Why Serrated Forceps Are Essential Medical Instruments

Serrated forceps are specialized medical instruments featuring textured or ridged jaw surfaces that provide superior grip and control during surgical procedures. Unlike smooth-tipped forceps, the serrated design prevents slippage and allows for more precise manipulation of tissues, dressings, and other materials.

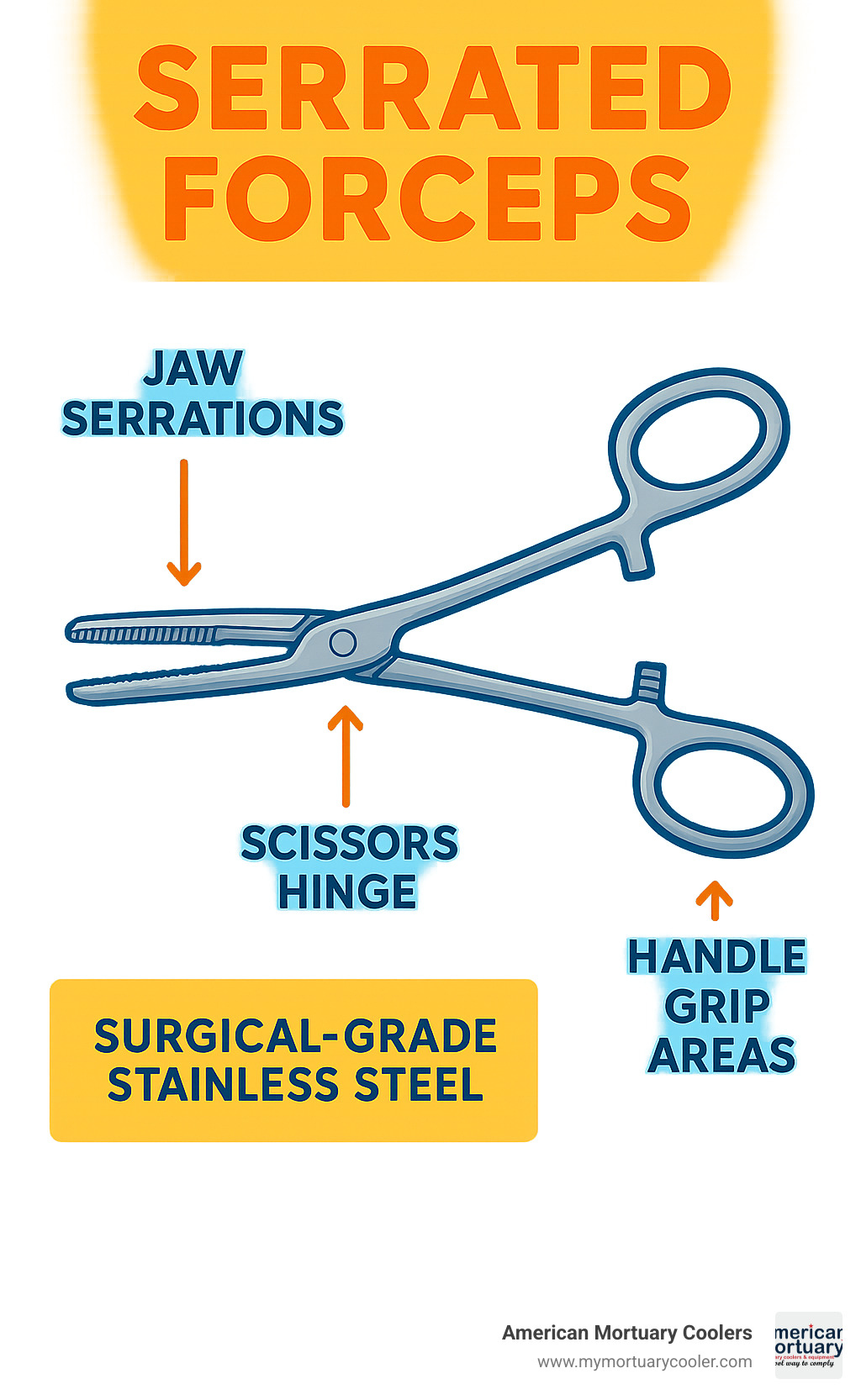

Key Features of Serrated Forceps:

- Textured jaws with ridges or cross-hatch patterns for improved grip

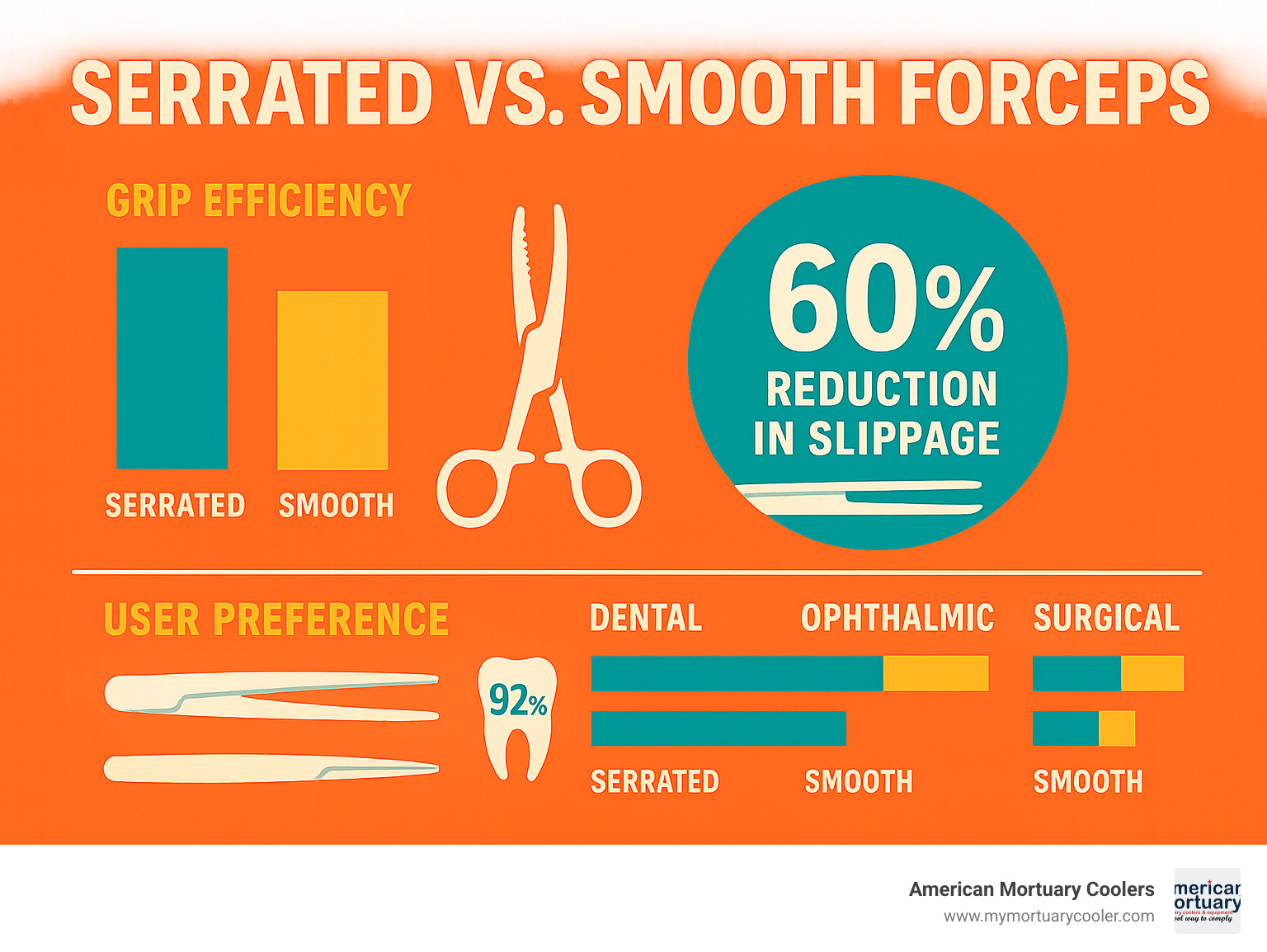

- Reduced slippage by up to 60% compared to smooth forceps

- Scissors-style hinge for even force distribution

- Surgical-grade stainless steel construction for durability

- Multiple sizes from 4.5" to 12" for different applications

Common Applications:

- Dental extractions (92% of dentists prefer serrated forceps for multi-rooted teeth)

- Wound dressing removal

- Ophthalmic microsurgery

- Laboratory dissections

- Mortuary preparation procedures

The serrations inside the jaws create a mechanical advantage that allows practitioners to maintain firm control without applying excessive pressure. This design feature makes them particularly valuable for delicate procedures where precision matters most.

As Mortuary Cooler, I've worked extensively with funeral home directors who rely on quality serrated forceps for preparation procedures, understanding how the right instruments impact both efficiency and results. My experience in the mortuary equipment industry has shown me that durable, well-designed serrated forceps are essential tools that deserve careful selection and proper maintenance.

Serrated forceps further reading:

Understanding Serrated Forceps

When you first pick up serrated forceps, you'll immediately notice how different they feel from regular smooth forceps. It's like comparing a regular tire to a snow tire - both do the job, but one gives you that extra grip when you really need it.

The magic happens in those tiny ridges and grooves on the jaw surfaces. While smooth forceps rely on pure squeezing power, serrated forceps use those textured surfaces to grab and hold with much less effort. Think of it as getting a better handshake - you don't need to crush someone's hand to show you mean business.

| Feature | Serrated Forceps | Smooth Forceps |

|---|---|---|

| Grip Strength | Superior - 60% less slippage | Standard compression only |

| Pressure Required | Lower force needed | Higher compression required |

| Tissue Trauma | Reduced when used properly | Higher risk of crushing |

| Applications | Extractions, dressing removal | General grasping tasks |

