Why Cooler Racks Are Essential for Professional Cold Storage

Cooler racks are specialized shelving systems designed to organize and store items inside walk-in coolers, freezers, and refrigerated spaces. These systems maximize storage capacity, improve airflow, and ensure safe temperatures while meeting health and safety standards.

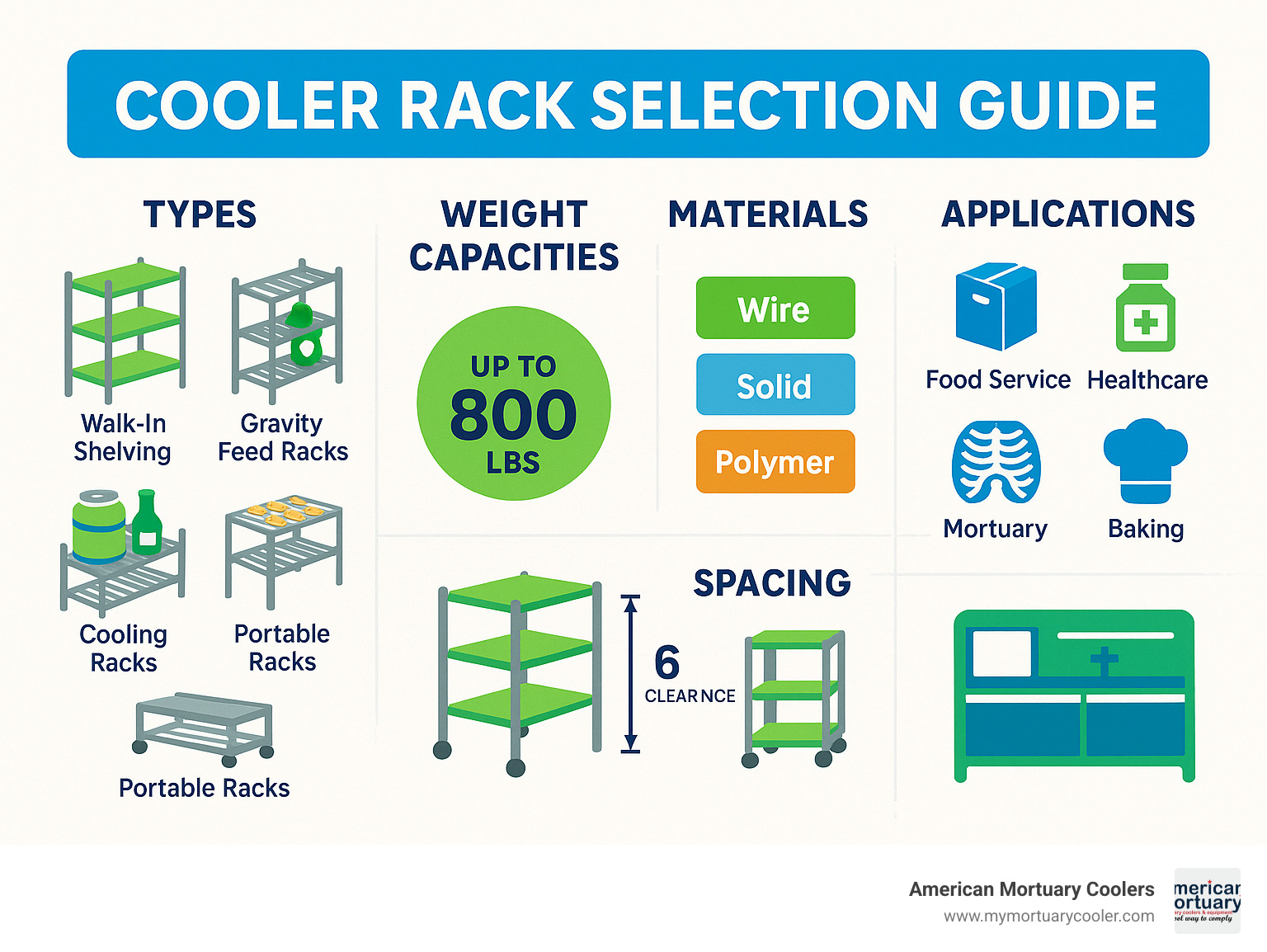

Types of cooler racks include:

- Walk-in cooler shelving - Heavy-duty wire or solid shelves with 800 lb weight capacity

- Gravity feed racks - Angled shelves that rotate stock automatically (FIFO system)

- Keg and beverage racks - Custom systems that can increase storage by up to 40%

- Cooling racks for baking - Liftd racks that prevent steam buildup

- Portable cooler racks - Vehicle-mounted systems for mobile operations

The right cooler rack system depends on your industry, storage needs, and space constraints. Proper rack selection ensures efficient operations, prevents contamination, and extends product shelf life.

Key benefits of quality cooler racks:

- Maintain proper airflow and temperature consistency

- Reduce spoilage through organized FIFO rotation

- Meet health code requirements (6-inch floor clearance)

- Maximize storage capacity in limited space

- Simplify cleaning and maintenance

As Mortuary Cooler, a national-level mortuary cooler supplier, I've helped funeral homes and medical facilities choose the right cooler racks for their specific needs. My experience with cooler racks has shown that proper selection and organization can dramatically improve operational efficiency while ensuring compliance with industry standards.

Cooler racks terms explained:

Cooler Racks 101: Definitions, Uses & Types

Let's explore cooler racks and explore what makes each type special. Think of this as your friendly guide to understanding which rack system will work best for your specific needs.

Walk-In Cooler Shelving Systems

Walk-in shelving forms the workhorse of most commercial cold storage operations. These aren't your typical home shelves - they're built tough to handle serious weight and harsh conditions.

The star of the show is epoxy-coated wire shelving. Each shelf can hold an impressive 800 lb capacity, which means you can stack quite a bit without worrying about collapse. The epoxy coating isn't just for looks - it creates a protective barrier that fights off rust and corrosion in those damp, cold environments.

Here's something neat: that epoxy coating also gives items better grip on the shelf. No more sliding boxes when humidity levels change or when someone bumps into the shelving unit.

Compliance matters too. Your shelving needs to sit at least six inches off the floor. This isn't just a random rule - it makes cleaning easier, keeps pests away, and helps inspectors see that you're following health codes.

The wire design isn't accidental either. It promotes excellent airflow throughout your cooler, which keeps temperatures consistent and prevents those dreaded hot spots that can spoil products.

