How to Improve Your Mortuary Cold Room Doors Service Maintenance in 7 Days

Why Mortuary Cold Room Doors Service Maintenance Is Critical

Mortuary cold room doors service maintenance is the foundation of reliable body preservation and regulatory compliance. Without proper maintenance, these critical barriers can fail, leading to temperature fluctuations, product spoilage, and potential health code violations.

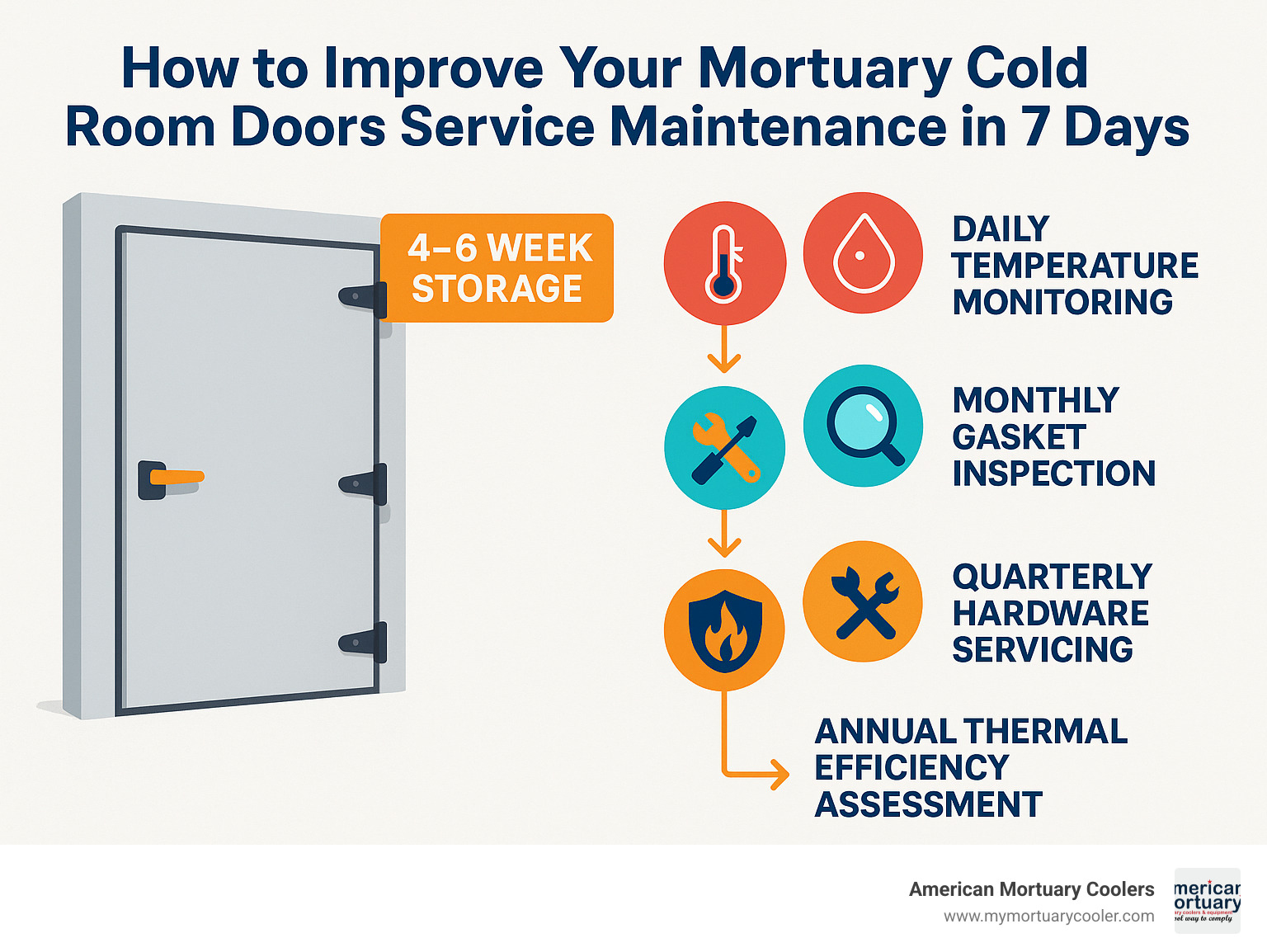

Essential Maintenance Schedule:

- Daily: Visual inspection of door seals and operation

- Weekly: Temperature log review and safety feature testing

- Monthly: Gasket inspection and cleaning protocol

- Quarterly: Hardware lubrication and sensor calibration

- Annually: Complete thermal scan and component replacement planning

Your mortuary cold room doors maintain temperatures between 2°C and 6°C with minimal variation of ±1°C. This precision requires doors that function as perfect thermal barriers. When gaskets fail or hinges misalign, your refrigeration system works harder, energy costs spike, and you risk losing the dignified storage conditions families expect.

Quality mortuary cold room doors can reduce energy consumption by up to 25% compared to older equipment. They typically pay for themselves within 3-5 years through energy savings and reduced maintenance costs. The key is consistent, preventive care.

Modern mortuary facilities store bodies for four to six weeks under correct conditions. Every component - from magnetic gaskets to OSHA-compliant release handles - must work flawlessly. A single door failure can compromise an entire storage system.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with experience in mortuary cold room doors service maintenance across funeral homes and morgues nationwide. My team has helped hundreds of facilities optimize their door maintenance programs to ensure reliable, energy-efficient operations that honor the families they serve.

Quick mortuary cold room doors service maintenance terms:

Why Mortuary Cold Room Doors Matter

Think of mortuary cold room doors as the silent guardians of dignity and compliance. These precision-engineered barriers maintain the exact conditions needed for respectful body storage, keeping that critical 2°C to 6°C range without fail.

When choosing between hinged versus sliding mechanisms, consider your space and workflow. Sliding doors work beautifully in cramped facilities because they glide parallel to the wall – no swing space needed, though they require more maintenance attention. Hinged doors offer simpler operation and easier upkeep, but need adequate clearance for the door swing.

Safety can't be an afterthought. Every mortuary cold room door must include OSHA-compliant interior release handles and anti-panic hardware. These features ensure that if someone accidentally gets trapped inside, they can exit immediately – meeting OSHA 1910.145 requirements and giving everyone peace of mind.

The R-value of your insulation directly impacts both your energy bills and temperature consistency. High-quality polyurethane insulation with proper thermal breaks prevents heat transfer and stops condensation from forming. Magnetic gaskets create those crucial airtight seals that keep warm air out and maintain the sterile environment families expect.

The Critical Barrier Between Compliance & Compassion

Thermal-break frames solve condensation and ice buildup problems through heated elements that keep surface temperatures above the dew point, eliminating moisture problems before they start.

Anti-panic hardware goes beyond basic safety requirements. Modern systems include audible alarms, LED indicators, and emergency communication features that activate when doors stay open too long, creating a safe work environment where staff can focus on serving families with dignity.

The energy savings from quality doors can be substantial – thousands of dollars annually for busy facilities. Doors with tight seals and efficient opening mechanisms minimize heat loss, while superior insulation reduces energy transfer. Most facilities see complete return on investment within 3-5 years.

Materials & Insulation Standards You Should Demand

304 stainless steel construction represents the gold standard for mortuary cold room doors. This material resists corrosion, supports thorough sanitization, and maintains structural integrity despite constant temperature cycling.

Polyester-coated galvanized steel offers excellent value while delivering solid performance. The polyester coating creates a smooth, non-porous surface that prevents bacterial growth and makes cleaning protocols much simpler.

For insulation, demand 42 kg/m³ density polyurethane foam – this isn't negotiable. This specific density provides R-values exceeding 28 per 100mm thickness while ensuring long-term stability without settling or degradation. Scientific research on insulation performance confirms that proper foam density directly correlates with energy efficiency and temperature stability.

Quality mortuary cold room doors service maintenance starts with choosing the right materials and specifications from day one. When you invest in proper construction and insulation standards, you're setting the foundation for years of reliable, efficient operation.

