What Is an Iced Evaporator?

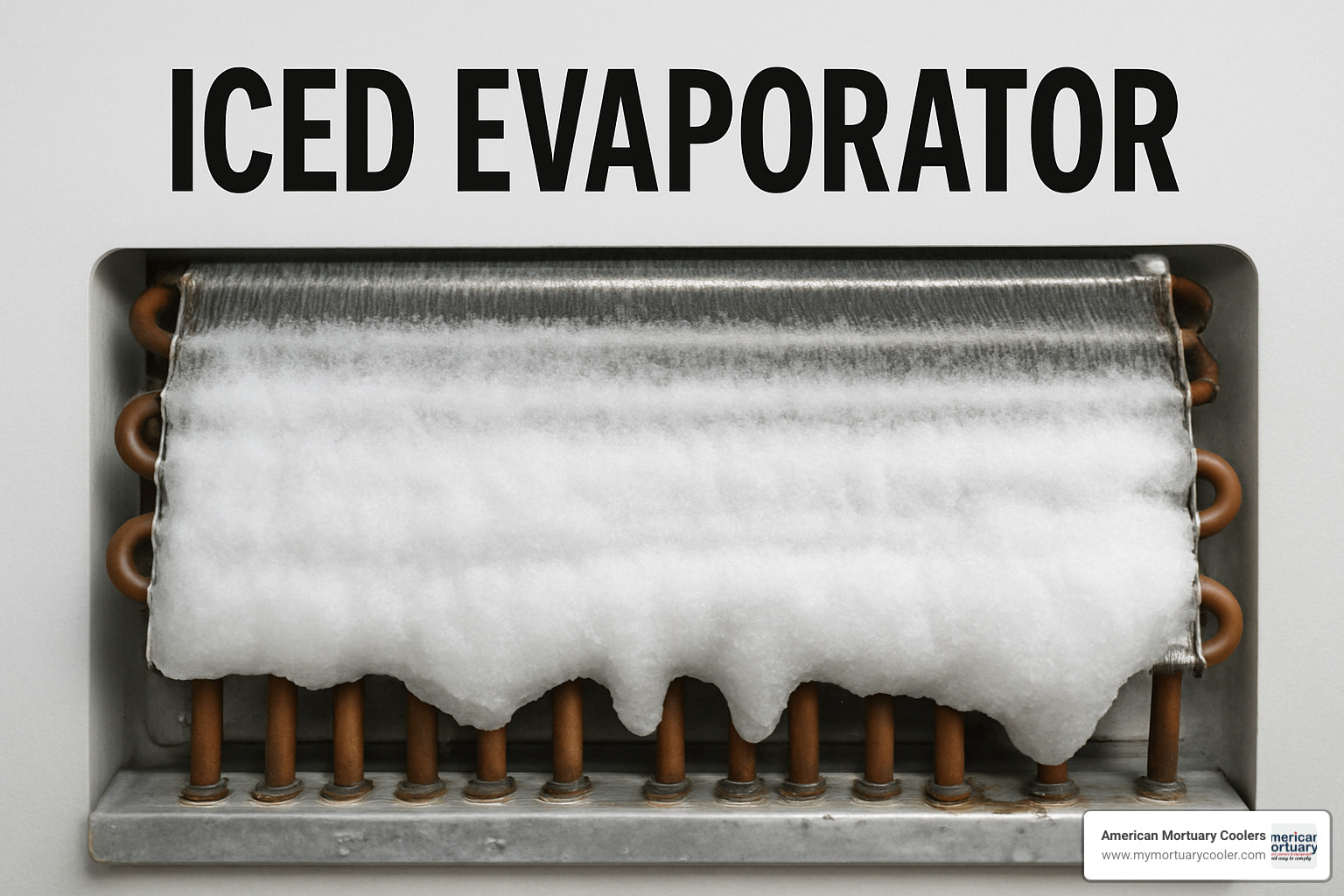

An iced evaporator is a common problem in refrigeration systems where frost and ice build up on the evaporator coils, blocking proper airflow and reducing cooling efficiency. If you're experiencing this issue, here's what you need to know:

Quick Guide to Iced Evaporator Issues:

- Causes: Low airflow, refrigerant leaks, dirty coils, defrost failures

- Signs: Reduced cooling, visible ice on coils, system running constantly

- Quick Fix: Turn off system, switch to fan-only mode to thaw, replace air filter

- Prevention: Regular filter changes, scheduled maintenance, proper airflow

An iced evaporator occurs when the temperature of your refrigeration coils drops below freezing, causing moisture in the air to freeze on the coil surface. This ice layer acts as an insulator, preventing the coil from absorbing heat properly and forcing your system to work harder while cooling less effectively.

