Understanding Retort Cremation: The Modern Approach to Final Disposition

Retort cremation is the process of reducing a human body to bone fragments and ashes using a specialized furnace called a retort that operates at temperatures between 1,600-2,000°F (871-1,093°C). This method has become increasingly common in the United States, with over 50% of Americans now choosing cremation over traditional burial.

Quick Facts About Retort Cremation:

- Definition: Uses a specialized furnace (retort) with refractory brick lining to cremate human remains

- Temperature: 1,600-2,000°F (871-1,093°C)

- Duration: Typically 1-3 hours depending on body size and retort efficiency

- Average Result: 4-6 pounds of cremated remains (bone fragments)

- Equipment Cost: $150,000-$200,000 for the retort alone, $300,000-$500,000 total investment

The heart of any cremation facility is the retort—a carefully engineered chamber designed to efficiently and respectfully reduce human remains to their basic elements. Modern retorts combine industrial-grade refractory materials with advanced control systems to ensure a dignified process that meets strict environmental standards.

"When others say no, we wonder how then make it work," explains one industry expert, highlighting the importance of choosing equipment that balances reliability with performance.

I'm Mortuary Cooler, a national-level mortuary cooler supplier specializing in American-made cremation equipment, and I've helped funeral directors across the country select and maintain reliable retort cremation systems that balance performance with long-term value.

Simple retort cremation glossary:

What Is a Retort? The Heart of Retort Cremation

When we talk about modern cremation, the retort is where the change happens. Far from being a simple furnace, today's cremation retort is an engineering marvel designed with dignity, efficiency, and environmental responsibility in mind.

