Why the Mopec Oscillating Saw Sets the Industry Standard

The mopec oscillating saw has become the go-to tool for forensic pathologists and mortuary professionals who need precise bone cutting without soft tissue damage. Here's what you need to know:

Key Mopec Models:

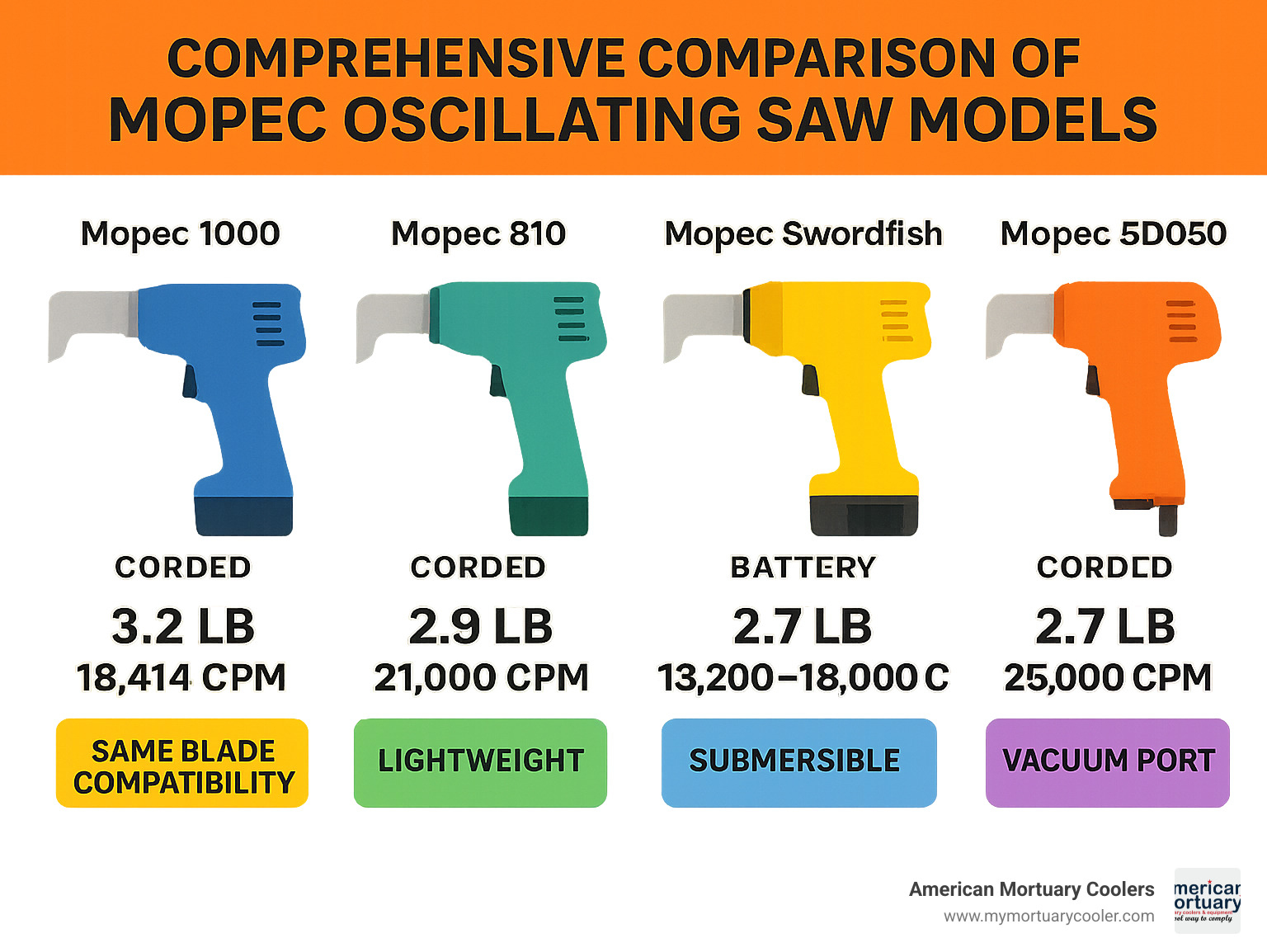

