Why Small Scissor Lifts Are Essential for Space-Constrained Operations

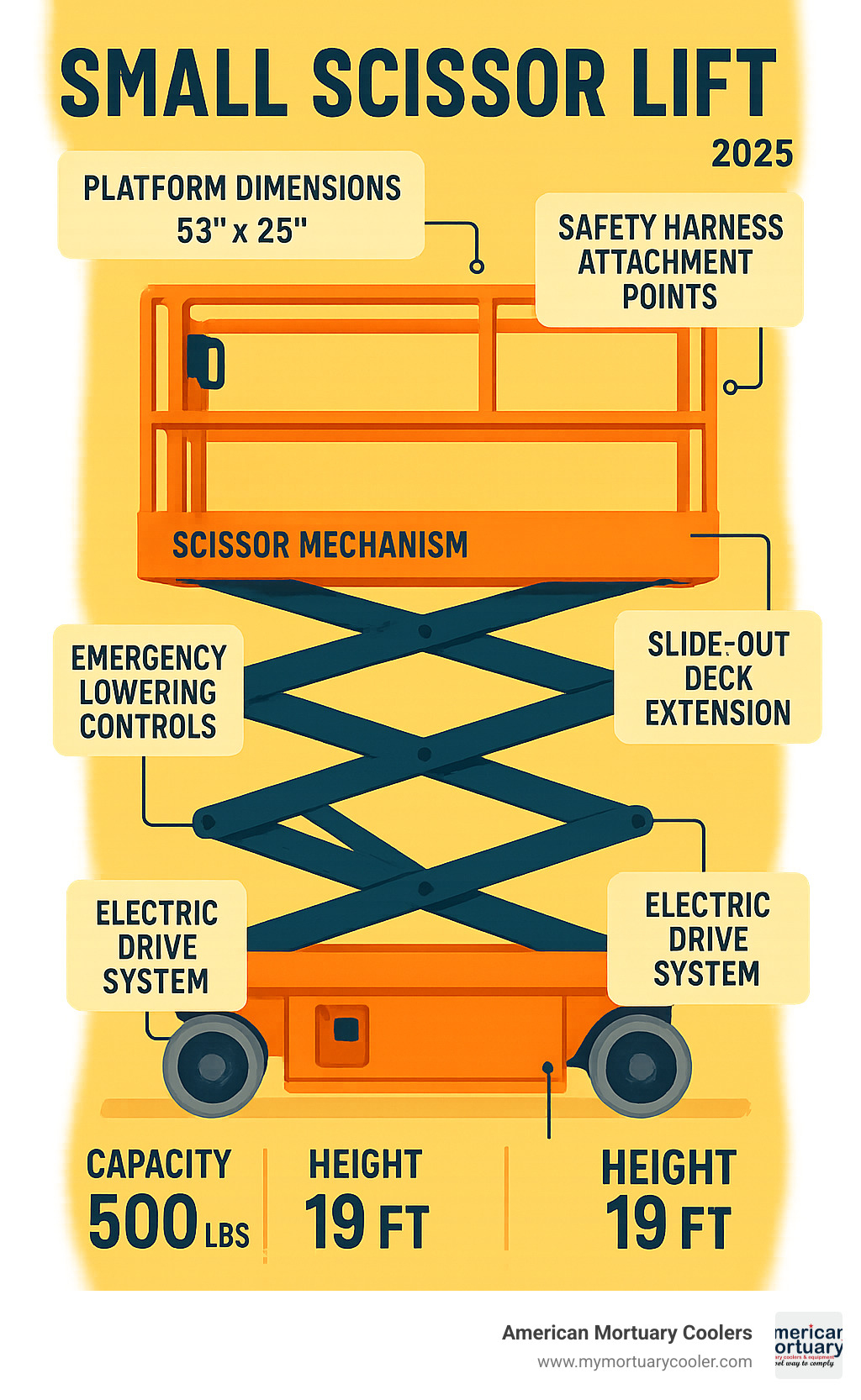

A small scissor lift is a compact vertical access platform designed to fit through standard doorways while providing safe lifted access up to 19 feet. These lifts typically support 500-550 pounds and weigh between 787-1,610 pounds, making them ideal for indoor maintenance, warehouse operations, and tight-space applications.

