Why Black Crushed Velvet Remains the Ultimate Luxury Fabric Choice

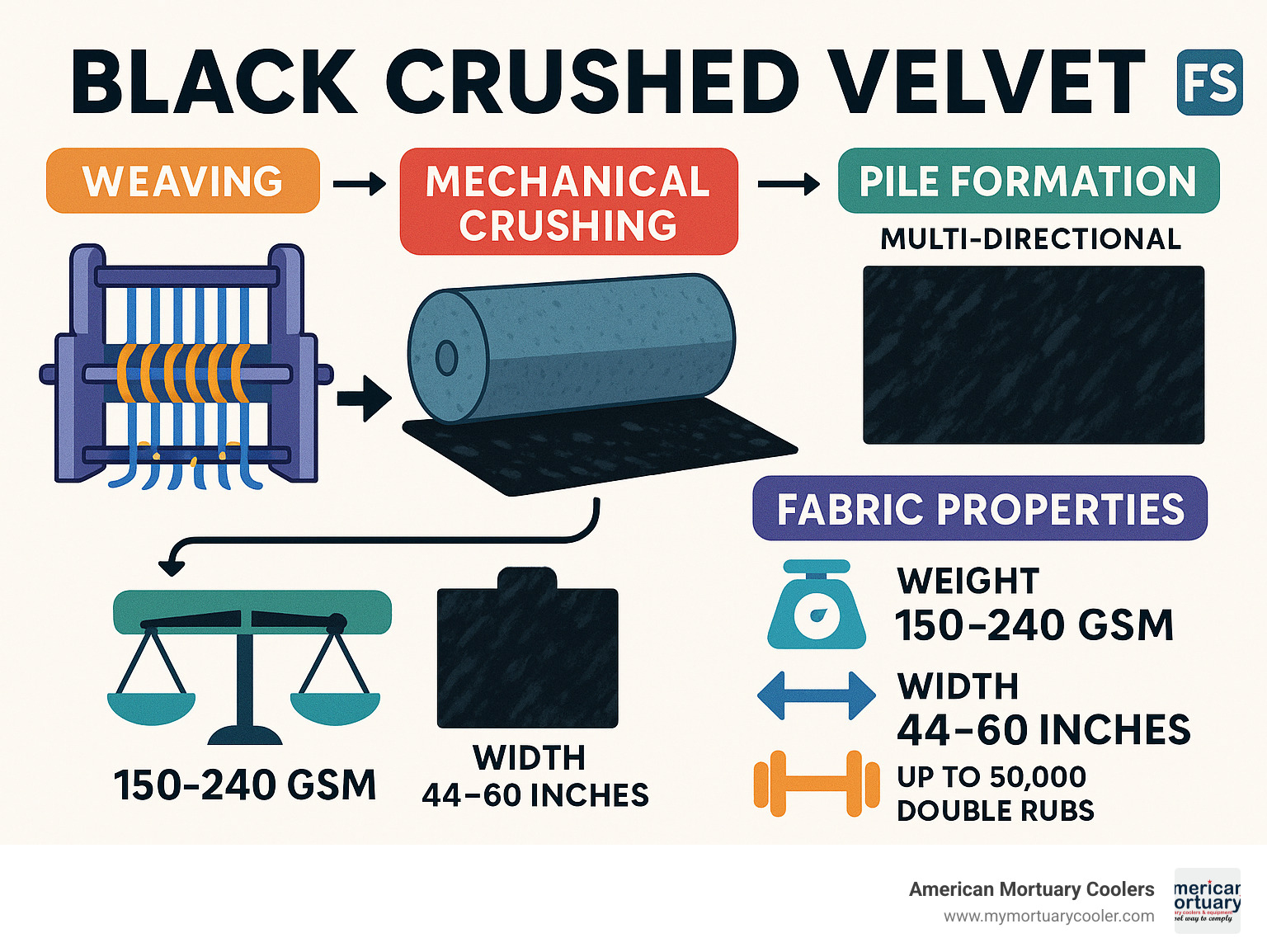

Black crushed velvet is a premium textile created by mechanically crushing velvet pile to create irregular light-reflecting surfaces that produce a distinctive lustrous sheen. This process transforms ordinary velvet into a fabric with dramatic visual depth and luxurious texture.

