The Evolution of Precision: Understanding Bone Saws in Modern Medicine

Bone saws are specialized cutting instruments designed to section bone tissue in medical, surgical, and pathological procedures. If you're looking for quick information about bone saws, here's what you need to know:

| Type | Primary Uses | Price Range | Key Features |

|---|---|---|---|

| Manual (Charriere, Satterlee) | Field surgeries, emergency procedures | $50-$500 | Portable, no power needed, 6-14" lengths |

| Electric/Oscillating | Surgical procedures, autopsies | $2,000-$7,000 | Precise cuts, doesn't damage soft tissue |

| Reciprocating | Delicate surgeries, neurosurgery | $1,500-$5,000 | Control for intricate procedures |

| Rotary | Cutting long/irregular bones | $2,500-$6,000 | Effective for larger bone sections |

The modern bone saw has evolved from battlefield origins to become a precision instrument. Today's bone saws integrate advanced materials, ergonomic designs, and specialized cutting mechanisms for applications in orthopedics, neurosurgery, pathology, and forensic medicine.

"The amputation saw was a major part of any amputation set. Without one, the set was seriously compromised," notes one historical collection, highlighting how bone saws have been essential surgical tools since the earliest days of medicine.

I'm Mortuary Cooler, a national-level supplier of mortuary equipment with extensive experience providing high-quality bone saws and related equipment to funeral homes, medical examiners, and pathology labs across the country.

Bone saws terms to remember:

Understanding Bone Saws: From Battlefield to Modern OR

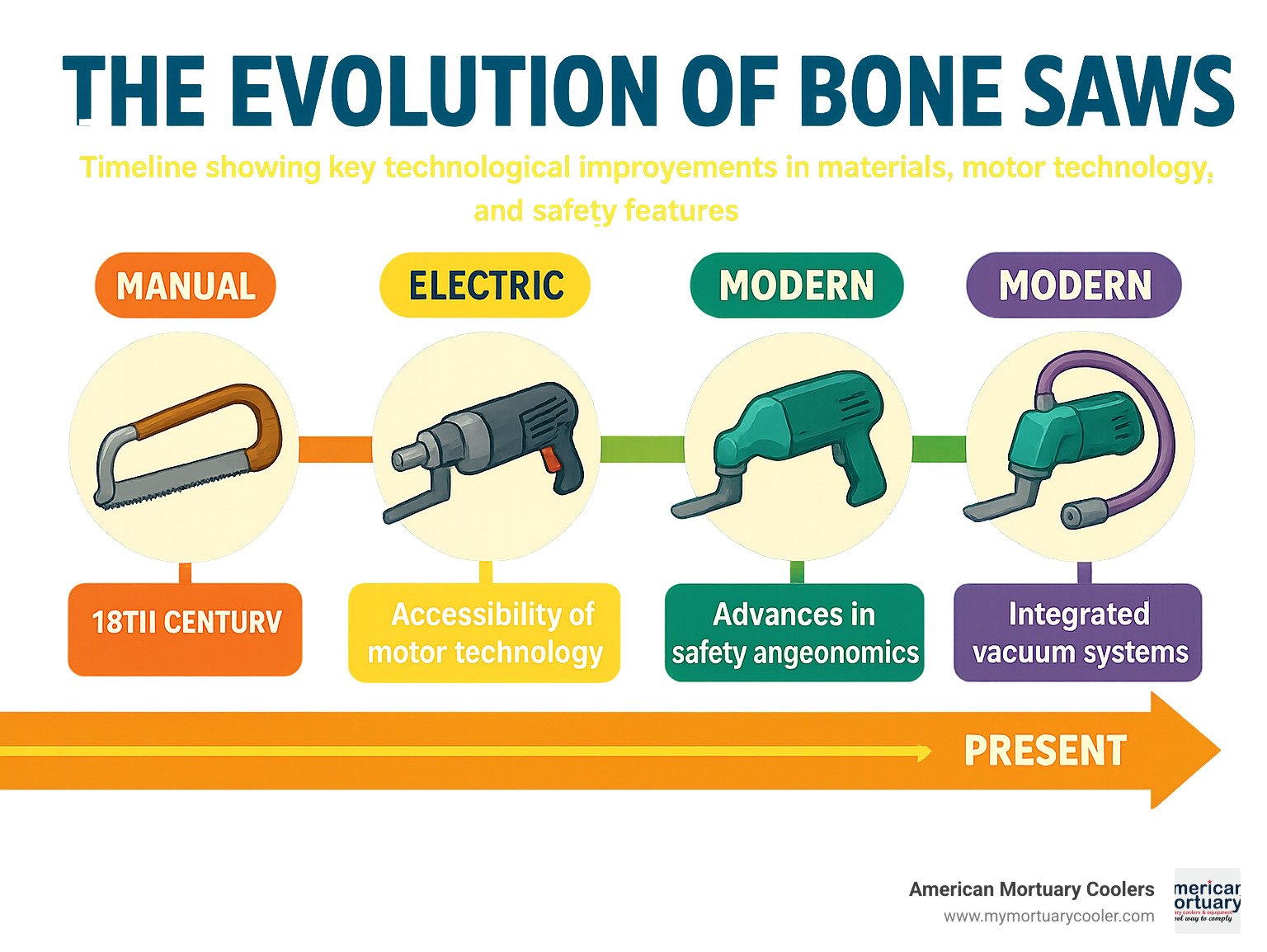

The journey of bone saws parallels the evolution of medicine itself. What began as battlefield tools for life-saving amputations has transformed into precision instruments for complex surgical procedures.

Ancient civilizations had bone cutting tools, but bone saws gained prominence during wartime medicine. Civil War surgeons carried distinctive amputation kits with bone saws as the centerpiece - often featuring handles crafted from ivory, ebony, or gutta percha. These historical instruments are now treasured by collectors.

"Amputation was not a surgeon's task until the mid-19th century," which makes bone saws among the earliest specialized surgical tools.

Anatomy of a Bone Saw

Modern bone saws share several key components:

The frame provides structural support, determining the saw's shape and balance. The blade and teeth form the cutting surface, with configurations designed for specific bone types. Manual saws incorporate a tensioning mechanism that ensures blade stability during cutting.

Every modern bone saw features an ergonomic handle designed for control and comfort. Contemporary models are crafted primarily from surgical-grade stainless steel that combines durability with resistance to repeated sterilization.

High-grade German surgical stainless steel has become the standard, featuring specialized metallurgical compositions with "higher carbon and lower chromium content for improved corrosion resistance."

How Design Has Evolved

The Charriere Amputation Saw represents classic design with its pistol-grip handle and bow-shaped frame. These saws typically reach up to 14 inches in length with detachable blades.

The Satterlee Bone Saw became known for its wide blade providing "unrivaled strength for cutting larger-diameter bones." At 13 inches overall, these saws feature a ring handle design for improved control.

The Gigli Saw innovation in the late 19th century introduced a flexible wire saw that can be threaded around bones, allowing resection with minimal damage to surrounding tissue.

Powered instruments marked a revolution in bone saw technology. Modern oscillating saws operate using high-frequency vibration rather than rotation, enabling precise bone cutting while sparing soft tissue. Today's models like the Mopec Swordfish feature integrated vacuum systems that capture bone dust during cutting.

Advanced bone saws now feature "totally submersible" designs for thorough cleaning, running on 40V power supplies that provide "reduced vibration and a cooler touch."

Types of Bone Saws and How They Work

Bone saws generally fall into two main categories: manual and powered. They also differ in their cutting mechanism - some use a back-and-forth motion while others rotate. Understanding these differences helps medical professionals select the right tool for each procedure.

| Feature | Manual Bone Saws | Powered Bone Saws |

|---|---|---|

| Power Source | Human force | Electric/battery |

| Precision | Moderate (operator-dependent) | High (mechanically consistent) |

| Portability | Excellent (no power needed) | Limited (requires power/batteries) |

| Applications | Emergency/field use, simple procedures | Complex surgeries, autopsies, pathology |

| Cost | $50-$500 | $1,500-$7,000 |

| Maintenance | Blade sharpening, tensioning | Motor service, blade replacement |

| Sterilization | Complete immersion/autoclave | Often partial disassembly required |

Manual Bone Saws Explained

Manual bone saws remain valuable in modern medicine, particularly during emergencies, field operations, or where reliable power is unavailable.