Key Small Scissor Lift Specifications:

- Platform Height: 10-19 feet maximum

- Load Capacity: 500-550 pounds (2 workers with tools)

- Platform Size: Typically 53" x 25" with optional slide-out extensions

- Weight: 787-1,610 pounds for easy transport

- Power Options: Manual, 12V DC electric, or lithium-ion battery

- Width: Narrow enough to pass through single doorways

Small scissor lifts solve a critical problem for businesses operating in confined spaces. Unlike boom lifts that extend horizontally or vertical mast lifts that lack platform space, small scissor lifts provide stable work platforms with zero turning radius for maximum maneuverability.

These compact lifts are particularly valuable in retail stockrooms, warehouses with narrow aisles, data centers with delicate flooring, and any facility where full-height drive capability and non-marking tires are essential. The combination of electric power (producing zero emissions) and lightweight construction makes them suitable for indoor use without floor damage concerns.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with experience in specialized lifting equipment for funeral homes and medical facilities. Having worked with numerous small scissor lift applications in space-constrained mortuary environments, I understand the critical importance of selecting equipment that balances compact design with reliable performance.

Easy small scissor lift word list:

What Is a Small Scissor Lift?

Think of a small scissor lift as the compact car of the aerial work platform world. These machines use crossed metal supports that look like scissors to lift a work platform straight up. They're built small enough to squeeze through doorways while remaining stable for safe work at height.

What makes these lifts truly "small" comes down to key numbers. Most small scissor lifts reach a maximum platform height of 10-19 feet, giving workers about 19 feet of actual working height. They're designed to carry 500-550 pounds - perfect for two people with tools and supplies.

The real game-changer is their compact footprint. These lifts fit through standard 36-inch doorways, even with safety guardrails deployed. Most models weigh between 787-1,610 pounds, making them light enough for easy transport.

Unlike boom lifts that swing out horizontally, scissor lifts move straight up and down only. This vertical-only travel provides exceptional stability and predictable operation.

| Feature | Small Scissor Lift | Standard Scissor Lift | Large/Rough Terrain |

|---|---|---|---|

| Platform Height | 10-19 feet | 20-40 feet | 40+ feet |

| Load Capacity | 500-550 lbs | 1,000-1,500 lbs | 2,000+ lbs |

| Weight | 787-1,610 lbs | 3,000-8,000 lbs | 10,000+ lbs |

| Width | 30-48 inches | 60-96 inches | 96+ inches |

| Primary Use | Indoor/tight spaces | General construction | Outdoor/heavy duty |

Core Differences From Standard & Rough-Terrain Lifts

Small scissor lifts achieve their compact size through smart engineering. The compact-frame design uses lighter materials while maintaining structural strength through smaller hydraulic cylinders, reduced battery capacity, and streamlined controls.

The indoor-safe tires are another key difference. Most small electric models come with non-marking solid rubber tires that won't streak floors, protecting surfaces from polished concrete to specialized medical facility flooring.

Small Scissor Lift vs Vertical Mast & Boom Lifts

When choosing between a small scissor lift and other aerial platforms, the differences become clear. Vertical mast lifts might have similar footprints, but their platforms are tiny - usually just big enough for one person with minimal tools.

Boom lifts excel at horizontal outreach but need tons of space to operate safely. A scissor lift's platform gives you superior workspace for two-person teams and materials. Many electric models offer zero turning radius, letting you work in spaces where boom lifts couldn't turn around.

Types of Small Scissor Lifts & Their Best-Fit Applications

Choosing the right small scissor lift becomes clearer once you understand the main types and their specific applications.