Quick Black Crushed Velvet Facts:

- Composition: Typically 90-92% polyester with 8-10% spandex for stretch, or 65% acetate/35% nylon blends

- Width Options: 44-60 inches standard, up to 118 inches for upholstery

- Weight Range: 150-240 GSM (grams per square meter)

- Price Range: $4.12-$24.99 per yard depending on quality and fiber content

- Durability: Commercial-grade options rated up to 50,000 double rubs

- Care: Most require dry cleaning, some polyester blends are machine washable

The mechanical crushing process brings out the luster of the fibers while adding incredible depth to the midnight black color. Unlike regular velvet with uniform pile direction, crushed velvet features multi-directional pile that creates the signature light-and-shadow effect.

Black crushed velvet serves countless applications - from evening gowns and theatrical costumes to luxury upholstery and funeral home drapery. The fabric's ability to absorb and reflect light makes it particularly effective for creating dramatic, sophisticated atmospheres.

I'm Mortuary Cooler, and through years of sourcing premium funeral home furnishings, I've seen how black crushed velvet lifts the dignity and elegance of memorial services. My experience helping funeral directors select the finest materials has taught me what separates quality crushed velvet from inferior alternatives.

Easy black crushed velvet word list:

Understanding Black Crushed Velvet

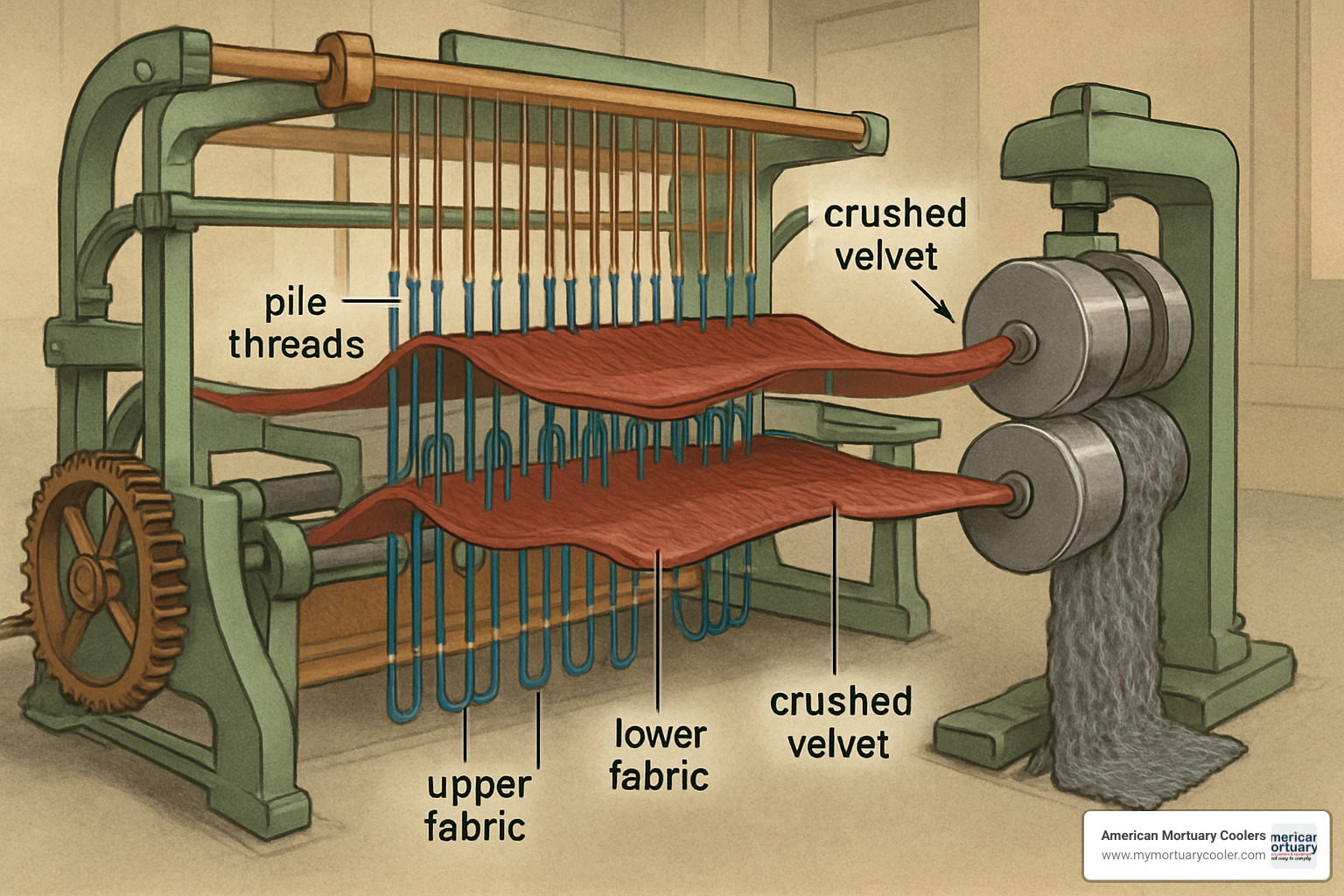

The story of black crushed velvet begins in textile mills where skilled craftspeople transform ordinary fabric into something extraordinary. This luxurious material starts on specialized double-cloth looms, where two separate fabric layers are woven simultaneously with connecting pile threads stretched between them.

What makes black crushed velvet special is the crushing process. After the basic velvet structure is complete, the fabric undergoes mechanical crushing through embossed rollers under controlled pressure. This creates irregular pile directions that catch and reflect light beautifully across the fabric surface.

