Understanding Modern Cremation Technology

A human cremation machine, also called a retort or cremator, is a specialized high-temperature furnace designed to reduce human remains to bone fragments and ash through controlled combustion. These machines operate at temperatures exceeding 1,6000F and use advanced automation to ensure consistent, environmentally compliant cremation cycles.

Key Components of Human Cremation Machines:

- Primary Chamber - Where the body is placed and initial combustion occurs (1,000-1,200 b0F)

- Secondary Chamber - Afterburner that eliminates smoke and odor (1,600-1,800 b0F)

- Control System - PLC-based automation with touchscreen interface

- Refractory Lining - Heat-resistant materials that retain thermal energy

- Emission Controls - Pollution control systems meeting EPA standards

Modern cremation technology has evolved significantly from older models. Today's machines feature automated cycles that can complete cremations in 60-120 minutes, compared to older units that required 2+ hours. Advanced models can finish cycles in just 45-60 minutes, while high-volume systems process cases in as little as 20-40 minutes.

The cremation industry has accepted digital controls and remote monitoring. Remote monitoring systems allow operators to monitor cremations remotely and receive diagnostic data in real-time. This technology reduces downtime and helps facilities maintain compliance with increasingly strict environmental regulations.

For funeral homes and crematories, understanding these machines is essential for operational efficiency, regulatory compliance, and cost management. With widespread adoption across North America and around the world, modern cremation equipment represents a significant investment that requires careful consideration of capacity, technology, and long-term maintenance needs.

b0F, 3) Secondary chamber processing at 1600-1800 b0F for emission control, 4) Cooling period of 10-15 minutes, 5) Cremains processing through cremulator to create fine ash - Human cremation machine infographic " src="https://images.bannerbear.com/direct/4mGpW3zwpg0ZK0AxQw/requests/000/107/330/164/3Be2PXkVAQ4Xb1WMQm78j1oNa/543bc994980093c8f56a95f9816f028b9f1f6237.jpg"/>

Step 1: The Core Components and How They Work

Let's pull back the curtain and peek inside a human cremation machine! It might look complex from the outside, but at its heart, it's a beautifully engineered system. Every part works together to make the cremation process efficient, respectful, and very kind to our planet. It all comes down to a powerful, carefully managed combustion process.