In mortuary coolers, this issue is particularly critical as consistent temperature control is essential for preservation. When your evaporator coils ice over, the cooling capacity diminishes rapidly, potentially compromising the integrity of your mortuary operations.

I'm Mortuary Cooler, a national-level supplier of mortuary refrigeration systems with extensive experience diagnosing and resolving iced evaporator issues in funeral home settings. Having worked with countless funeral directors to maintain optimal cooling performance, I understand how critical reliable refrigeration is for your daily operations.

Quick look at iced evaporator:

How an Iced Evaporator Sabotages Cooling

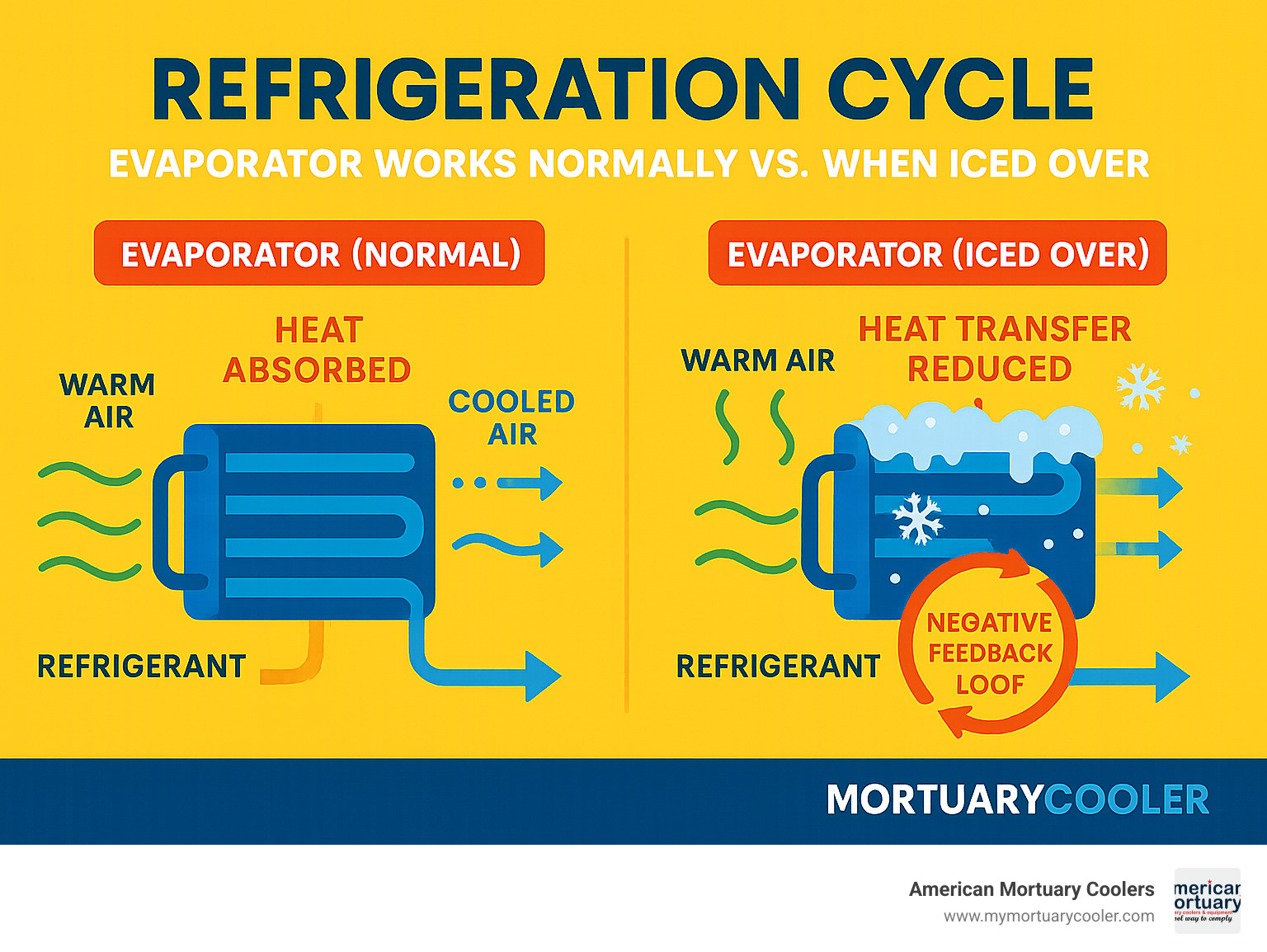

In a properly functioning refrigeration system, liquid refrigerant inside the evaporator coil absorbs heat from the surrounding air, causing the refrigerant to evaporate (change phase from liquid to gas). This phase change is what creates the cooling effect in your mortuary cooler.

When ice forms on the evaporator coil, it creates a double problem:

Physical Airflow Blockage: Ice physically blocks air from passing through the coil fins, reducing the volume of air that can be cooled.

Thermal Insulation: Ice acts as an insulator between the air and the refrigerant, dramatically reducing heat transfer efficiency.

As one HVAC technician with 20+ years of experience told us, "An iced evaporator is like trying to cool a room while wearing a winter coat – the cooling power is there, but it can't reach where it needs to go."

This creates a dangerous feedback loop: as ice builds up, cooling efficiency drops, causing the system to run longer to achieve the desired temperature. Longer run times create more opportunities for condensation and freezing, worsening the ice buildup. Without intervention, this cycle continues until the system fails completely or cooling becomes ineffective.

In mortuary coolers, where temperature stability is non-negotiable, this can quickly become an emergency situation requiring immediate attention.

1. Boost Airflow Immediately

When you're dealing with an iced evaporator, the first place to look is your system's airflow. In fact, insufficient airflow is the number one culprit behind those frosty coils. Think of it like trying to cool your home while breathing through a straw – it just doesn't work well.

The good news? This is often the easiest problem to fix.

