Understanding Telescoping Slides: The Complete Guide

Telescoping slides are specialized linear motion devices that allow objects to extend outward and retract back into a fixed position. They serve as the backbone for countless applications requiring smooth, controlled linear movement.

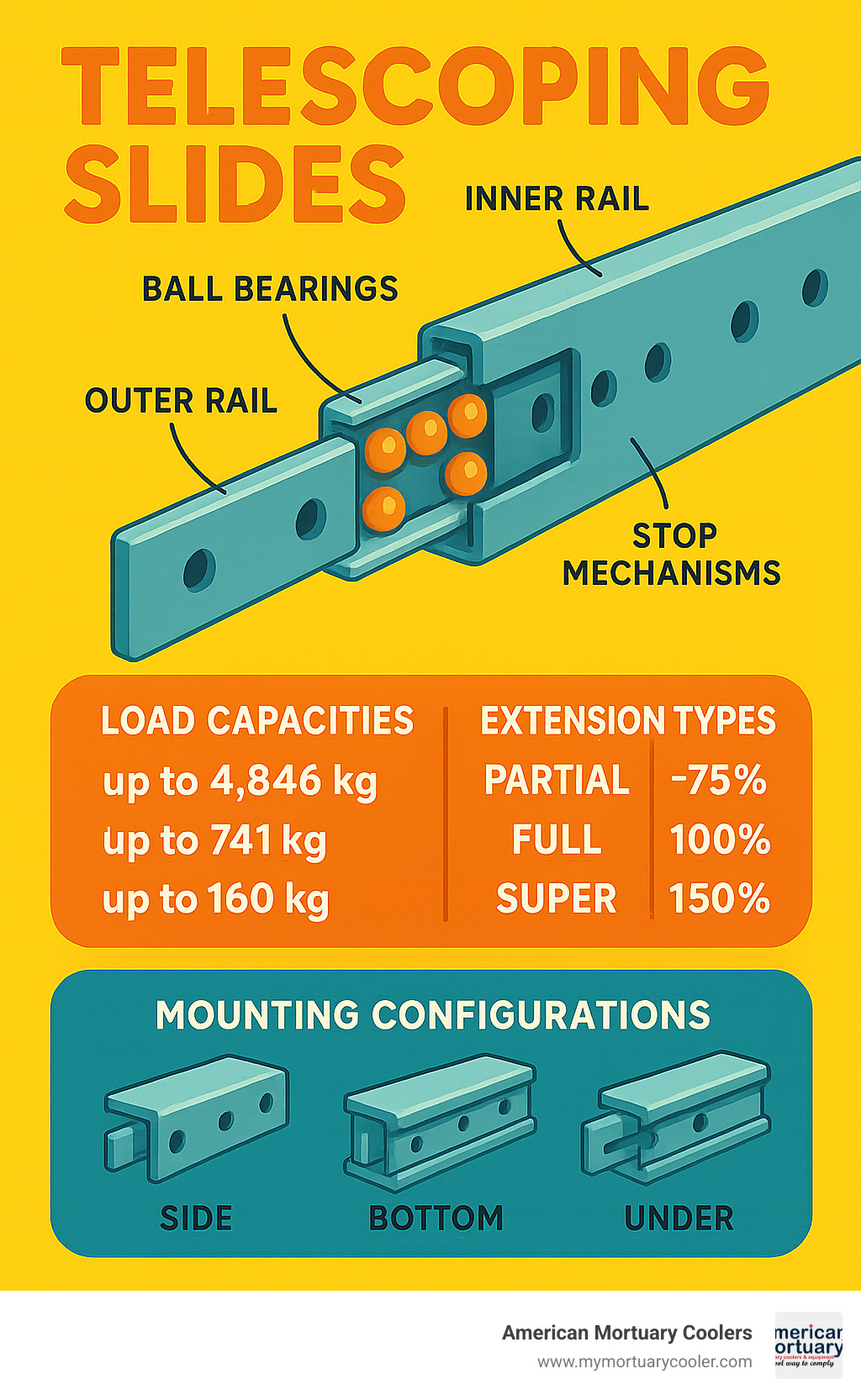

Quick Reference Guide to Telescoping Slides

| Type | Extension | Load Capacity | Best For |

|---|---|---|---|

| Partial Extension | ~75% of closed length | Up to 741 kg | Space-constrained applications |

| Full Extension | 100% of closed length | Up to 480 kg | Complete access needs |

| Super Extension | 150% of closed length | Up to 160 kg | Maximum accessibility |

| Heavy-Duty | Various | Up to 4,846 kg | Industrial and extreme applications |

Materials commonly used:

- Steel (most common, highest strength-to-cost ratio)

- Stainless steel (corrosion-resistant for harsh environments)

- Aluminum (lightweight with good corrosion resistance)

Mounting options:

- Side mount (highest load capacity)

- Under mount (clean appearance)

- Bottom mount (space-efficient)

Telescoping slides function through a system of nested rails that slide against each other using ball bearings or rollers. This design allows for smooth, controlled movement while supporting substantial loads. Whether you're looking for hardware for mortuary cooler trays, industrial equipment, or specialized cabinetry, the right telescoping slide can make all the difference in functionality and durability.

