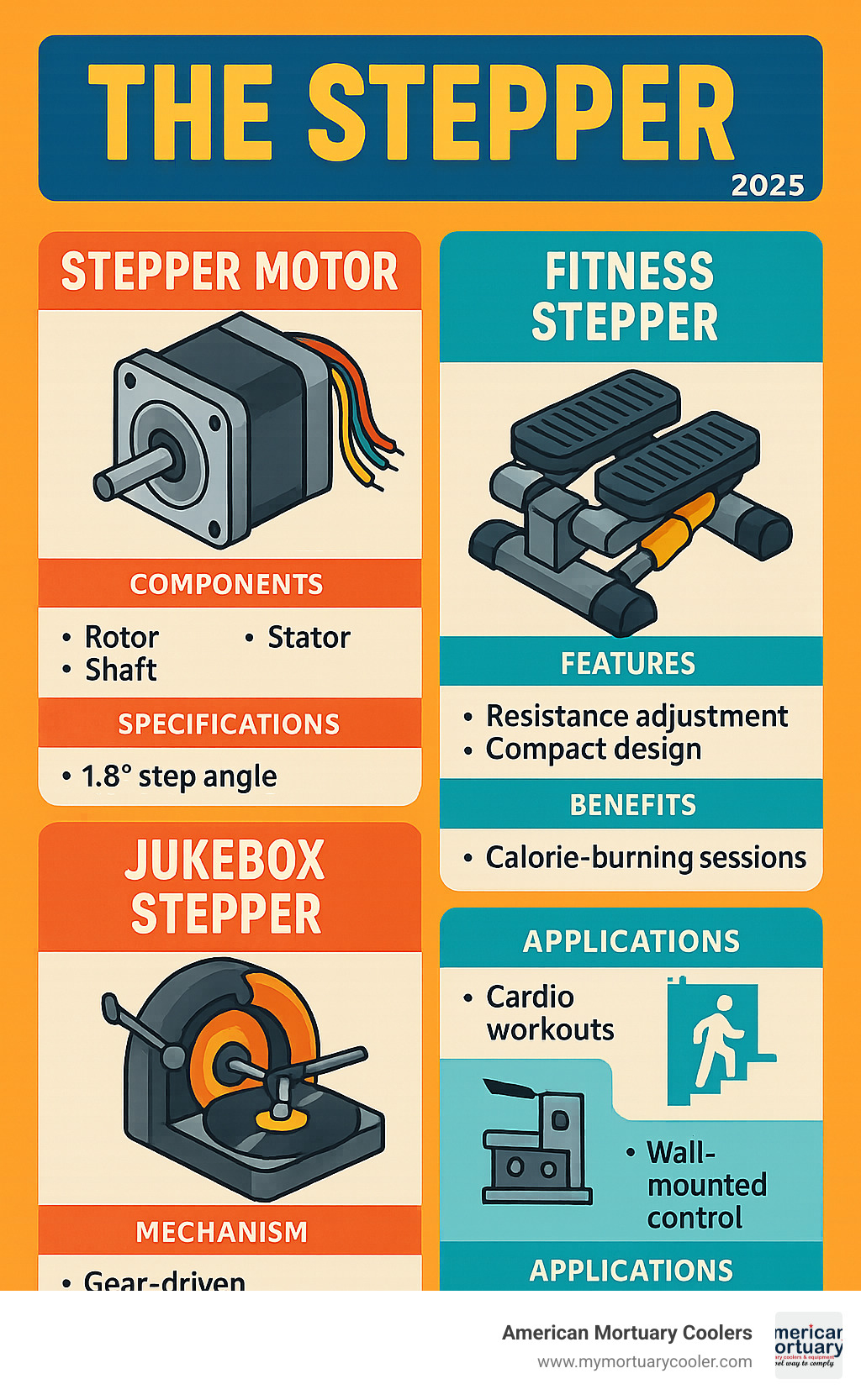

Understanding What "The Stepper" Really Means

The stepper refers to three distinct types of equipment that share a common stepping motion but serve completely different purposes. Here's what you need to know:

Types of Steppers:

- Stepper Motors - Precision electric motors that rotate in exact steps (typically 1.8° per step)

- Fitness Steppers - Exercise equipment that simulates stair climbing for cardio workouts

- Jukebox Steppers - Vintage mechanical devices that enable remote song selection from wall-mounted controls

Key Facts:

- Stepper motors power everything from 3D printers to mortuary lift systems

- Mini fitness steppers can burn significant calories in 30-60 minute sessions

- Jukebox steppers are rare vintage components that most collectors consider "miracles" to find working

The term "stepper" creates confusion because it spans multiple industries - from industrial automation to home fitness to vintage music equipment. Each type operates on stepping principles but uses completely different technologies and serves different needs.

Understanding which stepper you're dealing with matters whether you're selecting precision motors for equipment, choosing home workout gear, or restoring vintage jukeboxes. The wrong choice can mean wasted money, poor performance, or compatibility issues.

As Mortuary Cooler with experience in the stepper systems used in funeral home equipment, I've seen how proper stepper selection impacts everything from lift reliability to maintenance costs. My background includes working with electric stair-climbing systems and mortuary transport equipment where the stepper technology ensures smooth, reliable operation.

Important the stepper terms:

Understanding the Many Faces of The Stepper

The story of the stepper is really three stories rolled into one. Each type developed in its own world, solving different problems with the same basic idea: controlled, precise stepping motion.

What Makes a Stepper Motor Unique?

The stepper motor moves in exact, predictable steps unlike regular motors that just spin wildly. Most stepper motors take 200 steps to complete one full rotation, meaning each step is exactly 1.8 degrees. This precision makes them perfect for applications where you need to know exactly where something is positioned.

The magic happens through electromagnetic poles and hybrid design. Inside the motor, you've got a permanent-magnet rotor with tiny teeth, surrounded by electromagnetic coils in the stator. When electricity flows through these coils in the right sequence, it creates magnetic forces that pull and push the rotor forward, one precise step at a time.

The hybrid design combines the best features of two older technologies, giving you strong torque, excellent positioning accuracy, and solid holding power when the motor stops.

Why Fitness Fans Love the Stepper

The fitness world acceptd the stepper as the perfect solution for people who wanted serious cardio workouts without destroying their knees. Stair climbing research shows real weight loss potential when you use a stepper for 45-60 minutes daily. One reviewer managed 1,000 steps in about 45 minutes, while others report losing 5-6 pounds in just a few weeks of consistent use.

What makes fitness steppers so appealing is the low-impact, high calorie burn combination. You get your heart pumping and burn serious calories without the joint-pounding impact of running. The mini stepper trend has made this type of exercise more accessible than ever - you can use one while watching TV, and they're small enough to store under a bed.

The Vintage Charm of the Stepper in Jukeboxes

Jukebox steppers are mechanical marvels that made wall-box communication possible. You could walk up to a wall-mounted control box across the room and select songs remotely. The stepper mechanism translated your button presses into precise mechanical movements that told the jukebox which record to play.

The engineering involved gear sequencing that would make a Swiss watchmaker proud. Finding a working jukebox stepper today is like striking gold. Vintage audio enthusiasts consider them "miraculous" when they actually work. The original capacitors fail after about 50 years, and those white plastic gears crack and break over time.

Restoration requires replacing old capacitors with fresh components and hunting down rare black NOS (New Old Stock) gears that prove much more durable than the original white ones.

Inside a Stepper Motor: Components, Operation & Control Modes

Ever wondered what makes the stepper motor tick? These devices might look simple from the outside, but they're actually engineering marvels packed with precisely crafted components. Understanding how they work helps explain why they're perfect for everything from 3D printers to mortuary lift systems.

