Understanding Walk-In Freezers: The Backbone of Commercial Cold Storage

If you're searching for a walking freezer, you're looking for a commercial walk-in freezer that can keep products at 0 °F to –10 °F in high-demand environments. Think restaurants, pharma labs, or funeral homes.

Key points at a glance:

- Purpose: Bulk, reliable frozen storage.

- Construction: 5–6-in polyurethane panels, heavy-duty door, dedicated refrigeration package.

- Sizes: 6'×6' up to 16'×60'.

- Typical Cost: $15 k–$25 k plus installation.

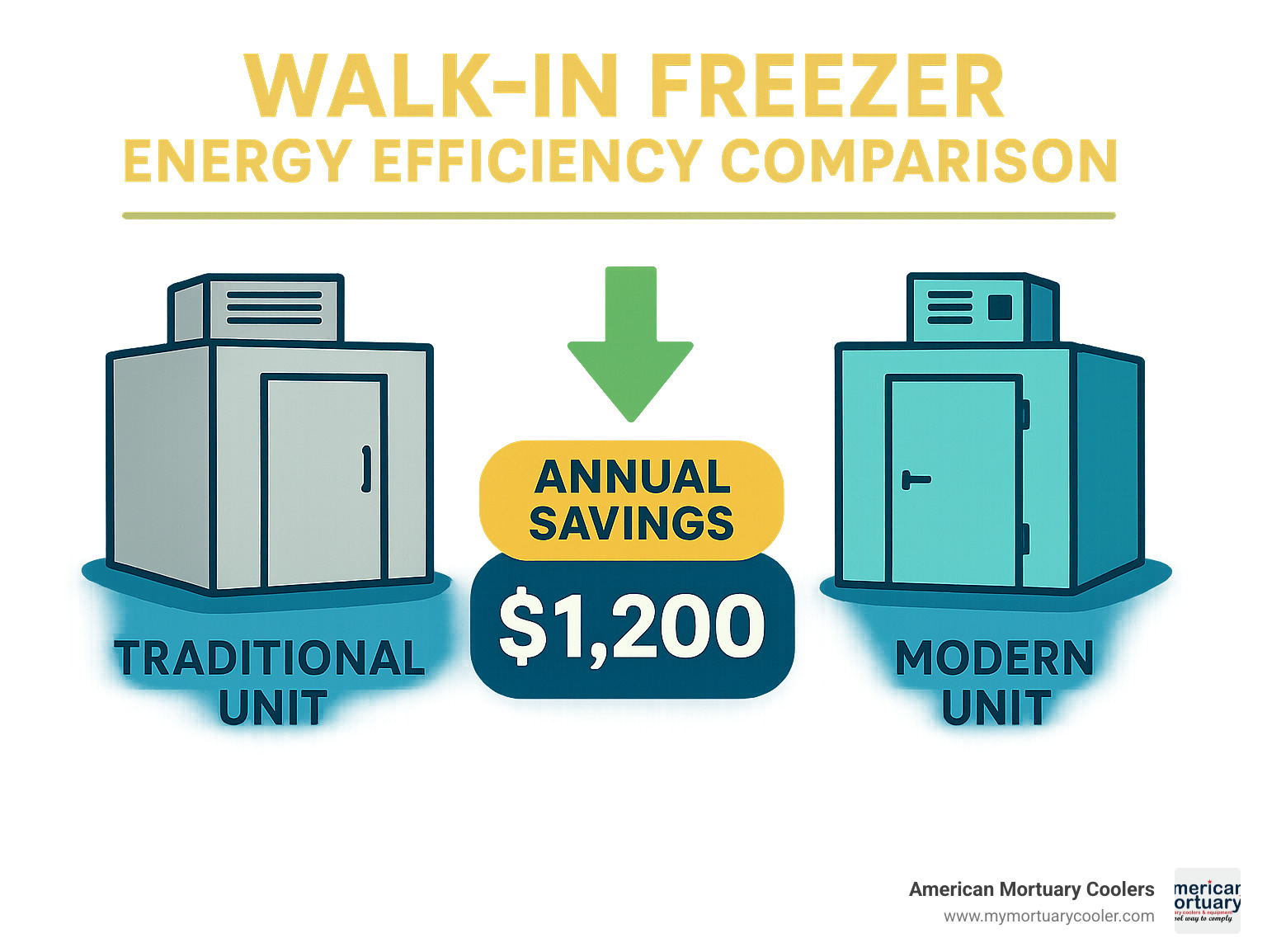

- Energy Focus: Upgraded insulation can cut annual power use by more than 50 %.

