Why Freezer Rooms Are Essential for Modern Cold Storage

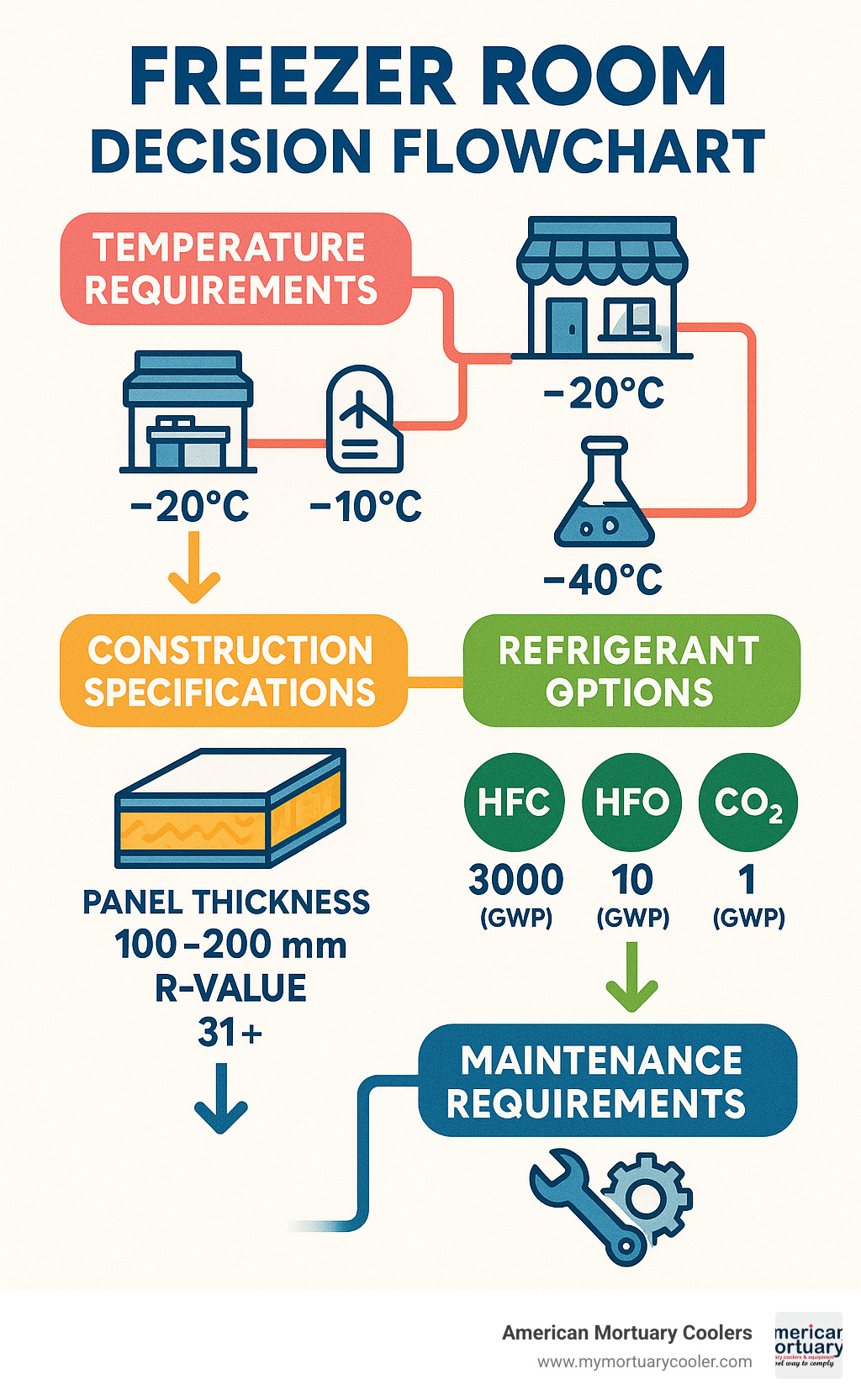

A freezer room is a specialized walk-in cold storage solution designed to maintain precise low temperatures for preserving perishable goods, biological materials, and other temperature-sensitive products. Unlike standard refrigeration units, freezer rooms create controlled environments that can sustain temperatures ranging from -10°C to -40°C or lower.

