Understanding Embalming Machine Components: The Foundation of Professional Preparation

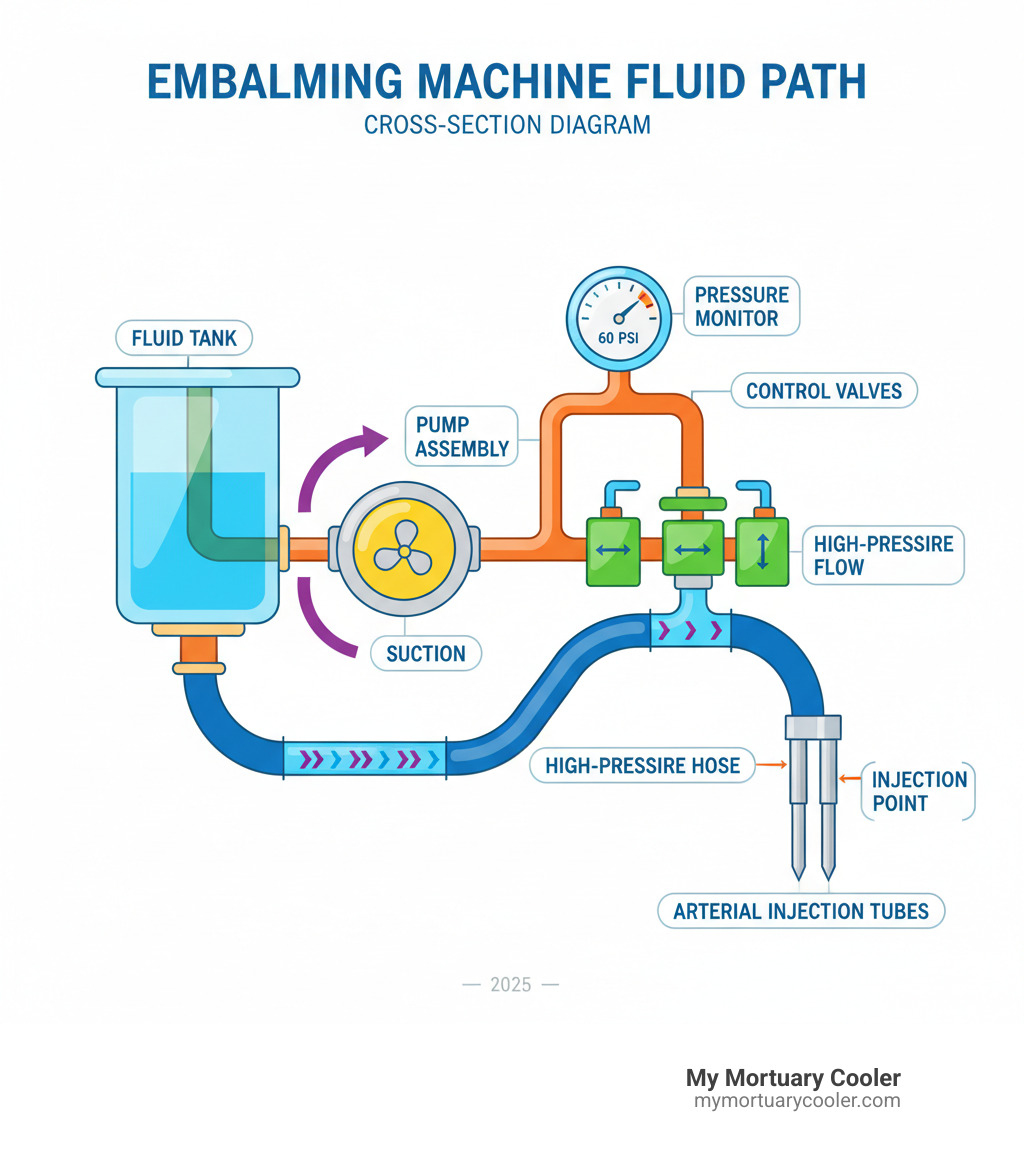

Embalming machine parts are the individual components that work together to deliver precise fluid injection during the arterial embalming process. These parts include pumps, motors, tanks, hoses, valves, gauges, filters, and control systems that ensure consistent pressure and flow rates for effective preservation.