Many companies make walk-ins—Kolpak, Polar King, Nor-Lake, U.S. Cooler, Arctic Industries, to name a few—but newer fiberglass units from American Mortuary Coolers have shown far lower kWh consumption in field tests.

I’m Mortuary Cooler, and for 20+ years I’ve helped funeral directors nationwide find energy-efficient cold storage that protects both budgets and the dignity of the deceased.

Simple guide to walking freezer terms:

What Is a Walk-In Freezer (Walking Freezer) and How It Works

A walking freezer is more than just a big cold box—it's a carefully engineered environment designed to keep products frozen while standing up to the demands of commercial use. Unlike your home freezer, these workhorses maintain steady temperatures even when doors are constantly opening, staff are moving in and out, and large volumes of product are being stored and retrieved.

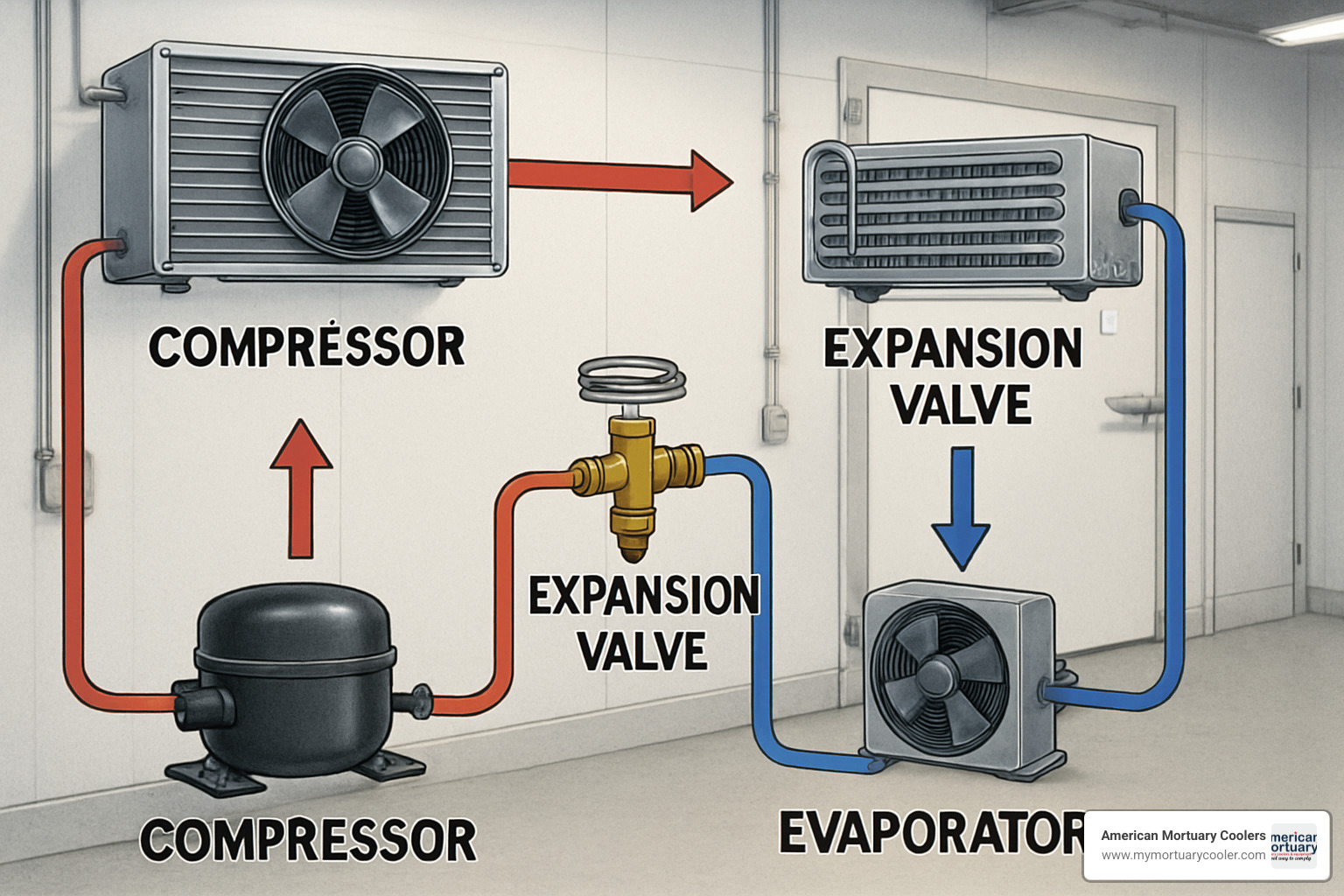

Think of the refrigeration cycle in a walking freezer as a continuous loop that moves heat from inside to outside—just like your home refrigerator, but on steroids:

- The compressor acts as the heart of the system, squeezing refrigerant gas to raise its temperature and pressure

- Next, the condenser releases this heat outside (that's the warm air you feel blowing behind the unit)

- The expansion valve then allows the refrigerant to suddenly expand, which dramatically cools it

- Finally, the evaporator absorbs heat from inside your freezer as the refrigerant turns back into gas

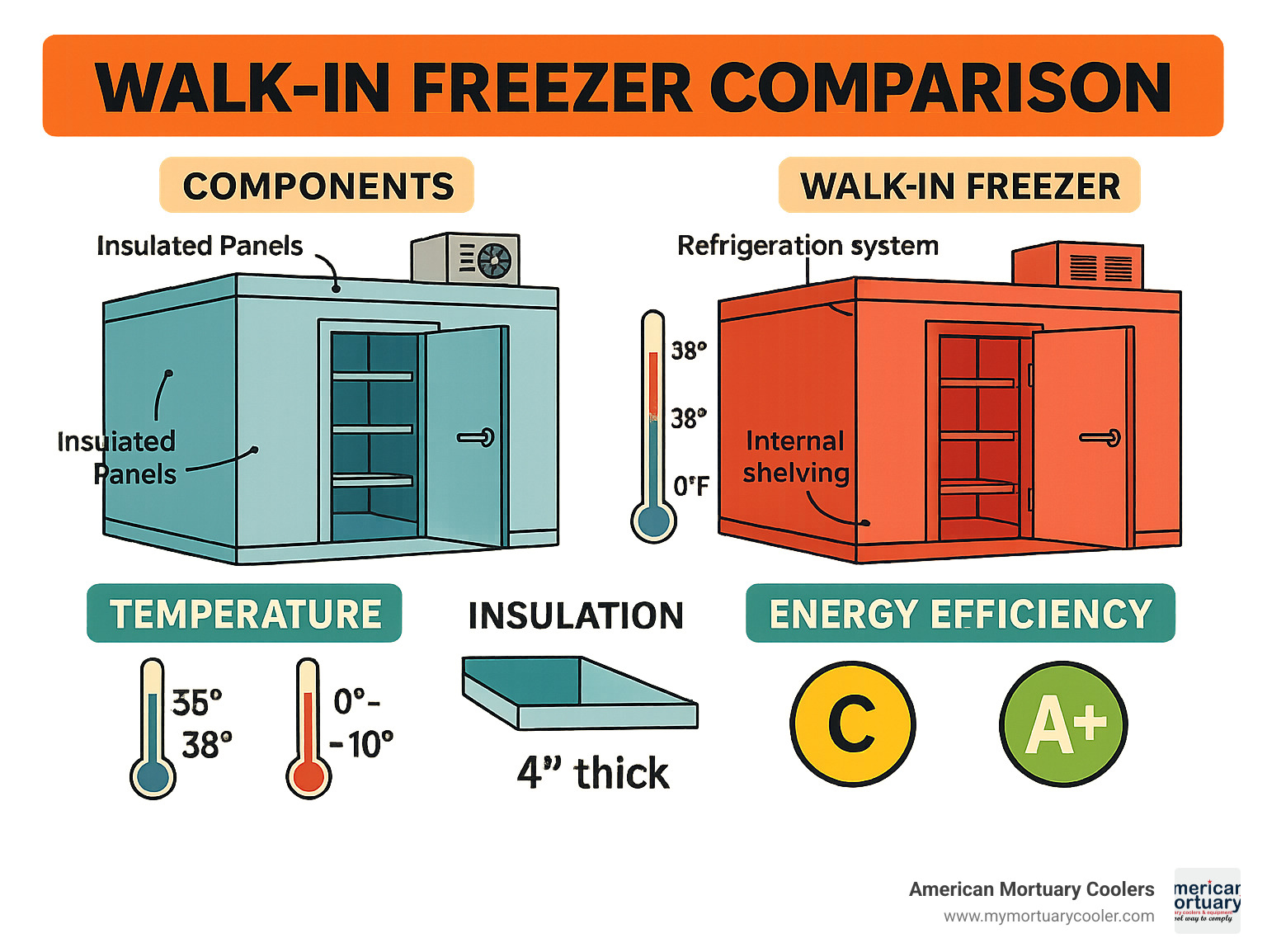

The biggest difference between a walk-in cooler and a walking freezer isn't just temperature—it's construction. Freezers need substantially thicker insulation (5-6" compared to a cooler's 4") to maintain those sub-zero temperatures without working your compressor to death. This extra insulation is what helps keep your energy bills manageable while maintaining those frigid temperatures.

