Why Mopec Stands Out in Pathology Equipment

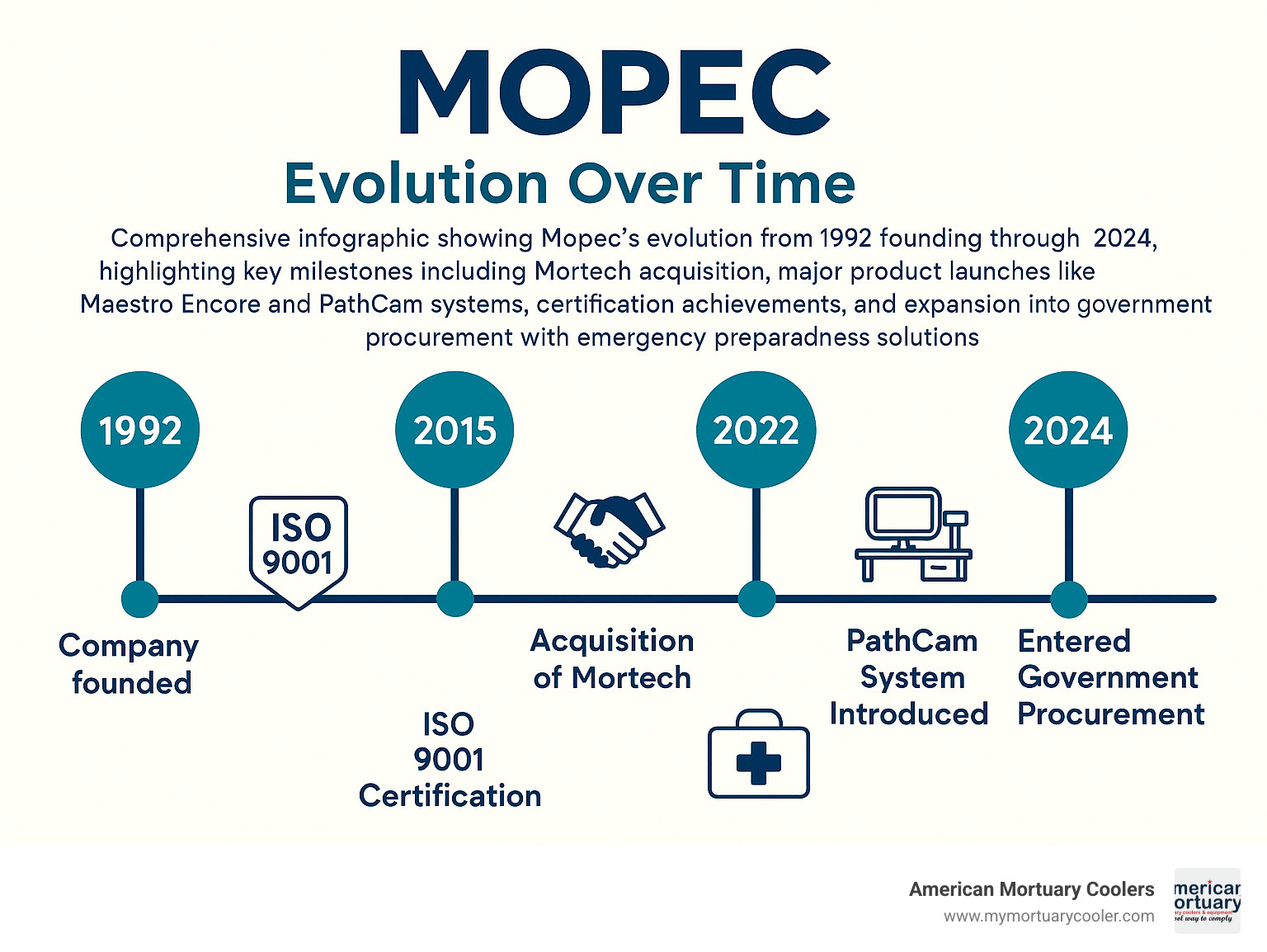

Mopec is a leading American manufacturer of anatomic and forensic pathology equipment, serving hospitals, medical examiners, and government agencies since 1992. With over 30 years of innovation and 9,747 completed projects, Mopec has become the trusted choice for institutions like Mayo Clinic, Cleveland Clinic, and the Department of Defense.

