Why Mold in Walk-In Fridges is a Critical Problem

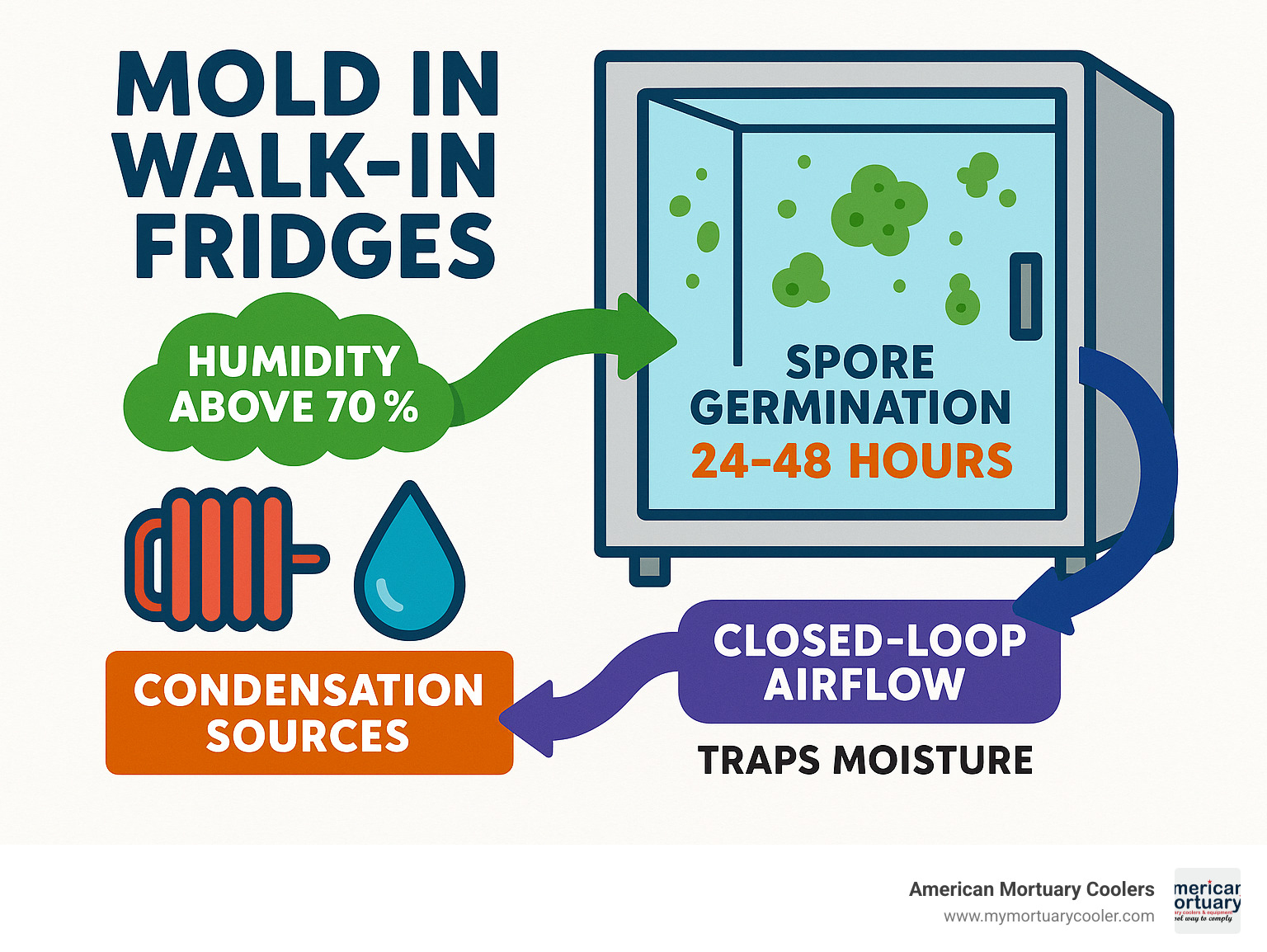

Mold in walk in fridge systems creates a triple threat to your business: inventory damage, health code violations, and potential liability issues. Despite cold temperatures, mold thrives in walk-in coolers when relative humidity exceeds 70% - a common occurrence in these closed-loop environments.