I'm Mortuary Cooler, and I've spent years working with telescoping slides in specialized mortuary equipment applications, designing optimal slide systems for body storage coolers that combine smooth operation with exceptional durability. The perfect telescoping slides ensure reliable access while maintaining critical temperature stability.

What Are Telescopic Slides and How Do They Work?

Ever pulled out a drawer smoothly and wondered what makes that magic happen? That's the work of telescoping slides in action! These clever devices are precision-engineered components that create controlled linear motion through nested rails that slide in and out while supporting themselves – no external support needed along their entire length.

Unlike standard fixed linear guides, telescoping slides can extend and retract while maintaining their structural integrity. As one industry expert from Linear Motion Tips notes, "Traditional linear guides can be joined for unlimited travel, but they lack a simple way to extend into and retract out of the work area—telescoping slides fill that gap."

The heart of these slides consists of two or more nested sections that slide relative to each other. The smooth movement comes from either ball bearing systems or cam roller mechanisms that create a low-friction interface between sections.

Most telescoping slides use steel balls that recirculate within carefully machined raceways in the slide profiles. These little spheres do the heavy lifting by providing multiple contact points between slide elements, which distributes weight evenly while keeping friction to a minimum. More sophisticated designs include an intermediate element between outer and inner rails, which significantly improves stiffness and reduces wobbling when extended.

When engineers think about load handling in telescoping slides, they consider two main types of forces:

- Radial loads (forces perpendicular to the extension direction) are typically the primary design consideration

- Axial loads (forces parallel to the extension) generally have lower capacity

Every slide must account for both static capacity (when stationary) and dynamic capacity (when moving), with the latter usually being the more limiting factor.

Anatomy of a Telescoping Slide

Think of a telescoping slide as a sandwich of precision parts working together. Here's what makes up these marvels:

The outer rail attaches to your stationary structure (like a cabinet), while the inner rail supports whatever you're extending (like a drawer). In three-section designs, an intermediate rail provides additional extension and stability.

Between these rails, you'll find the ball cage, which houses and positions the ball bearings. Stop bumpers prevent over-extension and provide cushioning when fully extended. Grease paths allow lubricant to maintain smooth operation, and precisely positioned mounting holes ensure secure attachment.

Higher-end models often include detent mechanisms to hold slides in closed or open positions, locking devices to secure slides at specific points, and dampers for controlled closing action – no more slamming drawers!

How Motion Is Achieved

The smooth gliding action of telescoping slides happens through one of two main mechanisms:

With ball bearing systems, hardened steel balls roll between rail sections in precision-machined raceways. The ball cage holds these balls in position. As you extend the slide, the balls recirculate through the cage, providing continuous support and nearly frictionless movement. This design offers the highest load capacity but can struggle in dusty or dirty environments.

Cam roller systems take a different approach, using cylindrical or conical rollers that follow cam paths in the rail profiles. These excel in contaminated environments and provide exceptionally smooth operation under varying loads. While they typically handle less weight than ball systems, they're perfect for challenging conditions.

The secret to both designs is maintaining precise clearances between components – too tight and the slide binds; too loose and it wobbles under load. That's why quality telescoping slides are manufactured with tolerances often measured in hundredths of a millimeter.

As one industry technical guide explains, "The most common construction uses an outer rail and one or more inner rails, often with an intermediate element to improve stiffness and reduce deflection; movement is guided by balls or cam rollers." This engineering precision is what transforms a simple concept into a reliable, smooth-operating component that can handle everything from kitchen drawers to industrial equipment to specialized applications like mortuary cooler trays.

Key Types of Telescoping Slides You'll Meet

Shopping for telescoping slides can feel overwhelming with all the options out there. Let's break down the different types you'll encounter in a way that makes sense, whether you're outfitting a mortuary cooler or tackling a DIY project at home.