Micro scissor lifts are the tiniest workhorses, typically handling 240-300 kg (530-660 lbs) and reaching 3-4 meters (10-13 feet) high. They're perfect for extremely tight spaces like narrow store aisles or data centers.

Mini scissor lifts hit the sweet spot for most indoor applications. With 500-pound capacity and 12-15 feet reach, they handle most maintenance and stocking tasks. Popular models like the DS-MSL-10 (reaching 9'10" at 787 lbs) and DS-MSL-12 (12'9" at 917 lbs) are warehouse workhorses.

Power source makes a big difference. Manual push-around models keep things simple and budget-friendly, while self-propelled electric units add convenience for frequent movement. Lithium-ion battery options run longer and charge faster than traditional lead-acid batteries.

For specialized needs, tracked chassis models provide stability on uneven surfaces, and rough-terrain micro units handle outdoor jobs. Check out our comprehensive guide to electric scissor lift options for detailed power system comparisons.

Manual & Push-Around Small Scissor Lift

Manual small scissor lifts are reliable workhorses that don't need to plug in. These hand-propelled units maintain the standard 500-pound capacity while rolling smoothly on 6-inch casters.

The biggest advantage? Lower purchase cost and no battery headaches. You'll never worry about charging or replacing expensive battery packs. These lifts have unlimited "runtime" since moving doesn't require electrical power.

Manual models shine in indoor stock-rooms for fixed-position work like changing fixtures or reaching high shelves. They're perfect for order-picking applications with short travel distances and facilities where charging stations would be complicated.

Self-Propelled Electric Small Scissor Lift

Electric drive systems transform these compact lifts into incredibly maneuverable work platforms. The zero-turn radius on models like the JLG ES1530L lets you operate in spaces where manual units would be tough to position.

Electric models feature slide-out deck extensions adding up to 30 inches of extra working area. Non-marking tires come standard, protecting delicate floors in retail stores, medical facilities, and clean environments. Full-height drive capability allows repositioning while lifted on smooth, level surfaces.

The integrated electric drive reduces complexity compared to hydraulic systems, meaning less maintenance and fewer potential problems. Many include automatic brake systems and diagnostic features for improved safety.

OSHA lift safety research emphasizes proper training and fall protection regardless of lift type.

Micro & Compact Rough-Terrain Units

Sometimes you need to take your small scissor lift outside or onto uneven surfaces. Tracked chassis models feature self-leveling capabilities and handle slopes up to 10° longitudinal and 5° lateral incline.

The Almac B1570 exemplifies this category with its 0.79-meter platform width and 15-meter working height, operating without stabilizers thanks to its tracked design. Tracks distribute weight more evenly than wheels, reducing ground pressure and enabling operation on soft or uneven surfaces.

How to Select the Best Small Scissor Lift for Your Job

Choosing the right small scissor lift doesn't have to be overwhelming. Think of it like buying a car – you need to match the equipment to your specific needs, not just grab the first one you see.

Platform height versus working height trips up many first-time buyers. Here's the key difference: platform height is where your feet stand, while working height includes your reach. A 12-foot platform height gives you about 18 feet of actual working height for tasks like changing light bulbs or reaching high shelves.

Load capacity planning goes beyond just counting workers. That 500-550 pound limit needs to cover everything: two workers, their tools, supplies, and maybe that heavy box of parts you're installing. We've seen too many people get caught off guard when they add up the real weight they're lifting.

Your workspace dimensions matter more than you might think. Most small scissor lifts squeeze through standard 36-inch doorways, but measure twice and buy once. Don't forget about stowed height either – you need somewhere to store this thing when it's not working.

Power source selection impacts your daily operations significantly. Battery runtime typically runs 4-8 hours depending on how much you're moving around. Lithium-ion batteries cost more upfront but charge faster and last longer than traditional lead-acid options. Manual models eliminate power worries entirely but require muscle power for repositioning.