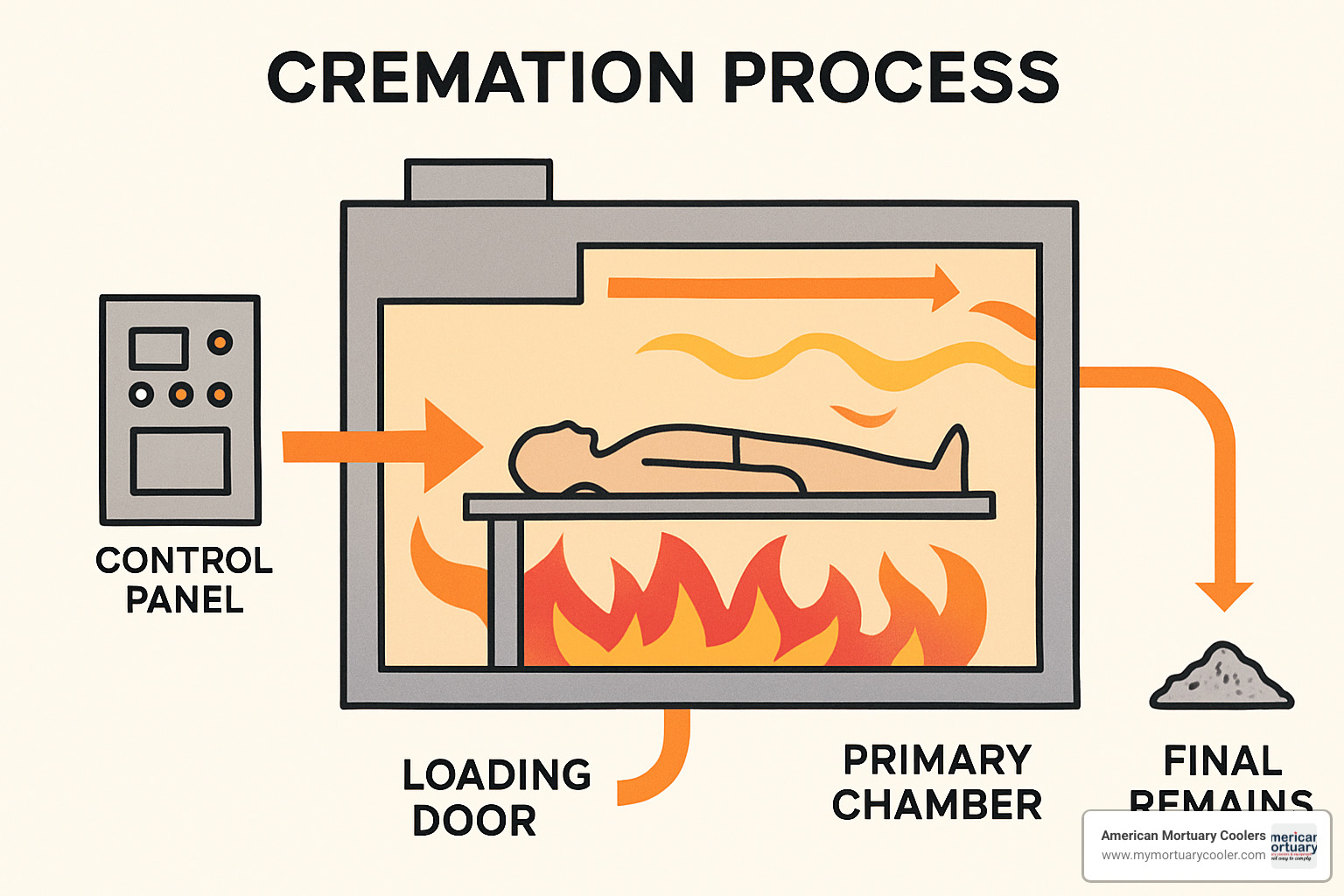

Picture a primary chamber surrounded by multiple layers of high-quality refractory brick—typically 6-inch U.S. refractory brick that offers up to 50% better durability and fuel savings than thinner imported alternatives. This chamber becomes the sacred space where the body rests during the cremation journey.