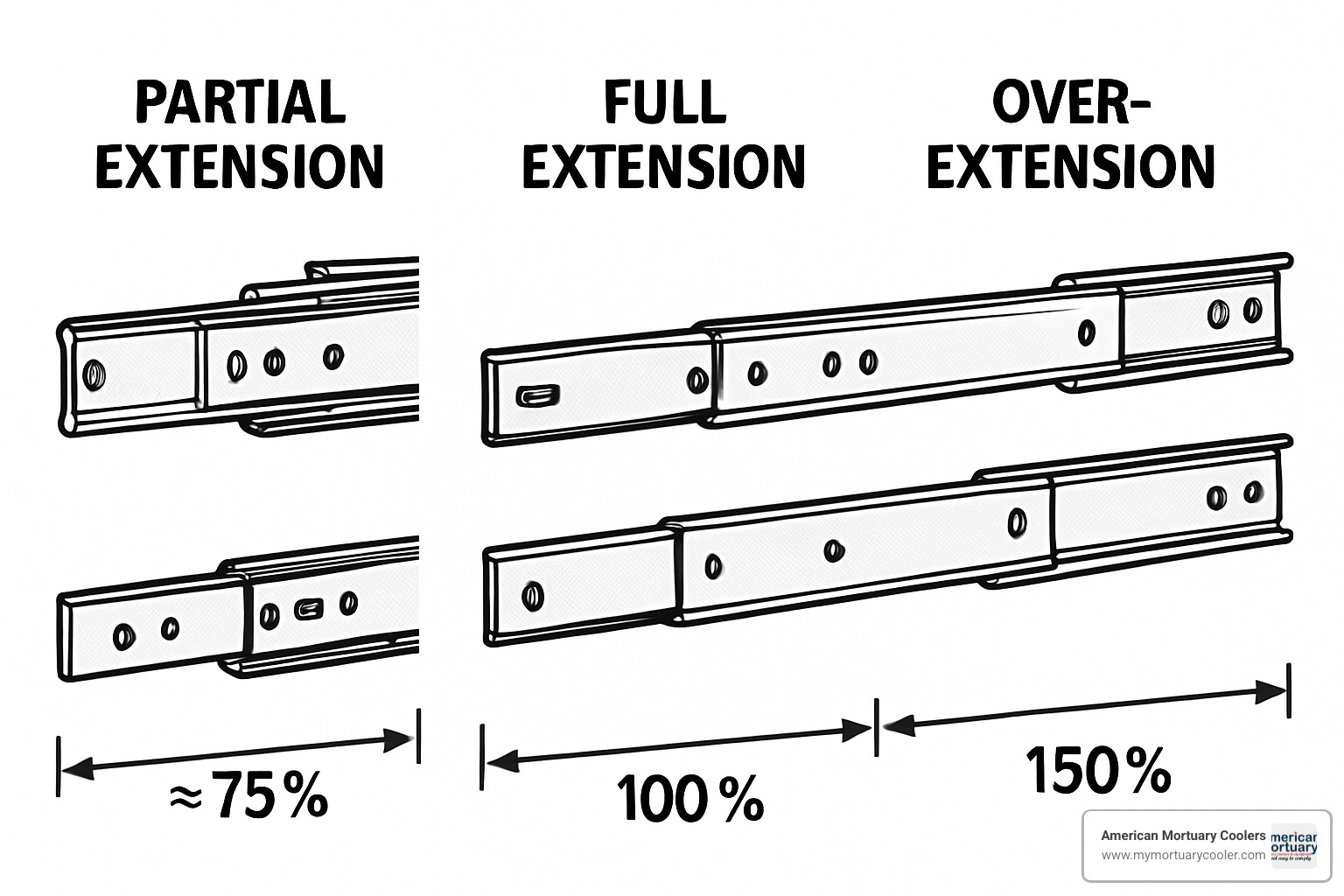

Extension Types

Think of extension as how far your drawer or tray can pull out. It's like the difference between peeking into a room versus stepping all the way inside.

Partial Extension Slides (75% Extension) are the peekers of the slide world. They let you access about three-quarters of your drawer's depth. If you have a 400mm drawer, you'll get around 300mm of access. These slides are sturdy workhorses, offering the highest strength-to-size ratio. They're perfect when space is tight and you don't need to see everything inside.

Full Extension Slides (100% Extension) are the most popular choice for good reason. They allow complete access to your drawer contents – a 500mm drawer gives you 500mm of travel. Nothing stays hidden at the back. It's like having the best of both worlds: good strength and full visibility.

Super/Over-Extension Slides (150% Extension) go above and beyond, literally. These slides extend beyond their closed length, typically reaching 150% extension. A 500mm slide gives you about 750mm of travel. As one manufacturer puts it, "Over-extension models can reach 200% of their closed length for maximized accessibility in tight spaces." These are game-changers when you need to bring contents completely clear of their housing.

Double Stroke Slides are the space-savers of the bunch. They deliver twice the extension for the same base length – perfect when you need maximum reach from minimal space.

Functional Variants

Beyond extension distance, telescoping slides come with various features that improve their performance.

Locking vs. Non-Locking Slides is an important distinction. Locking slides keep things secure when fully open or closed – crucial for mobile applications like mortuary transport carts where you don't want unexpected movement. Non-locking slides move freely, offering simpler operation when position holding isn't needed.

Some slides come with comfort features that make daily use more pleasant. Soft-close slides gently bring drawers to a stop instead of slamming shut – a feature your fingers will thank you for. Push-to-open mechanisms create a sleek, handle-free look while allowing easy access with just a gentle press. Disconnect slides let you completely remove the drawer when needed, making cleaning or maintenance much simpler.

How you mount your telescoping slides matters too. Side-mount slides attach to the sides of drawers and cabinets, offering maximum strength. Under-mount slides attach beneath the drawer, creating a clean look with no visible hardware. Bottom-mount slides connect to the drawer bottom and cabinet floor, useful in certain tight spaces.