Floor loading becomes critical in older buildings or specialized facilities. Transport weight ranges from 787-1,610 pounds, which sounds heavy but distributes across the tire footprint. Still, check your floor's weight limits before assuming everything's fine.

| Selection Factor | Key Considerations | Typical Range |

|---|---|---|

| Platform Height | Task requirements + safety margin | 10-19 feet |

| Load Capacity | Workers + tools + materials | 500-550 lbs |

| Platform Size | Workspace needed + material storage | 24"x46" to 53"x25" |

| Transport Weight | Trailer capacity + floor loading | 787-1,610 lbs |

| Battery Runtime | Daily usage hours + charging access | 4-8 hours |

| Stowed Height | Storage/transport clearance | 64-72 inches |

Manual vs Electric Small Scissor Lift – Decision Guide

The manual versus electric decision usually comes down to three things: how often you'll move it, your budget, and whether you have a place to charge it.

Manual models make sense when you're working in one spot for hours at a time. Think about maintenance work where you set up once and stay put. They're also perfect when budget is tight or you're working in areas where finding an electrical outlet feels like a treasure hunt.

Electric models shine when you're constantly moving around. If you're doing inventory work in a warehouse or maintenance rounds in a large facility, the electric drive pays for itself in time savings. The zero turning radius on models like the JLG ES1530L means you can spin around in spaces where manual models would require awkward pushing and pulling.

Budget considerations extend beyond purchase price. Electric models need charging infrastructure and eventual battery replacement, but they save labor costs on busy job sites. Manual models have lower upfront costs but might slow down productivity if you're moving frequently.

Comparing Popular Models & Specs

The JLG ES1530L sits at the premium end with good reason. Its 15-foot platform height and industry-exclusive zero turning radius make it ideal for demanding indoor work. At 6'2" machine height, it fits under most standard doorways while providing serious lifting capability.

The Hy-Brid HB1230 focuses on environmental friendliness with zero emissions and energy-efficient operation. Its slide-out extension deck adds 30 inches of working area – basically giving you a bigger platform when you need it without making the whole machine larger.

Ballymore's MSL-12 represents excellent value in the manual category. With 12'9" platform height and 917-pound weight, it's substantial enough for serious work but light enough for easy transport. The counterbalanced design eliminates outrigger setup, which saves time and hassle.

The Almac B1570 brings something different to the table with its compact design and specialized features for tight spaces. Each model has its sweet spot depending on your specific needs.

Latest research on JLG ES1530L specs provides detailed technical specifications if you want to dive deeper into the numbers.

Safe Operation, Compliance & Maintenance Essentials

Working safely with a small scissor lift isn't just about following rules—it's about getting everyone home safely. These compact lifts require the same serious approach to safety and compliance as larger units.

The ANSI A92.6 standard sets the foundation for scissor lift safety, while OSHA fall protection requirements kick in at surprisingly low heights. If you're working at 4 feet or higher in general industry (or 6 feet in construction), you need proper fall protection gear. Since most small scissor lifts reach 10-19 feet, harness use is mandatory.

Every morning should start with thorough inspection. Check your hydraulic system for leaks, examine platform and guardrails for damage, and verify tire condition. Don't forget battery charge levels, emergency lowering systems, and control responsiveness.

Pothole guards and tilt sensors deserve extra attention on rough-terrain models. Battery care extends beyond just plugging in the charger—clean terminals, check connections, and monitor electrolyte levels on lead-acid systems.

Keeping detailed records isn't just bureaucracy—it's proof of responsible operation. Document inspections, maintenance, and issues. This documentation becomes invaluable during safety audits or when problems develop.

Operator Training & Certification

Every operator needs proper training, regardless of lift size. The physics of falling don't care about equipment size.

Good training programs cover essentials: pre-use inspection procedures, safe operating practices, emergency procedures, and hazard recognition. Most programs conclude with a wallet card or certificate proving operator competence.

