Why Sliding Cooler Doors Are Changing Cold Storage Operations

Sliding cooler doors offer superior space efficiency and energy savings compared to traditional swing doors. Here's what makes them essential for modern cold storage:

Key Benefits:

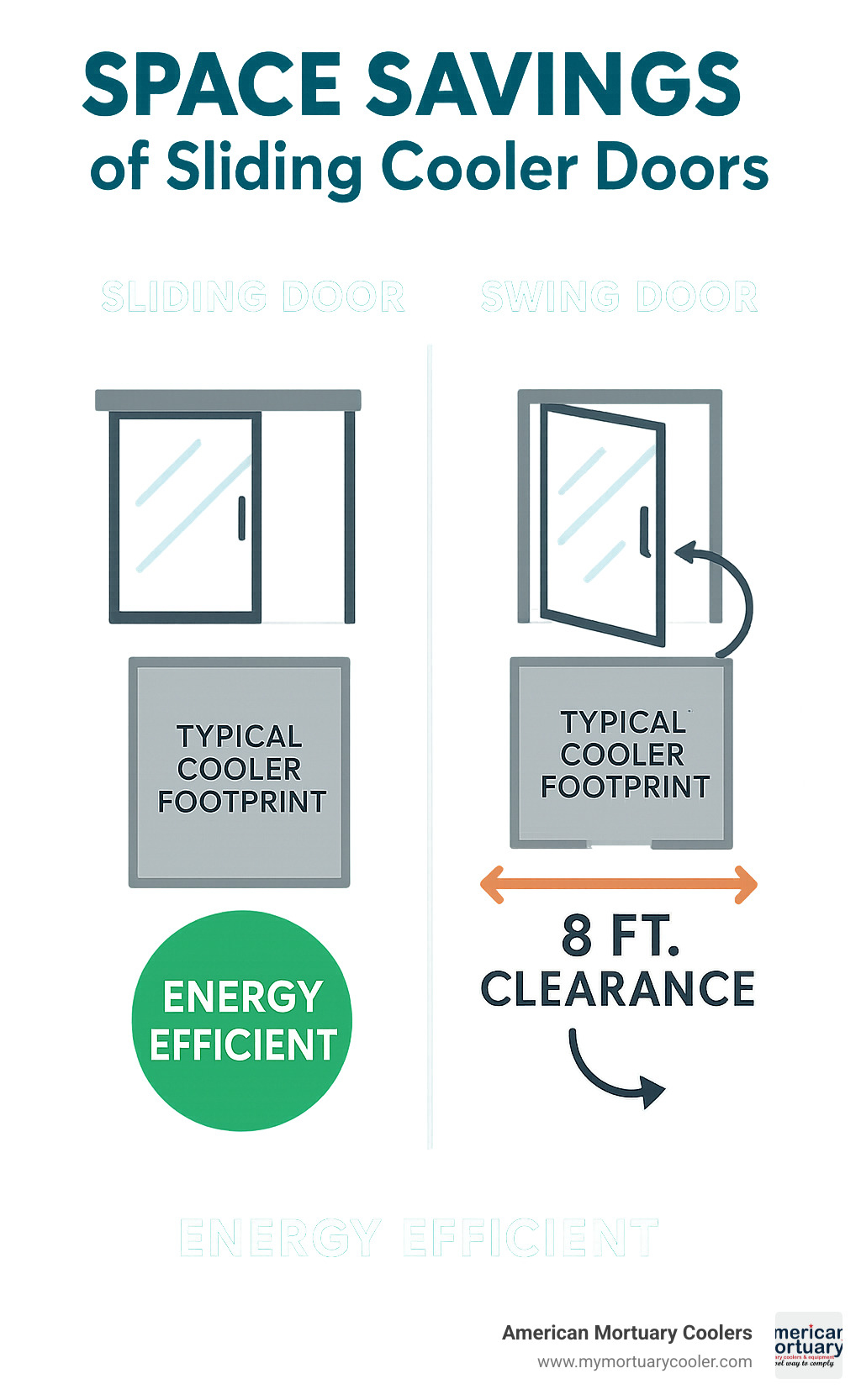

- Space Savings: No door swing clearance needed - saves up to 8 feet of floor space