Quick Solution Overview:

- Immediate action: Wear PPE, isolate affected areas, discard contaminated items

- Deep cleaning: Use dish soap and water, followed by 70% ethanol on metal surfaces

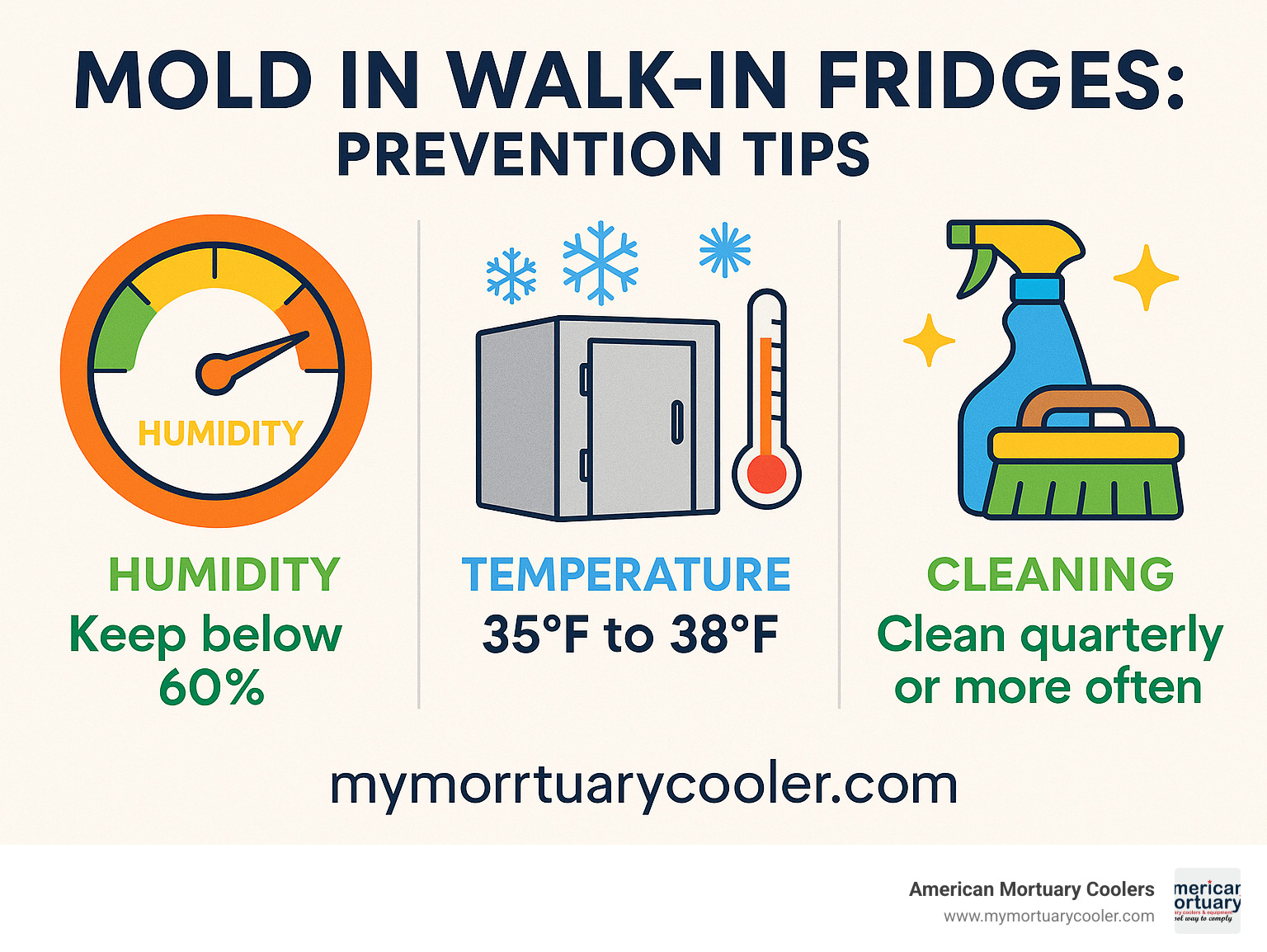

- Prevention: Maintain humidity below 60%, improve ventilation, establish cleaning protocols