While regular velvet has all its fibers lying in one direction, crushed velvet features multi-directional pile that creates varying angles of light reflection. This gives black crushed velvet that dramatic depth and lustrous sheen.

Modern black crushed velvet comes in several fiber compositions. Polyester-spandex blends (typically 90-92% polyester with 8-10% spandex) offer stretch properties, perfect for fitted garments and costumes.

Acetate-nylon blends (usually 65% acetate, 35% nylon) provide traditional velvet feel with no stretch, weighing about 6 ounces per linear yard. These offer excellent drape for formal wear and drapery applications.

Cotton velvet options bring natural fiber benefits with lighter weight suitable for upholstery projects. These typically rate at 35,000 double rubs for durability.

For sustainability, viscose options made from renewable plant sources are increasingly available. These eco-friendly alternatives maintain the luxurious feel while supporting responsible manufacturing.

The deep black color comes from lightfast dyes that resist fading. Quality black crushed velvet undergoes rigorous colorfastness testing to ensure that rich midnight black maintains intensity with light exposure and cleaning.

How Black Crushed Velvet Is Made

The manufacturing process starts with establishing the warp and weft foundation on a double-cloth loom. Two separate layers are woven simultaneously, with thousands of connecting threads forming the characteristic velvet pile when separated.

After the basic velvet structure is complete, the crushing process begins with heat-set crinkle techniques involving controlled heat and pressure through specially designed emboss rollers. These create the irregular pile patterns that give black crushed velvet its distinctive appearance.

The pile formation is critical to achieving proper light-reflecting properties. Unlike regular velvet where pile lies in one direction, crushed velvet features multi-directional pile creating varying light reflection angles.

Key Types of Black Crushed Velvet

Panne velvet features pile pressed firmly in one direction, creating high-gloss appearance with dramatic directional light reflection. This type offers the most striking sheen but requires careful handling.