Telescoping Slides for Light, Medium & Heavy Loads

The weight your slides need to support determines which category you'll need.

Light-Duty Slides (≤50 kg) handle everyday items with ease. They're perfect for standard drawers, light equipment trays, and general commercial applications. While they use thinner materials and smaller bearings to keep costs down, they offer smooth operation for daily use.

Medium-Duty Slides (51-99 kg) step up the strength game. They're the middle-ground champions, serving applications that need more muscle than standard drawer slides but don't require industrial-grade capacity. You'll find them in heavier furniture, commercial kitchens, and light industrial environments.

Heavy-Duty Slides (≥100 kg) are the industrial workhorses. These robust slides handle significant loads while maintaining smooth operation. With reinforced profiles and larger bearings, they're ideal for manufacturing equipment, industrial storage, and specialized applications like our mortuary coolers.

Extreme-Duty Slides (up to 4,846 kg) take strength to another level entirely. As one manufacturer notes, "Precision telescopic slides are available with load capacities up to 4,846 kg, suitable for extreme heavy-duty applications." These slides serve specialized industrial equipment, military applications, and heavy machinery where failure simply isn't an option.

Telescoping Slides with Integrated Locks

Safety matters, especially when dealing with heavy loads or sensitive equipment. That's why telescoping slides come with various locking options.

Lock-In Systems keep slides securely closed until you're ready to open them. They're essential for mobile applications like mortuary transport equipment where unexpected opening could be problematic.

Lock-Out Systems do the opposite – they keep slides fully extended and prevent accidental closing. They're invaluable when working with heavy equipment or when stability in the extended position is crucial for safety.

Manual Lever Locks offer flexibility by securing the slide at various positions. They typically require deliberate action to engage and disengage, putting you in complete control.

Safety Latches provide peace of mind by automatically engaging at specific positions. They require intentional action to disengage, adding an extra layer of safety for critical applications like mortuary cooler trays.

As industry experts note, "Lock-in/lock-out features secure the slide at fully closed or extended positions," making them essential when position stability isn't just convenient – it's critical for function and safety.