- Professional help: Call specialists if mold covers more than 10 square feet or keeps returning

The financial stakes are high. Professional mold remediation for commercial refrigeration units can cost more than $50,000, while health inspections can result in temporary closures and thousands in fines. One New York restaurant paid $8,600 in violations, with $1,200 directly related to their poorly maintained walk-in cooler.

Mold grows even in cold environments because refrigeration units produce moisture daily through condensation cycles. When warm, humid air enters through frequent door openings, it creates ideal conditions for fungal growth. The problem compounds in walk-in systems because they operate as closed ventilation loops - fresh air only enters when doors open, trapping humidity inside.

We're American Mortuary Coolers, a national-level mortuary cooler supplier with extensive experience helping facilities overcome mold in walk in fridge challenges through proper equipment selection and maintenance protocols. Our background in commercial refrigeration has shown us that prevention through smart design and consistent maintenance beats expensive remediation every time.

Easy mold in walk in fridge glossary:

Why Mold Grows Inside Walk-In Fridges

Here's something that surprises many people: mold in walk in fridge systems isn't stopped by cold temperatures alone. Mold actually thrives when relative humidity climbs above 70% - and walk-in coolers hit this threshold more often than you'd think.

The real culprit is how these systems work. Walk-in refrigeration units operate as closed-loop environments where the same air keeps circulating around and around. Fresh air only gets in when someone opens the door, which means moisture gets trapped inside like a fishbowl.

Every time that door swings open, warm humid air rushes in and hits those cold surfaces. Bam - instant condensation. The scientific research on refrigeration mold control shows mold can start growing on these wet surfaces within just 24 to 48 hours. We've seen this timeline play out in facilities from our home base in Tennessee all the way to the West Coast.

Several mechanical issues make the problem worse. Clogged drain pans create standing water that turns into humidity hotspots. Poor ventilation means that moisture-heavy air has nowhere to go. Temperature swings from people constantly opening doors create endless condensation cycles. And leaks from plumbing or refrigeration lines provide a steady drip of moisture that mold absolutely loves.

Key Conditions That Trigger Mold

Mold is pretty simple - it needs moisture, something to eat, and the right conditions to grow. Unfortunately, walk-in fridges serve up all three on a silver platter.

Moisture sources are everywhere in these units. Condensation forms when temperatures shift. Food prep creates spills. Door gaskets wear out and leak humid air inside. Drain pans fill with standing water. Floor drains back up. And every time someone opens the door, humid outside air comes flooding in.

The nutrient residues that feed mold are hiding in plain sight. Food particles stick to shelves and floors. Cardboard packaging leaves organic residues. Meat and dairy products deposit proteins on surfaces. Even produce and beverages leave behind sugars that mold can feast on.

We always recommend installing relative humidity gauges to keep an eye on conditions. When humidity creeps above 70%, you're in the danger zone. The dew point in a 40°F cooler should stay below 32°F to prevent that surface condensation that mold needs to get started.

High-traffic facilities face extra challenges. Busy restaurant kitchens where doors open constantly introduce warm, humid air that has to be cooled and dried out. More door openings mean more condensation cycles and higher mold risk.

Hidden Mechanical Contributors

Some of the biggest mold in walk in fridge problems come from equipment issues that aren't obvious at first glance. Through our work with facilities across the country, we've spotted several mechanical contributors that fly under the radar.

Oversized compressors cause what's called short cycling. When your condenser pumps out 12,900 BTU but your evaporator only needs 8,000 to 10,000 BTU, the system turns on and off too quickly. This prevents proper dehumidification, leaving humidity levels high enough for mold to move in and get comfortable.