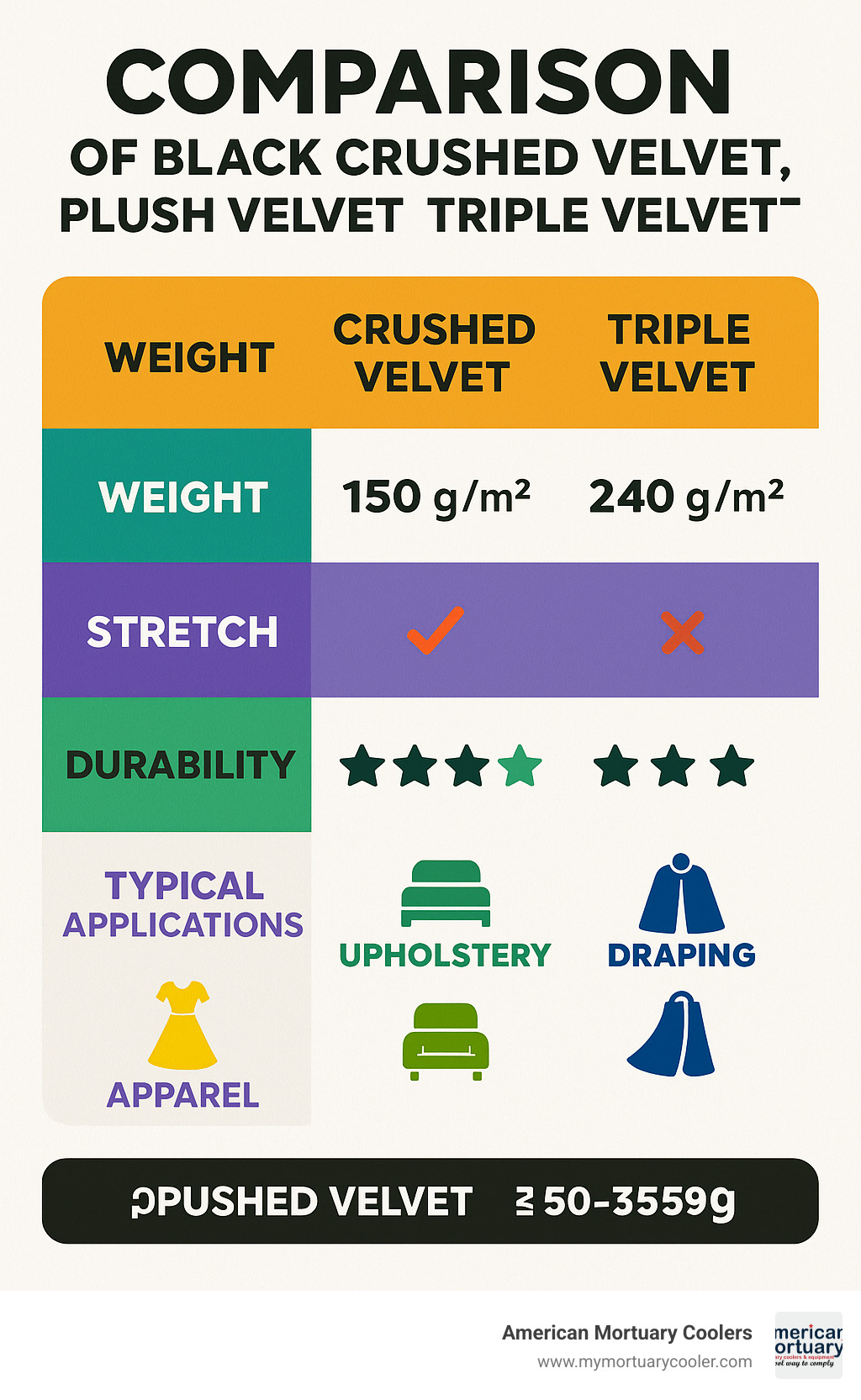

Plush velvet maintains denser, more upright pile structure even after crushing. Typically weighing 240 g/m², this provides excellent durability while retaining the crushed appearance, ideal for evening wear.