Key freezer room characteristics:

- Temperature range: -10°C to -40°C (commercial) or down to -80°C (ultra-low applications)

- Construction: Insulated panels with R-values of 31+ using polyurethane foam

- Applications: Food storage, pharmaceuticals, mortuary services, research facilities

- Components: Refrigeration system, insulated panels, door seals, temperature controls

Freezer rooms serve critical functions across multiple industries. In food service, they maintain frozen inventory at optimal temperatures between -18°C and -28°C. Mortuary facilities use specialized freezer rooms operating around -2°C to -10°C for dignified body preservation.

The construction involves high-performance insulated panels, typically 100-200mm thick, combined with commercial-grade refrigeration systems. Modern freezer rooms incorporate energy-efficient components and smart monitoring systems.

I'm Mortuary Cooler, a national-level supplier specializing in mortuary coolers and refrigeration solutions for funeral service professionals. My expertise in freezer room design helps funeral homes select reliable, customized cold storage systems.

Simple freezer room word guide:

Freezer Room Fundamentals: Temperatures, Uses & Core Parts

A freezer room maintains temperatures between -10°C and -25°C for most commercial uses, though some industrial applications push down to -40°C or colder. The system works through a continuous refrigeration cycle where the evaporator pulls heat from the air and the condenser releases it outside.

The walls use polyurethane (PU) or polyisocyanurate (PIR) panels ranging from 75mm to 200mm thick, achieving R-values of 31 or higher. The cam-locking construction with vinyl gaskets ensures every joint is airtight.

Key components include the semi-hermetic compressor, evaporator coils with PSC fan motors, expansion valves, digital temperature controls, and pressure relief ports. Proper airflow requires at least 6 inches clearance from floors and 2 inches between stored items and walls.

Freezer room - CRYO SYSTEMS refrigeration provides additional technical specifications.

What Makes a "Freezer Room" Different?

Cold rooms and freezer rooms serve different purposes. Cold rooms operate between -2°C and 5°C for fresh storage, while freezer rooms work at -15°C to -40°C for frozen storage.

| Feature | Cold Room | Freezer Room |

|---|---|---|

| Temperature Range | -2°C to 5°C | -15°C to -40°C |

| Insulation Thickness | 75-100mm | 100-200mm |

| Primary Use | Fresh storage | Frozen storage |

| Defrost Systems | Minimal | Essential |

Freezer rooms need thicker insulation, heated door frames, and pressure relief systems to handle sub-zero temperatures effectively.

Typical Temperature Bands & Industry Examples

Commercial food service: ice cream storage needs -25°C to -30°C, meat and poultry perform best at -18°C to -20°C, seafood varies from -18°C to -28°C.

Healthcare and research: pharmaceutical storage ranges from -20°C to -80°C, blood and plasma need -30°C to -80°C.

Mortuary applications: body preservation typically operates between -2°C to -10°C for dignified storage meeting health department standards.

Main Components Inside a Freezer Room

The refrigeration system centers around the compressor - semi-hermetic units from Bitzer, Copeland, and Emerson work best. The expansion valve controls refrigerant flow while the condenser releases absorbed heat.

Insulated panel construction uses tongue-and-groove panels with polyurethane foam cores and inner and outer metal skins. Cam-action locking devices create airtight seals.

The air distribution system uses evaporator fans with energy-efficient motors. Safety features include heated pressure relief ports, emergency release mechanisms, digital temperature controllers, and interior lighting with vapor-proof fixtures.