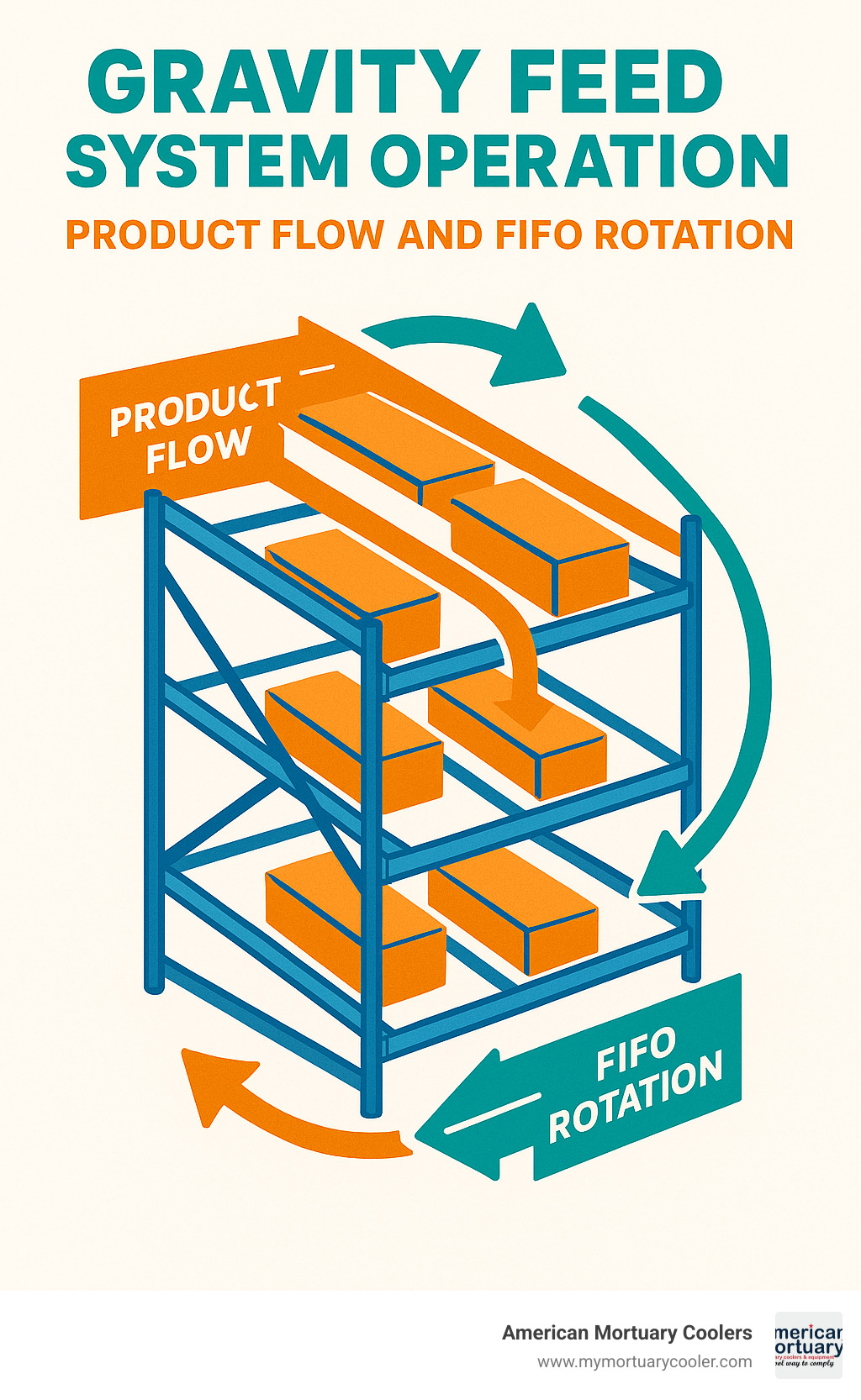

Gravity Feed Cooler Racks

Gravity feed systems are pretty clever when you think about it. They use simple physics to solve a common problem - making sure older products get used first.

These slanted shelf systems automatically handle FIFO rotation (First-In, First-Out). When someone takes a product from the front, gravity slides the next one forward. It's like having an invisible employee constantly restocking your shelves.

For retail sales, this creates a beautiful merchandising display that always looks full. Customers see a well-stocked cooler even when inventory runs low, which naturally encourages purchases.

The angled design also reduces how far customers need to reach into coolers, making the shopping experience more comfortable and reducing the chance of accidents.

Keg & Beverage Cooler Racks

Keg racks solve a problem that anyone who's worked with kegs knows all too well - they're heavy, awkward, and take up way too much space when stored poorly.

Here's some impressive beer math for you: custom beverage cooler racks can boost your storage capacity by 40% compared to just stacking kegs on the floor. That's like getting nearly half your cooler space back.

The keg lifter is a game-changer for safety. It raises kegs up to 45 inches off the floor while still fitting through 30-inch aisles. Your back will thank you, and so will your insurance company.

After three decades of installations, some manufacturers report zero warranty claims on their welded steel keg systems. That's the kind of durability you want when dealing with heavy loads day after day.

Cooling Racks for Baking & Food Prep

Baking cooling racks serve a completely different purpose but they're just as important for food operations. These specialized racks feature nonstick steel surfaces and raised feet that lift baked goods off countertops.