| Durability | Longer lasting grip surface | Wear affects performance less |

That 60% reduction in slippage isn't just a nice-to-have feature - it's a game changer. When you're working on delicate procedures, the last thing you want is your instrument slipping at the wrong moment. The serrated beaks create what engineers call "mechanical advantage," which is a fancy way of saying they make your job easier.

The scissors hinge design works hand-in-hand with those serrated surfaces. Instead of just clamping down like a vise, the hinge spreads the force evenly across the entire jaw surface. This is especially important during dental extractions, where you need to engage the crown without cracking it in half.

What Makes "Serrated Forceps" Unique?

Not all serrations are created equal, and understanding the difference can help you pick the right tool for your specific needs. It's a bit like choosing between different types of sandpaper - each pattern serves a purpose.

Criss-cross serrations look like tiny diamonds or a cross-hatch pattern etched into the metal. These little intersecting ridges create multiple grip points that work in all directions. If you need to twist or rotate during a procedure, this is your go-to pattern. Eye surgeons love these for delicate membrane work where they need precise control over tissue orientation.

Longitudinal serrations run straight down the length of the forceps jaws. These are your workhorses for procedures where you're mainly concerned about things sliding forward or backward. They're perfect for suture removal or changing dressings - anywhere you need that solid, straight-line grip.

The way these patterns distribute force makes a real difference in how the instrument performs. Criss-cross patterns spread the pressure more evenly, like distributing weight across a wider area. Longitudinal patterns concentrate the grip along specific lines, giving you that firm hold when you need it most.

Components and Materials of Serrated Forceps

Quality serrated forceps start with quality materials, and that usually means surgical-grade stainless steel. The most common type you'll see is AISI 440 steel, which hits the sweet spot between hardness and corrosion resistance.