The pre-use checklist should become second nature. Visual inspections, functional testing, and setup verification happen every time. Emergency lowering procedures require hands-on practice because panic situations aren't the time to figure out which valve does what.

Routine Maintenance & Inspection Schedule

Think of maintenance as insurance for your equipment investment. A well-maintained small scissor lift runs reliably, lasts longer, and keeps operators safe. Consistency is key—sporadic maintenance is almost as bad as no maintenance.

Daily tasks keep you ahead of problems: visual inspections catch obvious issues, battery charge verification prevents mid-job shutdowns, and basic function testing ensures everything works. Weekly maintenance includes detailed component inspections, cleaning, and lubrication. Monthly schedules cover hydraulic pressure testing, electrical system checks, and tire assessments.

Hydraulic leaks are often the first sign of developing problems. Tire wear patterns tell stories about alignment, loading, and operating conditions. Charger tests verify battery system performance when you need it most.

More info about rental rules covers additional compliance considerations for rental equipment.

Costs, Top Models, Transport & Storage Tips

When looking at small scissor lift options, the price range might surprise you. Most quality units fall between $8,000 and $18,000, with manual models hitting the budget sweet spot and fully-loaded electric models commanding premium prices.

Real numbers: The DS-MSL-10 starts at $8,309, while the DS-MSL-12 runs $10,022. Adding a hydraulic power unit costs an extra $1,614. These prices reflect the engineering that makes these lifts both compact and reliable.

Rental markets offer another path, typically running $60-$150 per day. Weekly and monthly rates sweeten the deal for longer projects. Magic number: if you're using a lift more than 60-80 days annually, purchasing usually makes more financial sense than renting.

One pleasant surprise is shipping costs. Their lightweight construction (787-1,610 pounds) means standard freight shipping instead of specialized heavy equipment transport, saving hundreds compared to shipping larger lifts.

Transport requires attention to proper tie-down points and manufacturer-recommended anchor locations. Most manufacturers provide detailed tie-down instructions—follow them religiously.

Storage considerations go beyond finding space. Indoor climate control protects battery life and hydraulic systems. Extreme temperature swings affect battery performance and hydraulic fluid consistency.

Recommended Small Scissor Lift Models & Accessories

Extension decks transform your workspace, with slide-out designs adding 24-30 inches of platform length. This extra room makes a huge difference when working with materials or multiple workers.

Pipe racks and material trays keep platforms organized and safe. Nobody wants tools rolling around loose on a lifted platform—these accessories provide secure storage improving both productivity and safety.

The real game-changer is lithium-ion battery upgrades. These powerhouses deliver 50% longer runtime per charge and 80% faster charging times compared to standard lead-acid batteries. They require less maintenance, perform better in temperature extremes, and last longer overall.

Tilt sensors add extra safety on uneven surfaces, while non-marking tire upgrades protect delicate flooring in medical facilities, clean rooms, and upscale retail environments.

Budgeting: Buy vs Rent

Total cost of ownership gets complicated. You're looking at purchase price, financing costs, maintenance expenses, insurance, storage costs, and depreciation. The utilization rate becomes your north star—frequent use justifies purchase, occasional use favors rental.

Well-maintained small scissor lift units typically retain 40-60% of original purchase price after 5-7 years. Popular models from established manufacturers like JLG, Genie, and Skyjack hold their value better.

The math usually works like this: if you're using equipment more than a quarter of the year, buying makes sense. Less than that, and rental costs stay manageable while eliminating maintenance headaches.

More info about lift resale provides detailed guidance on maximizing equipment value retention.

Frequently Asked Questions About Small Scissor Lifts

How high can a small scissor lift reach?

Small scissor lift models deliver impressive reach despite their compact size. Most units provide platform heights between 10-19 feet, which translates to working heights of up to 25 feet when you factor in a worker's natural reach.