Evaporator fan direction matters way more than most people realize. These fans should pull air across the coils toward the fan housing. When airflow runs backward, dehumidification drops and moisture starts building up in all the wrong places.

Gasket wear might seem minor, but even tiny gaps in door seals let in enough humid air to trigger mold growth. This is especially true in humid climates where the outside air is already loaded with moisture.

Aging insulation loses its effectiveness over time. Panels that are more than 10 years old allow temperature differences that promote condensation on interior surfaces. It's like having a cold drink on a hot day - moisture appears wherever warm meets cold.

Removing Mold in Walk-In Fridge: Step-by-Step Guide

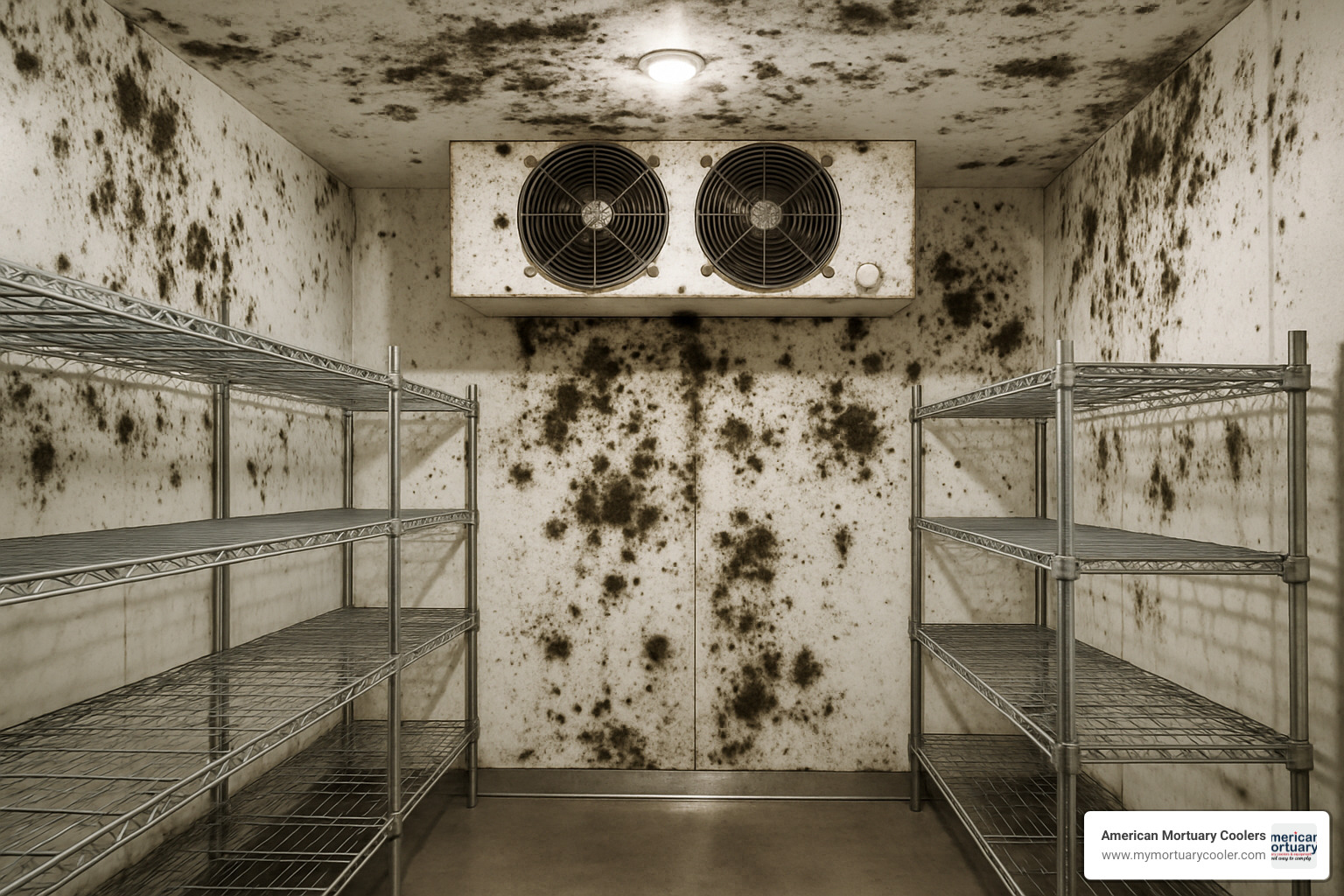

When you find mold in walk in fridge systems, immediate action prevents spread and minimizes damage. Our protocol, developed through years of helping facilities remediate mold issues, ensures safe and effective removal.

Personal Protective Equipment (PPE) Requirements:

- Disposable gloves (nitrile or latex)

- Long-sleeved lab coat or coveralls

- Safety goggles or splash protection

- N-95 respirator mask (for heavy mold only)

- Closed-toe shoes with non-slip soles

Step 1: Isolate the Area Shut down the walk-in cooler and remove all personnel. Post signs warning of mold remediation in progress. Ensure adequate ventilation in surrounding areas to prevent spore spread.

Step 2: Remove Contaminated Items Discard all visibly moldy food immediately. Remove any cardboard, paper products, or porous materials that show signs of contamination. These items cannot be effectively cleaned and will continue harboring spores.

Step 3: Initial Cleaning Start with basic dish soap and water for initial cleaning. This breaks down mold on most surfaces without damaging equipment finishes. Work from top to bottom to prevent recontamination of cleaned areas.

Step 4: Disinfection Apply 70% ethanol to metal surfaces for effective mold kill. Never use bleach on metal surfaces as it causes pitting and corrosion. For non-metal surfaces, a 1:10 bleach solution works effectively.