| Motor Type | Control | Precision | Speed | Cost | Best For |

|---|---|---|---|---|---|

| Stepper Motor | Open-loop | Excellent | Low-Medium | Low | Positioning, Low-speed precision |

| Servo Motor | Closed-loop | Excellent | High | High | High-speed precision, Robotics |

| DC Motor | Simple | Poor | High | Very Low | Fans, Pumps, Basic rotation |

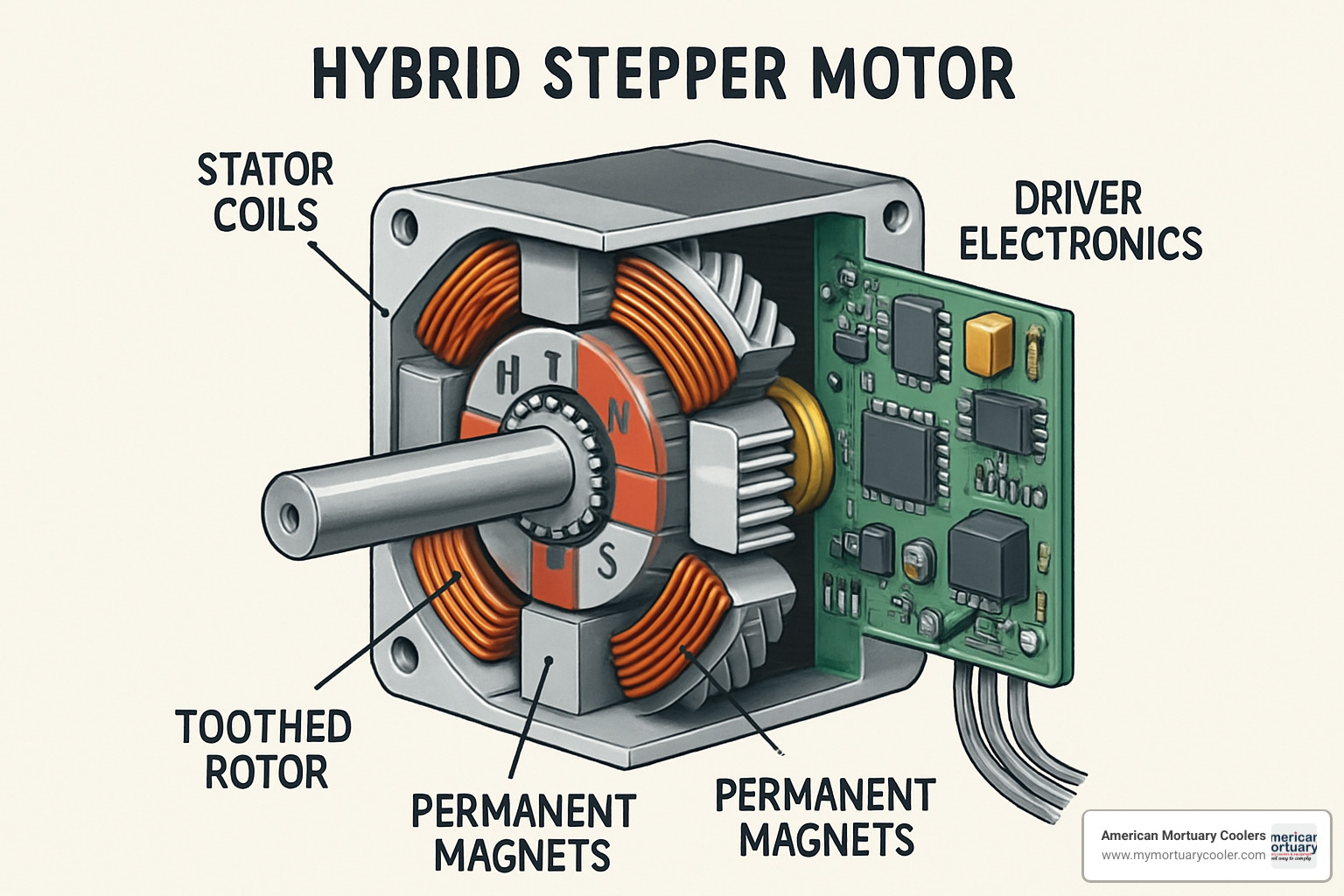

Anatomy of a Hybrid Stepper

The heart of the stepper motor lies in its tooth count and magnetic arrangement. Picture a gear system so precise that it can move in exactly 200 steps per revolution. That's what gives us the famous 1.8° step angle.