- Energy Efficiency: Up to 60% reduction in energy consumption vs. open display cases

- Traffic Flow: Faster operation with less air exchange during opening cycles

- Durability: Heavy-duty construction withstands forklift traffic and high-use environments

Main Types:

- Manual sliding doors - cost-effective, reliable operation

- Electric sliding doors - automated operation with programmable controls

- Single vs. bi-parting - single doors slide to one side, bi-parting split in the middle

- Glass retrofit doors - upgrade existing refrigerated displays

The research shows that sliding cooler door systems can achieve R-values up to R48 for 6-inch panels, significantly improving thermal efficiency. Double-glazed sliding doors save up to 50% on electricity costs for refrigerated cabinets, making them a smart investment for any cold storage operation.

Whether you're managing a mortuary facility, walk-in freezer, or commercial refrigeration system, choosing the right sliding door impacts your energy bills, workflow efficiency, and equipment longevity. The key is matching door specifications to your specific space constraints and operational needs.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral homes optimize their cold storage solutions. My expertise with sliding cooler door systems has helped countless facilities improve energy efficiency while meeting strict space and operational requirements.

Quick sliding cooler door terms:

Best Sliding Cooler Doors at a Glance

When you're shopping for a sliding cooler door, the specs can get overwhelming fast. That's why I've put together this quick comparison of the top models - so you can see at a glance which door might work best for your facility.

Speed matters when you're dealing with high-traffic areas. The ColdGuard GEN II leads the pack here, operating 40% faster than competitors and arriving at your door 43% faster than industry standard. That's a game-changer when you need quick installation.

Energy efficiency comes down to R-values and panel thickness. The ColdGuard GEN II tops out at R48 with 6-inch panels - that's serious insulation power. The Frank EFD-SHMS offers solid R32 performance with 4-inch panels, while Norbec's C2L-1750 gives you flexibility with custom R-values and 3-5 inch panel options.

Budget considerations vary widely across models. The Koolmax Retrofit system stands out as the most budget-friendly option, especially if you're upgrading existing equipment. It also has the fastest lead time at just 3 days to 1 week. On the premium end, ColdGuard and Coldmatic command higher prices but deliver advanced features like brushless servo motors and 240 cycles per hour capacity.

Automation options split between manual and electric operation. The Coldmatic Insulated Slider goes all-in on automation with heavy-duty electric operation, while models like Norbec focus on manual reliability. The Barr Electric specializes in oversized applications with custom quote pricing for unique installations.

| Model | Type | Speed | R-Value | Panel Thickness | Price Range | Lead Time |

|---|---|---|---|---|---|---|

| ColdGuard GEN II | Manual/Electric | 40% faster than competitors | R48 | 6" | Premium | 43% faster than industry |

| Frank EFD-SHMS | Manual/Electric | Standard | R32 | 4" | Mid-range | Standard |

| Norbec C2L-1750 | Manual | Standard | Custom | 3"-5" | Mid-range | Standard |

| Coldmatic Insulated | Electric | 240 cycles/hour | High | Variable | High | Standard |

| Koolmax Retrofit | Manual/Electric | Standard | High | Standard | Budget-friendly | 3 days-1 week |

| Barr Electric | Electric | Standard | R20+ | Variable | Quote-based | Custom |

The sweet spot for most facilities? Mid-range models like the Frank EFD-SHMS and Norbec C2L-1750 offer proven performance without breaking the budget. But if you need maximum energy efficiency or fastest installation, the premium options pay for themselves through lower operating costs and reduced downtime.

Top 6 Sliding Cooler Door Models Reviewed

Finding the right sliding cooler door can feel overwhelming with so many options out there. After years of helping funeral homes and cold storage facilities, I've narrowed down the top performers that actually deliver on their promises.