The best forceps often come from German manufacturers who use precision forging techniques. This isn't just about national pride - forging creates a denser, stronger structure than other manufacturing methods. It's like the difference between a hand-forged knife and a mass-produced one.

Those serrations aren't just scratched into the surface. They're carefully machined or etched using specialized equipment that ensures each ridge is the right depth and spacing. Get this wrong, and you end up with an instrument that either doesn't grip properly or tears tissue.

Some premium forceps take things a step further with tungsten-carbide inserts in the jaw tips. These inserts are incredibly hard and wear-resistant, though they do bump up the price and require special sharpening techniques. For high-volume practices, the extra cost often pays for itself in longevity.

Corrosion resistance is crucial because these instruments go through countless sterilization cycles. The chromium in surgical stainless steel forms a protective layer that fights off rust and pitting. Quality forceps should look as good after thousands of autoclave cycles as they did on day one.

As someone who works with funeral professionals through American Mortuary Coolers, I've seen how the right instruments make all the difference in achieving professional results. Just like our custom mortuary equipment, quality serrated forceps are an investment in both efficiency and craftsmanship.

Applications & Advantages

Serrated forceps have earned their place as essential tools across an impressive range of medical and scientific fields. What makes them so versatile? It all comes down to that fundamental advantage of superior grip control, which translates directly into better efficiency and improved patient safety.

You'll find these reliable instruments hard at work in dental offices during tooth extractions, where precision matters most. In surgical suites, they're carefully removing wound dressings without causing unnecessary discomfort. Ophthalmic surgeons depend on them for the most delicate microsurgery procedures, while veterinary clinics use them for everything from routine procedures to complex operations.

Laboratory settings showcase another side of their versatility. Whether it's educational dissections where students need dependable tools or research facilities conducting detailed tissue analysis, serrated forceps deliver consistent performance. Even in mortuary preparation work, these instruments provide the control and reliability that funeral professionals need for their important work.

The beauty of serrated forceps lies in how they make difficult procedures more manageable. That textured grip surface means less struggling with slippery materials and more focus on the task at hand. When you're working with delicate tissues or trying to remove stubborn dressings, that 60% reduction in slippage isn't just a statistic - it's the difference between a smooth procedure and a frustrating one.

Dental Extractions with Serrated Forceps

When it comes to dental extractions, serrated forceps have practically revolutionized the field. Presidential forceps with their distinctive split serrated beaks represent the gold standard for routine tooth removal. There's a good reason why 92% of dental professionals reach for serrated designs when dealing with multi-rooted teeth.

The magic happens in how those serrations create multiple contact points with the tooth structure. Instead of relying on brute force like smooth forceps, they distribute extraction pressure evenly across the tooth surface. This is absolutely crucial when you're working with multi-rooted teeth, where uneven pressure can spell disaster in the form of root separation or fracture.

Presidential forceps deserve special mention for their clever split-beak design. These instruments adapt beautifully to different tooth shapes and sizes, while the serrations maintain that secure grip even when the beak geometry isn't perfectly matched to the tooth. This flexibility means fewer instrument changes during complex extractions - something every dentist appreciates.

The scissors hinge mechanism in quality dental forceps works hand-in-hand with the serrated surfaces. This combination distributes force equally between the handles and jaws, minimizing the risk of instrument failure during high-stress extractions. Your hands will thank you too, as the even force distribution significantly reduces operator fatigue during those lengthy procedures.

Surgical & Laboratory Benefits

Beyond the dental chair, serrated forceps prove their worth in countless surgical and laboratory applications. Artery forceps with serrated jaws excel at controlling bleeding during procedures, maintaining secure vessel occlusion without the crushing pressure that could damage delicate vessel walls.

The concept of atraumatic handling really shines here. When surgeons can manipulate tissues with a lighter touch thanks to improved grip, surrounding structures stay healthier. This gentle approach is particularly valuable in microsurgery, where preserving every bit of healthy tissue can make the difference in patient outcomes.