Selecting the Ideal Refrigerant for Your Freezer Room

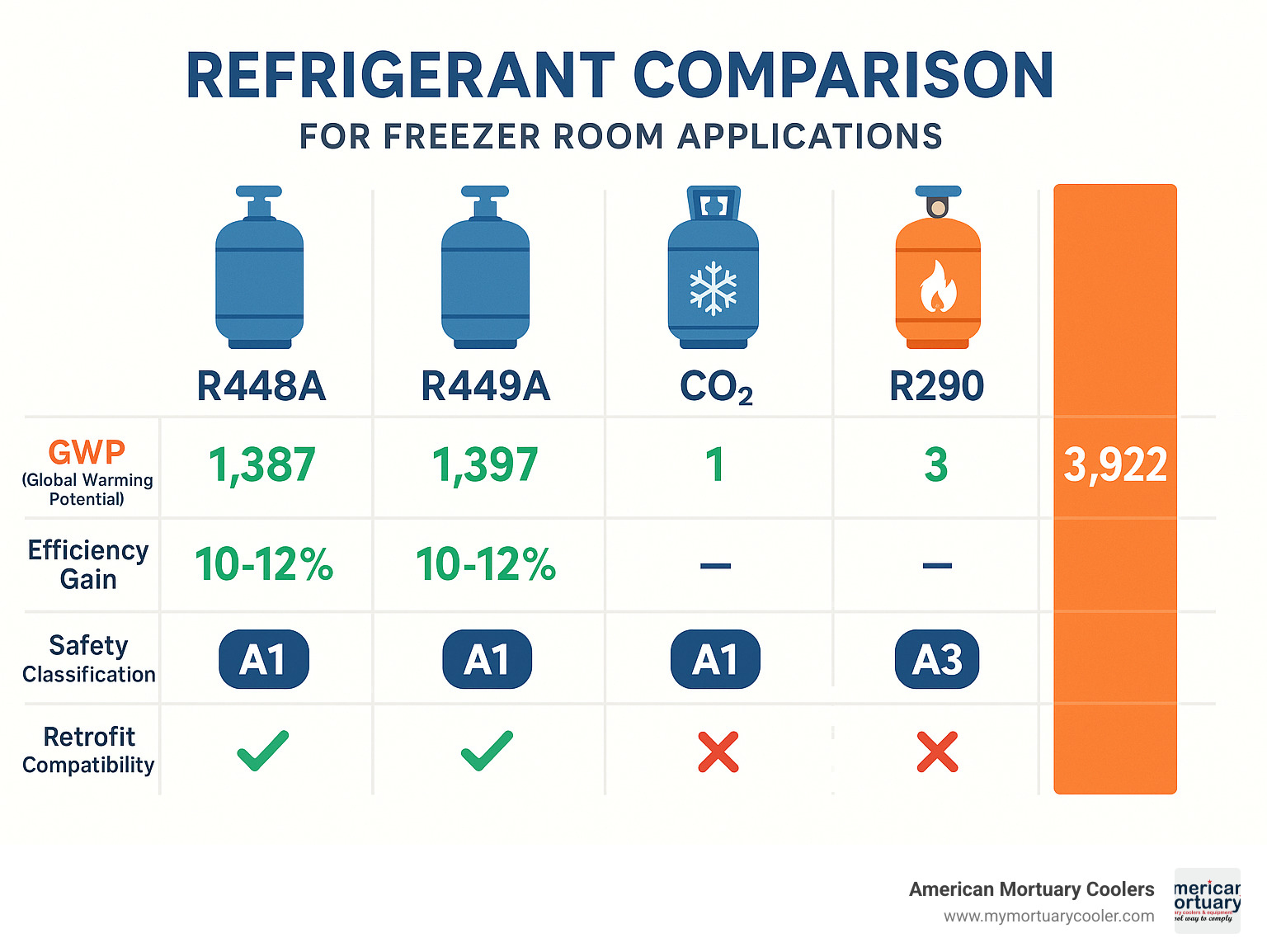

Choosing the right refrigerant affects energy bills, environmental compliance, and future regulations. Old refrigerants like R404A and R507 have Global Warming Potential (GWP) ratings above 3,900 and are being phased out.