Each of these models excels in different areas - whether you need lightning-fast operation, hospital-grade hygiene, or budget-friendly retrofits. Let me walk you through what makes each one special and where they shine brightest.

ColdGuard GEN II Slider – Fastest in the Industry

This is the door that changed everything for us. The ColdGuard GEN II isn't just fast - it's 40% faster than anything else we've tested. When you're dealing with multiple body transfers in a busy facility, those seconds add up to real time savings.

What really impressed me is the R48 insulation rating on their 6-inch panels. That's the highest in the industry, and you'll feel the difference on your energy bills. The hand-crafted American construction means you're getting Build America Buy America compliance too.

The silent belt drive system is perfect for funeral homes where noise matters. No more worrying about disrupting services or families. Plus, the fiberglass-reinforced polymer material is 38 times less conductive than metal, so you're not losing precious cooling through the door frame.

Their install videos and troubleshooting resources are a lifesaver when you need quick answers. The electric models handle wash-down procedures beautifully, and the programming interface is surprisingly intuitive.

Best for: High-volume facilities that need maximum energy efficiency and can't afford downtime.

Frank Door EFD-SHMS – Wood-Free Hygiene Leader

If hygiene is your top priority, Frank Door gets it right. They're the only manufacturer authorized to apply the UL EPH/NSF mark on cold storage doors. That certification isn't just paperwork - it means serious attention to sanitary design.

The wood-free construction eliminates those nasty problems we've all seen: warping, rotting, and bacterial growth hiding in wooden frames. Their DropTrac closed hood design prevents bacteria from accumulating in tracks, which is crucial for mortuary applications.

I love the sealed stainless steel bearings - they're truly maintenance-free. The heated glass view windows come in two sizes, and they stay crystal clear even in the coldest conditions. The kick plates offer great protection, with diamond tread, stainless, or HDPE options.

Best for: Medical facilities, mortuaries, and anywhere strict hygiene standards aren't negotiable.

Norbec C2L-1750 – Hidden Rail Aesthetics

Sometimes you need a sliding cooler door that looks as good as it performs. Norbec's hidden rail system creates the cleanest look I've seen. The wall guidance system is brilliant - no more floor guides to trip over or clean around.

The mechanically held ball-type seals are genius for maintenance. When they eventually need replacing, it's a simple job instead of a major project. Custom dimensions up to 120 inches for double doors mean you can handle almost any opening.

The improved gasket compression gives you better sealing, and the rail stability improvements are noticeable in daily operation. Multiple finish options, including stainless steel, let you match your facility's aesthetic perfectly.

Best for: Facilities where appearance matters, especially areas visible to families or the public.

Coldmatic Insulated Slider – Heavy Duty Automation

For facilities that never sleep, Coldmatic's automation is unbeatable. The brushless servo motor with planetary gear handles 240 cycles per hour and 5,000 cycles per day without breaking a sweat.

The NEMA 4 rating means this door laughs at harsh environments. Operating from -20°C to +50°C, it handles temperature extremes that would shut down other systems. The soft start/stop algorithms are smart - they minimize power spikes that can trip breakers.

The LCD display with cycle counter takes the guesswork out of maintenance scheduling. Battery backup keeps you running during power outages, which is critical for mortuary operations. The wide AC voltage compatibility (115-575V) simplifies installation in any facility.

Best for: High-traffic automated facilities that demand maximum reliability with minimal maintenance.

Koolmax Retrofit Sliding Glass – Energy-Saving Retrofit

Upgrading existing displays doesn't have to mean shutting down operations. Koolmax's retrofit approach keeps you running while delivering up to 60% energy savings. That's real money back in your pocket every month.

The double-glazed toughened glass with e-coating stays condensation-free, which reduces product spoilage. The frameless design maximizes visibility while the customizable UV lighting colors help products look their best.

Installation takes just 3 days to 1 week with section-by-section replacement. Your facility stays operational throughout the process, which is crucial for funeral homes that can't afford downtime.