Fibrotic membrane peeling presents one of the most challenging applications for any forceps. These tough, slippery tissues found in vitreoretinal surgery demand instruments that won't let go when precision matters most. The specialized 23GA serrated forceps used in these procedures feature jaw patterns specifically engineered for membrane manipulation - a perfect example of how serration design can be custom to exact surgical needs.

Educational dissections benefit enormously from the reliability that serrated forceps provide. Students learning complex anatomical structures need tools they can trust, allowing them to focus on understanding anatomy rather than wrestling with slipping instruments. When your forceps work consistently, confidence builds naturally, and the learning process accelerates. This advantage extends beautifully into veterinary training programs, where proper instrument handling forms the foundation of surgical skills.

Selection Guide & Purchasing Tips

Choosing the right serrated forceps can feel overwhelming with so many options available. But don't worry - once you understand what to look for, the decision becomes much clearer. Think of it like buying a quality tool for your workshop - you want something that fits your hand well, does the job reliably, and lasts for years.

The first thing to consider is beak design. Straight beaks give you the best visibility and work great for most procedures where you can see what you're doing clearly. Curved designs are your best friend when you need to reach into tight spaces or work around corners. The curve isn't just for show - it changes how the instrument sits in your hand and affects the working angle.

Size matters more than you might think. Delicate 4.5-inch instruments are perfect for precision work, while robust 12-inch models handle bigger jobs without breaking a sweat. The jaw width changes too - from tiny 0.3mm openings for eye surgery to several millimeters for general use. Using the wrong size is like trying to eat soup with a fork - technically possible, but frustrating.

Angle specifications include both the jaw angle and how the whole instrument is shaped. Some forceps have 60-degree angled jaws that let you reach into confined spaces much easier, while straight designs give you maximum power transfer. Think about where you'll be working most often - tight spaces call for angled designs, while open procedures work fine with straight instruments.

Don't overlook ergonomic handles - your hands will thank you later. Features like thumb grips, finger rests, and textured surfaces make a huge difference during long procedures. If you're going to be using these instruments for hours at a time, comfort isn't a luxury - it's a necessity.

When shopping for suppliers, create a simple checklist that covers warranty terms, return policies, and customer support. Quality manufacturers stand behind their products with solid warranties and actually answer the phone when you need help.

Scientific research on instrument ergonomics

Evaluating Quality: From Steel Grade to Warranty

Quality serrated forceps start with good materials and careful manufacturing - but how do you tell the difference between excellent instruments and expensive disappointments?

German forging represents the gold standard in surgical instruments. It's not just marketing hype - the forging process actually creates denser, stronger steel compared to casting methods. The result is instruments that stay sharp longer, resist corrosion better, and handle stress without breaking. When you see "German forged" on an instrument, you're looking at serious quality.

Steel grade specifications might sound boring, but they directly affect how long your instruments will last. AISI 440 stainless steel provides excellent corrosion resistance and stays hard even after thousands of sterilization cycles. Some manufacturers use their own special steel alloys that perform even better, but 440 stainless is the baseline for quality instruments.

Lifetime warranty claims need careful reading. A legitimate lifetime warranty covers defects in materials and workmanship - basically, if the manufacturer messed up, they'll fix it. But normal wear from regular use? That's on you. Read the fine print to understand what's actually covered and what the manufacturer considers "normal wear" for your type of work.

Quality control inspections should be documented and available if you ask. Good manufacturers keep detailed records and can provide certification paperwork. This isn't just bureaucracy - in clinical settings, you might need this documentation for regulatory compliance.

The surface finish affects both how well the instrument works and how easy it is to clean. Premium instruments have smooth, consistent finishes that don't harbor bacteria and clean up easily. Poor finishes can trap contaminants and make sterilization less effective.

Where to Buy "Serrated Forceps" Safely Online

Buying serrated forceps online can save money and time, but you need to be smart about where you shop. The internet is full of suppliers, and not all of them are created equal.