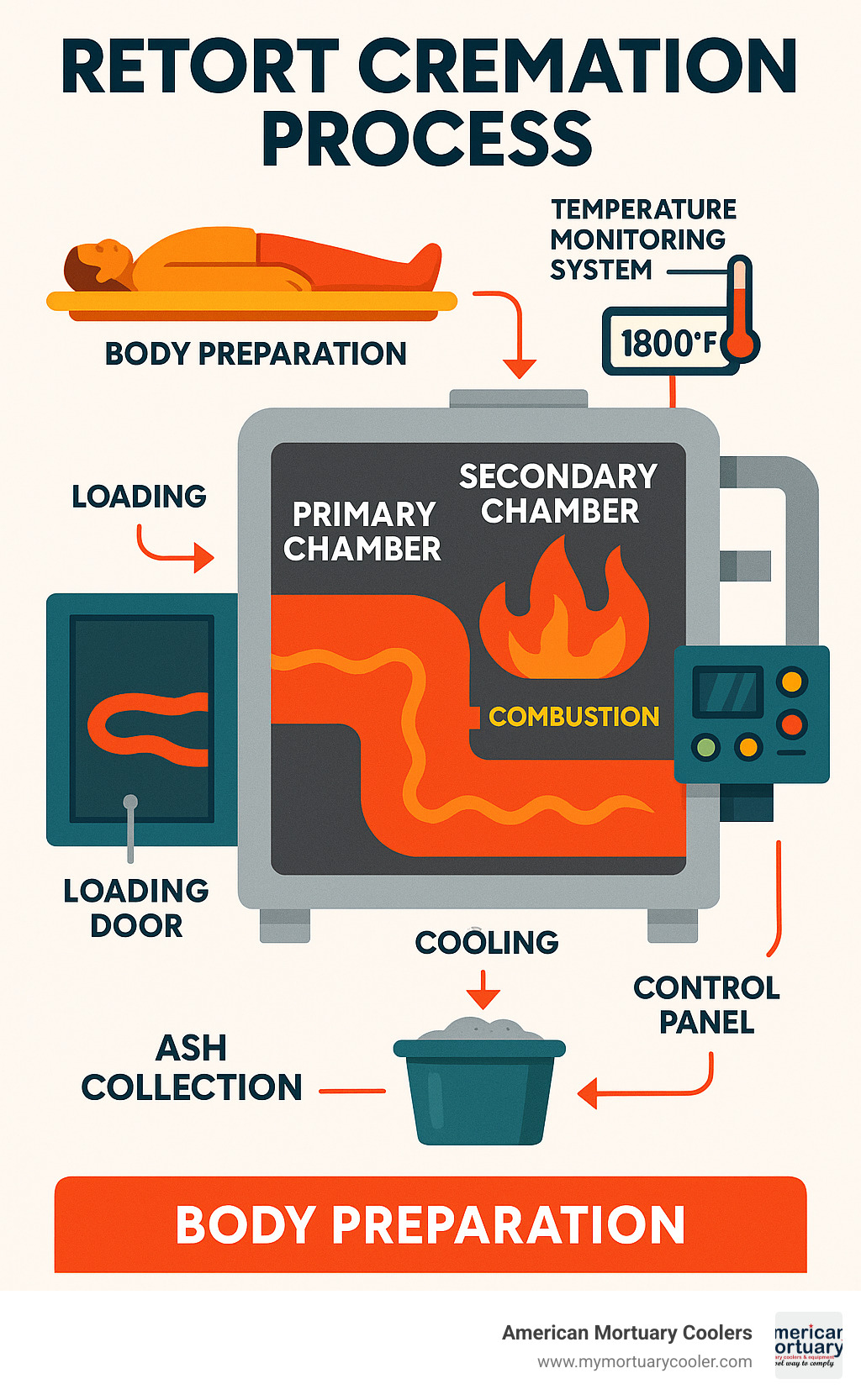

Retort cremation relies on a carefully designed system of primary and secondary burners, usually powered by natural gas or propane. The primary burners direct their heat into the main chamber, while secondary burners in the afterburner chamber ensure gases and particles are completely combusted before leaving through the stack—a crucial step for environmental compliance.

The technology behind modern retorts is impressive. Digital control systems precisely manage temperature, airflow, and fuel throughout the entire process. These controls maintain the necessary 1,600-2,000°F range while optimizing efficiency—a balance of respect and practicality.

As one manufacturer notes, "Our company prides itself as being the only manufacturer that offers a fully-automatic system based on the temperature of the equipment." This focus on precision makes a world of difference in the retort cremation process.

For more detailed information, you might find our article on Cremation Retort 101 helpful, or explore scientific research on cremation history for a broader perspective.

Key Components & Features

The modern cremation retort brings together several essential elements that work in harmony:

The insulated shell forms the exterior casing, containing heat while providing structural integrity. Inside, the hearth (where the body rests) often features a "Hot Hearth" system that instantly evaporates fluids on contact—a thoughtful design element that improves dignity and efficiency.

Multiple layers of refractory lining withstand thousands of cremation cycles, while carefully positioned baffles direct heat flow for optimal combustion. The primary burners are typically angled at 15° to minimize hearth erosion—a small detail that significantly extends equipment life.

The afterburner (or secondary chamber) ensures gases reach 1,800-2,000°F for complete combustion, with an opacity monitor verifying emissions are clear before exiting. A computerized control panel orchestrates the entire process, while the hydraulically operated loading door maintains a perfect seal to contain heat and emissions.

After cremation, the cooling system facilitates a faster cool-down for safe retrieval of remains—a thoughtful feature that honors both the deceased and those handling the remains.

Perhaps most innovative is the dished hearth surface combined with the Hot Hearth system, which effectively manages fluids during larger body cremations without requiring separate collection devices—dignity through design.

How a Retort Works Step-by-Step

The retort cremation process follows a carefully choreographed sequence that balances technical precision with respectful care:

The journey begins with pre-heating, bringing the retort to approximately 1,100°F before the body is introduced. Once the deceased is placed in the chamber and the door sealed, fuel ignition occurs, with primary burners directing flames at that carefully calculated 15° angle to preserve the hearth's integrity.

The computerized system then manages a temperature ramp, gradually increasing heat to the optimal 1,600-1,800°F range. This measured approach prevents thermal shock to the refractory materials, extending the life of the equipment.

Turbulence control plays a crucial role, with strategically positioned air inlets creating movement that ensures complete combustion. Meanwhile, modulating burner controls and oxygen sensors work together to find the perfect air-to-fuel ratio—efficiency with purpose.

As the process continues, gases move from the primary chamber to the secondary chamber, where temperatures of 1,800-2,000°F complete the combustion of remaining particles and gases. The fully combusted gases then pass through the stack, with the opacity monitor ensuring environmental compliance.

Finally, after cremation is complete, a cooling cycle of typically 15-30 minutes allows for safe retrieval of the remains—the final act of care in this technical yet deeply human process.

This carefully engineered journey ensures complete cremation while minimizing environmental impact and optimizing fuel efficiency—technology in service of dignity.

The Step-by-Step Retort Cremation Process

The journey of retort cremation involves much more than just what happens inside the chamber. From the first careful identification to the final moment when a family receives their loved one's remains, every step follows thoughtful protocols designed to maintain dignity, ensure accuracy, and respect both legal requirements and family wishes.

Pre-Cremation Checks & Preparation

Before your loved one begins their final journey, several important preparations take place behind the scenes.

Each person receives careful identification verification using multiple methods, including ID bands that stay with them throughout the process. We never rush this critical step – proper identification is our highest priority.