Key embalming machine parts include:

- Pumps - Magnetic drive, belt-driven, or direct drive systems that create pressure

- Motors - Typically 1/4 to 1/2 HP units that power the pump assembly

- Tanks - Glass, stainless steel, or plastic reservoirs holding 3-4 gallons of fluid

- Hoses and Tubing - High-pressure delivery lines and clear plastic tubing

- Valves - Pressure relief, flow control, and ball valves for system regulation

- Gauges - Pressure monitors ranging from 30-100 PSI capacity

- Filters - Tank screens and port filters that prevent clogs

- Control Units - Water control systems and pressure switches

The embalming machine market has grown significantly, valued at $115.2 million in 2022 and projected to reach $158.9 million by 2030. This growth reflects increasing demand for reliable, precise equipment in funeral homes worldwide.

Modern machines feature advanced components including pulsator systems, magnetic drive pumps, and quick-connect fittings. Understanding each component helps you maintain peak performance, identify wear, and source the right replacements. Whether you're troubleshooting pressure issues or planning preventive maintenance, knowing your machine's anatomy is essential.

The Heart of the Machine: Core Components Explained

At the center of every reliable machine, you'll find three essential embalming machine parts: pumps, motors, and tanks. These components are the workhorses that handle fluid delivery, create pressure, and keep everything flowing smoothly.

At My Mortuary Cooler, we understand that your embalming machine is the foundation of your daily work. When these core components function properly, everything else falls into place.

For a complete overview of different machine types and their capabilities, check out our comprehensive guide on Embalming Machines.