Step 5: Deep Cleaning Use a wet-vacuum with HEPA filtration to remove loosened mold and cleaning residues. This prevents spores from becoming airborne during the cleaning process.

| Cleaning Agent | Best For | Effectiveness | Safety Notes |

|---|---|---|---|

| Dish Soap + Water | Initial cleaning, all surfaces | Good for surface mold | Safest option, no fumes |

| 70% Ethanol | Metal surfaces, equipment | Excellent mold kill | Flammable, ensure ventilation |

| 1:10 Bleach Solution | Non-metal surfaces | Excellent mold kill | Never use on metal, causes corrosion |

| Quaternary Cleaners | Food-safe disinfection | Good ongoing prevention | Follow label dilution rates |

"Mold in Walk In Fridge" Emergency Cleanup Checklist

When mold appears suddenly, having a systematic approach prevents panic and ensures thorough remediation. We've developed this checklist based on successful cleanups across our service territories from Dallas to New York.

Pre-Cleanup Preparation:

- [ ] Don full PPE before entering contaminated area

- [ ] Shut down electrical power to prevent shock hazards during wet cleaning

- [ ] Document mold extent with photos for insurance/regulatory purposes

- [ ] Gather cleaning supplies: soap, ethanol, rags, wet-vac, HEPA filters

Cleaning Sequence:

- [ ] Remove all contaminated food and packaging materials

- [ ] Wipe surfaces top-down using soap and water solution

- [ ] Apply appropriate disinfectant based on surface material

- [ ] Vacuum with HEPA-filtered equipment to capture loose spores

- [ ] Dry all surfaces completely using fans or dehumidifiers

Post-Cleanup Verification:

- [ ] Monitor humidity levels with calibrated hygrometer

- [ ] Check for persistent musty odors indicating remaining mold

- [ ] Inspect hidden areas behind equipment and in corners

- [ ] Document completion with staff sign-off

For detailed cleaning protocols, refer to our guide on How to Clean a Cooler: 4 Methods That Guarantee Results, which covers specialized techniques for different types of contamination.

Post-Removal Verification: Keeping "Mold in Walk In Fridge" from Re-Emerging

Successful mold removal requires verification that the problem is truly resolved. We recommend a multi-step verification process to ensure mold in walk in fridge issues don't return.