The rotor sits in the center covered in precisely machined teeth and packed with permanent magnets. Surrounding it, the stator houses electromagnetic coils wound around more toothed poles. The "hybrid" name comes from combining the best of two worlds: permanent magnets provide holding torque when the motor stops, while the variable reluctance design enables pinpoint positioning through electromagnetic attraction.

How Current Turns into Motion

Converting electrical pulses into mechanical rotation happens through a beautifully orchestrated dance. When we send current to specific stator coils, it creates magnetic fields that attract or repel the rotor's permanent magnets.

The step sequence follows a specific pattern. In a basic two-phase system, we energize Phase A, then Phase B, then Phase A in reverse, then Phase B in reverse, and back to Phase A. Each pulse nudges the rotor exactly one step forward.

What makes the stepper truly special is its holding torque. When we keep current flowing through the windings, the motor grips its position. This means no need for fancy encoders or feedback systems.

Control Methods That Shape Performance

Full-step control gives us maximum muscle by energizing both windings alternately. This delivers the strongest holding power but creates more vibration and noise.

Half-step control offers a clever compromise by alternating between energizing one winding and both windings together. This effectively doubles our resolution to 400 steps per revolution while sacrificing about 30% of the torque.

Microstepping represents the smooth operator, using sine-cosine drive patterns to create incredibly fine resolution. Advanced microstepping drives can slice a full step into up to 256 microsteps, resulting in 51,200 steps per revolution. You'll lose about 30% of your torque, but the motion becomes silky smooth - crucial for mortuary equipment applications.

Advantages, Limitations & Selection Criteria

When you're deciding whether the stepper is right for your project, understanding both the strengths and weaknesses upfront saves a lot of headaches later.

Key Benefits of Stepper Motors

The biggest advantage of the stepper motor is its open-loop control capability. You don't need fancy feedback systems or expensive encoders to know where your motor is. Just count the pulses you send, and you know exactly where the shaft sits. This simplicity cuts costs dramatically compared to servo systems.

Ruggedness is another reason we love steppers in demanding applications. These motors have no brushes to wear out, which means they can handle tough environments. The stepper has standstill torque - when you stop sending pulses, the motor actively holds its position with full force. No need for separate brakes.

The cost-effective nature of stepper systems often surprises people. When you add up the motor cost, simple drive electronics, and skip the feedback sensors, the total system price usually beats servo alternatives by a wide margin.

When The Stepper Isn't the Best Choice

Speed limits represent the biggest drawback. As speed increases, available torque drops off quickly. Resonance can be a real pain around 100-200 Hz where the motor starts vibrating and might even stall.

Stall risk is another concern. If the load gets too heavy, the stepper just stops moving while still drawing current. Heat buildup happens because steppers draw constant current even when sitting still.

How to Pick the Right Stepper for Your Project

Selecting the right the stepper motor comes down to three main factors: torque requirements, speed needs, and environmental conditions.

Start with the manufacturer's torque-speed curve. Your application needs to fit comfortably within this envelope with room to spare. Load inertia matching matters - keep the ratio of your system's inertia to the motor's rotor inertia below 10:1.

In our mortuary applications, scientific research on stair climbing has helped us understand the biomechanical benefits of electric stair-climbing systems. Our experience with mortuary lift steppers has shown that proper stepper selection makes the difference between reliable equipment and constant service calls.

Real-World Applications: From Factory Floors to Living Rooms

Walk into any modern factory or peek inside someone's home gym, and you'll likely find the stepper hard at work.

Industrial Success Stories

The stepper motor has become the unsung hero of modern manufacturing. In CNC machining shops, these motors position cutting tools with incredible accuracy. A single CNC machine might use four or five stepper motors working together.

Electronics manufacturing tells an even more impressive story. Those tiny components on your smartphone's circuit board were likely placed by pick-and-place machines powered by the stepper technology. These systems can position parts smaller than a grain of rice with sub-millimeter accuracy.

The 3D printing revolution wouldn't exist without stepper motors. Every consumer 3D printer relies on multiple steppers to create those intricate plastic sculptures and functional parts. Medical equipment represents perhaps the most critical application, where the stepper controls fluid pumps and positions surgical instruments.