Triple velvet incorporates three layers in weaving, creating exceptional plushness with no stretch. The 65% acetate, 35% nylon composition provides soft hand with lightweight drape, perfect for capes and formal draping.

Velour uses knitted rather than woven construction providing natural stretch properties. Crushed velour offers comfort and flexibility for applications where movement matters.

IFR stage velour represents the specialized end - inherently flame-retardant black crushed velvet designed for theatrical and commercial applications meeting strict flammability standards.

The difference between 2-way and 4-way stretch depends on fiber composition. 2-way stretch provides flexibility in one direction, while 4-way stretch offers flexibility in both directions, giving designers maximum versatility.

Key Properties & Variations of Black Crushed Velvet

When shopping for black crushed velvet, understanding technical specs can save you from costly mistakes. I've seen funeral directors choose the wrong weight or width, only to find their drapes don't hang properly or upholstery won't hold up.

Weight matters significantly. Quality black crushed velvet typically weighs between 150-240 GSM (grams per square meter). The lighter 150 GSM works for flowing evening gowns and delicate drapery, while heavier 240 GSM provides substantial feel for upholstery and commercial installations. For funeral home applications, I recommend 200-240 GSM range for luxurious drape without looking flimsy.

Width options can make or break projects. Standard apparel fabrics come in 44-60 inch widths, fine for most clothing. But for funeral homes or theaters, those 118-inch upholstery widths become essential. Nobody wants visible seams running down draping.

Durability gets interesting with the numbers. Commercial-grade black crushed velvet can achieve 50,000 double rubs using the ASTM D4157-02 Wyzenbeek method. That's serious durability for busy funeral homes where chairs get moved daily and drapes see constant handling.

Stretch properties depend on spandex content. Pure cotton or acetate blends offer zero stretch, giving traditional formal look but requiring precise tailoring. Add 8-10% spandex, and you have forgiving fabric that moves with the body.

The luster scale varies dramatically based on fiber content. Nylon blends deliver the most dramatic sheen, catching light from every angle. Cotton blends provide subdued elegance for traditional settings.

For detailed information about abrasion standards and testing methods, we recommend reviewing Scientific research on abrasion standards to understand how these ratings translate to real-world performance.

Black Crushed Velvet vs Other Velvets

Black crushed velvet stands apart from other velvets in ways that matter for your project. The crushing process creates irregular pile directions that give you that signature light-and-shadow dance across the fabric surface. Regular plush velvet maintains uniform pile direction for more predictable appearance.

Plush triple velvet brings its own advantages. That 65% acetate and 35% nylon composition creates exceptional softness through three-layer construction. Perfect for consistent appearance - think cinema seating or formal conference room drapery - but won't give you the visual drama of black crushed velvet.

Panne stretch velvet offers controlled directional sheen through pile pressing, but it's limited compared to crushed varieties. The stretch properties work for fitted garments, but uniform appearance might leave you wanting more visual interest.

Cotton velvet brings natural fiber benefits like breathability and comfort, but typically maxes out around 35,000 double rubs for durability. That lighter weight works for home décor projects, but I wouldn't recommend it for commercial funeral home use.

Care requirements tell their own story. Most black crushed velvet needs dry cleaning to keep pile looking perfect, though some polyester-spandex blends handle gentle machine washing. Traditional cotton velvets almost always require professional cleaning to prevent pile matting and color fading.

Colorfastness & Durability Tests

Professional-grade black crushed velvet goes through rigorous testing. The ASTM D4157 Wyzenbeek test measures abrasion resistance by rubbing fabric samples against standard abrasives until they fail. When you see that 50,000 double rub rating, you're looking at fabric that handles serious commercial use.

Lightfastness testing follows AATCC 16 standards, measuring how well that black color holds up under controlled light exposure. Quality black crushed velvet achieves Grade 4 minimum ratings at 40 hours - meaning your investment won't fade after months of normal use.