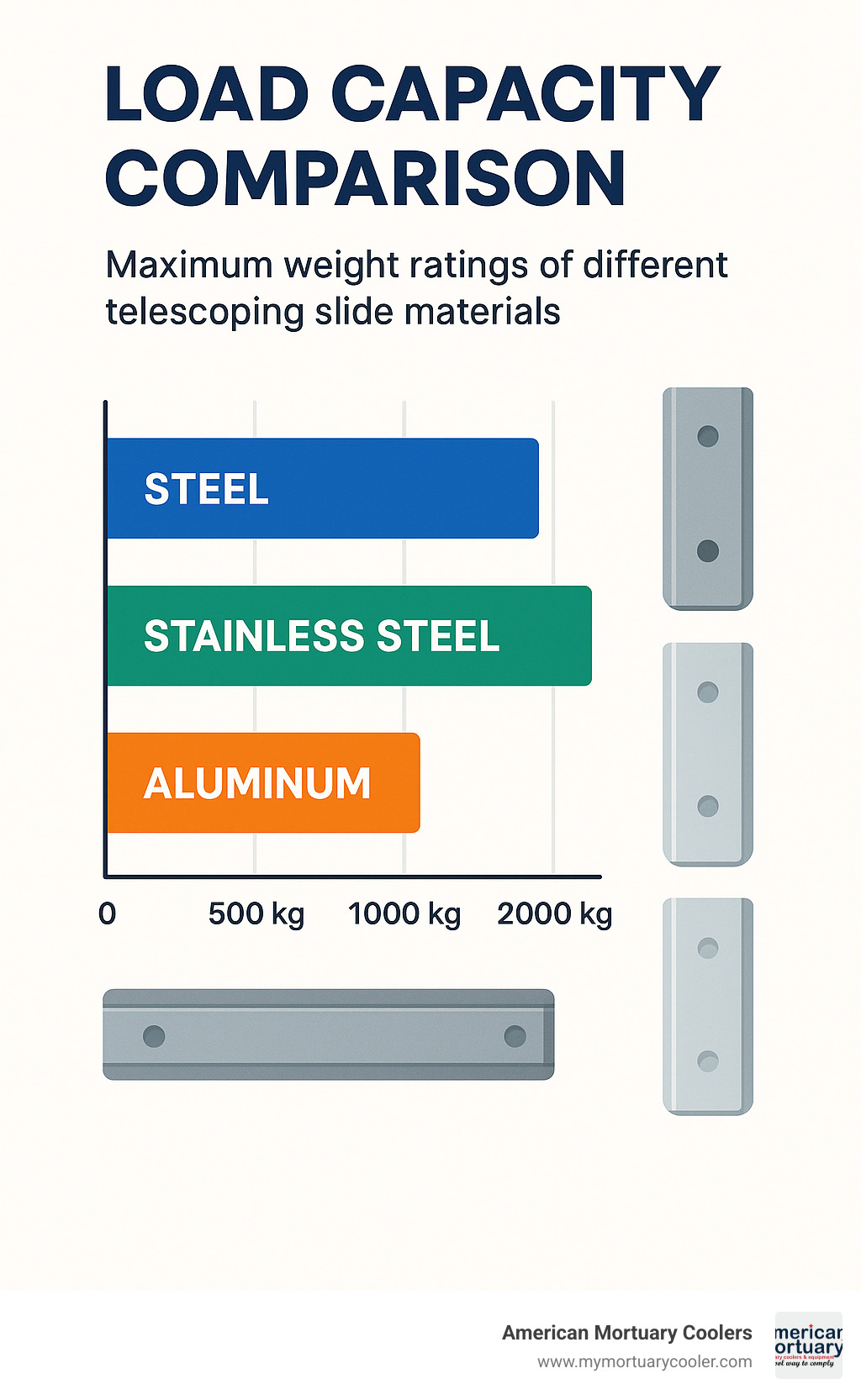

Materials, Finishes & Load Capacities: Choosing the Backbone

When it comes to telescoping slides, the materials you choose are like picking the foundation for a house—get it wrong, and everything else falls apart. Let's look at what goes into making these workhorses and how to pick the right one for your needs.

Primary Materials

Steel is the reliable workhorse of the slide world. Most slides you'll encounter are made from cold-drawn steel because it delivers the most strength for your dollar. Need something that can handle serious weight? Steel slides can support loads up to a whopping 4,846 kg in specialized designs. That's like holding up a small elephant!

The downside? Plain steel rusts faster than a neglected garden tool in the rain. It's also on the heavier side, which might matter if weight is a concern for your project.

Stainless Steel (316L) is what you want when things get wet, salty, or downright hostile. Think of it as steel's more resilient cousin. For mortuary coolers and other environments where moisture is constant, stainless is often worth the extra investment. As one manufacturer points out, "Marine grade stainless steel slides (1.4404/316L) are available with load capacities up to 2,000 kg, making them suitable for harsh environments." Yes, they cost more upfront, but they'll keep sliding smoothly long after steel has started to corrode.

Aluminum (7075-T6) is the lightweight champion. When every ounce matters, aerospace-grade aluminum delivers impressive strength at roughly a third the weight of steel. Industry specs show that "Aerospace grade aluminium slides (7075 T6) can support loads up to 400 kg, combining high strength with low weight." Perfect for applications where adding extra weight is like adding extra problems.

Surface Treatments and Finishes

Raw materials often need a little extra help to stand up to daily use:

Zinc Plating is like giving your steel slides a raincoat. This common finish (typically 12 microns thick) provides good protection for indoor environments. It's affordable and comes in various colors, though you'll most often see white or clear "blue-bright" finishes. For mortuary equipment used indoors, zinc-plated slides often provide the right balance of protection and value.

Hard Chrome Plating adds serious durability and a mirror-like shine. It's the finish of choice when slides will face heavy use and need to look good doing it. The distinctive chrome appearance also means these slides often end up in visible applications.

Nitriding is a surface-hardening process that makes slides tougher without changing their size. Think of it as creating a super-hard skin on the metal. For applications with thousands of cycles, nitrided slides keep performing when others would have worn out.

Anodizing is aluminum's best friend. This process creates a hard, corrosion-resistant layer that can be dyed in various colors. It's like giving aluminum armor that can match your color scheme.

Why Material Choice Matters for Telescoping Slides

The environment where your slides will operate should drive your material selection. For telescoping slides in clean rooms, stainless steel with specialized low-outgassing lubricants is often mandatory. In marine applications, 316L stainless is practically the only choice that won't surrender to salt spray. Food-grade applications require materials that won't contaminate products and can withstand frequent cleaning.

In our mortuary coolers, we've found that properly finished and sealed slides stand up to the unique challenges of constant cooling and occasional moisture exposure, ensuring reliable operation year after year.

Understanding Load Calculations & Deflection

Here's something that trips up many buyers: those impressive load ratings come with fine print. Most telescoping slides list their capacity per pair, assuming:

- You've distributed the weight evenly

- The slides are mounted on their sides (strongest orientation)