The legal side requires completion of necessary paperwork, including a death certificate and a cremation authorization form signed by the legal next of kin. These documents serve as both legal protection and a record of the family's wishes.

Your loved one is then placed in a combustible container – this might be a simple cardboard box or an neat cremation casket, depending on family preferences and budget. Whatever the choice, we ensure it meets all requirements for the cremation process.

Safety is paramount, which is why we carefully remove pacemakers and other battery-powered medical devices that could pose explosion hazards during cremation. Jewelry and personal items are also removed and returned to the family unless specific instructions state otherwise.

A unique metal identification disc accompanies your loved one throughout the entire process, ensuring positive identification at every stage. This small but crucial item becomes part of our meticulous documentation process, which includes maintaining a refrigeration log as part of the chain of custody.

Before proceeding, our staff verifies that the container is fully combustible and properly sealed within 72 hours of service, meeting industry standards for respectful care.

Inside the Chamber: Retort Cremation Process in Action

When all preparations are complete, the actual retort cremation begins with great care and precision.

The body and container are gently placed in the pre-heated retort using specialized loading equipment designed for both safety and dignity. Once positioned, the retort door is securely sealed, creating the controlled environment necessary for cremation.

The process unfolds in distinct phases. First comes the dehydration phase, where the body's moisture gradually evaporates as temperatures climb. Next, during the flame phase, the container and body begin to combust as temperatures reach 1,400-1,600°F, reducing organic materials through thermal decomposition.

At peak temperatures of 1,600-2,000°F, bone calcination occurs – the remaining organic material is consumed, leaving only bone fragments and any non-combustible items like metal implants. Throughout this process, the secondary chamber works diligently to ensure gases and particulates are completely combusted before exiting through the stack, minimizing environmental impact.

"Each cremation is unique," explains one of our experienced operators. "Factors like body composition, container type, and even atmospheric conditions influence how the process unfolds." This is why trained professionals monitor critical parameters like temperature and oxygen levels throughout the entire cycle, which typically takes between 1-3 hours.

You can learn more about this crucial stage in The Role of Cremation Retorts in the Cremation Process.

Ash Processing & Return to Family

After the cremation cycle completes, we begin the final, thoughtful stages of the process.

The chamber first cools for 15-30 minutes, allowing for safe handling of the remains. Then, with great care, the cremated remains – consisting primarily of bone fragments – are carefully swept from the chamber, making sure nothing is left behind.

We pass a magnet over the remains to gently remove any metal objects such as surgical pins, dental work, or other medical implants. These items are typically recycled through specialized programs rather than discarded.

The bone fragments then undergo processing in a machine called a cremulator, which in about 20 seconds reduces them to the consistent, sand-like texture families are familiar with. The processed remains generally weigh between 4-6 pounds for an adult, with men typically yielding about 1 kg more than women due to bone density differences.

With the same care shown throughout the process, the remains are placed in a sealed, airtight bag or container, which is then placed inside the urn selected by the family. Some families choose simple, temporary containers while others select personalized urns that reflect their loved one's personality or interests.

Final paperwork completes the documentation trail, maintaining the chain of custody and identification that began when your loved one first came into our care. The urn containing the cremated remains is then returned to the family, either through direct pickup at our facility or through careful delivery to your home.

For many families, this physical process marks the beginning of their personal journey of remembrance and healing – whether that involves a formal memorial service, a private scattering ceremony, or simply keeping their loved one's remains in a special place at home.

Equipment Maintenance, Costs, and Operator Safety

Maintaining a cremation retort is similar to caring for a high-performance vehicle—regular attention prevents costly breakdowns and ensures safe, efficient operation. At American Mortuary Coolers, we've worked with crematory operators across our service regions from Atlanta to Los Angeles, and we've seen how proper maintenance extends equipment life.

The most significant maintenance concern is the refractory lining. These specialized bricks face extreme temperatures daily and gradually erode over time. When a complete relining becomes necessary—typically every 7-10 years—crematory operators can expect to invest $15,000-$20,000 and experience a week or more of downtime. That's why many of our clients establish a maintenance fund by setting aside about $10 per cremation specifically for future hearth replacement.

"Preventive maintenance isn't just about saving money—it's about peace of mind and avoiding equipment failure during busy periods," explains one crematory manager from our Dallas service area.

Daily visual inspections cost nothing but time yet can catch small issues before they become major problems. Monthly burner and blower service might run $200-$500 but only requires a few hours of downtime. The middle ground—refractory patching as needed ($1,000-$5,000) and partial relinings every 3-5 years ($5,000-$10,000)—represents the most common maintenance expenses for retort cremation equipment.