The science behind this is fascinating. Proper air circulation prevents steam buildup that makes crusts soggy, and it helps optimize the Maillard reaction - that's the chemical process that creates browning and develops flavor in baked goods.

Modern versions are dishwasher-safe and use PFOA and PTFE-free coatings, addressing health concerns while maintaining easy release properties. This combination makes them practical for high-volume bakery efficiency operations.

Portable & Vehicle-Mounted Cooler Racks

Portable hitch racks open up possibilities for mobile operations. These systems mount securely on trailer tongue mount points or vehicle hitches, perfect for outdoor catering and special events.

Tailgater racks typically handle 25-quart coolers with interior dimensions around 10¼" x 18". Bundle packages often save money - a complete kit might cost $229 versus $257 for separate components.

The versatility of mounting on either trailer tongues or vehicle hitches makes these systems valuable for diverse mobile food operations. Just make sure you have the proper hitch inserts and pins for safe installation.

Materials, Durability & Performance Factors

When you're choosing cooler racks for your facility, the materials make all the difference between a system that lasts decades and one that fails within months. Let me walk you through the key materials and what makes each one special for different situations.

Think of it this way: your cooler environment is tough on equipment. You've got temperature swings, humidity, condensation, and heavy loads. The right material choice protects your investment and keeps your operation running smoothly.

Wire Shelving with Epoxy Coating

Epoxy-coated wire shelving has earned its reputation as the workhorse of cooler racks. The secret lies in that protective epoxy coating, which acts like armor against rust and corrosion for at least seven years. That's not just marketing talk - it's a real guarantee that manufacturers stand behind.

Here's something most people don't realize: that epoxy coating does double duty. Beyond protecting against rust, it creates traction that prevents stored items from sliding around. If you've ever dealt with boxes sliding off shelves in a humid cooler, you'll appreciate this feature immediately.

The 800 lb per-shelf weight capacity of quality epoxy-coated shelving means you can stack heavy items without worry. This impressive strength lets you use every inch of vertical space efficiently, which translates to more storage in the same footprint.

Installation couldn't be simpler with modern quick-assembly designs. You can literally start using these shelves the moment they arrive, which is perfect when you're expanding operations or dealing with emergency replacements.

| Feature | Epoxy Coating | Chrome Coating |

|---|---|---|

| Rust Protection | 7+ years | 3-5 years |

| Traction | Excellent | Good |

| Cost | Moderate | Higher |

| Durability | Superior | Good |

Stainless Steel & Aluminum Frames

When you need the absolute best in food-grade materials, stainless steel steps up to the plate. Yes, it costs more upfront, but the corrosion resistance and sanitation benefits make it worthwhile for demanding applications.

Stainless steel shines in environments where contamination prevention is critical. The smooth surface cleans easily and meets the highest health department standards. For medical facilities, laboratories, or high-end food service operations, this material choice often pays for itself through reduced maintenance and compliance costs.

Aluminum frames offer a smart middle ground. They're significantly lighter than steel, making installation and adjustments much easier. The natural corrosion resistance handles most cooler environments well, and the moderate cost makes aluminum attractive for many operations.

Both materials support thorough cleaning and sanitization protocols. When your reputation depends on cleanliness, these premium materials give you peace of mind.

Polymer & Hybrid Shelves

Modern polymer shelving systems bring unique advantages that metal alternatives simply can't match. These materials laugh at temperature extremes and resist chemicals that would damage traditional shelving.

The adjustability factor is impressive with polymer systems. Using threaded rods and hex nuts, you can achieve infinite height customization. This modularity becomes invaluable when you're working with unusual spaces or storage needs that change frequently.

Lightweight construction makes polymer systems a joy to work with during installation and reconfiguration. You won't need heavy equipment or multiple people to adjust these systems. However, keep those weight capacity limitations in mind when planning your storage loads.

Temperature tolerance is where polymer really shines. While metal expands and contracts with temperature changes, quality polymers maintain their shape and strength across wide temperature ranges. This stability prevents the warping and fitting issues that sometimes plague metal systems in extreme conditions.