Flammability testing includes FMVSS 302 automotive standards and NFPA 701-89 small scale testing for commercial applications. Many crushed velvets also meet California TB #117 Section E requirements for furniture upholstery.

Proposition 65 notices may apply to certain black crushed velvet products, particularly those containing flame retardant chemicals or specific dye compounds. Always review product specifications for required safety warnings.

Practical Applications & Design Ideas

Black crushed velvet brings luxury and drama to an impressive range of projects. Whether creating a show-stopping evening gown or adding elegance to a professional space, this fabric delivers that special "wow factor."

In fashion, black crushed velvet is a go-to choice for evening wear. The way it plays with light makes it perfect for formal gowns, cocktail dresses, and special occasion outfits. Polyester-spandex blends work beautifully for fitted garments because they move with your body while maintaining that luxurious look.

Cosplay enthusiasts love this fabric. It photographs beautifully under stage lights and creates authentic-looking period costumes and fantasy outfits. Whether crafting a Victorian-era cape or superhero costume, black crushed velvet adds professional touch that sets your work apart.

The funeral industry has acceptd this fabric for its ability to create dignified, respectful atmospheres. We've helped many funeral directors choose black crushed velvet for custom drapery installations because it brings both elegance and solemnity to memorial settings. The fabric's rich depth creates a comforting environment during difficult times. For guidance on selecting funeral drapery, check out our comprehensive guide to choosing the perfect purple drape.

For upholstery, black crushed velvet performs surprisingly well. Those commercial-grade options with 50,000 double rub ratings can handle restaurant seating, hotel furniture, and high-traffic residential pieces. The dark color hides everyday wear while maintaining luxurious appearance.

You'll also find this versatile fabric in RV interiors, where it transforms ordinary living spaces into something special. Jewelry makers use it for packaging because the soft texture protects valuable pieces while creating upscale presentation. Crafters love it for everything from decorative pillows to theatrical props.

Pros & Cons of Using Black Crushed Velvet

Let's be honest about what you're getting into with black crushed velvet. This fabric has amazing qualities, but it's not without challenges.

The luxury feel is best. When people touch quality crushed velvet, they immediately understand they're experiencing something special. The way it plays with light creates visual depth that few other fabrics can achieve.

Stain resistance depends on what you choose. Synthetic blends handle spills better than natural fibers, and that deep black color is forgiving when it comes to hiding minor stains and everyday wear.

Durability might surprise you. Quality black crushed velvet often outlasts traditional upholstery fabrics, with some commercial grades handling intensive use for years.

Now for the challenges. Pile crushing is real. If you stack heavy items on it or store it improperly, you can permanently flatten those beautiful texture variations.

Seam slippage can happen with lower-quality options, especially in high-stress situations. This is why choosing quality fabric and using proper construction techniques matters.

Stretch properties vary wildly between different types. No-stretch varieties require completely different sewing approaches than 4-way stretch options.

Sewing & Crafting Tips With Black Crushed Velvet

Working with black crushed velvet requires specific techniques, but don't let that scare you off. Once you know the tricks, it's quite manageable.

A walking foot is your best friend. This attachment helps feed the fabric evenly through your machine, preventing pile distortion that can ruin your project.

Nap direction matters more than you might think. Cut all pattern pieces with pile running the same direction, or your finished project will look like it's made from different fabrics. Run your hand over the fabric - it should feel smooth in one direction and rough in the other.

Always cut face-down to protect that beautiful pile surface. Sharp fabric shears work best - dull blades will snag and pull fibers.

Low-heat pressing is crucial. Use a pressing cloth and let steam do most of the work. Never press directly on the pile - you'll flatten it permanently.

When using a serger, adjust your settings for the specific weight and stretch of your fabric. Ballpoint needles work best for stretch varieties, while universal needles handle woven types well.

Stay-stitching helps control that pile during construction. Stitch just inside your seam allowances to prevent stretching, especially on curves and bias cuts.