- Mopec 810 - Industry standard, 32,000 oscillations/min, 3.2 lbs

- Mopec 1000 - Budget-friendly option, same blade compatibility

- Mopec Swordfish - Submersible design, 13,200 cycles/min, 2.8 lbs

- Stryker 810 - Legacy model now manufactured by Mopec

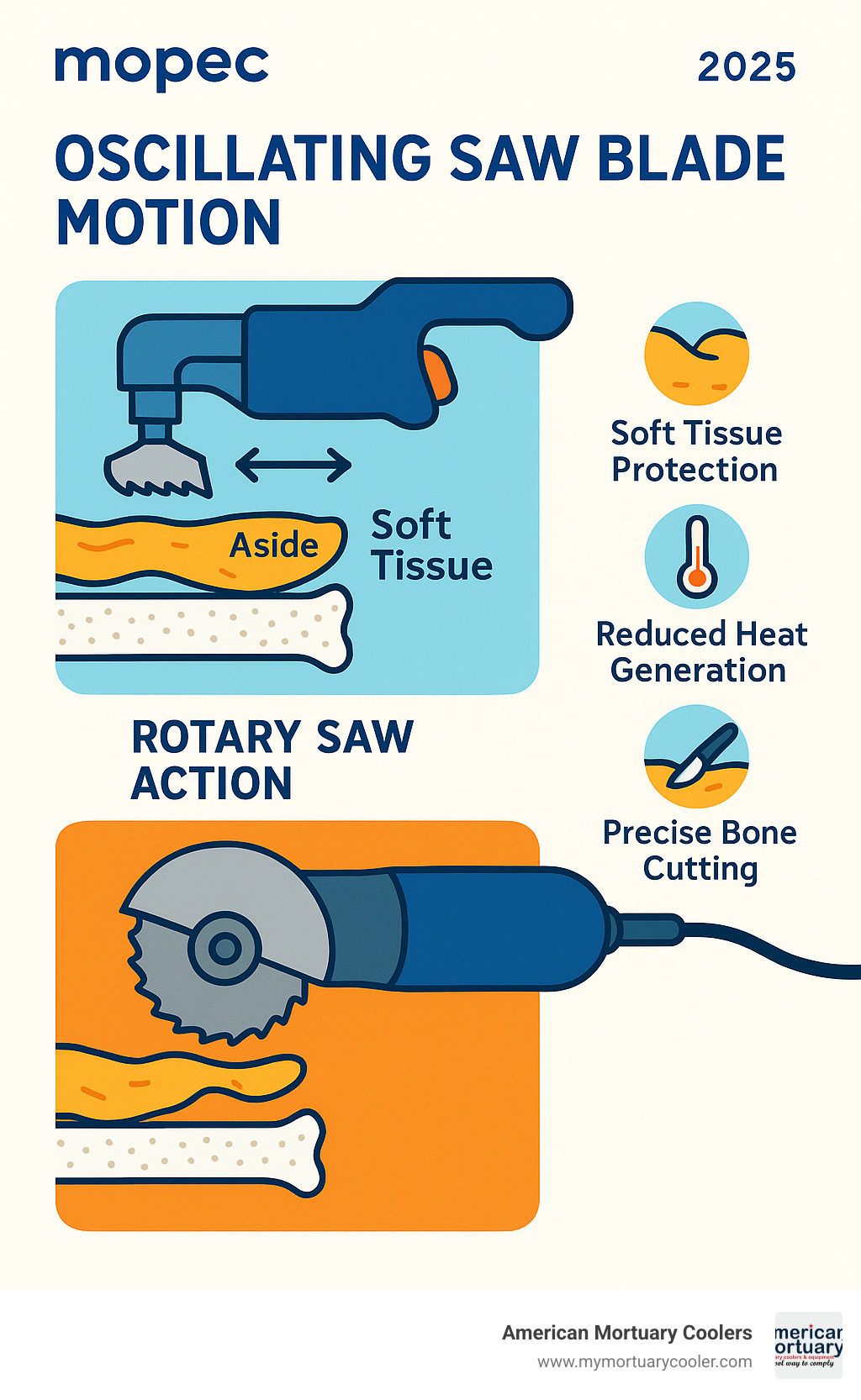

Why Oscillating Beats Rotary:

- Moves soft tissue aside instead of cutting it

- No blade guard needed

- Reduces heat buildup and bone dust

- OSHA-compliant for bloodborne pathogen safety

When Stryker globally obsoleted their 810 Autopsy Saw in March 2020, Mopec stepped in to fill the gap. As one industry expert noted: "The Mopec 810 Autopsy Saw remains as the industry standard in anatomic & forensic pathology."

The oscillating action works by moving the blade approximately 1/8 inch back and forth at speeds up to 32,000 oscillations per minute. This rapid motion cuts through bone efficiently while simply deflecting elastic skin tissue.

I'm Mortuary Cooler, and as a national-level mortuary cooler supplier, I've worked with countless funeral homes upgrading their mopec oscillating saw equipment. My experience with American-made mortuary equipment helps funeral directors choose reliable tools that last.

Mopec oscillating saw terms to know:

Mopec Oscillating Saw Unboxed & Key Specs

Opening the Mopec 810 oscillating saw box feels like unwrapping a precision instrument. The first thing you notice is the solid cast aluminum construction - this isn't some flimsy plastic tool. At 3.2 pounds (without the cord), it has enough weight to feel substantial without being cumbersome during long procedures.

The engineering specs tell the story of why this saw performs so well. The 17,000 rpm motor generates an impressive 32,000 oscillations per minute, creating that signature back-and-forth motion that cuts bone cleanly while deflecting soft tissue. The slender handle design makes it comfortable to grip, even during extended use.

Power flexibility is built right in - you can get 120V/60Hz models for US facilities or 230V versions for international labs. The 10-foot hospital-grade cord isn't just about reach; it's about safety in medical environments where proper grounding matters.

Here's something that'll save you time and money: the lifetime lubrication system. Unlike other saws that need regular oil changes, your mopec oscillating saw stays lubricated throughout its entire service life. One less maintenance task to worry about.

What's in the box?

Mopec doesn't skimp on the essentials. Your mopec oscillating saw arrives with everything you need to start working: an Allen wrench for quick blade changes, a 64mm large section blade (the go-to blade for most autopsy work), and a detailed instruction manual with safety protocols clearly explained.

The BD080 vacuum port compatibility means you can connect dust collection systems right away. There's also a spare set screw included - a small touch that shows Mopec understands real-world use. Having that backup screw on hand can save you from delays when you need the saw most.

The included large section blade is particularly thoughtful. Many manufacturers make you buy blades separately, but Mopec gives you a quality blade that handles everything from cranial procedures to linear bone cuts effectively.

Hands-on feel of the mopec oscillating saw

The balance is what strikes you first when you pick up the Mopec 810. The weighted bottom housing creates natural stability, while the handle stays light enough for precise control. During testing, we noticed significantly lower vibration compared to older models - your hands won't get tired as quickly.

The trigger placement feels intuitive, positioned right where your finger naturally rests. But here's the real confidence builder: try the thumb pressure test. Gently press the oscillating blade against your skin - it simply moves the tissue aside without cutting. This safety feature gives pathologists peace of mind during delicate procedures where soft tissue preservation is critical.

After handling dozens of autopsy saws over the years, the Mopec 810 stands out for its thoughtful ergonomics. It's clear this tool was designed by people who understand the demanding work of forensic pathology.

The Science Behind Oscillation: Safety, Speed & Precision

Understanding how the mopec oscillating saw works helps explain why it's become the gold standard in forensic pathology. The secret lies in that rapid back-and-forth motion that makes all the difference between clean cuts and messy procedures.

The blade sweeps just 1/8 inch in each direction - a small movement that creates big results. This tight oscillation pattern cuts through the hardest bone while simply pushing soft tissue out of the way. It's like the difference between a knife cutting through leather versus gently nudging silk aside.