| Feature | Walk-In Cooler | Walking Freezer |

|---|---|---|

| Temperature Range | 35°F to 45°F | 0°F to -10°F (down to -50°F for specialty units) |

| Insulation Thickness | 4" | 5-6" |

| R-Value | ~25 | ~32 (EISA compliant) |

| Typical Applications | Fresh produce, dairy, beverages | Meat, seafood, ice cream, pharmaceuticals |

| Defrost Cycles | Less frequent | 4+ times daily |

The science behind freezer insulation is fascinating. According to engineering research on thermal conductivity, the polyurethane foam used in quality walk-ins has a thermal conductivity of only 0.02 W/(m·K). In plain English? It's incredibly good at stopping heat from sneaking into your freezer.

Standard Temperature Ranges for a Walking Freezer

Not all walking freezers are created equal when it comes to temperature. The right temperature range depends entirely on what you're storing:

Standard freezers maintain 0°F to -10°F, perfect for most frozen foods and general storage needs. Low-temperature freezers drop down to -10°F to -20°F, which is ideal for ice cream. When you need specialized storage for pharmaceuticals or lab samples, ultra-low temperature freezers (-20°F to -40°F) are your go-to. And for operations that need to quickly freeze fresh products, blast freezers can plummet all the way to -50°F.

Main Applications & Industries

The versatility of walking freezers makes them essential across a surprising range of industries:

In restaurants and foodservice, these units store everything from premium steaks to pre-prepped ingredients. Grocery stores rely on them before products make their way to display cases. Breweries use specialized freezers for certain production processes.

Mortuaries and funeral homes have unique freezer requirements, where dignity and reliability are paramount concerns. While companies like Thermo-Kool and Master-Bilt offer general commercial freezers, American Mortuary Coolers specializes in solutions specifically designed for funeral directors.

Pharmaceutical companies trust walking freezers to protect temperature-sensitive medications worth thousands per vial. The cannabis industry uses them for flash-freezing fresh harvests to preserve potency. Farmers extend their selling season by freezing peak-harvest produce.

Food manufacturers store both raw ingredients and finished products, while logistics companies maintain the cold chain at distribution centers before products continue their journey to your local store.

Sizing, Configuration & Construction Options

A walking freezer can be as compact as 6'×6' or as large as 16'×60'. Most units are built from interlocking, foamed-in-place panels that assemble quickly on-site. Choose between

- Prefab boxes – factory-finished, fastest install.

- Modular panels – easiest to move or expand later.

- Custom builds – best for odd footprints or special clearances.

Indoor installs cost less, while outdoor models add weatherproof skins, roof membranes and higher snow-load ratings.

Materials drive durability:

- Fiberglass – seamless, rust-proof, premier energy saver.

- Galvanized steel – economical, solid for indoor use.

- Stainless – superior hygiene & corrosion resistance.