Annual manufacturer inspections are non-negotiable for safety and warranty purposes. These typically cost $1,000-$2,000 and require just one day of downtime. Think of it as your retort's yearly physical—well worth the investment.

As one Tennessee crematory manager told us, "I wish someone had explained refractory costs before I bought my machine; it's like replacing the engine in your car." This underscores why we at American Mortuary Coolers emphasize total cost of ownership in our consultations with funeral professionals.

| Maintenance Task | Frequency | Approximate Cost | Typical Downtime |

|---|---|---|---|

| Visual inspection | Daily | Staff time only | None |

| Burner/blower service | Monthly | $200-$500 | 2-4 hours |

| Refractory patching | As needed | $1,000-$5,000 | 1-2 days |

| Partial relining | Every 3-5 years | $5,000-$10,000 | 3-5 days |

| Complete relining | Every 7-10 years | $15,000-$20,000 | 7-10 days |

| Annual manufacturer inspection | Yearly | $1,000-$2,000 | 1 day |

Operator safety deserves equal attention to equipment care. Proper training and certification through programs like the Crematory Manufacturer Operators Training Program (CMOTP) aren't just good practice—they're essential. Personal protective equipment including heat-resistant gloves, face shields, and appropriate clothing should be non-negotiable for anyone operating a retort cremation chamber.

The combination of extreme heat, mechanical components, and the dignified nature of the work demands both technical skill and professional composure. That's why we recommend viewing this video on proper operational procedures and checking out our guide on Price Check: Navigating the World of Cremation Equipment Costs before making any equipment decisions.

The true cost of cremation equipment isn't just the initial purchase—it's the lifetime of maintenance, repairs, and operational considerations. When you work with American Mortuary Coolers, we help you plan for the entire journey, not just the first mile.

Environmental & Regulatory Considerations

The environmental footprint of retort cremation has become a hot topic in recent years, and for good reason. Each cremation releases about 240 kg (540 lb) of carbon dioxide—roughly equivalent to a 500-mile car trip—and consumes approximately 110 liters (28 US gallons) of fuel. As families become more eco-conscious, understanding these impacts has never been more important.

When I talk with funeral directors across our service regions, environmental regulations often top their list of concerns. The regulatory landscape looks different depending on where you're located, but generally includes:

Federal EPA standards limit particulate matter to 0.08-0.10 grains per dry standard cubic foot, with opacity (those visible emissions from the stack) restricted to below 10-20%. Think of opacity as the "visible smoke test"—if you can see it, you're probably exceeding limits.

State-level regulations often add another layer of complexity, sometimes with stricter requirements than federal standards. I remember when Florida tightened their emissions rules back in 1992, and many operators scrambled to upgrade their equipment. It's a good reminder that regulations evolve, and today's compliant facility might need upgrades tomorrow.

Local zoning laws can be particularly tricky, often restricting crematory placement relative to residential areas. One of our clients in Colorado had to relocate their planned facility by just two blocks to satisfy these requirements.

Many facilities also voluntarily follow the Cremation Association of North America (CANA) code, which establishes industry best practices beyond what regulations require.

Modern retort cremation equipment incorporates several technologies to minimize environmental impact. Mercury abatement systems capture mercury from dental amalgams (a significant concern for water quality), while advanced filtration reduces particulate emissions. Opacity monitoring ensures emissions remain clear and compliant, and modulating controls optimize fuel consumption to reduce waste.

As one of our Tennessee clients put it, "Environmental compliance isn't just about avoiding fines—it's about being a good neighbor and steward of our community."

Electric Retorts: The Future of Retort Cremation

An exciting development in the retort cremation world is the emergence of electric retorts. These units replace fossil fuels with electricity, offering some impressive environmental benefits when the electricity comes from clean sources.

When powered by renewable energy, electric retorts can be virtually carbon neutral. That's a game-changer for funeral homes marketing to environmentally conscious families. They also eliminate on-site combustion emissions, meaning cleaner local air quality for your facility and neighborhood.

Some forward-thinking European facilities are pioneering systems that capture waste heat from cremations to generate electricity. This heat recovery approach means the energy used isn't just lost—it's recycled back into the facility or even the local power grid.

Beyond the environmental benefits, electric retorts offer practical advantages: improved safety with reduced fire and explosion risks, and potentially lower operating costs as renewable electricity becomes more affordable.