The sweet spot for most applications falls in the 12-15 foot platform height range. This gives you plenty of reach for typical indoor tasks like changing light fixtures, accessing high shelving, or performing maintenance work in warehouses and retail spaces.

It's worth noting that "platform height" and "working height" aren't the same thing. The platform height is where you're standing, while working height adds about 6 feet for your arms and tools. So a 12-foot platform height actually gives you about 18 feet of total working reach.

Do I need fall protection on a small scissor lift?

Here's where size doesn't matter – OSHA treats small scissor lifts exactly like their bigger cousins when it comes to safety requirements. You absolutely need fall protection equipment for virtually all small scissor lift operations.

The rules are straightforward: fall protection is required for any lift operation exceeding 4 feet in general industry settings and 6 feet in construction applications. Since even the smallest scissor lifts reach 10+ feet, you'll need proper harness equipment and must attach it to the designated anchor points on the platform.

Don't let the compact size fool you into thinking these lifts are safer. A fall from 12 feet can be just as dangerous as a fall from 20 feet. The good news is that modern small scissor lift models come with clearly marked attachment points and guardrails designed to work with standard safety harnesses.

What flooring can a lightweight electric lift operate on?

Electric small scissor lift models are surprisingly versatile when it comes to flooring compatibility. The combination of non-marking tires and lightweight construction (typically under 1,600 pounds) makes them suitable for almost any smooth, level surface.

You can safely operate these lifts on polished concrete, hardwood floors, vinyl surfaces, and even specialized medical facility flooring without worrying about damage. The solid rubber tires are specifically designed to prevent marking or scuffing, which is crucial in high-end retail environments or healthcare facilities.

The lightweight design is a real advantage here. Unlike heavy industrial lifts that can crack floors or leave indentations, small electric scissor lifts distribute their weight gently. This makes them perfect for spaces like funeral homes, medical facilities, or upscale retail locations where floor protection is essential.

Just remember that "smooth and level" is key – these lifts aren't designed for outdoor use or uneven surfaces unless you specifically choose a rough-terrain model with tracks instead of wheels.

Conclusion

Choosing the right small scissor lift comes down to understanding your workspace and matching equipment capabilities to your real-world needs. After working with countless facilities across Tennessee, Atlanta, Chicago, and beyond, we've seen how the perfect lift can transform a challenging maintenance task into a routine operation.

The sweet spot for most applications sits around 12-15 feet of platform height with that standard 500-pound capacity. This gives you enough reach for most indoor tasks while keeping the equipment compact enough to actually fit where you need it. Don't forget that your working height extends about 6 feet beyond the platform height - so a 12-foot platform gets you to 18 feet for most tasks.

Electric models with zero turning radius have become game-changers for busy facilities. Being able to spin in place and reposition quickly makes all the difference when you're working in tight aisles or crowded stockrooms. The slide-out deck extensions add that extra workspace when you need it most.

But manual models still have their place, especially when budget matters or you're working in areas where charging isn't practical. We've seen plenty of operations where a simple push-around model handles 90% of their needs at half the cost.

Safety requirements don't shrink just because the lift does. Fall protection harnesses and proper training remain non-negotiable, regardless of whether you're 6 feet up or 16 feet up. The compact size actually makes compliance easier in many ways - you're not wrestling with massive equipment in tight spaces.

At American Mortuary Coolers, we've learned that the best equipment decisions happen when you take time to really understand your space constraints and usage patterns. Measure those doorways, check your ceiling heights, and think honestly about how often you'll need to move the equipment around.

Whether you're maintaining retail fixtures, stocking warehouse shelves, or handling specialized facility needs, the right small scissor lift becomes an extension of your team rather than just another piece of equipment to manage.

Ready to dive deeper into specialized lifting solutions? Our Detailed Guide to Choosing the Best Scissor Car Lift for Your Garage offers expert insights that apply across many lifting applications, helping you make equipment decisions with confidence.