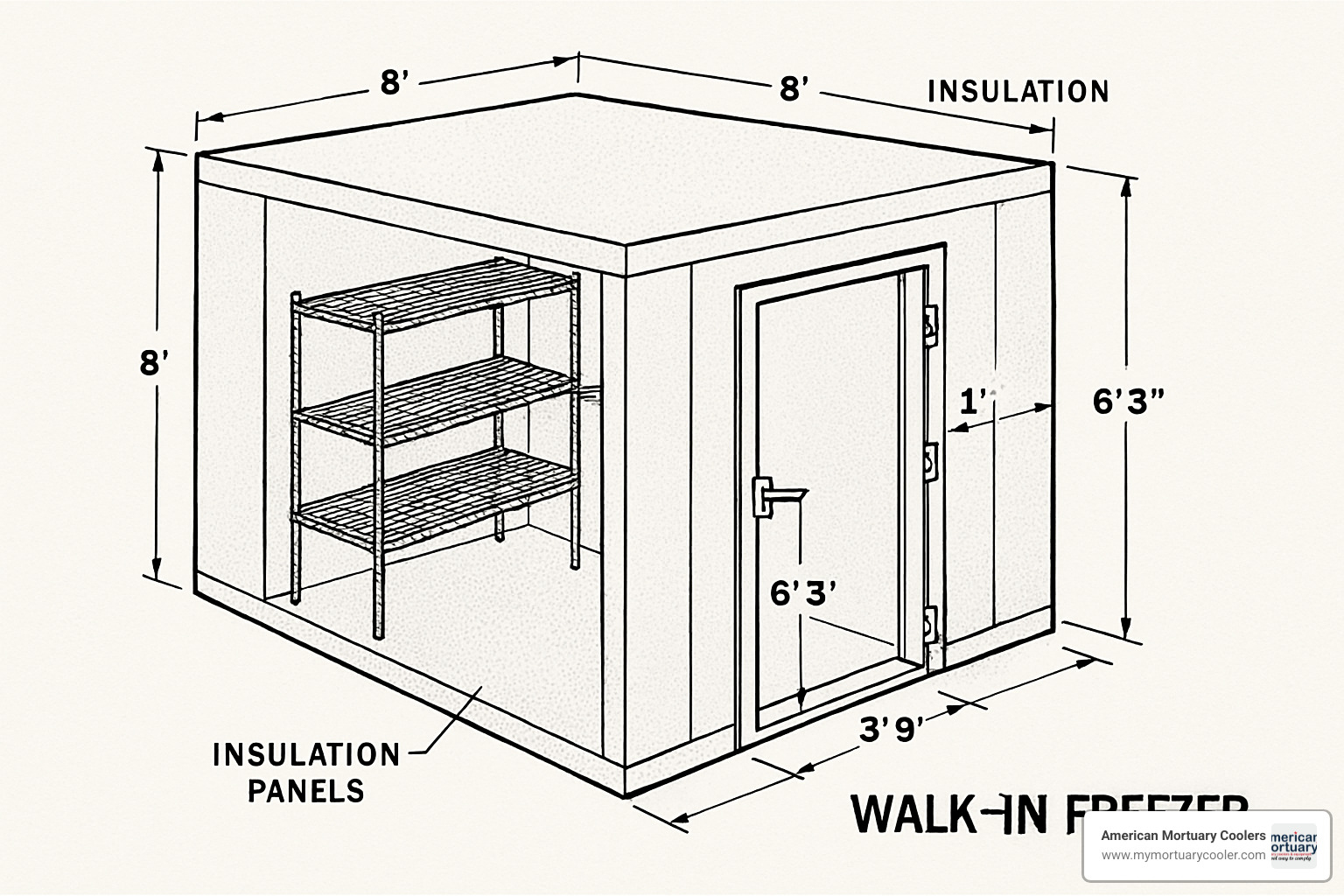

Inside every wall is 5–6 in of polyurethane (R-32 per EISA). Some manufacturers offer extruded polystyrene (XPS) for extra moisture resistance.

Choosing the Right Capacity

Rule of thumb: 1 ft³ per 28 lb of product, plus a 15–25 % buffer. For 5,600 lb you’d target about 250 ft³, which typically fits in an 8'×8'×8' box once shelving and aisles are included.

Doors, Floors & Accessories

The door is the main energy leak, so look for self-closing cam-lift hinges, magnetic gaskets, heated jambs, and an interior safety release. Options like strip curtains, view windows and ramps boost usability.

Floor choices range from standard aluminum to reinforced steel for pallet jacks. Non-slip coatings are a must in mortuary and foodservice environments.

For a pre-purchase checklist, see our Ultimate Checklist for Choosing a Walk-In Freezer Supplier.

Latest Tech in 60 Seconds

- EVI compressors – better low-ambient performance.

- Smart controllers – remote temp/alarm alerts.

- PCM eutectic plates – hold temps during power outages.

These features are now standard in the mortuary models from American Mortuary Coolers and premium lines from companies like Hussmann and CrownTonka.

Buying Checklist: Features, Costs, Compliance & Energy Efficiency

Quality walk-in freezers run $15 k–$25 k for the box and refrigeration, plus $2.5 k–$4 k for installation. Over 15 years, energy easily outruns the purchase price, so focus on kWh:

- 8'×14' fiberglass: ≈ 6,050 kWh/yr

- Same size metal panel: ≈ 16,100 kWh/yr

At $0.10/kWh that’s a $1,000 annual swing.