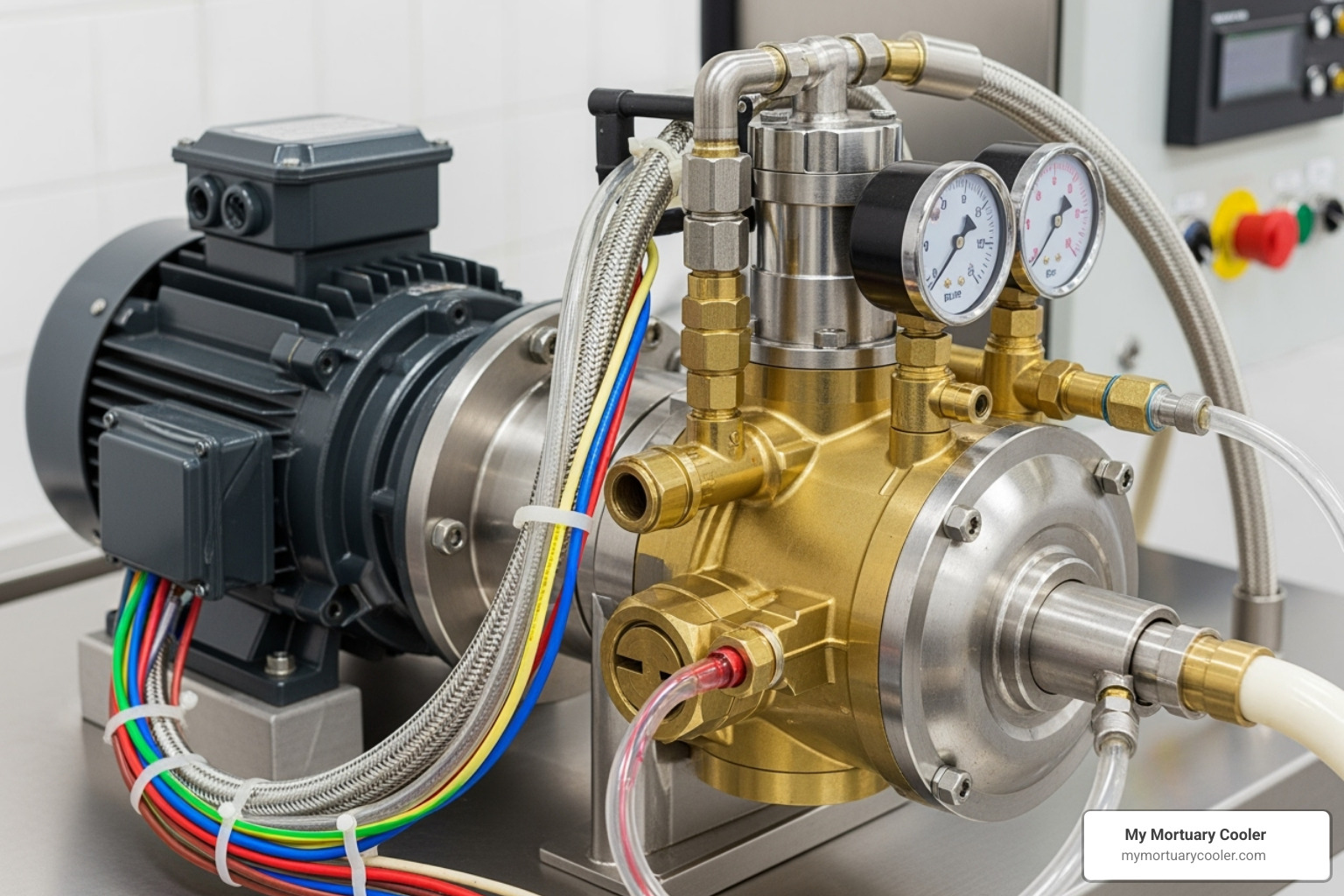

Pumps and Motors: The Driving Force

The pump and motor assembly creates the pressure that pushes embalming fluid through the arterial system. Without reliable pump performance, even the best embalming technique falls short.

- Magnetic drive pumps are a modern standard, using magnetic force to spin the impeller. This eliminates shaft seals that can leak or corrode, resulting in less maintenance and more consistent performance.

- Belt-driven pumps are a time-tested, reliable option that connects the motor to the pump via a belt system.

- Direct drive pumps couple the motor directly to the pump, creating a compact and efficient design.

Motor horsepower typically ranges from 1/4 HP to 1/2 HP, providing robust performance for maintaining steady pressure. The PSI range is crucial, with modern machines offering adjustable pressure up to 100 PSI. This flexibility lets you tailor the injection to each case. Some machines also include a pulsator feature, which mimics a natural heartbeat to improve fluid distribution.

Tanks and Reservoirs: Fluid Management

The fluid tank's design and material directly impact safety and effectiveness. This is where your embalming fluid is held before injection.

- Glass tanks offer excellent visibility for monitoring fluid levels and spotting contamination. Most hold 3-4 gallons but require careful handling.

- Stainless steel tanks provide exceptional durability and resistance to corrosion from harsh chemicals, making them a long-lasting investment.

- Plastic tanks are a practical middle ground, offering a lightweight and less breakage-prone option.

Don't overlook tank filter screens. These simple components prevent debris from entering your pump, protecting expensive parts from damage and clogs.

Here's how the three main tank materials compare:

| Material | Durability | Visibility | Chemical Compatibility |

|---|---|---|---|

| Glass | Moderate (fragile) | Excellent | Excellent |

| Stainless Steel | Excellent | Opaque | Excellent |

| Plastic | Good | Varies (translucent to opaque) | Good (depends on type) |

A reliable pump, a quality motor, and a well-designed tank system work in harmony to deliver dependable performance, making challenging cases manageable and routine procedures smooth.

A Deep Dive into Ancillary Embalming Machine Parts

While the pump, motor, and tank are the stars, the supporting cast of ancillary embalming machine parts makes the magic happen. These components—hoses, valves, gauges, filters, and connectors—guide and control the fluid on its journey.

For a comprehensive look at the tools that complement your machine, check out our guide: A Practical Guide to Embalming Tools, Find or Buy the Right Set.

Essential Embalming Machine Parts: Hoses, Tubing, and Connectors

The path your embalming fluid travels from tank to body is a critical highway demanding the right infrastructure. These parts form the lifeline of your operation.

- High-pressure hoses are robust conduits that must withstand significant pressure. When these hoses fail, your procedure halts.

- Clear plastic tubing serves as your window into the process, letting you monitor fluid flow and clarity in real-time.

- Gum rubber tubing brings flexibility and resistance to kinking and chemical damage.

- Quick-connect fittings allow you to rapidly attach and detach hoses, turning a time-consuming setup into a quick operation.

- Hose assemblies are pre-assembled units that include the hose, connectors, and sometimes stopcocks, ensuring compatibility.

- Stopcocks are precision valves integrated into the tubing that let you start, stop, or redirect fluid flow.

- Y-assemblies split fluid flow into two separate paths, allowing for simultaneous injection into multiple vessels.