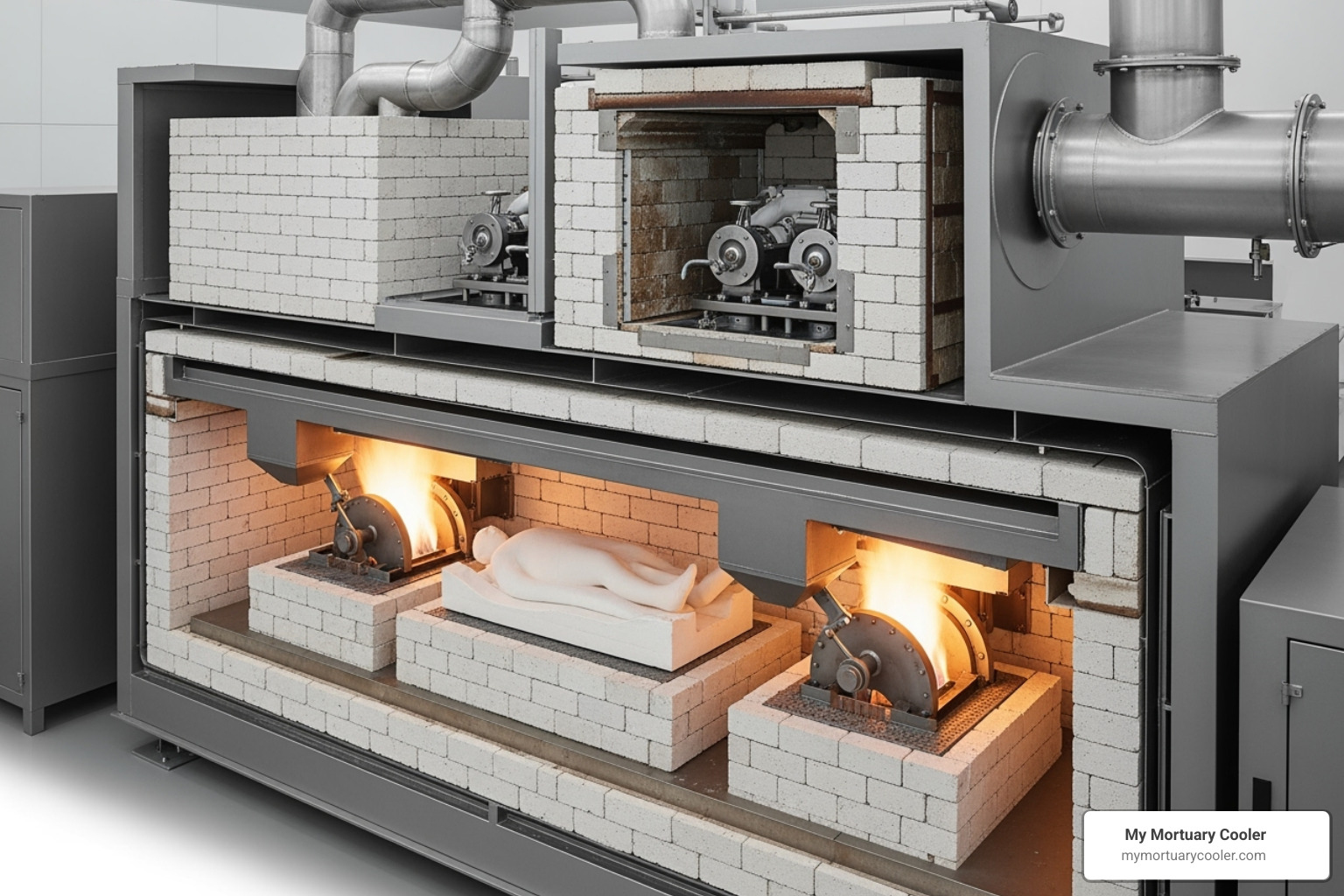

The Primary and Secondary Chambers

The journey truly begins in the primary chamber. This is where the body, usually in a simple container, is gently placed. Think of it as the main event space. Here, the initial combustion happens. Temperatures reach quite high, typically between 1,000-1,200°F (538-648°C). Many modern human cremation machines use a "hot hearth" design. This means the chamber floor itself is heated, making sure the combustion is thorough and even. Some really smart designs even have moving platforms to get the fire in just the right spots, which speeds things up!

But the job isn't done after the primary chamber. The gases and tiny bits of particulate matter from this first stage then move into the secondary chamber. You might hear this called the afterburner – and for good reason! This is where the magic of emission control really shines. The temperatures here are much, much hotter, soaring to 1,600-1,800°F (871-982°C). This extreme heat, combined with a vital retention time (about 1-2 seconds), makes sure that any smoke, odors, or remaining particles are completely destroyed. What's left are clean gases ready to exit through the exhaust stack, ensuring we protect our environment.

Refractory, Burners, and Controls

Now, how does a human cremation machine handle such incredible heat without melting down? That's where the refractory lining comes in. Think of it as the machine's super-tough, heat-resistant skin. These special materials line the chambers, acting like super-insulation. They do two big jobs: first, they keep the heat inside where it belongs, which saves energy. Second, they protect the machine's outer shell from getting too hot. This robust construction is key for heat retention, ensuring a long-lasting, reliable machine.

All that heat has to come from somewhere, right? That's the job of the burner system. Most modern human cremation machines run on either natural gas or propane. These burners are powerful, designed to create intense, focused heat. Many units use clever modulating process burners. This means they can precisely adjust the flame, giving perfect temperature control and making sure fuel is used as efficiently as possible. This smart approach boosts fuel efficiency and saves on operating costs.

Finally, pulling all these amazing parts together is the control panel. This isn't just a few buttons; it's the brain of the whole operation! Inside, there's a sophisticated PLC (Programmable Logic Control) system. This smart system orchestrates every single step, from starting the burn to the cool-down phase. It manages the automated cycles, making sure everything happens consistently, safely, and efficiently. This level of automation means less guesswork for operators and fewer chances for mistakes. It's about making a complex process smooth and worry-free.

Step 2: Key Features and Specifications of a Human Cremation Machine

When you're shopping for a human cremation machine, it's like choosing the right tool for any important job – you need to match the equipment to your specific needs. The key specifications that matter most include cycle time, capacity, fuel efficiency, and physical footprint.