Key Mopec Facts:

- Founded: 1992 in Madison Heights, Michigan

- Specialties: Grossing stations, autopsy tables, refrigeration, consumables

- Certifications: ISO 9001:2015, NSF, CE, LEED Green

- Manufacturing: 100% American-made, in-house production

- Notable Products: Maestro Encore grossing station, PathCam imaging system

- Government Codes: CAGE 701J0, DUNS 07-889-1126

The company operates as part of Mopec Group, which acquired Mortech Manufacturing in 2021 to expand their forensic pathology capabilities. Their integrated approach covers everything from formalin safety systems to emergency preparedness solutions.

What sets Mopec apart is their outcome-based engineering approach. They work directly with pathology professionals to develop equipment that improves diagnostic accuracy while prioritizing user safety. Their patented SafeDraft™ ventilation technology and comprehensive product ecosystem have made them the go-to supplier for America's top healthcare institutions.

Mopec terms to remember:

Mopec Group at a Glance

Mopec Group has built something special at their Madison Heights, Michigan headquarters. Their mission is simple but powerful: empower pathology and anatomy professionals with equipment that actually makes their jobs better. They focus on diagnostic accuracy, safety, research support, and education because these things matter when dealing with life-and-death diagnoses.

What really sets Mopec apart is their commitment to American manufacturing. Everything gets engineered, built, and assembled right here in the United States. With ISO 9001:2015 certification and over 9,747 completed projects, they've proven consistent quality delivery.

The big game-changer came in 2021 when Mopec acquired Mortech Manufacturing. This merger brought 36 years of specialized forensic pathology experience, creating a one-stop shop for virtually any pathology lab need - from routine tissue processing to mass casualty response.

Visit Mopec's Website to see their full range of products and get custom quotes for your specific needs.

Mopec History & Leadership

The leadership team brings impressive healthcare experience. Francis X. Dirksmeier (CEO) previously managed a $2 billion healthcare business at Henry Schein Animal Health. Wayne Oliver (CFO) helped generate over $1.1 billion in annual revenue at Covetrus. Lee Kramer (VP of Sales) has built relationships with institutions like Mayo Clinic, Cleveland Clinic, and Kaiser Permanente.

The Clinical Advisory Board of practicing pathologists and medical examiners provides real-world feedback during product development, ensuring Mopec equipment solves actual problems instead of theoretical ones.

Mopec Mission & Vision

Mopec's vision is straightforward: be the only logical choice for pathology and anatomy professionals. Their outcome-based engineering approach focuses on measurable improvements, asking better questions like: How can this help pathologists make more accurate diagnoses? How can we make the process faster and safer?