"We're seeing growing interest in electric options from our clients in California and the Pacific Northwest," notes our West Coast service team. "It's not mainstream yet, but the trend is clear."

Comparing Flame Cremation vs Alkaline Hydrolysis

Another alternative gaining traction is alkaline hydrolysis, sometimes called "water cremation" or "green cremation." This process uses water combined with an alkali solution at about 320°F under pressure, rather than direct flame.

While traditional retort cremation typically takes 1-3 hours, alkaline hydrolysis can take up to 16 hours—though newer systems have reduced this considerably. The energy usage difference is striking: alkaline hydrolysis uses roughly one-eighth the energy of flame cremation and reduces the carbon footprint by more than 75%.

The equipment costs more—$209,900-$329,900 compared to $150,000-$200,000 for traditional retorts—but operating costs are generally lower. Currently, alkaline hydrolysis is legal in about 20 states, with that number steadily growing.

One interesting difference is in the remains themselves. Alkaline hydrolysis typically returns about 30% more remains than flame cremation, which some families appreciate.

A Washington state facility we work with added alkaline hydrolysis as an option last year, and they were surprised to find it quickly accounted for 20% of their cremation cases. "Families really respond to the environmental benefits," their director told me. "It's not for everyone, but having the option matters."

At American Mortuary Coolers, we're constantly monitoring these technological developments from our headquarters in Johnson City, TN to our regional offices. Whether you're considering traditional retort cremation equipment or exploring newer alternatives, we're here to help you steer both the environmental considerations and the practical realities of your unique situation.

For more detailed information on the environmental impact of different funeral methods, we recommend reviewing this scientific research on environmental impact of funerals or our article on Hot Chambers and Cool Facts: Crematory Retorts Explained.

Family Services, Viewing Options, and Budget Planning

When families choose retort cremation, they're often surprised by the flexibility and personalization available to them. From simple, dignified options to more elaborate ceremonies, today's cremation services can be custom to honor your loved one in meaningful ways.

"Adding a viewing option completely changed how our families engage with the cremation process, offering closure to many," explains a funeral director from our Chicago service area.

The most straightforward approach is direct cremation, where the body is cremated shortly after death without a viewing or service beforehand. At $1,000-$3,000, this is typically the most budget-friendly option and has become increasingly popular for families seeking simplicity. You can learn more about this approach in our guide to The Benefits of Choosing Direct Cremation.

Many families prefer a cremation with memorial service, where the cremation happens first, and then family and friends gather with the urn present to celebrate their loved one's life. This middle-ground option usually costs between $2,500-$4,000 and allows for personalized tributes without the time constraints of a traditional funeral.

For those seeking a more traditional experience, a funeral service followed by cremation offers the comfort of familiar rituals. With this option, families can hold a viewing and funeral service before the cremation takes place, with costs typically ranging from $4,000-$8,000 depending on casket selection and service details.

Some cultural and religious traditions place special importance on witness cremation, where family members are present for the beginning of the cremation process. This is particularly meaningful in Hindu traditions and generally adds $200-$500 to the chosen package.

The container that holds your loved one during cremation also offers choices. Alternative containers made of simple cardboard or wood ($50-$150) meet the basic requirement for dignified disposition. Cremation caskets ($800-$3,000) are specifically designed for cremation while offering more aesthetic appeal for viewings. For families wanting a traditional appearance without the full expense, rental caskets ($800-$1,200) provide a beautiful exterior for the viewing with a removable interior that will be cremated with your loved one.

After the retort cremation is complete, families face perhaps the most personal decision – what to do with their loved one's remains. Traditional urns in metal, wood, ceramic, or stone ($100-$2,000) remain popular, while others choose scattering at sea, in gardens, or other meaningful locations. Columbarium niches offer permanent placement in a memorial building, while more unique options include memorial jewelry containing small portions of remains, memorial diamonds created from carbon extracted from the remains, or reef memorials that incorporate remains into designed concrete reef modules for marine habitats.

As you plan your budget, remember to consider not just the basic cremation cost but these additional services and memorialization options as well. With cremation projected to reach 78% of dispositions by 2035 according to the NFDA, more innovative and personalized options continue to emerge each year.

At American Mortuary Coolers, we work behind the scenes with funeral professionals nationwide to ensure they have reliable equipment to serve families like yours with dignity and care. While families don't directly interact with our equipment, knowing that your loved one's cremation is handled with modern, well-maintained systems can provide peace of mind during a difficult time.