Think of it this way: a small funeral home might need a reliable workhorse that handles a few cases per day, while a busy crematory requires a high-performance machine that can process case after case without missing a beat.

| Feature | Standard-Volume Machine | High-Volume Machine |

|---|---|---|

| Cycle Time | 100-150 minutes | 45-70 minutes |

| Capacity | 750-1000 lbs | 1000-1200 lbs |

| Burn Rate | 150-200 lbs/hr | 300-400 lbs/hr |

| Fuel Type | Natural Gas or Propane | Natural Gas or Propane |

| Footprint | Approx. 13' L x 5' W | Approx. 14' L x 6.5' W |

| Daily Output | 4-6 cases | 6+ cases |

Understanding Cremation Cycle Time and Capacity

The cremation cycle time is probably the most important number you'll look at when evaluating machines. This tells you exactly how long each cremation takes from start to finish. Modern technology has made incredible improvements here – where older machines might take 2+ hours, today's efficient units work much faster.

Standard machines average around 100-150 minutes per cycle, which works well for facilities with moderate volume. But if you need speed, high-efficiency models can complete a full cycle in just 45-60 minutes. Some high-volume systems can process cases in as little as 20-40 minutes.

Capacity is equally important – this is the maximum weight your machine can handle per cremation. Most modern human cremation machines can accommodate anywhere from 750 lbs up to 1,200 lbs. Standard machines handle 750+ lbs comfortably, while heavy-duty models can manage up to 1,200 lbs.

These two numbers work together to determine your daily throughput. High-throughput machines are specifically designed for 6+ cremations per day, making them perfect for busy operations that need consistent, reliable performance.

Evaluating Fuel Efficiency and Emissions

Most human cremation machines run on either natural gas or propane, each with specific pressure requirements. Natural gas typically needs 12-15" W.C., while propane operates at 10-14" W.C. Your choice often depends on what's available at your location and local utility costs.

Modern machines are engineered for impressive fuel efficiency. They achieve this through advanced burner designs, superior refractory insulation, and smart features like recirculated or pre-heated combustion air. Modulating process burners give you precise temperature control while using fuel more efficiently than older, simpler systems.

But efficiency isn't just about saving money on fuel – it's about environmental responsibility too. Every reputable human cremation machine comes equipped with sophisticated Pollution Control Systems that ensure complete combustion in the secondary chamber. This eliminates smoke and odor before anything reaches the atmosphere.

These systems must meet strict EPA requirements and local regulations. Many machines include opacity sensors that continuously monitor emissions to ensure you stay in compliance. Features like these aren't optional extras – they're essential for operating any modern crematory legally and responsibly.

The bottom line? Today's machines deliver both the performance you need and the environmental compliance your community expects.

Step 3: The Role of Modern Technology and Automation

Technology is changing every industry, and the cremation sector is no exception! Modern human cremation machines are far more than just furnaces. They are sophisticated pieces of equipment that use cutting-edge technology. This leads to improved control, amazing efficiency, and top-notch safety.

How Automation and Touchscreens Simplify Operations

Imagine a machine that almost runs itself. That's what PLC (Programmable Logic Control) operating systems bring to the table. These are like the clever brains inside the machine. They handle everything from start to finish, guiding operators with ease.

Thanks to friendly HMI (Human Machine Interface) touchscreens, operating these machines is super simple. You get a "one-step automatic operation" that lets you use "Set Point Programming." This means no more fiddling with old-fashioned timers or guessing temperatures. It takes all the hard work out of the process.

This amazing level of automation does wonders. It greatly cuts down on mistakes made by people. This leads to very consistent results every single time. It also makes things much easier for your team. Staff training becomes simpler, and your operators can work more smoothly. They can then focus on other important tasks, knowing the machine is doing its job perfectly. Plus, these automated cycles, including cool-down, follow precise steps, making the entire process reliable and safe.

The Benefits of Remote Diagnostics and Data Management

Modern tech doesn't just make daily work easier. It also gives us powerful tools for keeping machines running smoothly. Think about remote diagnostics and online monitoring. These are now common features.

Remote monitoring systems are fantastic examples. They let experts check on the cremation unit from anywhere with internet access. This means they can offer help during a cremation or even figure out what's wrong without having to be there in person. This capability really helps to reduce downtime. It means problems can be fixed faster, often before they become big issues. It helps with proactive maintenance, keeping everything in tip-top shape.