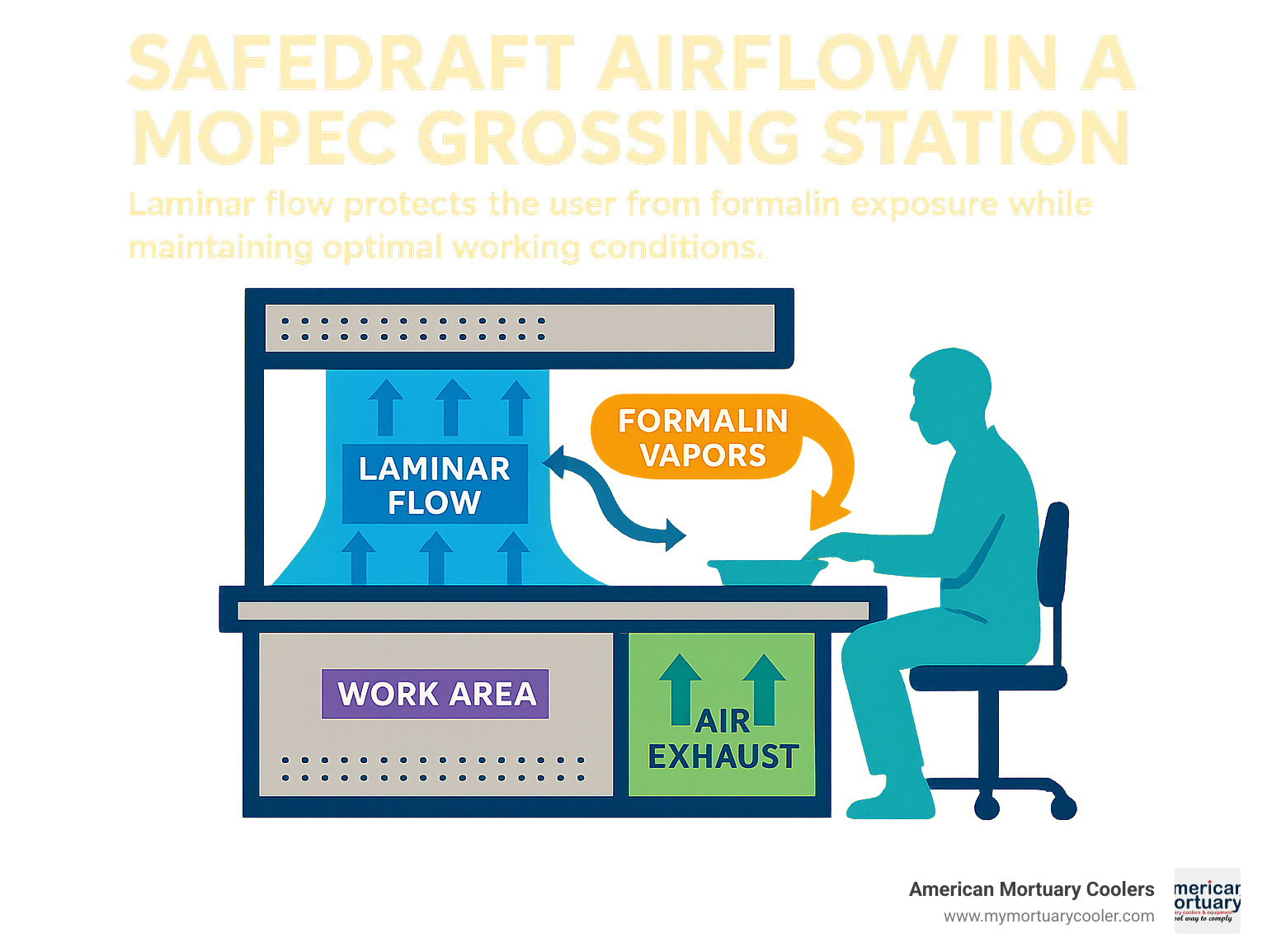

This thinking led to innovations like SafeDraft™ ventilation technology, which creates protective airflow patterns that keep harmful formalin vapors away from users. Safety isn't just about compliance for Mopec - they recognize that pathology professionals face real health risks from chemical exposure and repetitive stress.

Flagship Innovations: Grossing to Digital Imaging

Mopec has built its reputation on solving real problems that pathologists face every day. Their innovation pipeline creates solutions that make laboratories safer, more efficient, and more accurate.

Their approach to formalin safety led to SafeDraft™ technology that fundamentally changed how grossing stations protect users. This patented system creates precise airflow patterns that draw hazardous vapors away from pathologists before they can be inhaled.

The Maestro Encore grossing station represents the culmination of this safety-first thinking. It combines laminar airflow, HEPA filtration, and ergonomic design into an integrated safety system that protects users while improving work efficiency.

Mopec's PathCam® imaging system tackles specimen documentation challenges by integrating photography, barcoding, and workflow tracking into one seamless platform.

Beyond major equipment, their innovation extends to consumables like Harmony Dyes with standardized viscosity across nine colors, and premium biopsy bags with twisted, multiple-filament construction that improves fixation while being easier to handle with gloves.

Mopec Maestro Encore Grossing Station

The Maestro Encore represents years of collaboration with pathologists to understand exactly what they needed from a grossing station. SafeDraft™ ventilation creates laminar airflow that protects users from formalin exposure without creating turbulence that interferes with precision work.

The ergonomic workspace reduces fatigue during long grossing sessions. Digital scales, specimen shelves, and instrument storage are positioned for optimal workflow efficiency. The modular design allows configuration for everything from routine biopsies to complex forensic cases.

Integrated air filtration provides additional protection through HEPA and activated carbon filters, creating multiple layers of safety that work together seamlessly.

A Comprehensive Guide to Comparing Mopec Grossing Stations walks through different configurations and helps you select the right setup for your laboratory's needs.

Mopec PathCam Imaging System

Documentation requirements in pathology labs have exploded, but tools haven't kept pace. The PathCam system integrates specimen photography, barcode scanning, and workflow tracking into one platform that makes sense.