Different models offer varying speeds to match your needs. The oscillation range spans from 13,200 to 32,000 cycles per minute, with the Mopec 810 hitting that top speed for maximum efficiency. The Swordfish runs at the lower end but makes up for it with submersible cleaning capabilities.

One major advantage is reduced heat generation. Rotary saws create friction that heats up both the blade and the bone, potentially damaging tissue samples. The oscillating action of the mopec oscillating saw stays much cooler, preserving specimen integrity for accurate pathology results.

OSHA compliance isn't just a checkbox - it's built into the design philosophy. The oscillating motion produces significantly less airborne bone dust compared to traditional rotary saws. Less dust means safer working conditions for pathologists and technicians who use these tools daily.

The hermetic seals on models like the Swordfish take safety a step further. These seals prevent contamination of internal components, which is crucial when working with potentially infectious materials. No one wants to worry about cleaning every internal crevice after each procedure.

For deeper insights into autopsy procedures, check out The Essential Role of Bone Saws in Autopsies. The ThomasNet submersible saw release also covers the latest innovations in submersible designs.

Why upgrade to a mopec oscillating saw

The mopec oscillating saw represents more than just a tool upgrade - it's stepping into the modern era of forensic pathology. When Stryker left the autopsy saw market in 2020, many labs worried about parts availability and support. Mopec didn't just fill the gap; they improved on the original design.

CE certification ensures your equipment meets international safety standards, whether you're working in Tennessee or Tokyo. This certification process isn't easy - it requires rigorous testing and documentation that many manufacturers skip.

The lower handpiece temperatures make a real difference during long procedures. The Swordfish model runs on 40V operation, which generates less heat than traditional designs. Your hands stay comfortable, and you can focus on precision rather than fighting fatigue.

Industry standardization around Mopec brings practical benefits you'll appreciate daily. Parts are readily available, training materials are standardized, and you can easily find colleagues who know the equipment. When you're working on important cases, having that support network matters.

Most pathology labs we work with have made the switch to Mopec for these reasons. It's not just about having the latest equipment - it's about having reliable tools that won't let you down when precision matters most.

Model Showdown: 1000 vs 810 vs Swordfish vs Stryker

Choosing the right mopec oscillating saw can feel overwhelming with four solid models on the market. Let me break down the key differences so you can make the best choice for your facility.

The Mopec 1000 serves as the budget-friendly entry point at 3.2 pounds with 18,414 cycles per minute. Don't let the lower price fool you - this saw uses the same blade system as its pricier siblings and delivers reliable performance for routine procedures.

The Mopec 810 represents the industry gold standard. At 32,000 oscillations per minute, it cuts through bone faster than any other model. Weighing the same 3.2 pounds as the 1000, it's the workhorse choice for high-volume facilities that need maximum cutting power.

The Swordfish takes a different approach entirely. At 2.8 pounds, it's the lightest option and focuses on ergonomics over raw power. Its 13,200 cycles per minute might seem modest, but the reduced vibration and cooler-running motor make it ideal for extended procedures. The big advantage? It's fully submersible for thorough cleaning.

The Stryker 810 rounds out the lineup as the legacy option. When Stryker exited the market, Mopec took over manufacturing while maintaining the original specifications. If you're replacing an aging Stryker unit, this ensures seamless compatibility.

| Model | Weight (no cord) | Oscillation Rate | Cleanability | Price Tier | Submersible | Key Feature |

|---|---|---|---|---|---|---|

| Mopec 1000 | 3.2 lbs | 18,414 CPM | Wipe down | Budget | No | Same blade compatibility |

| Mopec 810 | 3.2 lbs | 32,000 CPM | Wipe down | Standard | No | Industry standard power |

| Swordfish | 2.8 lbs | 13,200 CPM | 15-min submersion | Premium | Yes | Ergonomic, hermetically sealed |

| Stryker 810 | 3.2 lbs | Variable | Wipe down | Legacy | No | Mopec-manufactured replacement |

The cleaning differences matter more than you might think. The standard models require careful wipe-down procedures, while the Swordfish can be completely submerged for 15 minutes. This makes decontamination much more thorough in high-risk environments.