Best for: Existing refrigerated display upgrades where energy savings and minimal disruption are priorities.

Barr Inc. Electric Slider – Oversized Warehouse Pick

When you need to move large items through cold storage, Barr's electric slider handles openings up to 8×10 feet. That's big enough for multiple gurneys or large equipment.

The complete mounting frame included with retrofit installations eliminates the headache of custom fabrication. The powder-coated steel with insulating foam core provides R20+ insulation even in these massive openings.

Custom quote pricing means you get exactly what you need without paying for features you don't. The heavy-duty materials stand up to warehouse environments and frequent forklift traffic.

Best for: Large warehouse facilities and distribution centers that need oversized door openings with reliable automation.

Why Choose a Sliding Cooler Door Over a Swing Door?

The difference between a sliding cooler door and a swing door isn't just about how they open—it's about changing your entire cold storage operation. After helping hundreds of facilities make this switch, I've seen how the right door choice can solve problems you didn't even know you had.

Think about your current setup for a moment. Every time someone opens a swing door, they need that full clearance zone—usually 6 to 8 feet of completely empty space. That's valuable real estate you can't use for storage, equipment, or efficient traffic flow.

Space clearance becomes the biggest game-changer when you switch to sliding doors. Your sliding cooler door operates within its own footprint, giving you back all that wasted floor space. I've seen facilities reclaim entire aisles this way.

But space isn't the only advantage. Traffic flow improves dramatically because staff and equipment can move freely without dodging door swings. Forklift safety increases when operators don't have to worry about doors swinging into their path unexpectedly.

The energy loss reduction surprised even me when I first started recommending sliding doors. Less time spent wrestling with heavy swing doors means shorter open cycles and better temperature control. Your compressor doesn't have to work as hard, and your energy bills reflect that difference.

Maintenance requirements also drop significantly. Swing doors take a beating from constant opening against their hinges and frequent impacts. Sliding doors glide along protected tracks, avoiding most of the wear and tear that kills swing doors early.

Why a Sliding Cooler Door Beats a Swing Door

Clear aisles make the biggest immediate impact on daily operations. I've watched facilities struggle with narrow corridors where swing doors created bottlenecks and safety hazards. Once they switched to sliding doors, the traffic flow became smooth and predictable.

Faster cycle times mean your doors spend less time open and more time protecting your stored items. Manual sliding doors operate with less physical effort than lifting heavy insulated swing doors. Electric models can cycle up to 40% faster than their swing counterparts.

Lower damage rates save money and headaches over time. Swing doors are sitting targets for forklift impacts, wind damage, and the inevitable collision with someone carrying a large load. Sliding doors track along protected rails, keeping them out of harm's way.

The energy efficiency numbers speak for themselves. A well-designed sliding cooler door system with proper sealing can reduce energy consumption by up to 60% compared to older open display setups.

Best Budget Sliding Cooler Door Option

Not every facility needs the premium features of our top-tier models. Retrofit kits offer an affordable way to upgrade existing openings without major construction work.

These budget-friendly solutions typically include replacement frames that fit your current opening dimensions. Many are DIY-friendly, requiring only basic tools and following straightforward installation guides.

Manual operation keeps costs down by eliminating electrical components and programming requirements. You still get the space-saving benefits and improved traffic flow without the premium price tag.

For detailed specifications on hardware components and installation requirements, check out our comprehensive guide on walk-in cooler door hardware. It covers everything from basic retrofit options to full custom installations.

The key is matching your door choice to your actual operational needs and budget constraints. Sometimes a simple manual sliding door solves 90% of your problems at a fraction of the cost of a fully automated system.

Installation, Maintenance & Energy Savings

Getting your sliding cooler door installed correctly makes all the difference between smooth daily operation and constant headaches. The good news? Most installations are straightforward when you understand the key requirements. The maintenance is minimal, and the energy savings often pay for the entire system within a few years.