On top of that, these advanced systems are great at data logging. Those digital touchscreens can remember all sorts of important details about each cremation. This information can be easily moved to a computer or even your phone with a simple flash drive. This recorded data is priceless! It helps with compliance records, showing that you're following all the rules. It also lets you look back at how things are working. It creates a clear, traceable history for every cremation. This brings both peace of mind and openness to how you operate.

Step 4: Environmental, Regulatory, and Safety Compliance

When we talk about operating a human cremation machine, it's not just about how fast or efficiently it works. It's also deeply about doing things right right by our environment, right by the law, and especially right by the wonderful people who operate these machines every day. We understand these standards are crucial for trust and for keeping everyone safe.

Meeting Environmental and Air Quality Standards

Caring for our planet is a big deal, and it's something modern cremation technology takes very seriously. Remember the two-chamber system we talked about? That's our secret weapon for pollution control! It ensures that everything burns completely, getting rid of smoke and odors before anything leaves the machine. The secondary chamber heats things up super hot, between 1,600-1,800 b0F, holding the gases there for a bit to make sure they're completely clean.

Many advanced machines have opacity sensors. Think of these as eyes constantly watching the air leaving the stack. They help ensure compliance with strict federal, state, and local EPA regulations. Facilities usually need specific air permits to operate, and even the design of the exhaust stack matters. In addition, many operators align with environmental management frameworks such as ISO 14001:2015 to strengthen their environmental stewardship.

Ensuring Operator Safety and Equipment Certification

The safety of the people working with these machines is always a top priority it's non-negotiable. Modern human cremation machines are packed with features to keep operators safe. For instance, automated hydraulic doors mean no heavy lifting or strain, protecting against common workplace injuries. There are also vital safety interlocks that ensure the machine won't start or operate unless everything is safe. For example, the burners won't ignite unless all flame safety checks pass, and there are emergency stops placed where they're easy to reach in a hurry.

Beyond these built-in features, look for equipment certification. Many units are UL Listed, which means Underwriters Laboratories has evaluated them for safety. This certification shows they meet recognized national safety standards. But technology is only half the story. Proper staff training, adherence to OSHA compliance, and the use of appropriate PPE create the safest possible working environment.

To stay completely up-to-date and informed on industry standards, see the Cremation Association of North America a fantastic resource for best practices and regulatory updates.

Step 5: Maintenance, Costs, and Post-Cremation Processing

Investing in a human cremation machine is a significant decision, and understanding the long-term aspects of maintenance and cost, as well as the final steps of the cremation process, is crucial. It's not just about today; it's about making a choice that supports your facility efficiently for years to come.

Understanding the Costs of a Human Cremation Machine

When you're considering adding a human cremation machine to your facility, it's a big step! And like any major investment, understanding the financial picture is key. The initial investment for a machine can vary quite a bit, sometimes from US$45,000.00 to US$200,000.00. But that's just the beginning, as they say!

You'll also need to factor in installation costs, which can cover everything from getting the machine delivered by truck and crane, to setting it up with all the right utilities, and even securing those important air permits. These are essential steps to get your new equipment up and running smoothly.

Once installed, operating costs will primarily include fuel consumption (whether you use natural gas or propane) and electricity. These expenses can fluctuate based on your local utility rates, how efficient your specific machine is, and of course, how many cremations you perform. To help keep these costs in check, we always recommend regular Preventative Maintenance Inspections (PMI). Annual inspections are a smart way to guard against unexpected service issues and downtime, which ultimately helps extend your machine's lifespan and optimizes those daily operational expenses. We're here to help our clients carefully evaluate the OPEX (Operational Expenditure) versus CAPEX (Capital Expenditure) model to ensure you make a sound financial decision.

Essential Maintenance and Post-Cremation Processing

Just like a car needs its oil changed, a human cremation machine needs diligent maintenance to keep it running safely and efficiently. The refractory lining, which bravely endures those extreme temperatures, will eventually need care and sometimes replacement.

Things like hearth replacement, in particular, could be a time-consuming process with older machines, often requiring jackhammers, specialized labor, and lengthy curing times. However, we're seeing exciting innovations in the industry, like modern modular hearth tile systems. This advancement has dramatically simplified the process, allowing for a full hearth replacement in as little as one day, without the need for curing or dry-out cycles! This significantly reduces downtime and helps keep your operations running smoothly. Beyond major repairs, annual service and inspections are vital to ensure your machine remains safe, efficient, and compliant with all regulations.