Buying, Care & Sustainability Guide

When shopping for black crushed velvet, expect to pay anywhere from $4.12 to $24.99 per yard. The price difference reflects real quality differences in fiber content, construction methods, and durability ratings.

Premium fabrics with superior acetate-nylon blends and commercial-grade construction naturally cost more than basic polyester versions. But that extra investment often pays off in better appearance and longer life, especially for important projects.

You'll find two main purchasing options. Buy by the yard for smaller projects like costumes or craft work. For larger installations - think funeral home drapery or extensive upholstery work - full bolts (usually 30 yards) offer better value through quantity discounts.

Always order samples first. This isn't just good practice - it's essential. Dye lots can vary between production runs, and black crushed velvet from different batches might not match perfectly. A $2 sample can save you from a $200 mistake.

Most suppliers offer quantity discounts that can reduce your per-yard cost by 5-15% when you order 15 yards or more. If you're planning a big project, it's worth calculating whether buying extra fabric at the discount price makes financial sense.

Care requirements vary dramatically based on what your black crushed velvet is made from. Some polyester-spandex blends handle gentle machine washing fine. Others, particularly acetate-nylon compositions, need professional dry cleaning to maintain their luxurious appearance.

The cleaning codes tell the whole story. Code S means solvent cleaning only - no water allowed. Code W permits water-based cleaning methods. Code X is vacuum-only maintenance. Don't guess on this - check the manufacturer's specifications or you might ruin expensive fabric.

For complete care guidance, the Recommended Care Instructions resource provides detailed explanations of all cleaning codes and proper maintenance techniques.

Sustainability options are improving in the black crushed velvet market. Some manufacturers now offer crushed velvet made from recycled plastic bottles, giving you the same luxurious look while supporting environmental responsibility. These recycled polyester options perform just as well as traditional versions.

Where to Buy Quality Black Crushed Velvet

Etsy consistently delivers quality with sellers averaging 4.9-star ratings for black crushed velvet. Customers praise the quality, fast shipping, and perfect condition of their orders. You'll also find specialty suppliers offering unique variations not available through mainstream retailers.

Walmart's craft section provides budget-friendly options perfect for hobby projects and temporary applications. The quality won't match premium suppliers, but for casual use or testing ideas, the accessibility and low prices make sense.

Fabric Guru specializes in remnants and offers 50-90% savings on quality fabrics. Their liquidation model means you can access premium black crushed velvet at fraction of retail prices. The catch? Selection varies based on what's available, so great deals require flexible timing.

SY Fabrics offers professional-grade options including their Plush Triple Velvet BLACK with detailed specifications and consistent quality. Their technical documentation helps ensure you select the right fabric for your specific needs.

Budgeting & Cost Factors for Black Crushed Velvet

Fiber blend drives the biggest price differences. Natural fiber content costs more than synthetic alternatives due to raw material costs and more complex processing. Acetate-nylon blends typically run higher than polyester-spandex varieties.

Width affects per-yard pricing because wider fabrics require specialized looms and reduce production efficiency. However, wider fabrics might actually save money on large projects by eliminating seaming requirements.

Abrasion ratings correlate directly with price. Higher-rated fabrics need premium fibers and construction methods. That commercial-grade black crushed velvet with 50,000 double rub rating costs more upfront but delivers better long-term value through superior durability.

IFR treatment adds significant cost but becomes essential for commercial applications. The specialized flame-retardant chemistry and required testing justify the premium pricing for these safety-improved fabrics.

Origin influences both price and availability. Korean-manufactured fabrics often provide excellent quality-to-price ratios. USA-made options may cost more but offer supply chain advantages and faster delivery.

At American Mortuary Coolers, we understand how fabric choice impacts the overall dignity of memorial settings. Quality black crushed velvet drapery creates the sophisticated atmosphere families deserve during difficult times.

Frequently Asked Questions about Black Crushed Velvet

Does black crushed velvet shrink or stretch over time?