Instead of juggling separate systems, pathologists get one integrated solution for all documentation needs. This reduces errors and improves compliance with strict accreditation requirements. The system captures consistent, high-quality images and ensures specimens are tracked accurately from receipt through final diagnosis.

Learn more at mopec.com/pathcam for detailed specifications and implementation guidance.

Beyond the Bench: Saws, Scalpels & Consumables

Mopec's attention to detail extends to every pathology workflow tool. The Mopec 810 autopsy saw delivers exceptional performance with its 17,000 rpm motor and 32,000 oscillations per minute, providing clean bone cuts while protecting soft tissue.

The Swordfish saw represents the first bone saw developed specifically for forensic pathology. Its submersible design allows thorough decontamination by submerging for up to 15 minutes, while the 40V hand-piece provides cooler operation with reduced vibration.

Mopec's premium biopsy bags feature twisted, multiple-filament construction ensuring proper fluid movement for optimal fixation. The Lumohs scalpel handles provide shadowless illumination millimeters from the surgical site.

All About Mopec Autopsy Saw: Features and Specifications provides comprehensive technical details for selecting the right saw for your facility.

Safety, Compliance & Quality Standards

When working with Mopec equipment, safety is built into every product's DNA. Mopec's SafeDraft™ ventilation technology creates smooth, predictable airflow patterns that pull formalin vapors away from breathing zones, like an invisible protective shield.

The system's effectiveness comes from dual-stage filtration - HEPA filters catch microscopic particles while activated carbon filters grab chemical vapors. Mopec also takes formalin safety seriously with neutralization systems that convert dangerous waste into safer compounds. Scientific research on formalin exposure shows how important this protection really is.

Ergonomic design elements like body positioners and low-fatigue benches keep users comfortable during extended examination sessions.

Certifications & In-house Manufacturing

Mopec's ISO 9001:2015 certification means systematic quality controls that get checked regularly. NSF certification validates equipment meets strict laboratory safety standards, while CE marking ensures European compliance and LEED Green certification demonstrates environmental responsibility.

Mopec manufactures everything in-house in the United States, controlling every step from materials to final assembly. This enables quick customization and repairs without overseas supplier delays. Their lean manufacturing approach keeps costs reasonable while investing in innovation and customer service.

Laboratory Workflow & Ergonomics

A well-designed pathology lab requires everything to flow together smoothly. Mopec understands that individual equipment pieces are only as good as how they work together in daily workflow.

Laminar airflow systems create perfect balance between safety and comfort - protection from hazardous vapors without uncomfortable drafts. Body positioners and ergonomic workbenches prevent fatigue and strain injuries during physically demanding work.

Integrated specimen tracking streamlines workflow by reducing manual data entry and associated errors. When grossing stations, imaging systems, and lab information systems communicate seamlessly, pathologists can focus on accurate diagnoses.

Emergency Preparedness & Government Procurement

When disaster strikes, morgues and medical examiners face impossible situations. Mopec's emergency preparedness solutions become literally life-saving during these critical times.

Guardian cold storage systems provide surge capacity during mass casualty events - complete temporary morgue solutions that deploy rapidly when existing facilities are overwhelmed. Mobile morgue trailers are self-contained units with examination tables, refrigeration, and utilities for conducting autopsies anywhere needed.

The MERC (Mobile Emergency Response Cooler) system provides immediate cooling capacity deployable within hours. Body bags and PPE become critical resources during emergencies, with Mopec maintaining substantial inventory for rapid supply when other suppliers are overwhelmed.

Government procurement uses Mopec's CAGE 701J0 and DUNS 07-889-1126 codes for rapid federal, state, and local agency purchasing when standard bidding is too slow.

More info about surge morgue solutions provides detailed specifications and deployment procedures.

Government & Military Deployments

Mopec equipment serves in America's most demanding environments. The Department of Defense, Department of Veterans Affairs, and Department of Health & Human Services rely on Mopec products for mission-critical operations.

With 9,747 completed projects spanning nearly four decades, Mopec has built an impressive government track record. Military installations require equipment that performs reliably in harsh conditions with limited maintenance support.

Quick-deploy morgue racks provide surge capacity installed rapidly when facilities are overwhelmed. County medical examiner offices face budget constraints while handling complex caseloads, making Mopec's rapid support capabilities essential.