7-Day Mortuary Cold Room Doors Service Maintenance Action Plan

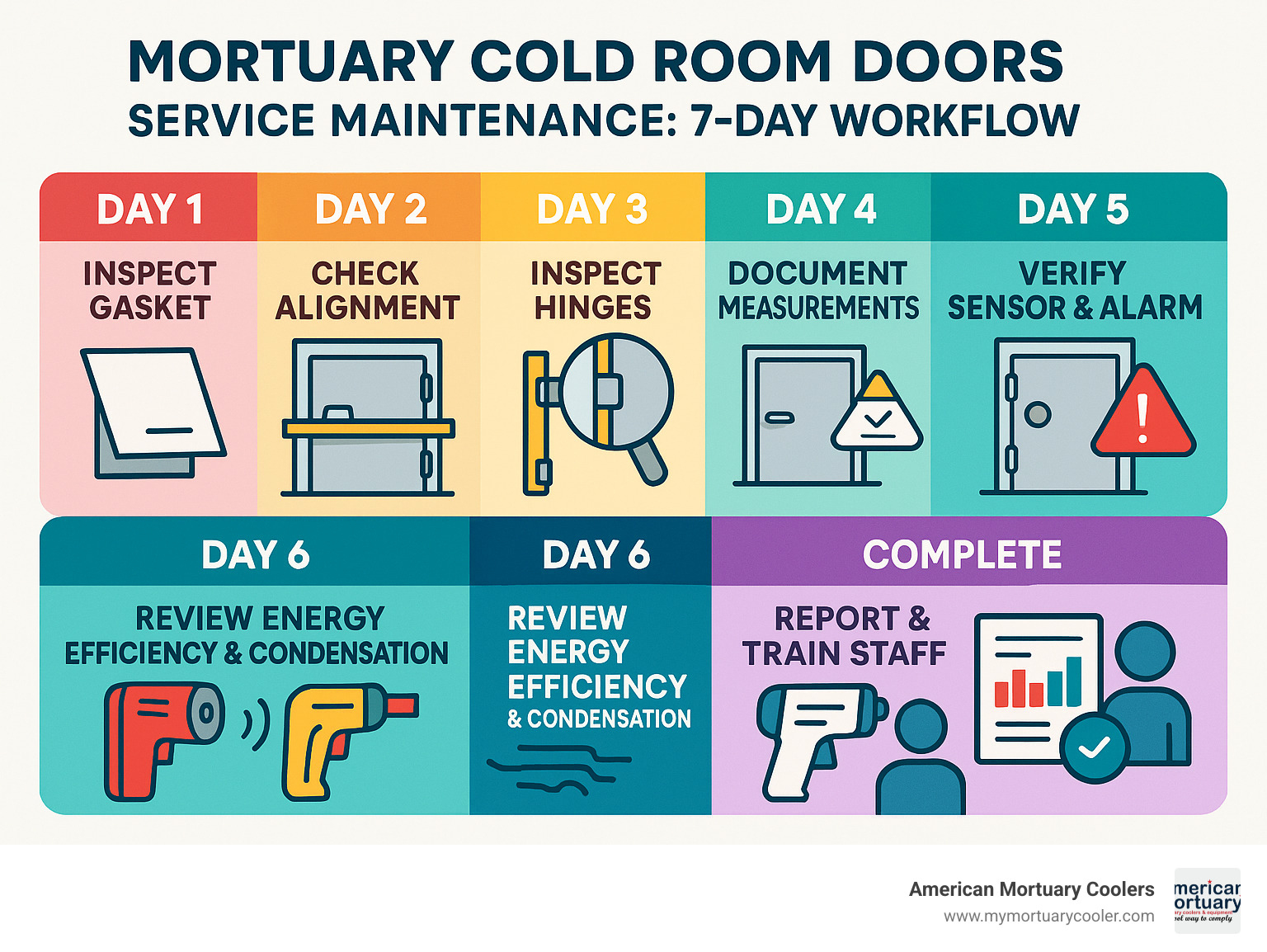

Think of mortuary cold room doors service maintenance like caring for a precision instrument. Each day of our seven-day program builds on the previous one, creating a complete picture of your door's health and performance.

This systematic approach catches small problems before they become expensive emergencies. Instead of waiting for something to break, you're staying ahead of wear patterns and potential failures. Each day focuses on specific components, using detailed checklists and specialized tools that take the guesswork out of maintenance.