Your mortuary cooler needs proper airflow like we need oxygen. When air moves too slowly across the evaporator coil, the temperature plummets below freezing, turning moisture in the air into ice on contact. Before you know it, you've got a winter wonderland inside your cooling unit – and not the kind anyone wants.

Replace those dirty filters first and foremost. I can't tell you how many service calls I've been on where a simple filter change would have prevented the problem entirely. For mortuary coolers, aim to replace filters every 30-60 days, and even more frequently if your environment is dusty. Trust me, your system will thank you.

Clear space around all vents and returns. That box of supplies might seem harmless leaning against the wall, but if it's blocking airflow, it's part of the problem. Maintain at least 18 inches of clearance around all vents in your mortuary cooler.

Are your evaporator fans running properly? Listen for unusual sounds – grinding, scraping, or wobbling noises often signal bearing failure. A fan that's not moving air at the right speed can't keep your coils frost-free.

If your system has ductwork, take a moment to inspect it. Collapsed, disconnected, or blocked ducts are silent airflow killers. A quick visual inspection can reveal problems that might otherwise go unnoticed.

For immediate relief, switch to fan-only mode on your thermostat to help melt existing ice (we'll cover more thorough thawing techniques in section 4). This simple step can get you back in business while you address the root cause.

Our service team at American Mortuary Coolers has found that about 65% of iced evaporator cases we handle are solved just by fixing airflow issues. That's a pretty compelling reason to start here!

How Poor Airflow Freezes an Iced Evaporator

The relationship between airflow and evaporator icing is fascinating, if a bit technical. In a healthy refrigeration system, your refrigerant temperature should hover around 40°F – cold enough to cool effectively but warm enough to prevent freezing on the coils.

When airflow gets restricted, things go downhill fast. Less warm air passes over the coil, causing the refrigerant temperature to nosedive, often dropping to 20°F or lower. At these temperatures, any moisture in the air instantly freezes when it touches the coil.

As one of our veteran Tennessee technicians likes to say, "It's a snowball-down-the-mountain effect. Once that first bit of ice forms, things tend to go from bad to worse in a hurry."