Must-Have Features

- Interior safety release & pressure-relief vent

- Heated door jamb and magnetic gasket

- LED lighting & remote temp monitoring

- R-32 insulation minimum

Compliance Snapshot

OSHA 1910.36 (egress), NSF-7 (food safety), UL 471 (electrical), EISA (insulation), ASTM E84 (fire). Outdoor units require snow & wind load certification.

Financing Options

Equipment leases (3–7 yrs), SBA or bank loans, and Section 179 deductions help soften the upfront hit. Energy rebates may apply if you choose low-GWP refrigerants like R-448A or R-449A.

For more FAQs see 13 Frequently Asked Questions (FAQs) About Walk-in Freezers.

Installation, Maintenance & Safety Best Practices

A level concrete slab (± 1/4 in over 10 ft) and 2 ft of overhead clearance are the main site requirements. Most freezers run on 208–230 V; always use a licensed electrician and certified refrigeration tech for hook-up.

Organize for Efficiency

- FIFO stock rotation

- 2 in clearance around walls for airflow

- Bottom shelf 6 in off floor

- Freezer-grade labels outside the door map inventory

Detailed tips: How to Organize a Walk-In Cooler or Freezer to Boost Profit and Reduce Waste.

Common Maintenance Issues & Fixes

- Ice on coils – verify defrost timer (4×/day typical).

- Door leaks – clean & inspect gaskets weekly.

- High head pressure – brush/vacuum condenser quarterly.

More on combo units: More info about walk-in combo solutions.

Employee Safety

Anti-slip floors, insulated gloves, time-limit protocols, and regular drills on the inside release handle keep staff safe.

Frequently Asked Questions about Walking Freezers

What amps and voltage does a typical walking freezer need?

Most units use 208–230 V. Single-phase freezers under 1 HP draw 8–12 amps; 2 HP three-phase models run 12–16 amps; 5 HP systems can pull 24–28 amps. Have an electrician verify capacity before you buy.

How do I clean and sanitize a walking freezer?

- Relocate product & power down.

- Let ice melt; remove shelves.

- Wash with freezer-rated cleaner, sanitize with NSF product.

- Dry fully, restart, restock once temp recovers.

Seamless fiberglass interiors from American Mortuary Coolers make this faster because there are no panel joints for bacteria to hide in.

Can one unit switch between cooler and freezer modes?

Dual-temperature boxes exist. They use 5–6 in insulation, a beefier refrigeration package, and a programmable controller to toggle between ≈ 38 °F and –10 °F. Energy use in cooler mode will be slightly higher than a purpose-built walk-in cooler.

Conclusion

Choosing the right walking freezer isn't just a purchase—it's an investment in your business's future. Throughout this guide, we've walked together through everything from basic components to advanced features, helping you understand what makes these commercial cold storage units tick.

When you're ready to make your decision, keep these critical factors in mind:

Size matters—make sure you account for your current needs plus that extra 15-25% for growth that always seems to happen sooner than expected. The quality of construction will determine how well your unit performs day after day, year after year, so don't compromise on that R-32 minimum insulation thickness.

While the sticker price might catch your eye first, the true cost of ownership comes down to energy efficiency. A less expensive unit that gobbles electricity might cost you thousands more over its lifetime than a premium model with better insulation and more efficient components.

Safety isn't optional. Make sure any unit you consider complies with OSHA, NSF, and industry standards—your employees and your business depend on it. Similarly, warranty coverage speaks volumes about a manufacturer's confidence in their product. Look for comprehensive protection that covers panels, refrigeration components, and parts.

The walking freezer industry continues to evolve in exciting ways. While companies like Polar King, Arctic Industries, and U.S. Cooler offer excellent general-purpose units, specialized needs often require custom solutions. Newer units offer remarkable energy efficiency, intuitive smart controls, and environmentally friendly refrigerants that reduce your carbon footprint while potentially qualifying for energy incentives that lower your costs even further.

Here at American Mortuary Coolers, we've built our reputation on crafting custom mortuary coolers and freezers that meet the unique and sensitive needs of the funeral industry. From our home base in Tennessee, we deliver and install our solutions across all 48 contiguous states, ensuring funeral homes from coast to coast receive cold storage solutions that perform flawlessly when it matters most.

Whether you're storing perishable food, temperature-sensitive pharmaceuticals, or providing dignified care for the deceased, your walking freezer is an essential part of your operation's success. By applying what you've learned in this guide, you'll make a choice that serves your needs reliably for years to come.

For specialized information about mortuary refrigeration solutions, our Mortuary coolers pillar page offers additional resources and assistance custom to funeral service professionals.