Choosing the right mopec oscillating saw for your lab

Your facility's needs should drive your decision. Budget-conscious operations will find the Mopec 1000 delivers excellent value without sacrificing blade compatibility or basic performance. It's perfect for smaller facilities or backup units.

High-volume labs benefit most from the Mopec 810's superior cutting speed. Those extra oscillations per minute add up to significant time savings across multiple procedures. The faster you cut, the sooner you can move to the next case.

Ergonomic considerations make the Swordfish shine for pathologists who perform lengthy procedures. The lighter weight and reduced vibration prevent hand fatigue, while the cooler-running motor stays comfortable during extended use.

Legacy compatibility concerns point toward the Stryker 810 replacement. If your staff is already trained on Stryker equipment or you have existing blade inventory, this maintains continuity while providing improved reliability under Mopec's manufacturing standards.

Blades, Dust Control & Maintenance Essentials

The right blade can make or break your mopec oscillating saw performance. After years of working with funeral directors across the country, I've learned that blade selection is where many facilities either excel or struggle.

Round blades are your workhorses for curved cuts and general bone sectioning. Think of them as the Swiss Army knife of autopsy blades - they handle most procedures you'll encounter. The large round blade that comes with your saw will cover about 80% of your cutting needs right out of the box.

When you need precision, section blades deliver those clean, straight cuts that make specimen preparation look professional. These are perfect for removing cranial caps and creating those textbook linear bone cuts that pathologists appreciate.

For the tricky work, spinal column blades feature specialized geometry that steers tight spaces around vertebrae. The narrow profile lets you steer through complex anatomy without fighting the tool.

Here's where budget meets reality: SuperCut blades cost more upfront but last significantly longer and cut faster than standard blades. For high-volume labs, the math works out - you'll spend less over time and get better results. If you're doing occasional procedures, standard blades work just fine.

The newer models feature an axial mount system that makes blade changes much safer. No more reaching around spinning components or wrestling with awkward angles. It's one of those small improvements that makes a big difference in daily use.

Dust control isn't just about cleanliness - it's about safety and compliance. The BD050 portable vacuum uses HEPA filtration to capture bone particles right at the source. For facilities with dedicated autopsy suites, the Series 5000 stationary vacuum offers more power and consistent performance.

The submersible cleaning capability on the Swordfish model represents a major advance in infection control. Being able to fully immerse the handpiece eliminates those hard-to-reach contamination zones that plague traditional designs.

For more insights on surgical bone saws and their applications, check out Saw It Coming: Top Surgical Bone Saws Reviewed.

Cleaning workflow

The Swordfish models change the game with their 15-minute submersion capability. You can fully immerse the handpiece in disinfectant solution, ensuring thorough decontamination between cases. This feature alone justifies the premium price for many facilities dealing with high-risk cases.

For the 810 and 1000 models, stick to external wipe-downs with lint-free cloths and mild detergent. Never immerse these models - you'll damage the motor and create serious shock hazards. I've seen too many facilities learn this lesson the expensive way.

Disinfectant choice matters more than you might think. Use only approved disinfecting sprays and wipes. Harsh chemicals can damage seals and housing materials, leading to premature failure. When in doubt, check with your chemical supplier about compatibility.

One critical rule: avoid autoclave sterilization entirely. None of the mopec oscillating saw models can survive autoclave temperatures. The heat permanently damages internal components, turning your precision instrument into expensive scrap metal.

Accessory checklist

Your mopec oscillating saw setup needs the right supporting cast. The bone-dust vacuum is essential - either the BD050 portable at $1,799.95 or the Series 5000 stationary system depending on your facility layout.

The blade clamp and wrench system ensures safe blade changes. The Swordfish includes these tools, while other models may require separate purchase. Don't try to improvise with shop tools - the precision tolerances demand proper equipment.

Spare blades inventory depends on your procedure mix. Stock round blades for general work, section blades for precision cuts, and specialty blades based on your specific needs. Having the right blade when you need it prevents delays and frustration.