Modern IoT monitoring systems can track door performance 24/7, sending alerts directly to your phone when something needs attention. Combined with proper service logs and spare parts inventory, you'll have everything needed for smooth operations.

An Essential Guide to Mortuary Cold Room Doors and Your Best Options provides the technical background that complements this hands-on maintenance approach.

Day 1 – Baseline Audit for Mortuary Cold Room Doors Service Maintenance

Start by becoming a detective. Your doors tell a story through their performance data, and Day 1 is about learning to read that story.

Temperature logging comes first. Take readings at multiple points around each door during door cycles, noting how quickly the system recovers after each opening. Document how often doors open during busy periods and how long they stay open.

The gasket inspection requires both your eyes and hands. Look for obvious cracks or tears, but also run your fingers along the seal. Feel for areas where the magnetic pull seems weak or where the gasket doesn't sit flush against the frame.

Photography becomes your best friend here. Take detailed pictures of current conditions, including any problem areas you find. These baseline images will help you track improvements and spot developing issues during future inspections.

Day 2 – Clean & Sanitize Seals and Frames

Day 2 focuses on creating the clean slate your doors need to perform their best. This isn't ordinary cleaning - mortuary environments demand specialized approaches that balance thorough sanitization with material preservation.

Food-grade detergents designed for mortuary use remove organic residues without damaging delicate gasket compounds. Regular household cleaners can actually degrade rubber seals or leave residues that attract more contamination.

Anti-microbial coatings provide ongoing protection between cleanings. These specialized treatments create invisible barriers against bacterial growth while maintaining the sterile environment families expect.

Your cleaning protocol should become second nature to staff. Document the approved products, application methods, and frequency requirements. Train everyone on techniques that clean thoroughly without compromising gasket magnetic properties or door alignment.

Day 3 – Hardware Tightening & Lubrication

Think of Day 3 as your door's spa day. All those moving parts that work silently in the background deserve some attention and care.

Hinges bear tremendous loads, especially on heavy mortuary doors. Check mounting points for any loosening or stress signs. Tighten hardware to manufacturer specifications - over-tightening can be as problematic as loose fasteners.

Sliding door systems require special attention to track alignment and roller condition. Clean tracks thoroughly before applying food-grade lubricants. Even small debris can cause binding or uneven wear that leads to premature failure.

Door handles and safety releases get tested extensively during emergencies. Ensure interior panic hardware operates smoothly with minimal force. Check that all locking mechanisms engage properly while safety features remain fully functional.

Day 4 – Gasket Testing & Replacement Schedule

Day 4 puts your gaskets through their paces with testing that reveals hidden problems before they cause temperature failures.

The pressure paper test sounds simple, but it's incredibly revealing. Close a thin sheet of paper in the gasket seal around the entire door perimeter. The paper should require consistent, moderate force to remove. Areas where it slides out easily indicate seal failure or door misalignment that needs immediate attention.

Monthly visual inspections should become routine practice. Train staff to spot early warning signs like surface cracking, magnetic weakness, or areas where gaskets don't make full contact. Catching problems early prevents emergency replacements during critical times.

Gasket replacement typically occurs every 2-3 years under normal conditions, but usage patterns and environmental factors can accelerate wear. Cold room door gaskets offers replacement options compatible with most mortuary door systems. Keep spare gaskets in inventory - waiting for shipping during a seal failure isn't an option in mortuary operations.

Day 5 – Sensor, Alarm & IoT Verification

Modern mortuary doors are smart systems that monitor themselves, but they need regular calibration to maintain accuracy and reliability.

Auto-close sensors prevent doors from staying open accidentally, but they must be positioned correctly to avoid interference with normal operations. Test sensor response times and adjust delay settings to allow adequate time for gurney movement while minimizing temperature loss.

Temperature probe calibration requires certified reference thermometers to verify accuracy. Even small calibration drift can cause temperature variations that compromise storage conditions or trigger false alarms.

Cloud-based IoT monitoring transforms door maintenance from reactive to predictive. Configure alerts for temperature deviations, extended door openings, and system malfunctions. These 24/7 monitoring capabilities provide peace of mind and immediate notification of issues requiring attention.