American manufacturing ensures supply chain security and availability during international crises while supporting domestic jobs and industry.

Mass Fatality Response Best Practices

Effective emergency response starts before disasters occur. Mopec works with emergency management agencies developing response plans based on real-world deployment experience.

Stockpiling critical supplies proves more effective than scrambling during emergencies. Rapid production ramp-up capabilities allow Mopec to increase output quickly when emergencies create demand spikes.

Respectful decedent handling remains paramount during mass casualty events. FEMA and DMORT guidelines provide mass fatality response frameworks, but equipment must work in field conditions. Mopec products meet these guidelines and have been tested in real-world deployments from natural disasters to public health emergencies.

Choosing the Right Mopec Equipment

Finding the perfect Mopec equipment starts with honestly assessing your facility's needs. Anatomic pathology labs typically prioritize efficiency and throughput for processing hundreds of routine biopsies. Forensic facilities require flexibility for complex cases and comprehensive documentation capabilities.

Mopec's customizable approach shines with their Maestro Encore grossing station offering different ventilation options, work surfaces, and accessories. This means you get exactly what you need without paying for unused features.

Refrigeration sizing is critical - too small creates overcrowding, too large wastes money and space. Mopec offers everything from compact specimen refrigerators to walk-in morgue coolers for proper sizing.

| Feature | Maestro Encore | Classic Stations |

|---|---|---|

| SafeDraft™ Ventilation | Standard | Optional |

| Integrated Air Filtration | Yes | No |

| Digital Scale Integration | Yes | Optional |

| Specimen Imaging | PathCam Compatible | Limited |

| Customization Options | Extensive | Moderate |

| Price Range | Premium | Standard |

Mopec vs American Mortuary Coolers: What's Best? provides detailed comparisons for evaluating different suppliers and options.

Product Comparison Guides

Grossing stations represent the biggest decision for most labs. Basic models work for low-volume facilities, while advanced systems like Maestro Encore provide comprehensive features for busy labs. Match capabilities to actual workflow rather than buying the most expensive option.

Cadaver lifts vary in capacity, height adjustment, and mobility. Fixed installations suit dedicated autopsy suites, while portable units provide multi-use flexibility. Weight capacity must match typical cases with appropriate safety margins.

Body bags vary in weight ratings and material specifications. Standard bags handle routine cases, while heavy-duty options become essential for bariatric decedents or challenging recoveries.

A Comprehensive Guide to Choosing a Mopec Cadaver Lift provides detailed technical comparisons and selection criteria.

Budgeting, Service & Warranty

Smart budgeting goes beyond initial purchase price. Mopec Certified Service provides comprehensive support that extends equipment life and maintains peak performance. Maintenance plans help budget ongoing service needs while ensuring reliability.

Genuine parts ensure compatibility and performance while maintaining warranty coverage. Generic parts might seem cheaper initially but can void warranties and cause expensive reliability problems.

Lifecycle costs include purchase, installation, training, maintenance, and replacement. Mopec equipment offers excellent lifecycle value through durability, reliability, and comprehensive support services.

Frequently Asked Questions about Mopec Products

When I talk with funeral directors and pathology professionals about Mopec equipment, the same questions come up again and again. Let me share the answers that matter most for your decision-making process.

What differentiates Mopec from other pathology suppliers?

The biggest difference with Mopec is their outcome-based engineering approach. While other suppliers build equipment to basic specifications, Mopec asks a better question: "How will this actually help pathologists work safer and more efficiently?"

This thinking led to breakthrough innovations like SafeDraft™ ventilation technology. Instead of simple exhaust fans that create turbulent airflow, SafeDraft™ creates precise laminar flow patterns that actually protect users from formalin exposure. That's the kind of real-world problem-solving that sets them apart.

American manufacturing gives Mopec advantages that overseas suppliers simply can't match. When everything is made in-house in Michigan, they control quality from start to finish. Need a custom modification? They can handle it quickly without dealing with international suppliers and shipping delays.

Their Clinical Advisory Board includes practicing pathologists and medical examiners who provide direct feedback on product development. This means Mopec equipment solves actual problems rather than theoretical ones. When Mayo Clinic and Cleveland Clinic choose your equipment, you know it works in demanding real-world conditions.