- The load sits centered between both slides

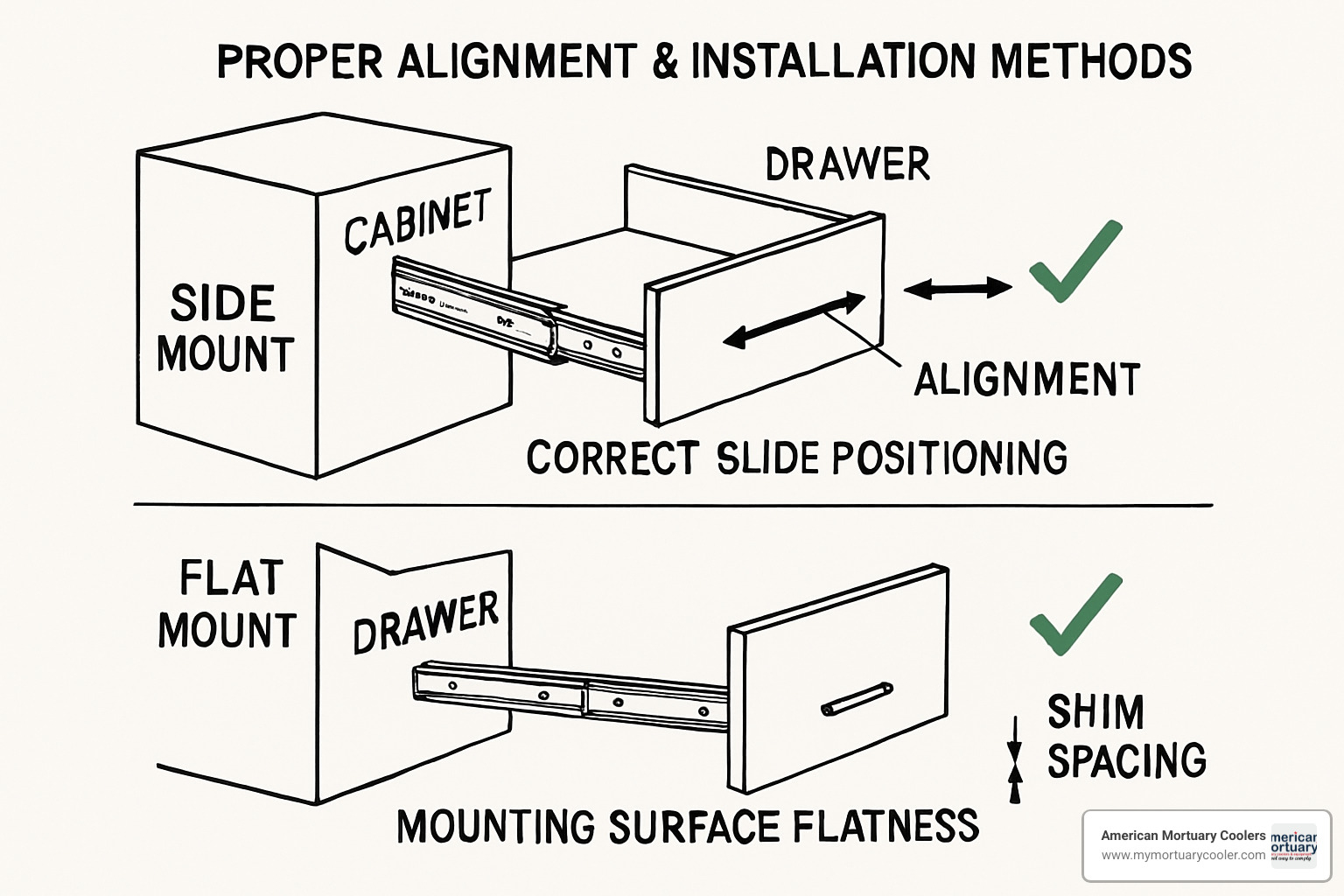

Change any of these factors, and reality might not match the brochure. For instance, mounting slides flat instead of on their sides can slash their capacity by 60-80%! It's like trying to carry a heavy box with your arms out to the sides instead of hugging it close—technically possible, but much harder.

Deflection is another critical factor that spec sheets often overlook. A slide might not break under weight, but if it bends too much, it can bind up or move unevenly. As one expert notes, "Flat mounting results in a large deflection, thus spacing adjustments are recommended." In practical terms, you might need shims or spacers to keep things running smoothly.

Don't forget about temperature either. Standard telescoping slides typically perform best between -20°C and 80°C. Need something for extreme cold or heat? Look for specialized designs and lubricants rated for temperatures from -50°C to 250°C.

At American Mortuary Coolers, we carefully match slide materials to the specific demands of mortuary environments, ensuring reliable operation and long service life for equipment that simply can't fail when you need it most.