Frequently Asked Questions about Retort Cremation

How is the identity of the deceased protected?

One of the most common concerns families share with us at American Mortuary Coolers involves identity protection. It's a question we hear from Nashville to Phoenix, and we understand why it matters so deeply.

The retort cremation process includes multiple layers of identity safeguards that work together like a safety net. When your loved one arrives at the facility, staff perform an initial identification using visual confirmation and documentation. Non-combustible ID bands remain with the body until the actual cremation begins.

Perhaps the most important safeguard is the metal identification disc—a small tag with a unique number that stays with your loved one throughout the entire process, including during cremation. This disc remains with the cremated remains until they're returned to your family.

"The metal ID disc is the gold standard in our industry," explains one crematory manager we work with in Atlanta. "It's our promise to families that their loved one never leaves our care."

Behind the scenes, detailed logbooks create a documented chain of custody, with verification signatures required at each step. And by law, only one person can be cremated at a time in a retort—providing another layer of certainty for families.

What happens to medical implants and jewelry?

Medical devices and personal items require thoughtful handling during the retort cremation process.

Pacemakers and other battery-powered medical devices must be removed before cremation—not just as a matter of preference, but as a critical safety measure. When heated to cremation temperatures, these devices can explode, potentially damaging the retort and creating a safety hazard for operators.

Joint replacements, dental work, and other metal implants tell a different story. These typically remain after cremation and are separated from the remains using magnets or careful manual sorting. Many crematories participate in recycling programs for these recovered metals, with proceeds often donated to charity—turning something seemingly insignificant into a final act of giving.

"We've helped fund over $10,000 in local hospice services through our implant recycling program," shared one funeral director from our Ohio service region.

As for jewelry, unless specifically requested to remain with your loved one, these items are typically removed and returned to the family before cremation. This is important to understand—if left on the body, precious metals will melt during the retort cremation process and cannot be recovered in their original form.