Selecting & Organizing Cooler Racks by Industry

Every industry has its own quirks when it comes to cooler racks. What works perfectly in a restaurant might be a disaster in a medical facility, and brewery needs are completely different from mortuary requirements. Let me walk you through the key considerations for each industry.

Food Service & Restaurant Cooler Racks

Restaurant kitchens are like choreographed dances - everything needs to be in the right place at the right time. Your cooler racks play a starring role in keeping that dance flowing smoothly while keeping everyone safe.

The golden rule of restaurant cooler organization is simple: produce goes on top, raw meat stays on the bottom. This isn't just tradition - it's food safety 101. Store your fresh produce on the highest shelves, followed by prepared foods, then dairy products in the middle, and finally raw meat in leak-proof containers on the bottom shelves. This arrangement prevents any nasty drips from contaminating ready-to-eat foods.

That six-inch floor clearance requirement might seem like a pain, but it's actually your friend. It makes cleaning so much easier when you can get a mop underneath those shelves. Plus, health inspectors love seeing daylight under your storage - it shows you're serious about sanitation.

Don't forget about airflow when loading your shelves. Leave 1-2 inches of space between products and shelf walls. Your refrigeration system will thank you, and your food will stay at safer temperatures. Cramped shelves make your cooler work overtime, which means higher energy bills and potential temperature issues.

More info about modular rack systems can help you create the perfect setup for your kitchen's unique needs.

Retail & Convenience Store Display Racks

Retail is all about the customer experience, and your cooler racks are part of your sales team. Gravity feed systems are absolute game-changers here - they keep your displays looking full and fresh while automatically rotating your stock.

Here's the magic: as customers grab items from the front, gravity slides the next products forward. Your cooler always looks fully stocked, even when you're running low. It's like having an invisible employee constantly restocking your shelves.

Theft reduction is another bonus of well-designed display racks. When products are clearly visible and organized, it's much harder for someone to slip something into their pocket unnoticed. Good visibility works both ways - customers can see what they want, and you can see what they're doing.

Temperature-controlled displays need special attention. Your shelving system needs to work with your refrigeration, not against it. Glass door coolers especially benefit from shelving designed specifically for merchandising beverages and grab-and-go items.

Need help with maintenance? The True Refrigeration service locator can connect you with qualified technicians who understand display rack systems.

Breweries & Beverage Operations

If you've ever tried to maneuver a full keg in a cramped cooler, you know why breweries need specialized cooler racks. These aren't just storage solutions - they're safety equipment that can prevent serious injuries.

Custom beverage storage systems can boost your capacity by 40% compared to just stacking kegs on the floor. That's like getting almost half your cooler space back for free. The math works out beautifully when you're paying premium prices for refrigerated square footage.

The Keg Lifter is one of those inventions that makes you wonder how we ever lived without it. This device lets one person safely position kegs up to 45 inches high while fitting through aisles as narrow as 30 inches. No more herniated discs or crushed fingers from awkward keg wrestling.

Walk-in cooler layouts can be surprisingly dangerous without proper planning. Cluttered aisles and unstable stacking create hazards that can shut down your operation faster than a bad health inspection. Structured shelving systems eliminate these risks while making your daily operations run like clockwork.

When every keg, case, and bottle has its designated spot, your staff spends less time searching and more time serving customers. It's amazing how much smoother everything runs when you're not playing hide-and-seek with your inventory.

Medical & Pharmaceutical Cold Storage

Medical cold storage is where precision meets paranoia - and rightfully so. When you're storing vaccines worth thousands of dollars or medications that could save lives, there's no room for error in your cooler racks setup.

Temperature monitoring becomes critical here, and your shelving system needs to work with your sensors, not against them. Racks that block airflow or interfere with sensor placement can create false readings that put your entire inventory at risk.