Once the cremation cycle is complete, the remaining bone fragments and ash are carefully collected from the primary chamber. These fragments are then transferred to a specialized piece of equipment called a cremulator. A cremulator is designed to gently grind these bone fragments into a fine, consistent powder, which is then placed into an urn. This step ensures that the final cremated remains are uniform and respectful. Additionally, some facilities use metal recovery processors to separate and reclaim any non-combustible metallic implants or medical devices that may have remained after the cremation process. It's a thorough and respectful end to the entire process.

Frequently Asked Questions about Human Cremation Machines

We know you might have some questions about how these incredible machines work, and we're here to help clarify! Let's explore some of the most common inquiries we receive about human cremation machines.

What is the average time for a single cremation?

It's a great question, and the answer can vary a bit, but generally, a modern human cremation machine is quite efficient. Most cremation cycles typically take anywhere between 60 and 120 minutes. Think of it like cooking – the exact time depends on a few factors! These include the specific model of the machine, the weight of the individual, and even the type of container used for the cremation.

What's really exciting is how far technology has come. Many high-efficiency models can now complete a full cycle in a remarkable 45-60 minutes. And for facilities with a very high volume, some specialized systems can even achieve speeds of 20-40 minutes per cremation. It's all about finding the right machine to match your operational needs and ensuring consistent, respectful service.

How hot does a human cremation machine get?

You might imagine it gets pretty warm in there, and you'd be right! A human cremation machine operates at incredibly high temperatures, which is essential for the process.

The journey starts in the primary chamber, where the body is placed. Here, temperatures typically range from 1,000-1,200°F (538-648°C). But that's not the hottest part! To ensure everything is completely consumed and to eliminate any smoke or odor, the gases and particulates then move into the secondary chamber, often called the afterburner. This chamber reaches even more extreme temperatures, operating consistently at 1,600-1,800°F (871-982°C). These intense temperatures are key to maintaining both efficiency and environmental responsibility.

How are emissions controlled during cremation?

This is a fantastic and very important question! Protecting our environment is a top priority, and modern human cremation machines are designed with sophisticated systems to control emissions.

The secret lies in a clever two-stage combustion process. After the initial combustion in the primary chamber, all the gases and any tiny particles are immediately routed into that super-hot secondary chamber, or "afterburner," we just talked about. Here, they're exposed to intense heat for a specific amount of time – usually a quick 1-2 seconds. This intense heat and retention time work together to destroy any remaining smoke, odor, or harmful particulate matter.

Only after this thorough cleaning process are the now-clean gases released safely through the exhaust stack. Many machines also come equipped with opacity sensors, which constantly monitor these emissions in real-time. This ensures that every cremation adheres to strict environmental regulations and maintains the highest standards for air quality.

Conclusion

Understanding the human cremation machine doesn't have to be overwhelming. Throughout this guide, we've walked through every aspect of these remarkable pieces of equipment - from the dual-chamber combustion system that reaches temperatures of 1,800°F, to the sophisticated PLC controls that automate entire cremation cycles with the touch of a screen.

What stands out most is how far cremation technology has evolved. Modern machines complete cremations in 60-90 minutes instead of the 2+ hours older units required. Environmental compliance isn't an afterthought - it's built into every component, from the secondary chamber that eliminates emissions to the opacity sensors that monitor air quality in real-time.

The technology powering today's cremators truly makes a difference in daily operations. Remote diagnostics mean less downtime, automated cycles reduce human error, and comprehensive data logging keeps facilities compliant with regulations. For operators, this translates to less stress and more consistent results.

Of course, the investment is significant - both in initial purchase costs and ongoing maintenance. But with proper care, including regular refractory maintenance and annual inspections, these machines serve facilities reliably for decades. Features like modular hearth systems have even simplified major maintenance tasks that once took weeks down to just one day.

At My Mortuary Cooler, we've seen how the right equipment transforms funeral home operations. As America's trusted authority in mortuary refrigeration and cremation equipment, we're committed to helping facilities find the professional-grade solutions they need. Whether you're evaluating your first cremator or upgrading existing equipment, understanding these systems is the foundation of making the right choice.

Ready to explore more essential equipment for your facility? Explore our complete guide to mortuary equipment to find how the right tools can improve every aspect of your operations.