ASHRAE 34 standards classify refrigerants: A1 refrigerants are non-flammable, A2L refrigerants are mildly flammable, and A3 refrigerants are highly flammable requiring extra precautions.

Comparing Popular Alternatives to R404A/R507

R448A offers GWP of 1,387 - over 60% lower than R404A - with 10-12% energy savings. R449A provides similar benefits with GWP of 1,397. Both work well as retrofit options.

CO₂ (R744) has GWP of just 1 but operates at higher pressures up to 140 bar, requiring specialized components. R290 (propane) delivers impressive efficiency with GWP of only 3 but requires strict safety systems due to flammability.

Low-GWP & Natural Options – Why They Matter

R404A phase-downs are happening now, with significant restrictions expected by 2030. Future-proofing your freezer room prevents emergency retrofits and often improves efficiency.

Natural refrigerants like CO₂ and hydrocarbons have GWP ratings of 1-3 and will never face regulatory restrictions. However, CO₂ systems need high-pressure components and hydrocarbon refrigerants demand strict safety protocols.

Flammable vs Non-Flammable: Design Implications

Non-flammable A1 refrigerants follow standard safety practices. Mildly flammable A2L refrigerants need refrigerant leak detection systems and improved ventilation. Highly flammable A3 refrigerants require charge limits under 150g, gas detection with automatic shutdown, and explosion-proof electrical equipment.

Design, Construction & Energy-Efficiency Best Practices

Effective freezer room design requires panels between 100-200mm thick achieving R-values of 31 or higher. The best panels use polyurethane foam cores with cam-locking construction and vinyl gaskets.

Commercial applications need 100-150mm panels with R-values of 31-40, while industrial applications require 150-200mm panels achieving R-40 or better. Floor insulation prevents ground heat transfer and structural problems.

Modern freezer rooms benefit from LED lighting with occupancy sensors, variable-speed evaporator fans, smart defrost controls, and remote monitoring capabilities.

Building New Versus Modular Expansion

Permanent construction integrates directly with building structure, offering maximum customization but sacrificing flexibility. Modular panel systems ship within 3-5 days for standard sizes and allow easy expansion or relocation.

Site preparation requires level, reinforced flooring, adequate clearance, proper electrical service, drainage for defrost water, and ventilation for condensing units.

Energy-Saving Upgrades You Shouldn't Skip

ECM evaporator fans use 50-70% less energy than traditional motors while providing variable-speed operation. Smart defrost controls eliminate waste by monitoring actual frost accumulation rather than running fixed schedules.

Door management systems including self-closing hinges, air curtains, and door alarms significantly improve efficiency. Heat recovery systems capture waste heat for hot water or space heating.

More info about walk-in cooler specs provides additional efficiency specifications for mortuary applications.

Retrofitting & Future-Proofing Existing Freezer Rooms

Upgrading your freezer room starts with assessing refrigerant type and charge levels, compressor condition, and insulation effectiveness. Compatibility determines success - many modern refrigerants need POE oils instead of mineral oils.

Component sizing often needs attention since different refrigerants operate at different pressures. Your expansion valve might need replacement, and evaporator coils may require modifications.

Step-by-Step Retrofit Plan for Lower-GWP Refrigerants

Successful retrofits follow a proven process: recover existing refrigerant safely, drain and flush old oil, inspect components for wear, and replace consumables like filter driers.

System modifications include installing refrigerant-compatible components, charging with appropriate POE oil, performing vacuum and pressure tests, then charging with new refrigerant according to specifications.

Commissioning involves programming controls, testing safety systems, verifying temperature uniformity, and training staff on operational changes. Most standard retrofits take 2-3 days.

Solving CO₂ & Hydrocarbon Challenges

CO₂ systems operate at 140 bar compared to 15-25 bar for conventional refrigerants, requiring high-pressure components throughout. Cascade systems offer middle-ground solutions using CO₂ for low-temperature work with conventional refrigerants for heat rejection.