The Satterlee bone saw features a wide blade and ring handle. These sturdy tools typically measure about 13 inches long and excel at cutting through larger bones. They're crafted from high-grade surgical stainless steel.

The Charrière amputation saw sports a bow design with a pistol grip. These versatile tools come in lengths up to 14 inches with 9-inch stainless steel blades and often feature detachable blades in different widths.

The Engel cast saw offers a compact 6-inch design specifically for removing medical casts with precision.

Manual saws remain standard equipment in field kits and orthopedic sets worldwide due to their reliability.

Powered Bone Saws: Autopsy & Pathology

Powered bone saws offer remarkable precision, efficiency, and safety features for autopsy and pathology applications.

The Mopec 1000 Autopsy Saw stands as the gold standard in modern autopsy tools. At around $2,399.95, it's an investment that reflects its advanced technology and safety features.

The Mopec Swordfish Pathology Saw can be completely submerged for thorough cleaning and runs on 40V power, which means less vibration and cooler operation during lengthy procedures.

The IMEB, Inc. Pathology Bone Band Saw handles bone specimens up to 3 inches in height with a water-cooled diamond blade that reduces dust and particles.

Oscillating bone saws feature the "cut-skin myth" - they won't easily cut flesh but are excellent at precision bone cuts. The rapid back-and-forth motion effectively cuts rigid materials like bone but tends to push away elastic tissues like skin.

Modern powered saws increasingly come with bone dust vacuum systems that address the health hazards of bone particles.

Reciprocating vs Rotary Mechanisms

Reciprocating Bone Saws move back and forth like a traditional handsaw but with mechanical power. They excel in delicate surgical operations where precise control matters, such as neurosurgical procedures. The sternal saw is a specialized version designed for dividing the sternum during chest surgeries.

Rotary Bone Saws use a circular blade that spins continuously. These are effective for cutting long bones and irregular bones where continuous cutting action provides greater efficiency. A specialized version is the neurosurgical drill with trephine attachment for creating precise circular openings in the skull.

Band saws offer another rotary option ideal for sectioning larger specimens in pathology and veterinary applications.

Choosing the Right Bone Saw for Surgery, Autopsy, or Veterinary Use

Finding the perfect bone saw requires matching the tool to the task. Dense bones from larger specimens need robust tools like the Mopec Swordfish. For delicate work, the precision of a Gigli wire saw might be preferable.

Portability matters for field applications. Manual saws don't need power sources, making them reliable in remote settings. Battery-powered units offer a middle ground, providing mechanical assistance without being tethered to an outlet.

Always check for regulatory marks like CE certification and FDA classification to ensure instruments meet established safety standards.

Key Selection Criteria

When investing in a bone saw, consider these factors:

Power source options each have advantages. Manual saws offer simplicity and never run out of battery. Powered options save effort but require outlets or charged batteries.

Noise level matters in surgical settings where communication is vital. Modern oscillating saws typically run quieter than older models.

Dust extraction is important for respiratory health. Integrated vacuum systems like those on the Mopec Swordfish capture particles at the source.

Sterilization compatibility is essential. Fully submersible designs make thorough cleaning easier.

Regulatory compliance isn't optional. Ensure equipment conforms with CE marking, FDA classification, OSHA standards, and IEC safety requirements.

Balance your budget thoughtfully. Quality instruments typically offer better value over time, with less downtime and fewer replacement costs.

Price & Availability Snapshot

Manual bone saws are relatively budget-friendly, typically running from $50 for basic models up to about $500 for premium surgical-grade instruments. A quality Satterlee Bone Saw costs around $310, while a 14-inch Charriere Bone Saw with both narrow and wide blades will set you back about $473.

Powered options represent a bigger investment, starting around $2,000, with advanced systems reaching $7,000. The popular Mopec 1000 Autopsy Saw costs approximately $2,400.