Day 6 – Energy-Efficiency & Condensation Review

Day 6 focuses on the invisible problems that drain energy budgets and compromise door performance over time.

Infrared thermal scanning reveals heat loss patterns that visual inspection misses completely. These scans identify insulation failures, thermal bridging, and air leakage that force refrigeration systems to work harder.

Door sweeps at floor level often get overlooked, but they're critical for preventing warm air infiltration. Check sweep adjustment and wear patterns. Proper sweeps eliminate air gaps while allowing smooth door operation.

Heater cables and tapes prevent ice formation on door frames and tracks, but they consume energy continuously. Verify proper operation and energy consumption levels. Malfunctioning heaters can waste significant energy while failing to prevent ice problems.

Day 7 – Final Mortuary Cold Room Doors Service Maintenance Report & Training

Day 7 transforms all your hard work into actionable intelligence and improved staff capabilities.

Service log updates create the permanent record that supports warranty claims, regulatory compliance, and future maintenance planning. Include photographic documentation, measurement data, and specific recommendations for addressing identified issues.

Staff training sessions ensure everyone understands their role in maintaining door performance between formal maintenance cycles. Cover daily inspection procedures, emergency protocols, and proper operation techniques that extend door life and maintain safety standards.

Statutory record keeping requirements vary by location, but thorough documentation always serves you well during inspections or insurance claims. Update maintenance records according to local health department requirements and manufacturer warranty specifications.

The continuous improvement aspect separates good maintenance programs from great ones. Review findings from all seven days to identify patterns or recurring issues that might indicate equipment upgrades or procedure modifications.

Troubleshooting Common Door Faults & Cost Impacts

When mortuary cold room doors start acting up, the problems usually announce themselves loud and clear. Ice buildup around door frames typically means your heater cables aren't working or too much humid air is sneaking in. This forces your refrigeration system to work overtime while creating dangerous conditions for staff.

Door misalignment might seem minor, but it's actually a major problem in disguise. When doors don't sit properly, gaskets can't compress evenly, which means air leaks in and temperature stability goes out the window. Misaligned doors also put extra stress on hinges and gaskets, meaning you'll be replacing parts much sooner than you should.

Fogging inside your cold rooms signals that air is infiltrating through compromised door seals, bringing moisture that can freeze into ice, encourage bacterial growth, and mess with your carefully controlled temperatures.

Hinge wear starts subtly but gets obvious fast. First, you'll notice doors feel heavier or make strange noises. Then they start sagging or feeling loose during operation. Worn hinges compromise everything from door alignment to seal integrity, and they never get better on their own.

The Definitive Guide to Mortuary Dead Body Storage Freezer Door Maintenance walks you through detailed troubleshooting procedures when these issues get complex.

Structural damage from impacts or excessive force needs immediate professional attention. A damaged door frame doesn't just look bad - it can compromise your entire insulation system and create safety hazards that affect your whole facility's operation.

Here's what these common problems actually cost when they hit:

| Door Fault | Quick Fix | Downtime Cost |

|---|---|---|

| Gasket tear | Replace gasket section | $200-500 |

| Hinge misalignment | Adjust mounting bolts | $100-200 |

| Ice buildup | Check heater cables | $150-300 |

| Handle malfunction | Replace handle assembly | $250-400 |

| Sensor failure | Recalibrate or replace | $300-600 |

The real eye-opener is energy loss from poorly maintained doors. When your mortuary cold room doors service maintenance falls behind, operating costs can spike by 15-30% annually. Regular maintenance prevents these efficiency losses while extending your equipment's lifespan and keeping those expensive emergency repair calls to a minimum.

The good news? Most of these problems are completely preventable with consistent care and attention. Catching issues early through regular maintenance saves money, prevents headaches, and keeps your facility running smoothly when families are counting on you most.

Choosing Professional Service vs In-House Teams

When it comes to mortuary cold room doors service maintenance, you're facing a choice that could impact your facility for years to come. Professional service contracts offer something invaluable - peace of mind. You get certified technicians who know these systems inside and out, guaranteed response times when things go wrong, and comprehensive warranty coverage that protects your investment.

