five years on doors and floors, up to 15 years on panels.

Costs range from CoolBot conversions around $5,000 to $25,000-$60,000 for most funeral homes, with fully custom installations exceeding $100,000 for large facilities.

Read our Chilling Facts About Mortuary Walk-In Coolers for more insights.

Common mistakes to avoid when buying or installing

Undersized compressor systems struggle during hot weather or busy periods. Poor insulation choices cost more in energy bills over 20+ years. Ignoring local requirements can result in expensive post-installation modifications. Lack of redundancy in critical systems can be catastrophic.

Future-ready upgrades you can add later

IoT sensors and remote monitoring provide real-time data and integrate with facility management software. Solar-assisted cooling can significantly reduce grid electricity consumption. Quick-swap condenser systems offer backup units that swap in hours rather than days.

Frequently Asked Questions about Walk In Mortuary Refrigerators

After helping funeral directors across the country select and install walk in mortuary refrigerator systems, I've noticed the same questions come up time and again. Let me address the most common concerns we hear from facility managers considering these systems.

The questions usually fall into three main categories: getting the temperature right, understanding the electrical requirements, and planning for future growth. These are all smart questions that show you're thinking about the long-term success of your facility.

How cold should a walk in mortuary refrigerator be?

The sweet spot for a walk in mortuary refrigerator is 2-4°C (36-39°F). This might seem like a narrow range, but there's real science behind these numbers.

Go too cold - below 2°C - and you risk freezing damage to tissues. This can create problems during viewings and make autopsy work more difficult. The cellular damage from freezing can also affect the accuracy of pathological examinations.

Go too warm - above 4°C - and bacterial growth accelerates rapidly. Even a few degrees can make a significant difference in how quickly decomposition progresses, especially during summer months when ambient temperatures are higher.

Most facilities set their target temperature at 38°F (3.3°C) with alarms programmed to alert staff if temperatures drift outside the acceptable range. Modern digital controllers make it easy to maintain this precise temperature control, and the data logging features help with regulatory compliance.

What electrical service is required?

The electrical requirements for your walk in mortuary refrigerator depend entirely on the size and configuration you choose. It's not a one-size-fits-all situation.

Smaller units designed for 4-8 bodies typically run on standard 115V single-phase power. These can often plug into existing outlets, though you'll want a dedicated circuit to avoid overloading your electrical system.

Larger systems need more substantial power - usually 208-230V service with dedicated circuits sized for the specific equipment. A 20-body capacity walk-in might need a 30-amp circuit, while larger installations could require 50-amp or higher service.

Don't forget about the interior lighting and alarm systems when calculating electrical loads. LED lighting doesn't draw much power, but it all adds up. Most installations require professional electrical work to ensure proper grounding and code compliance.

Your electrical contractor should verify local requirements before starting work. Some jurisdictions have specific rules about mortuary equipment that differ from standard commercial refrigeration.

Can I expand capacity later without replacing the whole cooler?

This is one of my favorite questions because the answer is a resounding yes - and it's one of the biggest advantages of choosing a modular walk in mortuary refrigerator system.

The modular panel construction makes expansion surprisingly straightforward. We can add panels to extend the length or width of your existing cooler without major reconstruction. I've helped facilities double their capacity by adding just a few panels and reconfiguring the rack systems.

Vertical expansion is another option if floor space is limited. Installing taller rack systems can increase storage density within your existing footprint. This works especially well if you initially installed basic racking and want to upgrade to more sophisticated cantilever systems.

Some facilities create separate temperature zones within the same structure - maybe keeping one section slightly warmer for short-term storage or creating a dedicated area for bariatric cases. The modular design makes this kind of customization possible.

The key is planning ahead during your initial installation. Make sure your electrical service can handle additional equipment, and consider how expansion might affect traffic flow in your facility. It's much easier to add capacity when you've thought through these details from the beginning.

Conclusion & Next Steps

Choosing the right walk in mortuary refrigerator is crucial for maintaining dignity, ensuring compliance, and creating a professional environment that serves your community for decades.

The modular design and precise temperature control make walk-in systems the clear choice for quality-focused facilities. Whether storing 4 bodies or 100+, the scalability means you can start with current needs and expand as your business grows.

At American Mortuary Coolers, based in Tennessee, we help funeral directors across the contiguous 48 states design and install custom mortuary cooling solutions. Our experience ranges from small funeral homes to large hospital morgues requiring complex multi-zone systems.

A quality walk-in system with proper maintenance serves your facility reliably for 20+ years while meeting all regulatory requirements. Modern systems improve staff safety, reduce energy costs, and provide compliance documentation that health departments require.

See our complete range at Walk-In Coolers and Freezers: Essential Solutions for Your Mortuary Needs at American Mortuary Coolers.

Ready to move forward with your walk in mortuary refrigerator project? Contact us today for a consultation and custom quote. We'll help you steer technical details, local code requirements, and installation process so you can focus on serving families in their time of need.