Segregation isn't just organization - it's compliance. Different medications and vaccines often have different storage requirements, and mixing them up can be costly or even dangerous. Dedicated shelving zones help maintain proper inventory control while making it easy to track expiration dates.

Your shelving system also needs to accommodate the unique packaging of medical supplies. Vaccine boxes, medication bottles, and laboratory samples all have different size and weight requirements that standard shelving might not handle properly.

Mortuary & Laboratory Applications

Mortuary work requires a special kind of cooler racks - ones designed with dignity and functionality in mind. These aren't just storage solutions; they're part of providing respectful care for families during difficult times.

Body racks and roller systems need to be built to completely different standards than typical shelving. They must provide secure, dignified storage while making it possible for staff to access what they need without physical strain or safety risks.

Quality roller systems enable single-person operation, which is crucial in smaller funeral homes where staff might be working alone. Smooth operation and reliable locking mechanisms aren't just conveniences - they're essential safety features that protect both staff and the families they serve.

Rack and Roll: Top Mortuary Body Racks for Your Needs provides detailed guidance for selecting the right systems for your facility.

At American Mortuary Coolers, we understand that every funeral home has unique needs. We specialize in custom mortuary rack solutions that work perfectly in your space and support your daily operations. Whether you're in Johnson City TN, Atlanta GA, Chicago IL, or anywhere else in the contiguous 48 states, we deliver solutions built to last.

Installation, Maintenance, Innovations & FAQs

Getting your cooler racks installed properly and keeping them running smoothly makes all the difference in your operation. I've seen too many facilities struggle with problems that could have been avoided with the right approach from the start.

Installing Cooler Racks Safely & Efficiently

Before you even think about unpacking your new racks, grab that measuring tape. Getting accurate measurements prevents headaches later, especially when you're working in tight spaces. Six-inch floor clearance isn't just a suggestion - it's required by health codes and makes your life easier when cleaning time comes around.

Modular systems are your friend during installation. These boltless designs go together quickly without needing a toolbox full of specialized equipment. If your storage needs change down the road (and they probably will), you can reconfigure these systems in minutes rather than hours.

For permanent setups, welded systems provide rock-solid stability. They're particularly important when you're dealing with heavy loads or tall rack configurations that need extra security.

Don't skip the anchor points if you're installing tall systems or expecting heavy loads. I've seen racks tip over because someone thought they could save time by skipping this step. It's not worth the risk to your staff or your stored items.

Take those assembly instructions seriously, even if you've installed racks before. Each system has its quirks, and proper weight distribution keeps everyone safe while protecting your warranty coverage.

Maintaining & Cleaning Cooler Racks

Keeping your racks clean isn't just about appearances - it's about food safety and getting the most life out of your investment. Set up a sanitation schedule and stick to it. Those joints and connection points where debris likes to hide need extra attention during cleaning.

Your condenser coils and fan blades need monthly cleaning with a soft brush, more often if you're in a dusty environment. This simple maintenance step prevents your refrigeration system from working overtime and keeps temperatures consistent throughout your cooler.

NSF compliance requires specific cleaning procedures and approved sanitizing agents. Keep documentation of your cleaning schedules - health inspectors appreciate good records, and it shows you're serious about food safety.

Rust prevention starts with regular inspections. Catch coating damage early, and you can fix it with touch-up paint. Wait too long, and you're looking at rack replacement costs that could have been avoided.

Latest Innovations in Cooler Rack Design

The cooler rack industry keeps getting smarter, and these innovations can make your operation more efficient. Glide sheet systems have revolutionized gravity feed racks by eliminating moving parts while keeping products flowing smoothly. No more cleaning rollers or dealing with stuck mechanisms.

IoT temperature sensors are becoming more affordable and practical. These systems integrate with your rack setup to provide real-time monitoring and alerts. You'll know about temperature problems before they become product loss problems.

Modular kit designs give you custom solutions without custom prices. Standard components combine in different ways to fit unusual spaces or specific needs. It's like having building blocks for grown-ups.