Humidity Monitoring: Maintain a humidity log for at least two weeks post-cleanup. Levels should stay consistently below 60% to prevent re-growth. Any spikes above 70% indicate ventilation or moisture control problems that need immediate attention.

Spore Testing: Consider professional air and surface sampling to verify mold levels have returned to normal. While not always necessary for small cleanups, testing provides peace of mind for extensive remediation projects.

Odor Assessment: Persistent musty odors often indicate hidden mold that wasn't addressed during cleaning. Trust your nose - if the cooler still smells moldy after thorough cleaning, additional investigation is needed.

Staff Training: Ensure all personnel understand signs of mold recurrence and reporting procedures. Early detection prevents small problems from becoming major remediation projects.

Preventing Mold in a Walk-In Fridge Forever

The good news? Once you understand what causes mold in walk in fridge problems, preventing them becomes straightforward. After helping facilities from coast to coast tackle mold issues, we've learned that smart prevention beats expensive remediation every single time.

Think of mold prevention like maintaining your car - a little regular attention prevents major breakdowns down the road. The key is creating an environment where mold simply can't get a foothold in the first place.

Humidity control forms your first line of defense. Keep relative humidity at 60% or below whenever possible. This might sound technical, but it's actually simple - install a basic hygrometer (humidity gauge) and check it regularly. When humidity creeps above 70%, you're in the danger zone where mold can establish itself within 24-48 hours.

Quarterly deep cleaning prevents mold food sources from accumulating. Even if everything looks clean, microscopic food particles and organic residues build up over time. Schedule thorough cleanings every three months, covering all surfaces, equipment, and those hard-to-reach corners where problems often start.

Modern technology offers some impressive solutions too. UV air purification systems like Bluezone technology kill 99.9% of mold and bacteria right in the air stream. These systems work continuously, zapping spores before they can settle and start growing on surfaces.

Door protocols make a bigger difference than most people realize. Every time someone opens the door, warm humid air rushes in and has to be cooled down - creating condensation in the process. Train your team to gather what they need before opening doors and close them quickly. Vinyl strip curtains in high-traffic areas can cut air exchange by up to 80%.

Smart storage practices also help tremendously. Use FIFO rotation (First-In-First-Out) to prevent food from spoiling and becoming mold food. Install slotted shelving that promotes airflow instead of solid shelves that trap moisture. Always maintain clearance around stored items so air can circulate freely.

Spill, Leak & Condensation Management

Here's the truth about mold in walk in fridge prevention: every single drop of water that sticks around becomes potential mold habitat. It sounds dramatic, but we've seen major mold problems start from something as simple as a clogged drain or ignored spill.

Drain pan maintenance should happen weekly, not when you remember. Those evaporator drip pans collect condensation constantly, and when they clog or overflow, you've got standing water - mold's favorite hangout spot. Use compressed air to clear blocked drain lines, and make sure pans tilt properly so water flows out instead of pooling.

The immediate response rule is simple: clean spills within minutes, not hours. We've watched facilities where staff work around puddles for days, then wonder why mold appears. Train everyone to treat spills like emergencies, because in terms of mold prevention, they really are.

Hidden leaks cause some of the worst problems because you don't see them until mold starts growing. Schedule regular inspections of water lines, ice makers, and drainage systems. That slow drip behind equipment or under flooring creates perfect conditions for extensive mold growth that's expensive to remediate.

Hygrometer alarms provide early warning when conditions shift toward mold-friendly territory. Set alerts for humidity above 65% - this gives you time to investigate and fix problems before mold gets established. Modern systems can even send alerts to your phone, so you catch issues even when you're not on-site.

For detailed maintenance schedules and best practices, check out our comprehensive guide on maintaining and cleaning your mortuary cooler for longevity.

Staff Training & SOPs

Even the best equipment and protocols don't work if your team doesn't understand or follow them. We've seen facilities with excellent mold prevention systems fail because staff weren't properly trained on the "why" behind the procedures.