Maximizing Results with The Stepper in Home Workouts

The fitness world has acceptd the stepper with surprising enthusiasm. Those compact mini steppers you see on social media aren't just trendy gadgets - they're delivering real results for people who want effective workouts without gym memberships.

Users regularly report burning significant calories during 45-60 minute sessions while binge-watching their favorite shows. The Sunny Health mini-stepper exemplifies how modern fitness steppers combine lower-body stepping with upper-body resistance training.

Success with the stepper comes down to consistency and proper technique. Starting with shorter sessions and gradually building endurance works better than jumping into marathon sessions.

Mortuary & Funeral Transport Innovations

The funeral industry has quietly acceptd the stepper technology to solve some of their most physically demanding challenges. Electric stair-climbing systems now use stepper motors to provide controlled, dignified transport when navigating stairs becomes necessary.

These electric stair-climbers represent a significant advancement in funeral service equipment. The stepper motors control descent speed and provide smooth movement that reduces physical strain on funeral personnel. With weight capacities often reaching 375 pounds, these systems essentially serve as a "second attendant" during challenging transfers.

Battery-powered stair chairs can handle up to 500 pounds while providing enough battery life for 30 five-story trips per charge. Stretcher integration systems often incorporate stepper motors for height adjustment and positioning, ensuring smooth, respectful transfers during difficult times.

Using, Maintaining, and Troubleshooting The Stepper

Keeping the stepper running smoothly isn't rocket science, but it does require some attention to detail. From our experience at American Mortuary Coolers, most stepper problems are completely preventable with basic maintenance.

How to Keep The Stepper Motor Running Smoothly

Heat is the stepper motor's biggest enemy. Since these motors draw current even when sitting still, they generate heat constantly.

Cooling should be your top priority. Make sure there's plenty of air circulation around your stepper motor. If it's enclosed in a tight space, consider adding a small fan. We've seen motors last twice as long with proper ventilation.

Wiring checks might sound boring, but loose connections cause more stepper failures than anything else. Take a few minutes every few months to look for corroded terminals, frayed wires, or connections that have worked loose from vibration.

Your driver electronics need some love too. Keep them clean and dust-free, and double-check that the current settings match your motor's specifications. Most the stepper motors will happily run for 10,000+ hours with this basic care.

Care Tips for Fitness Steppers

Using a fitness stepper correctly starts with proper posture. Stand up straight, keep your core engaged, and resist the urge to lean heavily on those handrails.

Storage is simpler than you might think. Keep your the stepper somewhere dry, and give it a quick once-over before each workout. The platform itself needs occasional attention - wipe it down regularly and keep an eye out for excessive wear.

Safety-wise, always use the stepper on a level, non-slip surface with plenty of room around you. Start with shorter sessions and work your way up.

Fixing a Faulty Jukebox Stepper

Jukebox steppers are like vintage cars - charming when they work, but they need some TLC to keep running after 50+ years.

Capacitor replacement tops the repair list. Those old capacitors are basically guaranteed to fail after half a century. Do yourself a favor and buy fresh, recently manufactured capacitors.

Gear replacement often becomes necessary because those original white plastic gears get brittle over time. Black replacement gears (part numbers 80-4462 and 80-4463 for many models) are more durable than the originals. Expect to spend around $13 per gear.

Spring tension adjustment requires patience and a gentle touch. You want just enough tension for the stepper to wind and unwind smoothly without binding up or slipping. The contact sequencing needs to be spot-on for proper communication between the wall-box and jukebox.

Frequently Asked Questions about The Stepper

People often get confused about the stepper technology, especially since the term covers everything from precision motors to home workout gear. Let me clear up the most common questions I hear from customers and industry professionals.

What differentiates a stepper motor from a servo motor?

The biggest difference between the stepper motor and a servo motor comes down to how they handle positioning. Stepper motors move in precise, discrete steps without needing any feedback sensors to know where they are. It's like climbing stairs - each step is a fixed distance, and you can count steps to know exactly how far you've traveled.