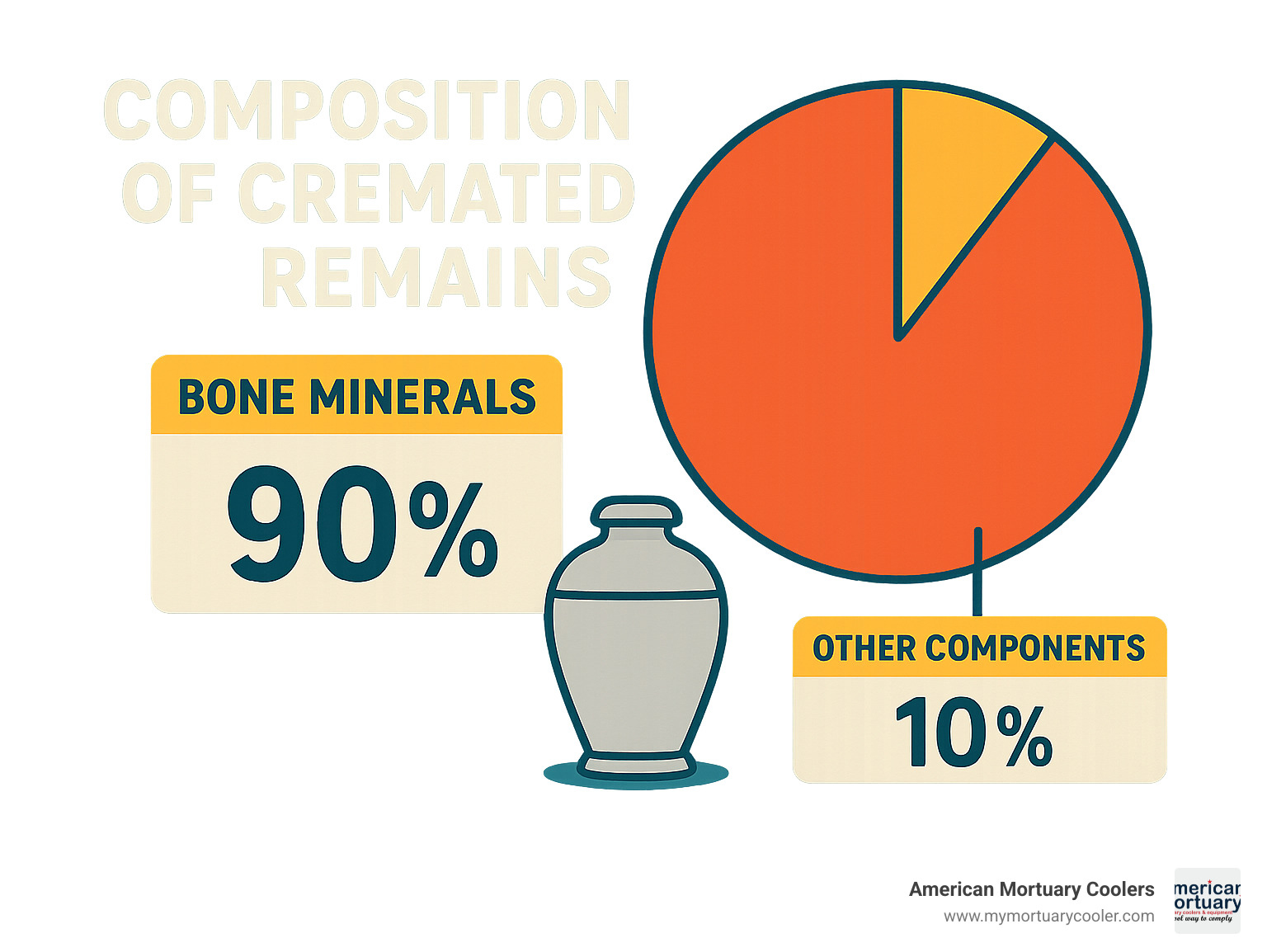

How much do ashes weigh and what are they made of?

After the retort cremation process completes, families often wonder what to expect when receiving their loved one's remains.

The cremated remains of an adult typically weigh between 4-6 pounds (1.8-2.7 kg), with men's remains generally weighing about 2.2 pounds more than women's. This variation reflects natural differences in bone density and body size.

What many people don't realize is that cremated remains aren't actually "ashes" in the traditional sense. They're primarily composed of bone fragments—the only part of the human body that doesn't completely combust during cremation. These fragments consist mostly of calcium phosphates and other minerals that naturally make up our skeletal structure.

After careful processing in a machine called a cremulator, these remains take on a sand-like consistency with a color ranging from white to light gray. The texture is often described as similar to coarse beach sand.

"We prefer the term 'cremated remains' rather than 'ashes' or the industry shorthand 'cremains,'" notes one of our funeral director clients in Kentucky. "It's more accurate and honors the dignity of what these remains truly represent—the final physical connection to someone deeply loved."

At American Mortuary Coolers, we've found that helping families understand these practical details often provides comfort during a difficult time. Knowledge removes uncertainty, allowing families to focus on what matters most—honoring their loved one's memory.

Conclusion

The journey of retort cremation represents one of humanity's oldest practices transformed by modern engineering and compassionate service. What began as ancient funeral pyres has evolved into a carefully designed process that honors the deceased while meeting today's environmental and regulatory standards.

Throughout this exploration, we've seen how the modern cremation process typically takes between one and three hours, followed by a respectful cooling period and careful processing of remains. Behind these technical details lies something more profound—a commitment to dignity that guides every step from identification protocols to the final return of remains to grieving families.

The shift toward cremation continues to grow across America, with projections suggesting cremation rates will reach 78% by 2035. This remarkable change reflects evolving values around cost, environmental impact, and religious flexibility in how we honor our loved ones.

Here at American Mortuary Coolers, we witness how funeral professionals steer these changing preferences. From our home base in Johnson City, Tennessee, we've helped funeral homes across all 48 contiguous states find equipment solutions that match both their technical needs and their commitment to families.

Retort cremation equipment represents a significant investment—often $150,000 to $200,000 for the retort alone, with additional costs for processing stations and proper cooling systems. But as one of our long-time funeral director clients wisely observes, "Cheap isn't always inexpensive." This is especially true when considering that quality equipment, properly maintained, will serve your community for decades.

The future of cremation points toward greater environmental responsibility, with innovations like electric retorts and heat-recovery systems already appearing in forward-thinking facilities. These developments align with what families increasingly seek—meaningful disposition options that reflect their values around both remembrance and sustainability.

Whether you're considering adding cremation services to your funeral home or upgrading existing equipment, understanding these fundamentals helps you make choices that will serve families with the care and respect they deserve during their most vulnerable moments. After all, behind every technical discussion about refractory brick and temperature controls is the simple human desire to honor those we've lost with dignity and grace.

We at American Mortuary Coolers remain committed to supporting funeral professionals with equipment that enables this essential service—built with the reliability, efficiency, and durability that American craftsmanship represents.