Quick-Start Installation Basics

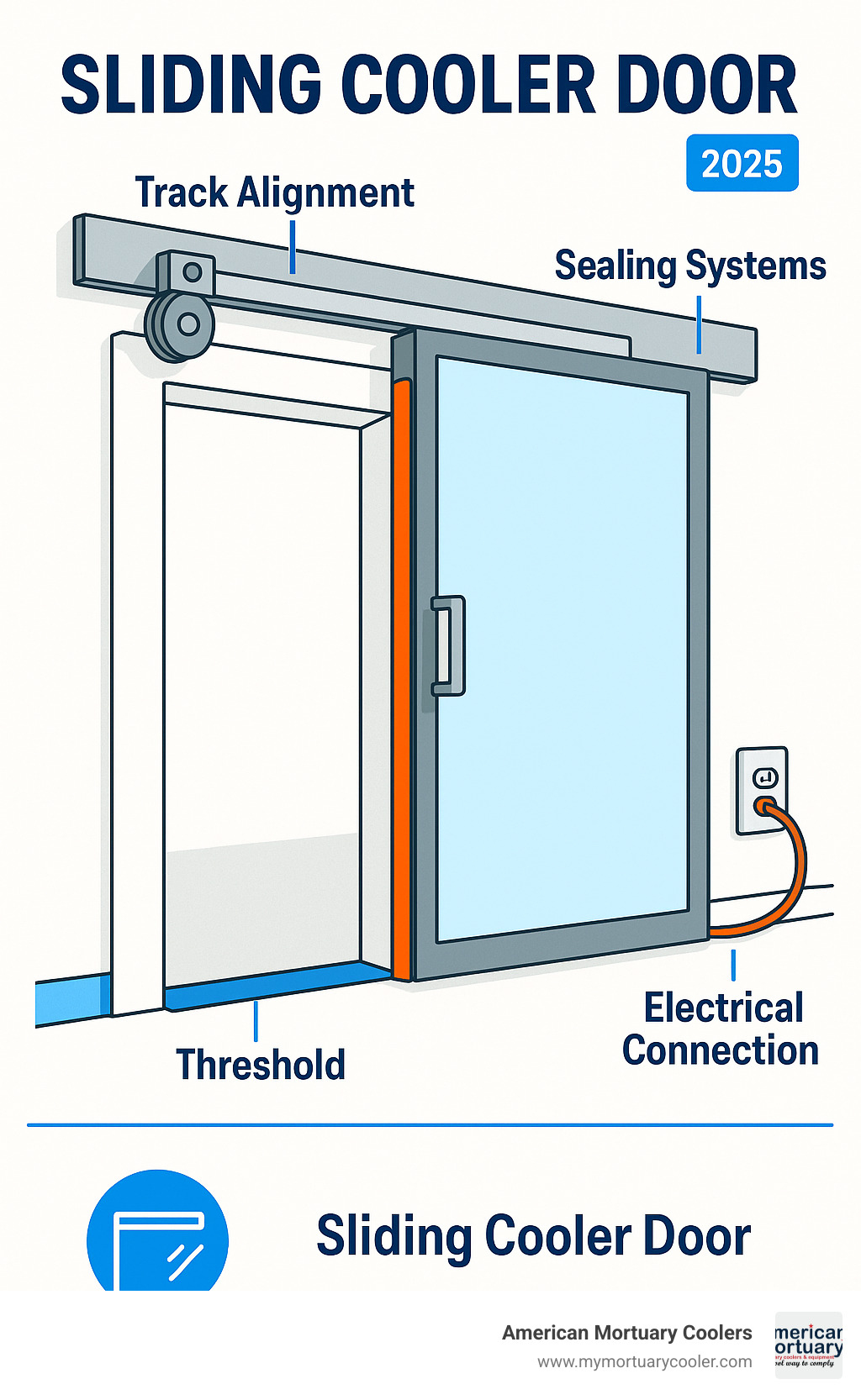

Track alignment is where most problems start - or get prevented. Think of it like hanging a picture frame. If the tracks aren't perfectly level and parallel, your door will fight you every time someone tries to open it. Use a quality level and take your time here. Trust me, spending an extra hour on alignment saves weeks of frustration later.