Replacement blades range from $20 for standard manual saw blades to $300 for specialized powered attachments. Replacement frequency depends on use - typically every 3-6 months for frequently used blades.

At American Mortuary Coolers, we provide custom quotes for larger orders with significant volume discounts.

Compliance & Certification Essentials

Regulatory compliance for bone saws includes:

CE Marking indicates a product meets European Economic Area standards for health, safety, and environmental protection.

FDA Classification helps understand the risk level and necessary controls. Most bone saws fall under Class I (general controls) or Class II (special controls).

OSHA Workplace Standards protect teams from hazards like bone dust and sharps injuries.

IEC Safety Standards address electrical safety for powered instruments used around fluids.

American Mortuary Coolers offers bone saw products that meet or exceed all applicable standards.

Safety, Sterilization & Maintenance Best Practices

Safety with bone saws requires a three-pronged approach: proper training, appropriate equipment, and established protocols.

Personal protective equipment is essential - eye protection shields against bone fragments, face shields provide broader coverage, and respiratory protection prevents inhalation of bone dust.

For manual saws, regularly check blade tension to prevent unexpected releases. For powered models, schedule electrical safety inspections according to manufacturer guidelines.

Operating Bone Saws Safely

Modern bone saws feature skin-sparing oscillation - oscillating saw blades that cut rigid bone but tend to push away elastic tissues like skin. While impressive, this should be considered a backup safety feature, not primary protection.

Physical barriers like guard rings and blade shields create distance between hands and cutting edges, particularly important with rotary designs.

Foot switches on powered models provide hands-free control and immediate power cutoff if needed.

Proper training remains essential. Before independent operation, users should receive formal instruction and supervised practice covering both normal operation and emergency procedures.

Cleaning & Sterilizing Procedures

Proper cleaning of bone saws ensures both infection control and equipment longevity.

Follow manufacturer's disassembly guidelines, paying attention to joints, crevices, and blade attachment points. Newer models with tool-free disassembly simplify this process.

Models with water-tight housings like the Mopec Swordfish allow complete submersion during decontamination.

An enzymatic soak helps break down protein residues before mechanical cleaning. This is particularly important for saws used in autopsy or pathology settings.

For autoclave sterilization, follow precise temperature and duration parameters. Most stainless steel components handle standard cycles well, but verify with manufacturer guidelines for powered components.

Use dedicated drying racks designed for specific instruments to ensure complete air circulation.

Long-Term Care & Storage

Consistent maintenance ensures bone saws remain in optimal condition:

Use only manufacturer-approved lubricants that can withstand sterilization without breaking down.

For manual saws, blade sharpening should be handled by qualified personnel. With powered saw blades, replacement is typically preferable to resharpening.

Maintain inspection logs documenting examination dates, findings, and maintenance actions. Inspections should cover corrosion checks, blade integrity, and function testing.

Establish replacement schedules based on manufacturer recommendations and usage patterns, aiming for proactive replacement before component failure.

Specialty Bone Saws & Accessories

Beyond standard models, specialized bone saws cater to unique needs across medical, forensic, and veterinary fields.

Trephines create precise circular openings in the skull. While their fundamental design remains true to ancient origins, today's versions incorporate modern materials and ergonomic improvements.

Sternal saws feature distinctive blade shapes for dividing the sternum during chest procedures, balancing clean cuts through dense bone while protecting vital structures beneath.

Skull breakers like the Virchow model provide controlled separation of cranial bones during autopsy procedures, available with varying blade thicknesses.

Cast saws employ oscillating blades designed to cut through rigid casting materials while minimizing risk to skin underneath.

Dust vacuums have evolved from optional accessories to essential companions for powered bone saws, addressing both contamination control and respiratory protection.

Guides and jigs provide steady-handed assistance for precise cuts, particularly important in orthopedic surgeries where millimeter-perfect bone resection impacts healing outcomes.

Unique Roles of Niche Bone Saws

Veterinary trephines are "small sized, circular blade saws used in veterinary orthopedic procedures." These precision instruments create clean openings with minimal collateral damage, valuable in small animal neurosurgery.