Think about it this way: when a door fails at 2 AM on a weekend, do you want to scramble for solutions, or have a certified technician on their way within hours? Professional service providers maintain current knowledge of safety regulations, manufacturer updates, and industry best practices that keep changing. Their expertise ensures your maintenance meets OSHA requirements, health department standards, and manufacturer warranty conditions without you having to become an expert yourself.

The numbers tell a compelling story. ROI calculations for professional service typically show positive returns within 3-5 years through reduced energy costs, extended equipment life, and minimized emergency repairs. Professional maintenance also provides the documentation you need for regulatory compliance and insurance claims - paperwork that becomes critical during inspections or unfortunate incidents.

Emergency response capabilities become absolutely critical when door failures threaten storage integrity. Professional service providers maintain spare parts inventory and offer 24-hour response capabilities that minimize downtime and protect the dignity of those in your care. More info about cold room maintenance services shows the comprehensive service offerings available for mortuary cold room systems.

What to Look For in a Service Provider

ISO 9001 certification should be at the top of your checklist. This certification ensures consistent quality management and standardized service procedures. It means the provider maintains documented processes for maintenance activities, staff training, and quality control - not just winging it when they show up.

Response time guarantees protect your facility from extended downtime during emergencies. Look for providers offering 4-hour emergency response within your service area, with guaranteed technician arrival times. When you're dealing with mortuary operations, time isn't just money - it's dignity and compliance.

Spare parts inventory management ensures common components stay readily available for immediate repairs. Qualified providers maintain stock of gaskets, handles, hinges, and sensors specific to your door systems. Nothing's worse than waiting days for a simple gasket while your energy bills skyrocket.

Customer references from similar mortuary facilities provide real insight into service quality, reliability, and problem-solving capabilities. Request references from facilities with comparable door systems and usage patterns. A provider who excels with restaurant walk-in coolers might not understand the unique demands of mortuary operations.

When DIY Still Makes Sense

Daily cleaning and visual inspections can absolutely be performed effectively by trained facility staff using proper procedures and approved cleaning products. These routine activities prevent minor issues from developing into major problems, and honestly, you know your facility better than anyone else.

Simple adjustments like door alignment, gasket positioning, and basic lubrication fall within the capabilities of maintenance-trained staff. However, these activities require proper training and documentation to maintain warranty coverage. Don't let enthusiasm override expertise - know your limits.

Monthly inspection checklists help facility staff identify developing issues before they require emergency repairs. These inspections include gasket condition assessment, temperature monitoring, and operational performance evaluation. Think of it as your early warning system - catching problems while they're still manageable and affordable to fix.

Frequently Asked Questions about Mortuary Cold Room Doors

The most common questions we receive at American Mortuary Coolers revolve around maintenance schedules, safety requirements, and energy savings. After helping hundreds of funeral homes across the contiguous 48 states, we've learned that proper mortuary cold room doors service maintenance starts with understanding these fundamentals.

How often should gaskets, hinges, and handles be serviced?

Your door gaskets need attention more frequently than you might expect. Monthly visual inspections should become as routine as checking your facility's daily temperatures. Look for small cracks, tears, or areas where the magnetic seal doesn't grip properly against the door frame.

Replace gaskets every 2-3 years under normal usage conditions, but don't wait if you notice problems during monthly checks. A failing gasket can cost you hundreds of dollars in wasted energy before you even realize there's an issue.

Hinges require quarterly lubrication with food-grade lubricants specifically designed for mortuary environments. Never use standard automotive or household lubricants that could contaminate your sterile environment. Well-maintained hinges can serve your facility reliably for 15-20 years.

Annual adjustment checks ensure hinges remain properly aligned and don't develop the slight misalignments that gradually worsen over time. These small adjustments prevent major problems down the road.

Test handles weekly for proper operation and safety release function. This isn't just about convenience – it's about life safety. If a handle's safety mechanism fails or becomes difficult to operate, replace the entire handle assembly immediately. Staff safety cannot be compromised.

What safety features are mandatory for body cooler doors?