Hydrocarbon refrigerants demand respect for flammability with charge limits under 150g, mechanical ventilation with emergency exhaust, and explosion-proof electrical equipment in hazardous zones.

Installation, Maintenance & Safety Checklist

Proper freezer room installation starts with foundations that handle full loaded weight. Critical checkpoints include level foundations, adequate condensing unit clearance, proper electrical service with disconnects, and drainage systems for defrost water.

Door installation needs heavy-duty gaskets for low-temperature applications, heated door frames preventing ice buildup, and self-closing hinges for temperature control. Safety features include emergency release mechanisms, glow-in-the-dark pull cords, non-skid flooring, and emergency lighting.

Routine Maintenance Calendar

Daily tasks include checking door operation, gasket condition, temperature displays, and listening for unusual noises. Weekly tasks involve cleaning door gaskets, watching defrost cycles, and checking fan operation.

Monthly maintenance includes lubricating door hardware, cleaning accessible coils, testing safety systems, and checking refrigerant levels. Semi-annual professional service covers thorough coil cleaning, refrigerant analysis, and control calibration.

Dirty coils reduce efficiency by 20-30% - clean them twice yearly minimum.

Keeping Your Freezer Room Safe & Compliant

Personnel safety requires emergency release mechanisms, non-skid flooring, and proper ventilation preventing CO₂ buildup. Heated pressure relief ports solve door-opening difficulties from pressure differentials.

Regulatory compliance covers FDA/USDA for food safety, OSHA for workplace safety, EPA for refrigerant handling, and local building codes.

Understanding The Difference Between Cold Room & Freezer Room provides helpful regulatory context.

Frequently Asked Questions about Freezer Rooms

How does a freezer room maintain −20°C even in a 35°C kitchen?

Your freezer room works like a thermal fortress with R-values of 31+ creating incredible thermal barriers. The refrigeration system continuously removes heat that infiltrates through insulation or door openings, accounting for ambient temperature, stored product heat, and infiltration loads with safety margins for reliable operation.

Can I retrofit my R404A freezer room to propane without replacing every component?

Your compressor might survive if compatible with POE lubricant, and coils often stay after proper cleaning. However, expansion valves need replacement, you'll need new filter driers and POE oil, plus safety upgrades including gas detection, improved ventilation, and explosion-proof electrical equipment. Total retrofit costs often approach new system pricing.

What panel thickness is best for an ultra-low −80°C application?

Ultra-low applications require 200-250mm thick panels minimum with R-values of 50+, using high-density polyisocyanurate foam. Floor insulation becomes absolutely essential, and every wall penetration needs thermal breaks. These systems typically require cascade refrigeration and specialized components designed for extreme temperatures.

Conclusion & Next Steps

Choosing the right freezer room means matching your preservation needs with proper temperature control, energy efficiency, and safety features. Your temperature requirements drive system design - whether -2°C for mortuary applications or -25°C for frozen storage.

The refrigerant landscape is changing fast with high-GWP options facing restrictions. Alternatives like R448A and R449A often improve efficiency while reducing environmental impact. Natural refrigerants offer ultimate future-proofing but require careful safety planning.

Energy efficiency features like ECM motors, smart defrost controls, and proper insulation can cut operating costs by 20-30%. Maintenance makes or breaks any system - simple daily checks and professional service prevent expensive emergencies.

At American Mortuary Coolers, we customize solutions for each funeral home's unique needs. Our experience across diverse climates from Tennessee humidity to California heat helps specify the right components for your environment.

We deliver directly across all 48 contiguous states from our Tennessee facility. Whether you're dealing with humidity challenges or heat loads, we understand how local conditions affect freezer room performance.

More info about custom walk-in fridges shows how we customize solutions for different funeral home requirements.

Your next steps: Document your temperature needs and space constraints, consider future growth with modular panels, evaluate refrigerant options, and plan efficiency features matching your usage patterns.

Partner with people who understand your industry. Mortuary refrigeration demands specialized expertise and commitment to your success. Your freezer room supports your ability to serve families with dignity when they need it most.