Established suppliers like gSource and Katena have earned their reputations over years of serving medical professionals. They provide detailed product information, answer technical questions, and stand behind what they sell. When you're buying precision instruments, this kind of established presence matters.

Wholesale registration portals can offer significant savings if you qualify. You'll typically need professional credentials and might face minimum order requirements, but the access to professional-grade products and bulk pricing can be worth the extra paperwork.

Authenticity verification becomes crucial when you're spending serious money on precision instruments. Legitimate suppliers provide detailed specifications, manufacturer information, and serial number tracking. If a supplier can't or won't provide this documentation, or if their prices seem too good to be true, keep looking.

Customer reviews from other professionals in your field provide the best insights into both supplier reliability and product quality. Look specifically for reviews from verified purchasers who actually use the instruments in similar applications to yours. Their experiences will be most relevant to your needs.

Buying quality instruments is an investment in your work. Cheap knockoffs might save money upfront, but they'll cost you more in the long run through poor performance, frequent replacement, and potential safety issues.

Care, Sterilization & Best Practices

Taking proper care of your serrated forceps isn't just about making them last longer - it's about keeping your patients safe and your procedures running smoothly. These precision instruments deserve the same attention you'd give any valuable tool that people's well-being depends on.

The moment you finish using serrated forceps, the clock starts ticking. Blood and tissue debris love to hide in those tiny serration grooves, and once they dry, they become much harder to remove. A quick rinse with cool water right after use makes all the difference. Think of it like washing dishes - you wouldn't let spaghetti sauce sit on a plate for hours before cleaning it.

Enzymatic soaking is where the real cleaning magic happens. These special detergents contain enzymes that literally eat away protein deposits hiding in the serration patterns. It's like having microscopic cleaning crews working in places your brush can't reach. Follow the manufacturer's instructions for concentration and soaking time - more isn't always better.

The ultrasonic cleaning bath takes things to the next level. Those high-frequency sound waves create tiny bubbles that collapse and create cleaning action in every microscopic crevice. For serrated instruments, this step is particularly valuable because it reaches areas that even the most thorough hand cleaning might miss.

When it comes to autoclave sterilization, consistency is key. Most surgical instruments need 121°C (250°F) for 15-20 minutes, but your specific autoclave and load configuration might require adjustments. Position instruments carefully so steam can circulate freely, and avoid letting them touch each other or the autoclave walls.

After sterilization comes the inspection phase - and this is where many practices fall short. Check each instrument for serration integrity, smooth hinge operation, and any signs of wear or damage. If something doesn't look right, trust your instincts and remove it from service. It's better to be cautious than sorry.

More info about Adison forceps guide

Cleaning & Sterilizing Serrated Forceps

The textured surfaces that make serrated forceps so effective also create unique cleaning challenges. Those helpful serrations can trap debris in ways that smooth instruments simply don't experience. But with the right approach, keeping them spotless becomes routine.

Rust prevention starts with thorough drying. Water loves to pool in serrated grooves, and where water sits, corrosion follows. Use forced-air drying or lint-free cloths to eliminate every drop of moisture before sterilization. It might seem like overkill, but rust spots are much harder to remove than water drops.

Moving parts need regular lubrication to stay smooth and prevent premature wear. But here's the catch - only use lubricants specifically designed for surgical instruments. Regular oils or lubricants can leave harmful residues or break down under sterilization temperatures. Apply sparingly to hinge mechanisms and wipe away any excess.

Storage protocols matter more than most people realize. Sterile instruments should stay in protective packaging until use. Tossing them loose in a drawer might be convenient, but it risks both contamination and damage to those precise serration patterns. Treat them like the precision tools they are.

Setting up regular maintenance schedules helps catch problems before they become serious. Weekly or monthly inspections, depending on usage volume, can identify wear patterns and potential issues. Document what you find - patterns in wear or damage can reveal training opportunities or technique improvements.

Technique Tips to Avoid Common Mistakes with Serrated Forceps

Even the best serrated forceps won't perform well if they're used incorrectly. The good news is that most common mistakes are easy to avoid once you know what to watch for.