The answer depends mainly on what your black crushed velvet is made from and how you care for it. If you've got a polyester-spandex blend, you're in luck - these fabrics barely shrink at all when you treat them right. Just follow the care instructions and you'll be fine.

Acetate-nylon blends are a bit trickier. They can shrink if you get them too hot or clean them the wrong way. Cotton velvet is the most likely to shrink, especially if you toss it in the washing machine without checking the care label first.

As for stretching, fabrics with spandex can lose their bounce over time. Think of it like an old rubber band - it doesn't snap back quite the same way after years of use. The elastic fibers get tired from being stretched repeatedly or exposed to high heat. Higher quality black crushed velvet keeps its stretch much longer than cheaper versions, so it's worth investing in good fabric from the start.

How do I prevent lint trails and pressure marks?

Nobody wants their beautiful black crushed velvet leaving a trail of fuzz everywhere it goes. Lint trails happen when loose pile fibers come off the fabric. The best defense is buying quality fabric in the first place - cheap velvet sheds like a cat in summer.

For day-to-day care, vacuum your velvet regularly using the right attachment. Never brush against the pile direction, and handle the fabric gently. Think of velvet pile like pet fur - stroke it the right way and it stays smooth.

Pressure marks are those annoying flat spots that show up when something heavy sits on your velvet. Prevention is key here. Store your fabric rolled up instead of folded, and never pile heavy stuff on top of finished projects. If you do get pressure marks, try steaming them out gently. But honestly, it's much easier to prevent them than fix them later.

Is black crushed velvet safe for high-traffic upholstery?

This is where quality really matters. Commercial-grade black crushed velvet with a rating of 50,000 or more double rubs can absolutely handle busy areas. That rating actually beats many traditional upholstery fabrics, so it's perfectly fine for restaurant seats, hotel lobbies, or that family room chair everyone fights over.

The key word here is "commercial-grade." Budget velvet won't hold up to heavy use, but professional-quality fabric will surprise you with its durability. I've seen black crushed velvet in funeral home settings that looks perfect after years of use because they chose the right grade for their needs.

The one thing to watch out for is pile crushing in high-traffic spots. Even tough velvet can get flattened if people constantly sit in the same spot or lean against it. Regular maintenance and smart installation choices help keep everything looking fresh. Consider where people actually sit and move, then choose your fabric grade accordingly.

Conclusion

Planning your black crushed velvet project starts with understanding exactly what you need. Think about how the fabric will be used - is it for a flowing evening gown that needs stretch, or sturdy upholstery that must handle daily wear? Your durability checklist should include checking those abrasion ratings, understanding whether you can machine wash or need dry cleaning, and making sure the width and stretch properties match your project.

Getting your fabric from the right source makes all the difference between a project you're proud of and one that disappoints. I always recommend ordering samples first - you want to see and feel the actual fabric before committing to yards of it. Check that dye lots match if you're ordering multiple pieces, and stick with suppliers who have solid reputations for quality and service.

Here at American Mortuary Coolers, we've learned through years of working with funeral homes across Tennessee and beyond that premium materials truly matter. When families are saying goodbye to loved ones, every detail needs to reflect dignity and respect. Black crushed velvet brings that sophisticated elegance that can transform any space into something truly memorable.

Whether you're designing custom drapery for a memorial service or choosing upholstery for a luxury funeral home interior, black crushed velvet delivers both stunning visual impact and the durability you can count on. We help funeral directors incorporate these premium fabrics into their spaces, making sure every element honors the families they serve.

The beauty of black crushed velvet lies in its versatility - it works beautifully in formal settings while being practical enough for regular use. From theatrical costumes to commercial upholstery, this fabric continues to prove its worth across countless applications.

For more guidance on selecting funeral home furnishings and understanding how premium textiles contribute to meaningful memorial experiences, check out our More info about funeral furnishings. We're here to help you create spaces that truly honor life's most important moments.