Sustainability initiatives are driving development of recyclable materials and energy-efficient designs. These improvements help the environment while often reducing operating costs.

What is the ideal spacing and airflow for cooler racks?

Getting spacing right makes the difference between a cooler that works efficiently and one that struggles. Keep 1-2 inches of clearance between stored items and between items and shelf walls. This spacing prevents air from getting trapped while allowing proper circulation throughout your cooler.

Your walk-in cooler performs best when it's 75% to 90% full. Less than that causes excessive compressor cycling as the system tries to maintain temperature in too much empty space. More than that restricts airflow and creates hot spots where products can spoil.

Keep your fan access clear. Shelving placement needs to consider where fans are located and how air moves through your space. Block the airflow, and you'll create dead spots where temperatures vary from the rest of the cooler.

How do I prevent rust and corrosion on cooler racks?

Epoxy coatings provide the best bang for your buck when it comes to rust prevention. Quality coatings come with guarantees extending up to seven years. Regular inspection helps you spot coating damage before rust takes hold.

Stainless steel upgrades eliminate rust worries completely, though they cost more upfront. In harsh environments or when you need maximum longevity, this investment pays for itself over time.

Routine drying of rack surfaces prevents moisture buildup that accelerates corrosion. Good ventilation and humidity control support rack longevity while maintaining the storage conditions your products need.

What mistakes should I avoid when choosing cooler racks?

Overloading racks beyond their rated capacity creates dangerous situations and premature failure. Those weight limits aren't suggestions - they're engineering specifications. Distribute loads evenly across shelf surfaces to get the performance you paid for.

Wrong material selection for your environment leads to early replacement costs and potential contamination issues. Consider your temperature ranges, humidity levels, and any chemical exposure when choosing materials.

Ignoring health codes results in compliance violations that can shut down your operation. Understanding requirements for your industry and location should happen before you make purchasing decisions, not after an inspector shows up.

At American Mortuary Coolers, we help funeral homes avoid these common mistakes by providing guidance based on decades of experience with specialized cooling applications. Our custom solutions ensure you get racks that work properly in your specific environment.

Conclusion

Choosing the right cooler racks transforms your cold storage from chaotic to organized, from inefficient to optimized. Throughout this guide, we've explored everything from heavy-duty walk-in cooler shelving with 800 lb capacity to specialized gravity feed systems that can boost your storage efficiency by up to 40%.

The materials matter more than you might think. Epoxy-coated wire shelving gives you seven years of rust protection, while stainless steel upgrades provide lifetime durability in harsh environments. Whether you're storing kegs in a brewery or vaccines in a medical facility, the right material choice prevents costly replacements down the road.

Installation and maintenance aren't just technical requirements - they're your insurance policy. That six-inch floor clearance isn't arbitrary; it keeps health inspectors happy and makes cleaning possible. Proper spacing ensures your refrigeration system doesn't work overtime, saving energy costs while maintaining safe temperatures.

Different industries face unique challenges, and we've covered solutions for each. Restaurant operators need cross-contamination prevention and easy cleaning. Breweries require keg lifters for safety and custom racks for maximum capacity. Medical facilities demand precise temperature control and product segregation.

At American Mortuary Coolers, we've spent years perfecting custom cooler solutions for funeral homes and medical facilities. Our Tennessee-based manufacturing expertise, combined with direct delivery across all 48 contiguous states, means you get quality equipment without the middleman markup.

We serve communities from Johnson City TN to Los Angeles, from Chicago IL to Dallas TX. Whether you're in the Northeast, Southeast, Midwest, Southwest, Rocky Mountain, or Pacific regions, we understand local requirements and deliver solutions that work.

Your operation deserves cooler racks that perform reliably for years. The investment in quality systems pays dividends through reduced spoilage, improved efficiency, and peace of mind during inspections.

Ready to optimize your cold storage? The Ultimate Guide to the Best Cooler Rack Options provides detailed specifications and selection criteria to ensure your investment delivers maximum value and performance for your specific needs.