That initial ice further blocks airflow, which makes the coil even colder, which creates more ice... you see where this is going. Without intervention, this cycle continues until your system is essentially a block of ice trying to cool your mortuary space.

For mortuary facilities specifically, consistent temperatures throughout the cooling chamber are non-negotiable. When airflow is compromised, you'll likely experience temperature stratification – warm spots and cold spots that can compromise preservation quality. This insufficient airflow leading to a frozen coil isn't just inefficient; it can impact the integrity of your work.

Want to learn more about keeping your system in top shape? Check out our guide on Maintaining and Cleaning Your Mortuary Cooler for Longevity for additional tips beyond just fixing airflow issues.

2. Locate and Repair Refrigerant Leaks

When your mortuary cooler isn't performing properly, low refrigerant might be the culprit behind your iced evaporator. It sounds counterintuitive, I know—how could less cooling substance actually make things too cold? But that's exactly what happens in refrigeration systems.

Think of your refrigeration system as a closed circuit—a carefully balanced loop where refrigerant should never escape. Any drop in refrigerant levels means you've got a leak somewhere that needs attention. Our service records at American Mortuary Coolers show that nearly a third of all iced evaporator cases we encounter in funeral homes stem from these sneaky refrigerant leaks.

Beyond just causing performance headaches, these leaks raise environmental concerns too. Many refrigerants have significant global warming potential—something none of us wants to contribute to unnecessarily.

If you suspect low refrigerant might be behind your cooling troubles, here's what you need to know:

The telltale sign is often a partially iced coil—typically starting at the inlet—combined with your system running longer while cooling less effectively. Unlike a completely frozen coil (which usually points to airflow or defrost problems), refrigerant leaks create distinctive icing patterns that experienced technicians can spot right away.

This isn't a DIY fix, though. EPA regulations require certified technicians to handle refrigerants, and for good reason. Our team at American Mortuary Coolers maintains all proper EPA certifications precisely because we take these regulations seriously.

When our technicians arrive, they'll use specialized tools—electronic leak detectors, UV dyes, or soap solutions—to track down even the tiniest leaks in your system. Once identified, they'll properly repair the leak, pressure-test the system to ensure all issues are resolved, and then recharge with exactly the right type and amount of refrigerant your system needs.