The biggest mistake? Over-compression. Those serrations provide so much extra grip that many practitioners use way more pressure than necessary. Start light and gradually increase pressure only if needed. Your tissues will thank you, and your instruments will last longer too.

Proper alignment makes all the difference, especially in dental extractions. The forceps should align with the natural axis of whatever you're grasping. Fighting against natural angles puts stress on both the instrument and the target structure. Take a moment to position correctly rather than forcing an awkward angle.

For single-use instruments, the rule is simple: use once, dispose properly. No exceptions. The temptation to "just clean it really well" for one more use isn't worth the risks. Single-use instruments are designed with specific safety margins that reuse can compromise.

Before starting any procedure, run through a quick inspection checklist. Are the serrations intact? Does the hinge move smoothly? Is everything clean and properly sterilized? This 30-second check can prevent complications that would take much longer to resolve.

Frequently Asked Questions about Serrated Forceps

What advantages do serrated forceps offer over smooth forceps?

The difference is dramatic - serrated forceps reduce slippage by up to 60% compared to smooth alternatives. This improved grip means you can use less pressure while maintaining better control. Less pressure means less tissue trauma and reduced operator fatigue during long procedures. It's like comparing regular tires to snow tires - both work, but one gives you much better control under challenging conditions.

How often should serrated forceps be sharpened or replaced?

High-quality serrated forceps with proper care can handle thousands of procedures before needing attention. Watch for visible wear in the serration patterns, difficulty maintaining grip, or any damage to the jaw surfaces. Professional sharpening can restore performance in many cases, but severely worn instruments should be replaced rather than repaired. When in doubt, err on the side of caution.

Can serrated forceps handle delicate tissues safely?

Absolutely, and often better than smooth forceps. The key is choosing the right serration pattern and using proper technique. Fine, shallow serrations work beautifully for delicate tissues, while deeper patterns suit tougher materials. The improved grip actually enables gentler handling because you need less pressure to maintain control. It's counterintuitive, but the "grippier" surface often means less trauma.

Conclusion

Serrated forceps have truly transformed how medical professionals approach delicate procedures. After exploring their design, applications, and benefits throughout this guide, it's clear why these instruments have become indispensable across so many fields.

The numbers speak for themselves - that 60% reduction in slippage compared to smooth forceps isn't just a technical specification. It means fewer complications during dental extractions, less tissue trauma during wound care, and more confidence during delicate microsurgery. When 92% of dental professionals choose serrated designs for complex extractions, they're voting with their experience and patient outcomes.

What makes serrated forceps special goes beyond just better grip. The mechanical advantage they provide allows practitioners to work with precision while using less force. This translates to reduced patient discomfort, fewer procedural complications, and less fatigue for the healthcare provider. Whether you're a seasoned surgeon or a student learning proper technique, these instruments make challenging procedures more manageable.

Investing in quality pays off with serrated forceps. While the upfront cost might be higher than basic alternatives, premium instruments with proper steel grades and precise manufacturing deliver years of reliable service. The difference between a well-made instrument and a budget option becomes obvious after just a few uses.

Even the best serrated forceps need proper care to maintain their performance. Following those cleaning and sterilization protocols we discussed isn't just about compliance - it's about protecting your investment and ensuring consistent results for every patient.

At American Mortuary Coolers, we've built our reputation on understanding that professionals need tools they can rely on. While we specialize in crafting durable custom mortuary coolers and equipment for funeral professionals throughout the contiguous 48 states, we appreciate the same attention to quality and reliability that makes serrated forceps essential instruments. Just as we deliver custom solutions direct from our Tennessee facility, the right medical instruments should be chosen with the same commitment to excellence that defines professional practice.

Whether you're performing routine procedures or tackling complex cases, serrated forceps offer the control and confidence that lead to better outcomes. The investment in quality instruments reflects your commitment to providing the best possible care.