A replacement parts kit with set screws, O-rings, and other wear items keeps your saw running smoothly. These small components wear out over time, and having spares on hand prevents downtime when you need the tool most.

Frequently Asked Questions about Mopec Oscillating Saw

When we help funeral homes choose their mopec oscillating saw, these three questions come up every time. Let me share what we've learned from years of working with pathology labs across the country.

How does the oscillating action protect soft tissue?

Here's the brilliant part about the mopec oscillating saw - it's designed to work with your body's natural tissue properties, not against them. The blade moves back and forth up to 32,000 times per minute, but only in a tiny 1/8-inch arc.

When that rapid motion hits hard bone, it cuts right through. But when it touches elastic skin or soft tissue, something different happens - the tissue simply gets pushed out of the way instead of being cut. It's like the difference between trying to cut a rubber band with a knife versus poking it with your finger.

This is why you'll never see a blade guard on a mopec oscillating saw. The oscillating action is inherently safer than rotary saws that can grab and tear soft tissue. It's one of those simple engineering solutions that makes you wonder why anyone would design it any other way.

Which blades fit the Mopec 810, 1000, and Swordfish?

The blade compatibility story is pretty straightforward, but there's an important distinction to know about. The Mopec 810 and 1000 are essentially siblings - they use the exact same blade mount and accept identical blades. This means you can stock one set of blades for both models, which is a huge advantage for inventory management.

Even better, these models are compatible with legacy Stryker 810 blades and most generic autopsy saw blades. So if you're upgrading from an older system, your existing blade inventory probably still works.

The Swordfish is different - it uses a specialized axial mount system with its own blade designs. Swordfish blades come in round, section, large round, and spinal column configurations, but they won't fit the 810 or 1000 models. The trade-off is that the axial mount makes blade changes safer and more secure.

The universal compatibility of the 810/1000 models is honestly one of their biggest selling points. You're not locked into a single supplier, and replacement blades are readily available from multiple sources.

What routine maintenance does the saw require?

One of the best things about the mopec oscillating saw is how little maintenance it actually needs. We've had customers tell us they were surprised at how hands-off these units are compared to older equipment.

Your daily routine is simple - just wipe down the external surfaces with disinfectant after each use and check that the blade is properly tightened before starting procedures. That's it for most days.

Weekly, take a moment to inspect the power cord for any damage and clean out any bone dust that might have settled in crevices. Monthly blade inspections are important because dull blades create more friction and heat, which makes the saw work harder than it needs to.

Here's what you'll never need to do: add lubrication, clean internal components, or maintain bearings. The lifetime lubrication system handles all of that automatically. It's a major time-saver compared to older models that required regular oiling and internal maintenance.

The sealed design of these units means less can go wrong, and when something does need attention, it's usually obvious and easy to address.

Conclusion

When it comes to precision autopsy work, the mopec oscillating saw stands out as the clear winner. After testing all the models - from the budget-friendly 1000 to the innovative Swordfish - we can confidently say you're getting a tool built specifically for the demanding world of forensic and anatomic pathology.

What really impressed us during our evaluation was how seamlessly the transition from Stryker to Mopec has been. The improved build quality makes a noticeable difference in daily use, while better parts availability means less downtime when you need replacements. The improved safety features give pathologists the confidence they need during delicate procedures.

At American Mortuary Coolers, we've seen how the right equipment transforms a facility's capabilities. Based here in Tennessee, we've been helping funeral directors and pathologists across the contiguous 48 states choose tools that perform reliably for years. Our experience with durable, American-made equipment has taught us that quality equipment isn't just about features - it's about consistency when you need it most.

The mopec oscillating saw represents more than just an upgrade from older technology. It's a commitment to precision, safety, and professional excellence that will serve your facility well into the future. Whether you're performing routine autopsies or complex forensic examinations, having the right saw makes all the difference.

For comprehensive information about all your mortuary equipment needs, visit our main resource page. We understand that choosing equipment is a significant investment, and we're here to help you make the decision that's right for your specific situation.

The mopec oscillating saw isn't just another tool in your arsenal - it's the foundation for precise, safe, and efficient pathology work that honors the important role you play in forensic science and medical examination.