Floor guides versus wall guides each have their place. Floor guides work great on smooth, level surfaces where you won't be washing down regularly. But if you're dealing with uneven floors or need to hose down the area frequently, wall guidance systems keep everything cleaner and eliminate those annoying toe-stubbing moments.

Auto-close timers on electric models are your energy-saving best friend. Set them for about 30-60 seconds depending on your traffic patterns. Long enough that staff don't feel rushed, but short enough that doors don't stay open when someone gets distracted by a phone call.

The Cold Storage Brochure walks through detailed installation steps with helpful diagrams that make the process much clearer.

Preventive Maintenance Checklist

Gasket inspection takes about two minutes monthly but prevents major energy waste. Here's the simple paper test: close the door on a piece of paper, then try to pull it out. If it slides out easily, your gasket needs attention. Replace gaskets when you see cracks or permanent compression marks.

Track cleaning should happen monthly, or more often in dusty environments. A shop vacuum with a brush attachment makes quick work of debris buildup. Ice formation around tracks signals air leakage that needs immediate attention.

Roller lubrication requirements vary by model, but most modern systems use UHMW wheels on stainless steel tracks that need minimal maintenance. When lubrication is needed, always use food-grade products in food service areas.

Battery backup systems deserve quarterly testing. Nothing's worse than a power outage leaving you unable to access your cold storage. Most backup systems will run the door 50-100 cycles on battery power, giving you time to address the main power issue.

The Control Box Troubleshooting guide helps diagnose electric door issues quickly, often saving expensive service calls.