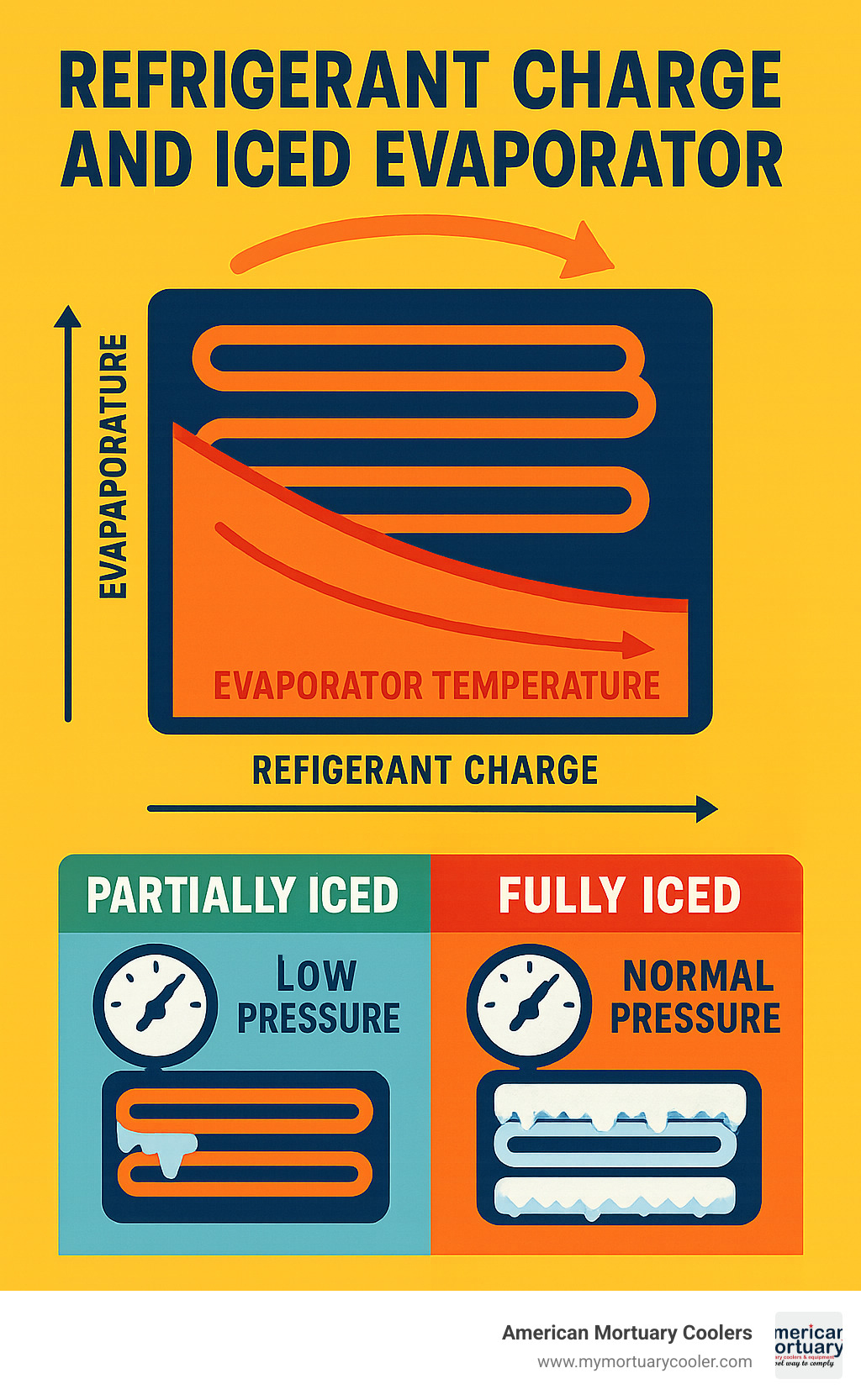

Why Low Refrigerant Turns Your Iced Evaporator into an Icebox

The science behind this problem is fascinating, if a bit counterintuitive. There's a direct relationship between pressure and boiling point in refrigerants—lower the pressure, and you lower the temperature at which the refrigerant boils (or evaporates).

When refrigerant leaks out, system pressure drops. With lower pressure, the remaining refrigerant starts boiling at temperatures well below what your system was designed for—often significantly below freezing. This creates what technicians call "localized super-cooling," where the refrigerant absorbs heat at temperatures so low that any moisture in the air instantly freezes on contact with the coil.

"You can actually diagnose the problem type by the ice pattern on the coil," explains one of our senior technicians. "A fully iced evaporator usually means airflow or defrost problems, while refrigerant leaks typically cause uneven icing concentrated at the inlet side."

For mortuary coolers specifically, maintaining proper refrigerant charge isn't just about preventing an iced evaporator—it's essential for the precise temperature control needed for proper preservation. The specialized environment you maintain for the deceased requires exactness that simply isn't possible with incorrect refrigerant levels.

Scientific research confirms this relationship between refrigerant levels and coil icing. According to studies highlighted by Purl Sheet Metal, the pressure-temperature relationship in refrigeration systems directly impacts how and why evaporator coils freeze.

If you're interested in learning more about energy efficiency in mortuary cooling systems (which proper refrigerant levels greatly impact), check out our Ultimate Guide to Energy-Efficient Coolers.

3. Reset or Upgrade the Defrost Cycle

For mortuary coolers operating at low temperatures, regular defrost cycles are essential to prevent an iced evaporator. The defrost system temporarily halts cooling and applies heat to melt accumulated frost before it builds up into problematic ice.

Signs that your defrost system may be contributing to an iced evaporator include:

- Thick, uniform ice covering the entire evaporator coil

- Ice buildup that returns quickly after manual defrosting

- System running continuously with poor cooling performance

- Visible ice or frost on products or interior walls

Common defrost system components that may need attention:

Defrost timer: Controls when and how often defrost cycles occur. Most walk-in mortuary coolers are designed to defrost 1-4 times per day, depending on usage patterns and humidity levels.

Defrost heaters: Electric resistance heaters that warm the coil during defrost. These can burn out over time.