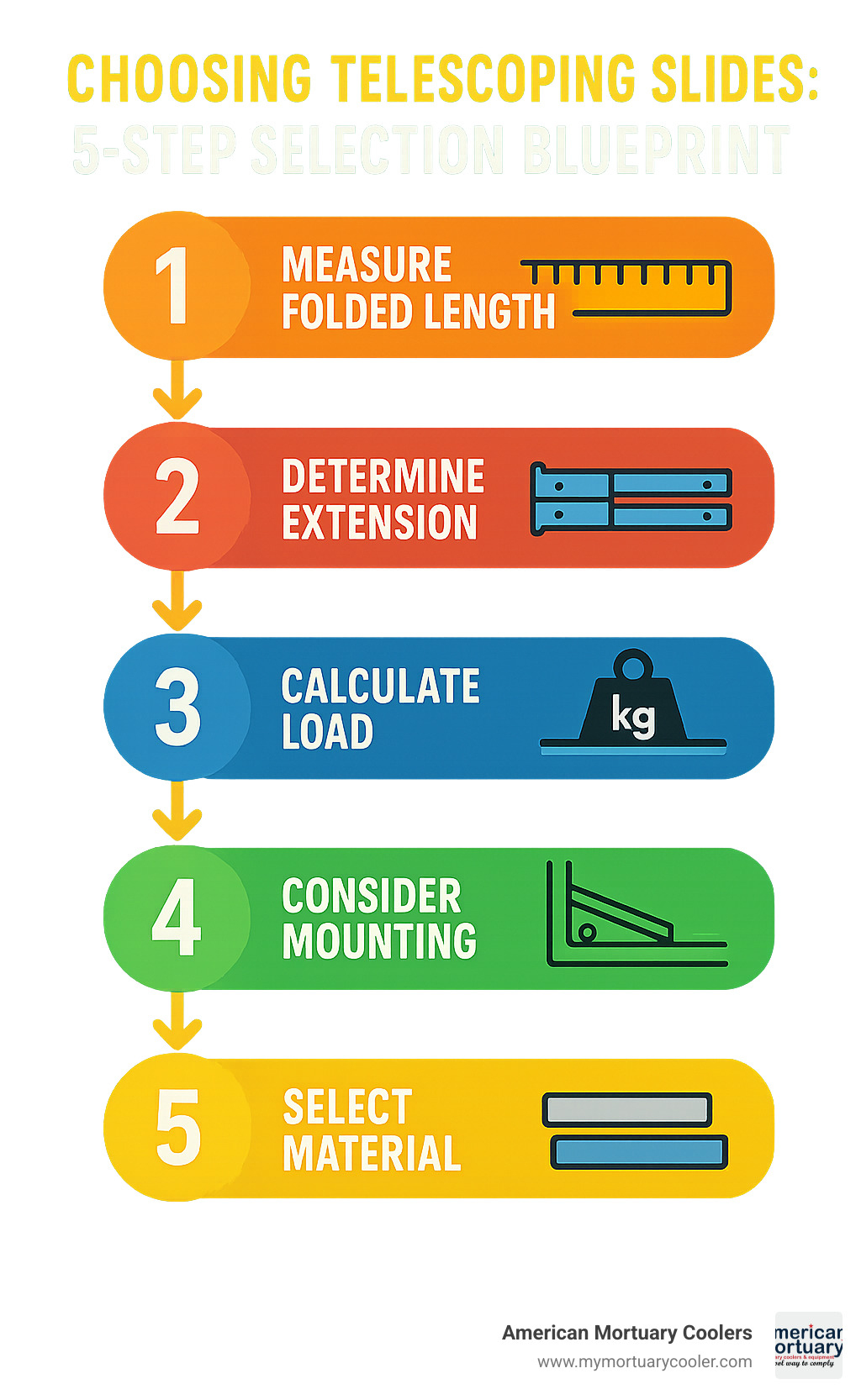

Choosing Telescoping Slides: 5-Step Selection Blueprint

Finding the perfect telescoping slides for your project shouldn't feel like solving a puzzle. I've helped countless customers steer this process, and I've found that following a simple 5-step approach makes all the difference in getting exactly what you need.

Think of this as your roadmap to slide success. As one of my industry colleagues once told me, "It's not easy to find your way around such a wide range of products! That's why we detail these five steps to understand and determine the exact ball bearing slide you need."

Step 1 – Measure the Folded Length

Let's start with the basics – how much space do you actually have? This is your folded length, and it's the foundation of everything that follows.

For drawer applications, measure the interior depth of your cabinet, making sure to subtract any space needed for drawer construction or hardware. In machinery or specialized applications like our mortuary trays, you'll need to identify the maximum available length in the retracted position.

Most standard telescoping slides come in lengths from 150mm to 2000mm, typically in 50mm or 100mm increments. Don't worry if you need something unusual – custom lengths are available for special applications. We've sourced plenty of non-standard sizes for our mortuary coolers when the situation called for it.

This measurement is crucial because it directly determines how far your drawer or tray can extend. As my supplier always reminds me, "The folded length must fit the available space; don't try to force a longer slide into a tight cabinet!"

Step 2 – Decide on Extension Percentage

Now that you know how long your slides need to be when closed, let's figure out how far they need to extend. This is where you'll choose between three main options:

Partial extension (75%) gives you access to about three-quarters of the drawer depth. A 500mm partial-extension slide typically provides around 375mm of travel. These are perfect when you don't need to see all the way to the back, and they generally offer the highest strength-to-size ratio.

Full extension (100%) lets you pull the drawer completely out, giving access to everything inside. A 500mm full-extension slide provides approximately 500mm of travel – essentially allowing the drawer to come all the way out to the cabinet face.

Super-extension (150%) goes beyond the cabinet face, with a 500mm super-extension slide providing approximately 750mm of travel. These are fantastic for situations where you need to access items from multiple angles or need extra workspace.

Each extension type affects both accessibility and load capacity. I've found that as extension percentage increases, the maximum load capacity typically decreases for a given slide size – it's a trade-off worth considering.