Pathology band saws like the IMEB, Inc. model can "cut bone specimens up to 3 inches in height" with "water-cooled diamond blades to reduce dust and particles."

Spinal blades feature specialized shapes optimized for vertebral cutting. The spine's complex geometry demands tools designed specifically for its unique architecture.

Mortuary vacuums integrate with cutting tools to capture bone dust at the source, available in both portable options and fixed systems.

Accessory Must-Haves

Several accessories improve the functionality, safety, and longevity of bone saws:

Vacuum collectors protect respiratory health and keep working areas clean and visible.

Blade guards provide physical protection during operation and storage.

Jigs ensure repeatable precision, particularly valuable in orthopedic procedures.

Scabbards with belt loops provide safe storage and transport for manual saws.

Spare batteries for cordless models ensure continuous operation, particularly important in field applications.

American Mortuary Coolers offers comprehensive solutions including both primary instruments and necessary accessories, helping customers assemble complete systems for their specific needs.

Frequently Asked Questions about Bone Saws

Do oscillating bone saws really not cut skin?

Yes, it's true! Bone saws using oscillating technology resist cutting skin while effectively cutting bone. This isn't magic - it's physics.

The rapid back-and-forth motion interacts differently with rigid materials (bone) than with elastic tissues (skin). While the blade cuts through brittle bone structure, it tends to push away flexible skin tissue. This phenomenon has even appeared in films like "Night Watch."

However, these tools should still be treated with respect. While oscillating saws are safer than alternatives, they can cause abrasions with prolonged contact and the blade can heat up during use. Always follow all safety protocols.

How often should blades be replaced?

Bone saw blade replacement depends on usage frequency and materials cut:

- Daily use facilities: Every 3-6 months

- Moderate usage: Every 6-12 months

- Occasional use: Annual evaluation with replacement as needed

Visual inspection is crucial - any dulling, pitting, or blade deformation indicates replacement is needed regardless of timeline. Some facilities track procedure counts rather than calendar time.

American Mortuary Coolers recommends keeping replacement blades on hand for each saw type to prevent workflow interruptions.

What is the difference between a Gigli saw and a reciprocating saw?

These bone saws approach cutting in completely different ways:

A Gigli saw is a flexible wire made of twisted metal strands with cutting edges. It's threaded around bone using a carrier needle, allowing cutting from inside outward with minimal surrounding tissue damage. Available in lengths from 12 to 28 inches, it requires manual operation with handles attached to each end.

A reciprocating saw is a powered instrument using a straight blade moving back and forth along its axis - like a motorized traditional handsaw. These provide consistent cutting power without operator fatigue but lack the flexibility to thread around structures.

The choice depends on the specific procedure. Gigli saws excel when minimal access is required or when cutting from within confined spaces. Reciprocating saws are better for straightforward cutting tasks where power and consistency are priorities.

Conclusion

We've explored the remarkable evolution of bone saws from battlefield origins to sophisticated modern instruments. From the simplicity of manual Satterlee and Charriere designs to advanced powered systems like the Mopec Swordfish with integrated vacuum collection, these specialized tools play vital roles across numerous disciplines.

Choosing the right bone cutting instrument requires careful consideration of application, work environment, and regulatory requirements. Whether equipping a surgical suite, autopsy facility, or veterinary clinic, understanding the advantages of different saw types can significantly impact outcomes.

At American Mortuary Coolers, we take pride in being your trusted partner for bone saws and associated equipment. We're a Tennessee-based company specializing in durable, custom solutions for the funeral industry with direct delivery across the contiguous 48 states.

Our commitment to quality extends beyond our flagship mortuary coolers to a comprehensive range of equipment for modern mortuary operations, including an extensive selection of bone saws. With locations across the country - from Johnson City TN to Atlanta GA, Chicago IL, and beyond - we're always close by to provide responsive service and expert guidance.

Want to learn more about our offerings, including custom morgue coolers and specialized cutting equipment? We'd love to hear from you! Just learn more about our custom morgue coolers to see how we can help equip your facility with the best tools in the business.

When it comes to precision instruments like bone saws, you deserve a partner who understands your unique needs and delivers solutions that make a difference in your daily operations.