These components are consumables that need regular inspection and replacement. Their integrity directly impacts the efficiency and safety of every procedure. For a deeper dive into all the supplies that support your embalming work, explore Everything You Need to Know About Embalming Supplies.

Control and Monitoring: Valves, Gauges, and Switches

Precision in embalming is everything. This network of control and monitoring parts gives you complete command over pressure and flow.

- Pressure gauges are your mission control, providing real-time feedback to prevent over- or under-injection. A fluctuating or non-responsive gauge is often the first sign of a system issue.

- Flow valves put you in the driver's seat, giving you precise control over fluid delivery rates to manage distribution.

- Relief pressure valves are a crucial safety net, automatically opening to release excess pressure and protecting both the machine and the tissues.

- Ball valves serve as reliable on/off switches for fluid paths with robust and straightforward operation.

- Pressure switches automate the process by detecting pressure thresholds, often enabling automatic shut-off features for improved safety.

- Water control units streamline your setup by consolidating water-related functions into one convenient package, keeping your prep room organized.

Maintenance, Longevity, and Troubleshooting

Embalming machines and their intricate embalming machine parts require diligent care to perform at their best. Skipping maintenance can lead to costly repairs, unexpected downtime, and inconsistent results that compromise your professional reputation.

At My Mortuary Cooler, we emphasize a proactive approach to equipment care. A smooth-running prep room is essential when families are counting on you. For insights on optimizing your entire workspace, check out The Complete Guide to Choosing the Best Prep Room.

Extending the Life of Your Machine

Regular maintenance is the secret to extending the lifespan of your embalming machine. It's about being smart with your investment and ensuring reliability.

- Daily: After each use, thoroughly flush the system with clean water to remove residual fluid and prevent chemical buildup. Wipe down the machine's exterior with a disinfectant.

- Weekly: Use a dedicated tank cleaner to remove stubborn residues. Carefully inspect all hoses and tubing for cracks, kinks, or hardening. Check and clean or replace tank filter screens and inline filters.

- Monthly: If your machine requires it, lubricate moving parts according to the manufacturer's guidelines. Check pressure gauges for accuracy and inspect the motor, pump, and electrical connections for unusual noises or wear.

Proper storage also matters. Ensure hoses are drained and stored without kinking. These practices maintain your machine's efficiency and ensure consistent pressure and flow. For comprehensive industry best practices, always refer to your machine's manual and trusted resources like the NFDA.

Recognizing Signs of Wear and When to Replace Parts

Even with meticulous care, parts will eventually wear out. Recognizing the warning signs early can prevent a crisis.

- Visual Inspection: Cracked hoses or discolored tubing are clear indicators that replacement is needed. Hardening or discoloration signals material degradation.

- Leaks: Any leak from seals or connections means pressure loss and potential chemical exposure. Check all fittings and seals regularly.

- Performance Changes: Inconsistent pressure readings suggest problems with the pump, clogged lines, or faulty gauges. If your machine struggles to maintain PSI, investigate the cause.

- Unusual Noises: A motor that whines, grinds, or vibrates excessively often indicates worn bearings or other internal problems.

- Flow Problems: Slow or inconsistent flow might indicate partial clogs, worn pump impellers, or malfunctioning flow valves. Constantly clogged filters may signal a need for more thorough tank cleaning.

When troubleshooting, start with the most common culprits like hoses and filters before moving to complex internal components.

Sourcing, Safety, and Compatibility

When it comes to embalming machine parts, knowing where to find quality components and how to handle them safely can make the difference between smooth operations and costly downtime. At My Mortuary Cooler, we've seen how the right approach to sourcing and safety keeps prep rooms running efficiently.

For insights on creating an efficient workspace, check out our guide on Embalming Stations, Durable Steel, Affordable USA.

Finding the Right Parts for Your Machine

Can you use parts from one brand on another machine? The short answer is sometimes, but it's complicated.

Manufacturer-specific parts are the norm for critical components like pumps, motors, and specialized control valves. A relief pressure valve from one brand likely won't fit another, as these parts are engineered for a specific design. Using the wrong part can damage your machine or create safety hazards.

Universal parts do exist, but they're typically consumables like standard tubing or some quick-connect fittings. Always verify that the dimensions and pressure ratings align before using a universal part.