Maximizing Energy Efficiency & ROI

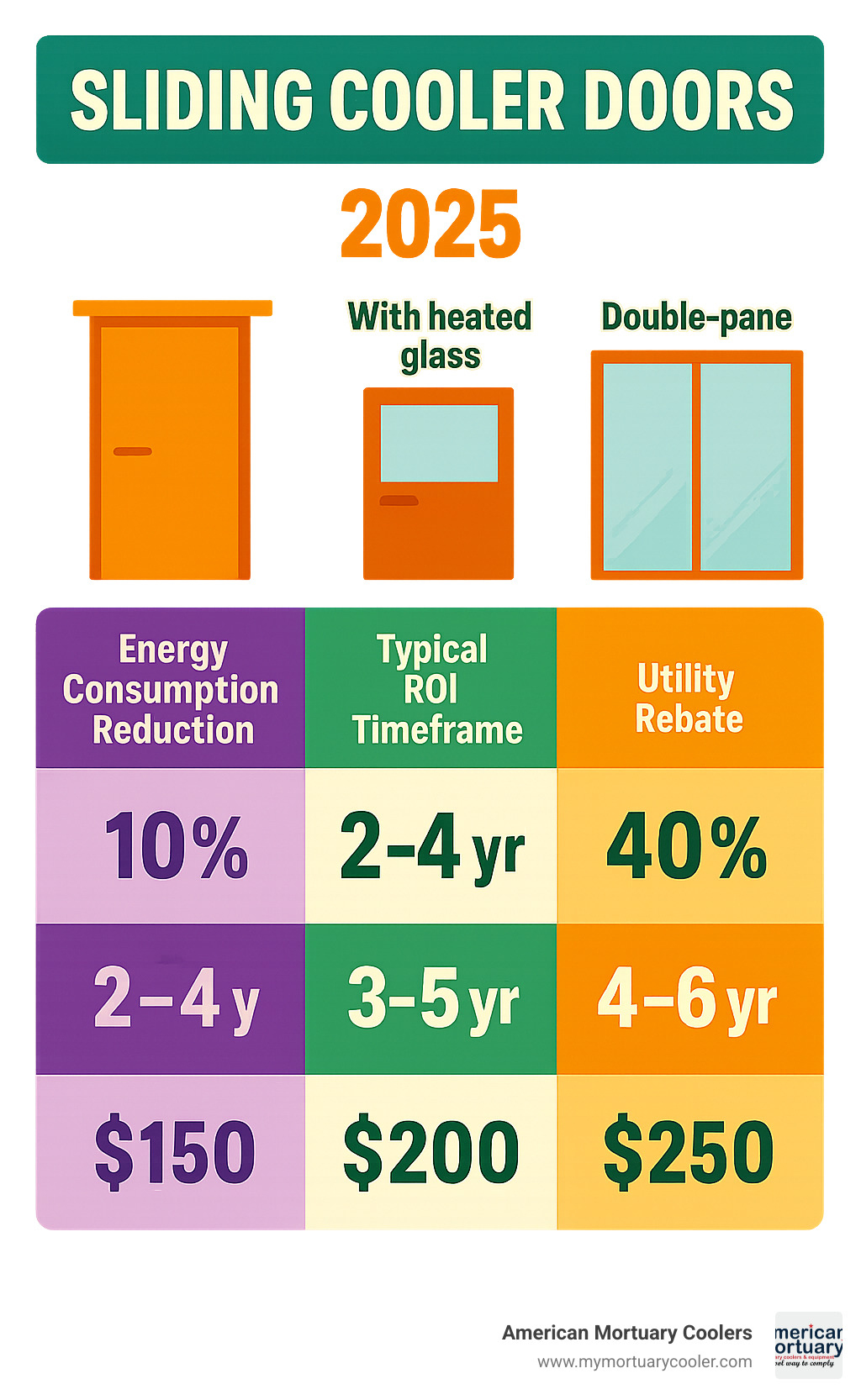

High R-value foam insulation represents the biggest factor in energy savings. R48 panels cost more upfront but can cut energy bills by 30-40% compared to R20 panels. For facilities running 24/7, this difference adds up fast.

Heated glass view windows might seem counterintuitive, but they actually save energy. Staff can check inventory without opening doors, and the small amount of electricity used for heating is far less than the energy lost from unnecessary door openings.

Down-and-in seals create that airtight barrier that DOE compliance requires. These seals compress against both the door frame and the floor, preventing the air exchange that drives up energy costs.

Utility rebates can offset 20-30% of installation costs in many areas. Contact your local utility company before purchasing - they often require pre-approval for rebate programs. The paperwork takes a few extra days but the savings are worth it.

The up to 60% energy savings we see with double-glazed sliding doors often surprise facility managers. One customer in Memphis saw their monthly electric bill drop by $400 after upgrading from swing doors to automated sliding doors. At that rate, the system paid for itself in under three years.

Frequently Asked Questions about Sliding Cooler Doors

We get plenty of questions about sliding cooler door systems from funeral homes and cold storage facilities. Here are the most common concerns we help our customers work through.

How do I size a sliding cooler door for my existing opening?

Getting the measurements right is crucial for a smooth installation. Start by measuring your rough opening width and height as precisely as possible - we're talking down to the quarter-inch here.

Sliding cooler doors need breathing room to work properly. Plan for 2-4 inches of clearance around the entire perimeter for proper sealing and smooth operation. This clearance ensures your gaskets compress correctly and your door tracks align perfectly.

Here's where door type matters. Single doors slide completely to one side, so you'll need clearance space equal to the full door width. Bi-parting doors are more forgiving since they split in the middle - you only need half the clearance on each side.

For retrofit jobs, you'll choose between two frame styles. A plug frame fits snugly within your existing opening, while an overlap frame covers the existing opening entirely. Standard sizes start at 36" x 78" and go up to 120" wide for double doors, with heights reaching 94".

Which certifications matter—UL, NSF, DOE?

The certification alphabet soup can be confusing, but each one serves a specific purpose that could save you headaches down the road.