Entry limitations serve dual purposes - they control humidity infiltration and prevent CO₂ buildup that can be dangerous. OSHA's safety limit of 5,000 ppm CO₂ can be reached in about 55 minutes with four people in a closed cooler. We recommend limiting occupancy to a maximum of 2 person-hours per 24-hour period.

Cleaning schedules need to be documented, not just discussed. Start with quarterly deep cleans and adjust frequency based on your usage patterns and contamination risk. Maintain cleaning logs so you can prove consistency to health inspectors and catch any gaps in your routine.

Inspection checklists turn routine entries into prevention opportunities. Train staff to quickly check for condensation, verify fans are running properly, inspect door seals, and look for standing water on every visit. When everyone becomes a mold detective, problems get caught early.

PPE training ensures everyone knows the difference between routine cleaning and mold remediation. Standard disposable gloves and lab coats work fine for regular maintenance, but if you find actual mold growth, respirators and eye protection become necessary for safety.

The most important training element? Help your team understand that mold prevention protects their workplace and job security. Health code violations can shut down operations, and nobody wants to work around mold contamination. When everyone sees prevention as protecting their own interests, compliance becomes much easier.

Legal, Health & Business Implications

The moment mold in walk in fridge systems appears, you're not just dealing with a cleaning problem - you're facing potential legal, health, and financial consequences that can seriously impact your business.

FDA Food Code compliance becomes your first concern. Health inspectors don't take mold lightly, and for good reason. The Food Code specifically requires easily cleanable surfaces and proper temperature control in commercial refrigeration. When inspectors find mold growth, they can issue immediate violations and closure orders. We've seen facilities shut down within hours of a failed inspection.

The health risks are real and varied. Mold exposure triggers allergic reactions and asthma attacks in sensitive people. Some mold species produce mycotoxins that cause food poisoning or more serious health effects. Black mold (Stachybotrys) presents the most serious threat, potentially causing stachybotrystoxicosis - a condition that can lead to serious respiratory problems.

Your financial exposure extends far beyond the initial cleanup costs. Professional mold remediation for commercial refrigeration units typically costs more than $50,000. That's just the beginning. Add lost inventory, business interruption costs, and potential liability claims from affected customers or employees, and you're looking at six-figure losses.

OSHA regulations add another layer of complexity. Worker safety rules apply to any mold cleanup activities in your facility. You must provide appropriate PPE and training for staff involved in remediation. Skipping these requirements can result in additional citations and fines that compound your existing problems.

Insurance coverage for mold damage remains limited at best. Many policies exclude mold damage entirely or cap coverage at amounts far below actual remediation costs. The key is documenting all prevention efforts and maintenance activities before problems occur. Insurance companies look more favorably on claims when you can demonstrate proactive maintenance.

Reputation damage spreads faster than mold itself in today's social media environment. A single contamination event can damage your reputation for years, affecting customer trust and business relationships. The funeral industry especially depends on trust and professionalism - mold problems can undermine both.

The good news? Prevention costs a fraction of remediation. Investing in proper humidity control, regular maintenance, and staff training protects you from all these consequences while keeping your operation running smoothly.

Frequently Asked Questions about Walk-In Fridge Mold

Why does mold grow even at 38°F?

Here's something that surprises many people: mold in walk in fridge systems can thrive even at typical refrigeration temperatures. While most folks assume cold kills everything, mold is surprisingly resilient and can grow at temperatures well below what you'd expect.

The real culprit isn't temperature - it's moisture. When relative humidity climbs above 70%, mold spores can germinate and establish colonies even in your chilly walk-in cooler. Cold temperatures do slow down the growth rate, but they don't stop it entirely.

What makes this worse is that cold surfaces actually help mold grow in a sneaky way. When warm, humid air hits those cold walls and shelves, it creates condensation - basically free water for mold to drink. It's like providing room service for unwanted guests.

Think of it this way: your walk-in cooler is like a giant dew collector every time someone opens that door. The temperature difference between the warm kitchen air and cold interior creates the perfect storm for moisture buildup.

When should I call a professional remediator?

Sometimes DIY just isn't enough, and knowing when to call in the pros can save you thousands in the long run. We've seen too many facilities try to handle major mold problems themselves, only to make things worse.