The integrated ecosystem approach is another key differentiator. Mopec designs their grossing stations, imaging systems, and consumables to work together seamlessly. You're not cobbling together equipment from different suppliers and hoping it all plays nicely together.

Which Mopec certifications matter most for my lab accreditation?

ISO 9001:2015 certification is absolutely crucial if you're seeking CAP (College of American Pathologists) accreditation. This certification proves that Mopec has systematic quality management processes in place. CAP inspectors look for this kind of vendor validation when they're evaluating your equipment choices.

NSF certification validates that Mopec equipment meets strict safety and performance standards for laboratory environments. This certification is particularly important for grossing stations and other equipment that handles biological specimens.

If your facility has international accreditation requirements or serves international clients, CE marking becomes important. This European compliance standard demonstrates that Mopec equipment meets international safety requirements.

LEED Green compliance supports environmental management system requirements that many healthcare facilities now maintain. This certification shows that Mopec manufacturing processes meet environmental responsibility standards.

The documentation that comes with Mopec equipment is designed to support accreditation inspections. You'll get comprehensive validation records, maintenance procedures, and compliance documentation that inspectors expect to see.

How does Mopec support labs during mass-casualty events?

Mopec's emergency preparedness solutions have been tested in real-world disasters, and their performance speaks for itself. During the COVID-19 pandemic, their Guardian cold storage systems provided crucial surge capacity when existing morgue facilities were overwhelmed.

Mobile morgue trailers offer complete temporary facilities that can be deployed anywhere. These aren't just refrigerated trucks - they're fully equipped autopsy facilities with examination tables, utilities, and proper ventilation systems. When Hurricane Katrina hit or during major mass casualty events, these trailers have provided essential services.

The quick-deploy equipment can be installed rapidly when time is critical. Mopec maintains inventory of essential items like body bags, PPE, and portable refrigeration units specifically for emergency response.

Their government procurement codes (CAGE 701J0, DUNS 07-889-1126) enable rapid purchasing when standard bidding processes are too slow for emergency situations. The ARPA funding calculator helps agencies identify available federal funding for preparedness purchases.

Technical support during emergencies includes rapid response for equipment issues and consultation on temporary facility setup. Mopec's experience with DMORT deployments and federal agencies provides valuable expertise that can make the difference between effective response and chaos.

Having worked in the mortuary industry, I've seen how critical proper equipment becomes during emergencies. Mopec's comprehensive approach to emergency preparedness gives facilities the confidence that they can handle whatever comes their way while maintaining the dignity and respect that families deserve.

Conclusion

After three decades and over 9,000 completed projects, Mopec has proven itself as the partner that pathology labs and medical examiners turn to when accuracy, safety, and reliability matter most.

What makes Mopec special isn't just their impressive client list - Mayo Clinic, Cleveland Clinic, and the Department of Defense. It's their understanding that pathology professionals face real daily challenges, from formalin exposure risks to emergency surge capacity needs.

Their SafeDraft™ ventilation technology came from listening to pathologists concerned about long-term health. Emergency preparedness solutions were created because communities needed better ways to handle mass casualty events with dignity and efficiency.

The Mopec ecosystem approach makes sense in action. Instead of cobbling together equipment from different suppliers, you get grossing stations, imaging systems, and consumables designed as a unified solution.

Their American manufacturing provides quality control, supply chain reliability, and quick customization ability. When you need equipment that works flawlessly under pressure, domestic manufacturing provides peace of mind.

At American Mortuary Coolers, we've seen how Mopec equipment performs in real-world conditions. Our customers across Tennessee, Georgia, Illinois, South Carolina, Texas, California, New York, and Pennsylvania consistently report excellent experiences.

The pathology industry keeps evolving with new safety requirements and technological advances. Mopec stays ahead through their Clinical Advisory Board and outcome-based engineering approach. When you invest in Mopec equipment, you're partnering with a company that will help you adapt to tomorrow's challenges.

Whether upgrading a single grossing station or planning complete laboratory renovation, Mopec offers the expertise and product range to meet your needs. Their government procurement codes and emergency response capabilities provide additional value for facilities facing potential surge situations.

Learn about morgue refrigeration options to find how American Mortuary Coolers can help you implement Mopec solutions in your facility. We're committed to providing the same level of quality service and local support that Mopec brings to equipment manufacturing.