Defrost termination switch: Ends the defrost cycle when the coil reaches approximately 60°F, preventing excessive heating.

Drain line heaters: Prevent condensate from refreezing in the drain line during defrost.

At American Mortuary Coolers, we typically recommend the following defrost settings for mortuary applications:

- Medium-temperature coolers (35-45°F): 4 defrost cycles daily, using air defrost (fan-only) or mild electric defrost

- Low-temperature coolers (below 35°F): 4 electric defrost cycles daily, with fail-safe termination set to 35-45 minutes

Signs Your Iced Evaporator Has a Defrost Failure

Defrost failures can manifest in several ways:

Solid ice sheet: Unlike normal frost that appears white and fluffy, defrost failures often result in clear, solid ice completely encasing the coil.

Extended run times: When the evaporator can't efficiently transfer heat due to ice buildup, the system runs longer trying to reach set temperature.

Temperature fluctuations: Failed defrost systems often cause wide temperature swings as the system struggles to maintain proper conditions.

Water accumulation or ice stalagmites: Improper drainage during defrost can cause water to pool and refreeze, creating ice formations inside the cooler.

A maintenance director at a multi-location funeral home chain shared this experience: "We were having constant issues with an iced evaporator in our main cooler. Turns out the defrost heater had failed, but the defrost timer was still cycling. The system would stop cooling for defrost but had no way to melt the ice. Once we replaced the defrost heater assembly, the problem was solved completely."

For mortuary coolers specifically, proper defrost is critical not just for system efficiency but also for maintaining precise temperature control. Defrost cycles must be frequent enough to prevent ice buildup but not so frequent or long that they compromise temperature stability.

4. Safely Thaw and Clean the Coil

Finding an iced evaporator can feel like a crisis, especially in a mortuary setting where temperature stability is non-negotiable. But take a deep breath – with some patience and the right approach, you can safely restore your system to peak performance.

The key word here is "safely." I've seen well-meaning funeral directors attempt to speed up the process with screwdrivers, ice picks, or even blowtorches – approaches that almost always end with damaged coils and expensive repairs. Those delicate aluminum fins and copper tubing deserve gentle treatment.

Here's the safest way to thaw your frozen coil: First, switch your system to "off" at the thermostat. If possible, keep the fan running on "on" mode – this circulates room temperature air across the ice, speeding up the melting process naturally. Don't forget to place some old towels or a shallow container beneath the unit to catch the inevitable meltwater – your maintenance staff will thank you later!

Patience truly is a virtue here. Natural thawing might take a few hours, but it's worth the wait to protect your equipment. If you're in a hurry (and who isn't these days?), you can safely accelerate the process with a standard room fan blowing across the coil, or a hair dryer on low heat kept at least 18 inches away from the coil surface.

Step-by-Step Coil Care to Prevent the Next Iced Evaporator

Once your coil is completely ice-free, you've got a perfect opportunity for preventive maintenance. Safety first: turn off power to the unit at the breaker before you begin cleaning.

Apply a non-acidic, foaming evaporator coil cleaner specifically designed for refrigeration equipment. These specialized cleaners cling to the coil surface, breaking down the buildup of dust, biofilm, and debris that can restrict airflow. Work methodically from top to bottom, ensuring complete coverage, then allow the cleaner to work its magic for 5-10 minutes (always follow the specific product instructions).

Rinsing thoroughly is just as important as the cleaning itself. Using clean water in a spray bottle, rinse in the opposite direction of normal airflow – this pushes dirt out the way it came in. While the coil dries, take a moment to clean the condensate drain pan with mild detergent and verify the drain line is flowing freely.

Once everything is dry, restore power and run a test cycle. A properly cleaned coil not only prevents future icing but can significantly improve system efficiency and cooling performance.

| DIY Cleaning | Professional Service |

|---|---|

| Cost: $20-50 for supplies | Cost: $150-300 service call |

| Time: 2-3 hours | Time: 1-2 hours |

| Equipment needed: Coil cleaner, spray bottle, soft brush | Specialized equipment and cleaning solutions |

| Best for: Light cleaning, accessible coils | Best for: Heavily soiled coils, difficult access |

| Risk: Potential for fin damage | Experience minimizes damage risk |

"The fastest way to turn a minor icing issue into a major repair bill is using a pressure washer on evaporator coils," our service manager often reminds clients. "Those high-pressure streams might feel satisfying, but they bend and damage the delicate aluminum fins, actually making future icing more likely."