Call professional mold remediation services when you're dealing with more than 10 square feet of visible mold. That's roughly the size of a standard door - if your mold problem is bigger than that, you need specialized help.

If mold in walk in fridge keeps coming back despite your best cleaning efforts, there's likely a hidden source you're missing. Professional remediators have thermal imaging cameras and moisture meters that can find problems behind walls or in HVAC systems that you'd never spot.

Here's a red flag that always warrants professional help: staff complaining about breathing problems, headaches, or allergy symptoms when they enter the cooler. Mold exposure can cause serious health issues, and some people are more sensitive than others.

Local health inspectors sometimes require professional remediation for compliance, especially if you've had violations or if the contamination is extensive. Don't risk your operating license trying to save a few dollars on cleanup costs.

Professional services bring equipment most facilities don't have - negative air machines, industrial dehumidifiers, and specialized antimicrobial treatments that actually work long-term.

What humidity level should my walk-in target?

The magic number for mold in walk in fridge prevention is 60% relative humidity or lower. This isn't just a suggestion - it's based on scientific research showing that mold struggles to establish colonies below this threshold.

Many facilities can maintain humidity levels between 30-50%, which creates an environment where mold simply can't get a foothold. It's like making your cooler inhospitable to unwanted microbial visitors.

Now, we understand that some stored items make this tricky. Fresh produce, floral arrangements, and certain specialty items need higher humidity to stay fresh. When you can't get below 60% humidity, you'll need to compensate with other prevention strategies.

Focus on improved air circulation when humidity runs high - get those fans moving air around every corner. Increase your cleaning frequency and consider UV air purification systems to kill spores before they can settle and grow.

The key is monitoring your humidity continuously, not just checking it once in a while. Install a good hygrometer with alarms so you know immediately when conditions favor mold growth. Prevention is always cheaper than remediation.

Conclusion & Next Steps

Mold in walk in fridge systems might seem like an impossible problem to solve, but it's actually quite manageable when you know what you're dealing with. The secret lies in understanding that mold prevention costs a fraction of what remediation does - and it's much less stressful too.

Here at American Mortuary Coolers, we've been helping facilities tackle these challenges for years across our service territories. From our home base in Johnson City, TN to busy operations in Atlanta, Chicago, Columbia, Dallas, Los Angeles, New York, and Pittsburgh, we've seen just about every mold scenario you can imagine. The good news? Most problems have straightforward solutions.

Our custom-built coolers aren't just boxes with cooling units. We design them with mold prevention in mind - proper drainage systems, optimal airflow patterns, and surfaces that actually stay clean instead of harboring growth. When you're dealing with sensitive applications like mortuary work, these details matter more than you might think.

The facilities that succeed long-term are the ones that treat mold prevention as an ongoing process, not a one-time fix. They invest in proper humidity control, stick to consistent cleaning schedules, and train their staff to spot problems early. It's like maintaining a car - a little attention now prevents major repairs later.

We deliver our solutions directly across the contiguous 48 states because we understand that mold in walk in fridge problems don't wait for convenient timing. Whether you're dealing with humid summers in the Southeast or dry winters in the Southwest, each climate brings its own challenges.

For those working in mortuary applications specifically, our detailed guide Keep It Clean: Essential Tips for Maintaining Your American Mortuary Cooler covers the unique maintenance requirements your facility faces.

Your next steps are straightforward: Start by checking your current humidity levels and cleaning protocols. If you find mold, address it immediately using the methods we've outlined. Then focus on the prevention strategies that make sense for your operation and budget.

Don't let mold in walk in fridge systems become the problem that keeps you up at night. The combination of proper equipment design, smart maintenance practices, and staff training creates an environment where mold simply can't establish itself.

Contact us today if you'd like to discuss how our custom cooling solutions can help you achieve permanent mold elimination. Our experience across diverse climates and applications means we've probably solved a problem similar to yours before. The best time to address mold problems is before they start - schedule your assessment today and take that first step toward a cleaner, safer operation.