Servo motors work completely differently. They spin continuously and rely on encoders to constantly report their position back to the control system. Think of it like driving a car with GPS - you need constant feedback to know where you are and make corrections.

The stepper motor can hold its position with full force when stopped, which makes it perfect for applications like mortuary lifts where you need reliable holding power. Servo motors, on the other hand, need to keep making tiny adjustments to stay in position, and they usually need mechanical brakes to hold steady.

From a practical standpoint, stepper systems are much simpler to set up. You just send step and direction signals, and the motor does what you tell it. Servo systems require complex tuning and sophisticated control electronics, which is why the stepper often wins for cost-sensitive applications.

Can I lose weight using a mini stepper alone?

This question comes up a lot, especially with all the social media buzz around mini steppers. The honest answer is that the stepper can definitely help with weight loss, but it's not a magic solution by itself.

Users who stick with consistent 45-60 minute daily sessions often see real results. I've heard from people who lost 5-6 pounds over a few weeks using their stepper religiously. The key word here is "consistent" - you need to make it a daily habit, not just use it when you remember.

The stepper works because it gets your heart rate up without beating up your joints like running does. Most people can manage about 1,000 steps in 45 minutes, which burns a decent number of calories while watching TV or listening to music.

But here's the reality check - you can't out-exercise a bad diet. The stepper works best when combined with sensible eating habits and maybe some resistance band exercises for your upper body. Think of it as one piece of your fitness puzzle, not the whole picture.

Why does my stepper motor skip steps at high speed?

Step skipping is probably the most frustrating problem people encounter with the stepper motors. It usually happens because you're asking more from the motor than it can deliver at that speed.

The stepper motor loses torque as it spins faster - that's just physics. If you're trying to move a heavy load at high speed, the motor might not have enough oomph to complete each step. It's like trying to sprint while carrying a heavy backpack - eventually, you can't keep up the pace.

Resonance issues can also cause problems, especially around 100-200 Hz where the motor starts vibrating. This creates a situation where the stepper literally shakes itself out of sync. You can usually fix this by switching to microstepping mode or adjusting your operating speed to avoid the problematic frequency range.

Sometimes the problem is simply inadequate power supply. The stepper motor needs enough voltage and current to maintain torque at higher speeds. If your driver isn't providing sufficient power, the motor will start missing steps when you push it hard.

In our mortuary equipment applications, we've learned that proper motor sizing and driver selection prevents most step-skipping issues. It's better to oversize slightly than deal with reliability problems in critical applications.

Conclusion

After exploring the fascinating world of the stepper, it's clear that this versatile technology has found its way into remarkably different corners of our lives. From precision motors that power 3D printers to mini steppers helping people lose weight, and even vintage mechanical marvels that once brought music to life in jukeboxes.

What ties these three technologies together isn't just their stepping motion - it's their reliability and precision. The stepper motor delivers exact positioning without complex feedback systems, making it perfect for everything from CNC machines to mortuary equipment. Fitness steppers provide consistent, low-impact workouts that actually work when used regularly. Even those quirky jukebox steppers represent engineering excellence from a bygone era.

The key to success with any the stepper technology comes down to understanding what you're working with. Choose stepper motors when you need precise positioning at reasonable speeds. Pick fitness steppers for accessible cardio workouts that won't punish your joints. And if you're lucky enough to find a working jukebox stepper, treat it like the mechanical treasure it is.

At American Mortuary Coolers, we've learned how critical proper stepper selection becomes in funeral service equipment. Whether it's the smooth operation of electric stair-climbing systems or the reliable positioning of mortuary lifts, the stepper technology proves its worth daily across Tennessee and beyond.

The beauty of stepper technology lies in its straightforward approach to complex problems. No fancy feedback loops or complicated programming - just reliable, predictable motion when you need it most. That's probably why the stepper has thrived across such diverse applications for decades.

If you're working in funeral services and need guidance on stepper-based equipment, we're here to help. Check out our detailed information about mortuary lift steppers to see how the stepper technology can improve your operations.

Whether you're building, buying, or fixing, the stepper offers proven solutions when you match the technology to your actual needs.