OSHA takes mortuary cold room safety seriously, and so should you. OSHA-compliant interior release handles are absolutely required on all mortuary cold room doors per OSHA 1910.145 standards. These handles must work easily from inside the cold room without any tools, keys, or special knowledge.

Think of it this way: if someone accidentally gets locked inside, they need to escape quickly and safely, even if they're panicked or unfamiliar with your facility. The handle should work intuitively under stress.

Anti-panic hardware goes beyond basic release handles. Modern systems include audible alarms that sound when doors remain open too long, LED indicators that show door status from across the room, and emergency communication systems that activate during emergencies.

NSF-7 cleanability standards govern every surface material and design feature in your cold room doors. These standards ensure you can thoroughly sanitize all door components without damaging them or leaving areas where bacteria could hide.

ADA compliance ensures accessibility for all facility staff and emergency responders. This includes proper handle heights, operating forces, and clear floor space around doors.

How does proper maintenance cut energy bills by up to 25%?

The energy savings from proper mortuary cold room doors service maintenance often surprise facility managers. Well-maintained door seals prevent warm air infiltration that forces your refrigeration system to run almost continuously.

When gaskets fail or doors become misaligned, warm humid air constantly seeps into your cold storage area. Your refrigeration system works overtime trying to remove this heat and moisture, driving up energy costs month after month.

Thermal-bridge prevention through proper insulation and frame maintenance reduces conduction heat transfer. Regular maintenance ensures your insulation stays intact and prevents thermal bridging that increases cooling loads significantly.

Efficient door operation might seem like a small factor, but it makes a huge difference. Smooth hinges, proper alignment, and reliable closing mechanisms reduce how long doors stay open during normal operations. Every second a door remains open allows heat infiltration that your cooling system must remove.

The math is straightforward: reduce heat infiltration, reduce cooling costs. Most facilities see energy savings of 15-25% within the first year of implementing proper door maintenance programs. These savings continue year after year, making maintenance programs essentially pay for themselves.

At American Mortuary Coolers, we've seen Tennessee funeral homes reduce their monthly energy bills by $200-500 just through better door maintenance. Those savings add up quickly and free up budget for other facility improvements.

Conclusion

At American Mortuary Coolers, we know that mortuary cold room doors service maintenance isn't just about keeping equipment running—it's about honoring the families who trust you with their loved ones. Our Tennessee-based team has spent years perfecting custom solutions that funeral homes across all 48 contiguous states rely on every single day.

Think about it: when you follow the 7-day maintenance program we've outlined, you're not just checking boxes. You're building a foundation of reliability that can last 15-20 years while cutting your energy bills and keeping inspectors happy. That's the kind of peace of mind that lets you focus on what really matters—serving families during their most difficult moments.

We've seen too many funeral homes struggle with emergency repairs that could have been prevented. A torn gasket here, a misaligned hinge there—these small issues snowball into major headaches. But with consistent maintenance schedules, quality replacement parts, and proper staff training, these problems become rare exceptions rather than costly disruptions.

Our service network spans from Johnson City TN to Los Angeles, from Chicago IL to Dallas TX—because we understand that mortuary equipment doesn't break down on a convenient schedule. Whether you're in Atlanta GA, Columbia SC, New York NY, or Pittsburgh PA, our team provides the ongoing support that keeps your maintenance program running smoothly.

Record-keeping might feel tedious, but it's your best friend during regulatory inspections. The systematic documentation from proper mortuary cold room doors service maintenance supports warranty claims, satisfies insurance requirements, and shows everyone—from health inspectors to grieving families—that you maintain the highest professional standards.

Planning ahead for upgrades keeps you current with safety standards and energy efficiency improvements. Our regional expertise across the Midwest, Northeast, Rocky Mountain, Southeast, Southwest, and Pacific regions means we understand local requirements and can help you modernize without breaking the bank.

The bottom line? Good maintenance isn't an expense—it's an investment in your reputation and your bottom line. More info about mortuary coolers includes everything you need to develop a customized maintenance program that ensures reliable, efficient operation for years to come.

Ready to transform your maintenance approach? Contact our team today. We'll help you create a program that protects your investment while serving families with the dignity they deserve.