Part numbers are your best friend when sourcing replacements. Using the specific part numbers from your manual ensures you get exactly what your machine needs.

If you encounter discontinued parts, consult the manufacturer for compatible alternatives, work with a specialized supplier, or consider upgrading if multiple critical parts are unavailable.

For reliable sourcing, we recommend working with established suppliers. The ICCFA Supply Link provides an excellent directory of trusted vendors: Find trusted suppliers via the ICCFA Supply Link.

Safety First: Handling and Replacing Components

Working with embalming machine parts involves chemical exposure and pressurized systems. Never take shortcuts on safety.

- PPE: Always wear chemical-resistant gloves, eye and face protection, and protective clothing when handling any components.

- Disconnect Power: Before touching any part, disconnect the power to prevent accidental startup and electrical shock.

- Depressurize: Slowly release any residual pressure in the lines to avoid sudden fluid sprays.

- Handle with Care: Assume every component has chemical residue. Keep spill containment materials nearby and never use bare hands.

- Proper Disposal: Contaminated hoses, filters, and other parts may qualify as biohazardous waste and must be disposed of according to local regulations.

Respect the chemicals, the pressure, and the process. Your safety protocols protect everyone in your facility.

Frequently Asked Questions about Embalming Machine Components

We get questions about embalming machine parts all the time. These are the three that come up most often.

How often should I replace my embalming machine's tubing?

Tubing replacement depends on wear, not a strict calendar. Factors include usage frequency, the type of embalming fluids used, and your maintenance practices. Look for these signs of degradation:

- Visible cracks or splits, especially near connection points.

- Hardness and inflexibility.

- Significant discoloration that doesn't wash away.

- Any signs of leakage.

Many professionals replace high-pressure hoses annually as a preventive measure. Always follow your manufacturer's recommendations.

Can I use a part from a different brand on my machine?

For most critical embalming machine parts like pumps, motors, and specialized valves, mixing brands is not recommended. These components are engineered for a specific machine's design, pressure requirements, and electrical specifications. Using an incompatible part can lead to:

- Compatibility issues: Incorrect fit, wrong pressure ratings, or mismatched electrical connections.

- Reduced performance: The machine may not operate efficiently or safely.

- Damage: The wrong part can cause a domino effect, damaging other components.

- Voided warranty: Using non-approved parts will almost certainly void your warranty.

While some generic accessories like basic tubing might be interchangeable if dimensions match, always stick with the exact part number for critical components.

What is the most common part to fail on an embalming machine?

Based on our experience, some parts tend to wear out faster than others:

- Hoses and tubing: Constant exposure to chemicals, high pressure, and physical manipulation causes them to crack, harden, or leak over time.

- Seals and gaskets: These wear down from chemical exposure, leading to leaks and pressure drops.

- Filters: Tank screens and inline filters do their job by catching debris, but they can become clogged, restricting flow and stressing the pump.

- Pump components: After years of service, impellers, bearings, or internal seals can wear out.

- Pressure gauges: These can lose calibration or get damaged, compromising the precision of your work.

Preventative maintenance is your best defense against the failure of these common parts.

Conclusion

Understanding embalming machine parts is about mastering the tools that help you serve families with dignity and professionalism. Every component, from the robust pumps to the delicate gauges, plays a crucial role in the work of preservation.

Throughout this guide, we've explored how core components work together and examined the network of ancillary parts that guide fluid with precision. We've also equipped you with practical knowledge about maintenance, troubleshooting, and safety, because a well-maintained machine is a reliable partner.

The embalming machine market continues to grow, projected to hit $158.9 million by 2030. This reflects an industry-wide investment in quality equipment that delivers consistent, reliable results.

At My Mortuary Cooler, we've built our reputation as America's trusted authority in mortuary refrigeration and professional-grade equipment. We understand that operational efficiency starts with knowing your tools. Whether you're replacing a hose or upgrading a pump, every decision impacts your ability to provide exceptional care.

Quality embalming machine parts are investments in your professional excellence. When you choose reliable parts and maintain them properly, you ensure your equipment performs flawlessly when families need you most. From our locations across the USA and Canada, we're here to support your commitment to professional preparation with equipment you can trust.

Ready to deepen your expertise? Learn more in our practical guide to embalming instruments and their uses and find how the right tools make all the difference in your daily practice.