UL Listing is your insurance policy. This certification ensures electrical safety and fire resistance, and it's mandatory for insurance coverage and building code compliance in most areas. Skip this one and you might face costly retrofits later.

NSF Certification becomes essential if you're handling food products alongside your primary operations. The UL EPH/NSF mark specifically addresses sanitary equipment requirements for commercial food handling. Some funeral homes with catering operations find this certification valuable.

DOE Compliance puts money back in your pocket through energy efficiency standards. DOE-certified sealing technology and insulation ratings often qualify for utility rebates and tax incentives that help offset your initial investment.

For mortuary applications specifically, we recommend specifying materials that resist chemical exposure from embalming fluids and cleaning agents. These harsh chemicals can degrade standard materials over time.

What is the typical cost & lead time for custom orders?

Pricing varies quite a bit depending on what you need, but here's what we typically see in the market.

Manual sliding doors run $2,000-$5,000 for standard sizes - a solid investment for most funeral homes. Electric sliding doors jump to $5,000-$15,000 depending on the automation level you choose. The convenience factor often justifies the extra cost in high-traffic facilities.

Large warehouse doors start at $10,000+ for oversized openings, while retrofit glass doors typically cost $1,000-$3,000 per linear foot. These retrofit options work well when you're upgrading existing equipment gradually.

Lead times tell an interesting story. You can get retrofit installations done in as little as 3 days, while custom engineered solutions might take 12+ weeks. ColdGuard stands out with lead times 43% faster than industry average, while most standard manufacturers need 8-12 weeks.

Don't forget to budget for the extras. Installation costs, electrical connections, and structural modifications for proper mounting can add up quickly. Professional installation protects your warranty coverage and ensures optimal performance from day one.

At American Mortuary Coolers, we help Tennessee funeral homes and facilities across the contiguous 48 states steer these decisions. Our experience with custom solutions means we can guide you toward the right sliding cooler door system for your specific needs and budget.

Conclusion

After reviewing dozens of sliding cooler door systems, one thing becomes crystal clear: the right door transforms your entire cold storage operation. Whether you're drawn to the lightning-fast ColdGuard GEN II or the wood-free hygiene excellence of Frank Door's design, each system we've covered solves real problems that funeral directors face daily.

At American Mortuary Coolers, we've spent years helping funeral homes across Tennessee, Atlanta, Chicago, Columbia, Dallas, Los Angeles, New York, Pittsburgh, and beyond find the perfect balance between performance and budget. What we've learned is that mortuary facilities have needs that go far beyond basic refrigeration - you need reliability when families are counting on you.

The space efficiency advantage alone makes sliding doors a game-changer. When you're working in tight quarters and every square foot matters, eliminating that 6-8 foot swing clearance opens up possibilities you didn't know you had. Add in the energy savings of up to 60%, and suddenly you're looking at equipment that pays for itself while making your daily work easier.

We can't stress enough how critical proper installation and maintenance are for getting the most from your investment. A perfectly engineered door that's poorly installed becomes a constant headache. That's why we always recommend working with certified installers who understand the unique demands of mortuary environments.

Don't overlook the importance of certifications either. UL listing isn't just paperwork - it's peace of mind when inspectors come calling. NSF certification matters if you handle any food service, and DOE compliance can open up utility rebates that offset your initial costs.

The funeral industry deserves equipment built to handle whatever comes through your doors. Whether you need a simple manual slider for basic cold storage or a sophisticated electric system with all the automation bells and whistles, the right sliding cooler door will quietly do its job while you focus on serving families.

We provide custom cold storage solutions designed specifically for mortuary applications, with direct delivery across the contiguous 48 states. Our durable, custom solutions understand that when it comes to caring for the deceased, there's no room for equipment failure.

Ready to see what the right sliding door can do for your facility? Get in touch for a custom quote on sliding cooler door solutions that fit your specific space and needs. For a complete picture of how all the pieces fit together, check out our comprehensive solutions guide covering everything from morgue coolers to essential equipment that keeps your operation running smoothly.