For mortuary coolers specifically, we recommend professional cleaning at least once a year, with more frequent attention in dusty environments or facilities with higher usage rates. This small investment in maintenance prevents the disruption and potential crisis of an iced evaporator when you least expect it.

Regular coil maintenance isn't just about preventing ice – it's about ensuring your facility maintains the consistent, reliable cooling that families expect and deserve during their most difficult moments. If you're unsure about tackling the cleaning yourself, our guide on walk-in cooler repair can help you decide when to DIY and when to call in the professionals.

5. Schedule Preventive Maintenance & Professional Help

Let's face it – nobody wants to deal with an emergency cooling situation when they're caring for the deceased. The best defense against an iced evaporator is a good offense: regular preventive maintenance. Our service records at American Mortuary Coolers tell the story clearly – systems that receive regular TLC are 80% less likely to develop those middle-of-the-night icing emergencies that no funeral director wants to handle.

Think of your mortuary cooler maintenance like caring for a car. Some things you can handle in-house, while others require a professional's touch. For your monthly check-ups, your staff should inspect and replace air filters (the number one culprit behind airflow issues), make sure the condensate drain isn't clogged, verify all fans are humming along nicely, and keep an eye out for any unusual frost patterns that might be developing.

Every few months, take things a step further by cleaning those outdoor condenser coils, checking door gaskets for wear and tear, making sure the defrost cycle is doing its job, and giving those interior evaporator fins a gentle cleaning if you can safely access them.

Once a year, it's time to bring in the pros. Our technicians will give your system the full workup – checking refrigerant levels, testing electrical components, performing a thorough coil cleaning, calibrating controls, and verifying your defrost system is working properly. Think of it as your system's annual physical – catching small issues before they become big problems.

"I skipped maintenance for two years to save money," one funeral director from Missouri told us. "Ended up with an iced evaporator during a heatwave with three bodies in care. The emergency service call cost three times what those maintenance visits would have. Never again."

When an Iced Evaporator Means It's Time to Call a Pro

Some cooling issues wave red flags that say "call for backup immediately." If your system develops an iced evaporator shortly after you've just thawed it, something fundamental needs professional diagnosis. When your compressor starts making concerning noises – grinding, banging, or squealing – that often indicates damage from liquid refrigerant returning due to those icing issues.

Watch your electric bill, too. A sudden spike usually means your system is working overtime due to efficiency losses. And in the funeral business, temperature stability isn't just about comfort – it's essential. If you're seeing fluctuations greater than three degrees in either direction, it's time for expert eyes on the problem.

Water leakage around your unit that continues after defrosting suggests drain problems that could lead to property damage – another clear sign to make that service call.

One of our longtime clients in Georgia shared a valuable lesson: "We noticed our mortuary cooler temperature bouncing around, and found an iced evaporator inside. We thawed it ourselves, but within a day, it was iced up again. When the American Mortuary Coolers technician arrived, he quickly found a failed defrost termination switch that was causing incomplete defrost cycles. The repair took less than an hour and saved us from what could have been a complete system failure."

We understand that refrigeration issues rarely happen at convenient times. That's why American Mortuary Coolers offers emergency service throughout our coverage areas. Our factory-trained technicians specialize specifically in mortuary refrigeration systems – they understand the unique requirements and critical nature of funeral service operations.

From our Tennessee headquarters to our service locations in Atlanta, Chicago, Columbia, Dallas, Los Angeles, New York, and Pittsburgh, we're never far away when an iced evaporator or other cooling emergency strikes. Our nationwide coverage ensures that no matter where your funeral home is located, we can provide the expert service you need.

In the funeral industry, refrigeration isn't just about equipment—it's about ensuring you can provide dignified care for the families you serve. A properly maintained cooling system is an essential part of that mission.

For preventive maintenance scheduling or emergency service when you're facing an iced evaporator, contact us at American Mortuary Coolers. Our dedicated team is ready to ensure your refrigeration system operates at peak efficiency, providing the reliable performance your funeral home requires every day of the year.