Step 3 – Verify Load & Duty Cycle

Getting the load capacity right is absolutely critical – I've seen too many customers underestimate what they need and end up with premature failures.

Start by calculating the maximum weight your slides will need to support. Include both the weight of the drawer or platform itself plus everything that will go inside. Then add at least a 25% safety margin – trust me, it's better to have too much capacity than too little.

Think about how the weight will be distributed. Telescoping slides are typically rated based on centered, uniform loads. If your weight will be concentrated on one side or in one area, you'll need to account for that by choosing higher-capacity slides.

Also consider how often the slides will be used. For something opened occasionally, like holiday decoration storage, standard-duty slides are fine. But for high-traffic applications like a busy mortuary facility, where slides might be operated dozens of times daily, you'll want heavy-duty options with larger bearings and hardened raceways.

Load ratings are almost always specified per pair of slides, and they assume side mounting. As one of my suppliers plainly states, "Load is given per pair of slides, uniformly distributed on the mobile element, and measured on horizontal major-axis mounting."

Step 4 – Match Material to Environment

The environment where your telescoping slides will operate makes all the difference in how long they'll last. This is a step many people overlook, but it's critical for long-term performance.

For standard indoor environments with normal humidity and temperature, cold-rolled steel with zinc plating works perfectly fine. This is what you'll find in most household cabinetry and basic industrial applications.

If you're dealing with high humidity or occasional water exposure, you might want to consider stainless steel or improved coatings on steel slides. In our mortuary coolers, where condensation can sometimes be an issue, we've found that proper material selection dramatically extends service life.

For outdoor or marine environments, don't mess around – go straight for marine-grade stainless steel (316L). It costs more upfront but saves a fortune in replacement costs.

Food processing and medical applications typically require stainless steel with food-grade lubricants. And for weight-sensitive applications, aluminum slides offer significant weight savings while still providing good strength.

I've had customers trying to save money on material choices, but as one of my industry friends wisely puts it, "Aluminium can be a good alternative for high corrosion resistance at a much lower price than stainless steel." Sometimes the middle option is the perfect balance.

Step 5 – Add Functional Options

With the fundamentals decided, now comes the fun part – adding special features that make your telescoping slides work even better for your specific needs.

Locking mechanisms keep slides secure in open or closed positions – essential for safety in mobile applications or when stability in the extended position is crucial. We use these extensively in our mortuary coolers to prevent unexpected movement.

Soft-close dampers prevent slamming and reduce noise – a small feature that makes a big difference in the perception of quality. Similarly, self-closing mechanisms automatically complete the closing action once the drawer is pushed most of the way in.

Disconnect features allow complete removal of the drawer or platform, which can be incredibly handy for cleaning or maintenance. Push-to-open systems enable handleless operation for a cleaner look or when hands might be full.

Many of these options can be added later, but some require factory integration, so it's best to think about them upfront. As one of my suppliers notes, "Beyond standard offerings, slides can be fully customized in length, extension, surface treatment, grease, and quick-install features."

At American Mortuary Coolers, we've refined this 5-step approach through years of practical experience. When you're designing equipment that funeral professionals rely on daily, selecting the right telescoping slides isn't just about functionality – it's about creating trust through reliability and smooth operation.

Latest Innovations & Trends in Telescoping Slides

The world of telescoping slides is constantly evolving, with exciting new developments that make these humble hardware components more capable than ever. Let's explore some game-changing innovations that are changing what's possible in linear motion.

Improved Extension Capabilities

Remember when 150% extension was impressive? Today's cutting-edge slides are pushing boundaries with 200% extension capabilities. These engineering marvels incorporate additional intermediate sections and cleverly designed ball cages that maintain rock-solid stability even when extended to twice their closed length.

As one slide expert recently pointed out, "These telescopic linear guides aren't only for grunt work — they're good for precision stuff as well." This perfectly captures how modern engineering has bridged the gap between extreme extension and precision movement that was once thought impossible.

Compact Four-Point Rails

Traditional telescoping slides relied on simple two-point contact between sections, but that's changing fast. The latest compact four-point rail designs dramatically improve rigidity while keeping profiles slim and unobtrusive. By creating four distinct contact points between sections, these slides significantly reduce wobbling and deflection, even under substantial loads.

According to one manufacturer's documentation: "Telescoping linear guide rails are engineered for industrial applications demanding exceptional rigidity and precision. Featuring a compact design with four-point bearing contact, these telescopic slides provide smooth, reliable performance and optimal load-bearing capacity."

Radial Slides

One of the most exciting breakthroughs has been the development of radial slides, which represent a complete departure from traditional linear designs. These innovative telescoping slides combine linear extension with curved travel paths, enabling complex motion profiles in a single mechanism. This opens up fascinating new possibilities for applications where space is at a premium.

Several manufacturers have been at the forefront of this technology, creating solutions that were previously impossible with standard linear slides.

Sealed Raceways and Contamination Control

Anyone who's dealt with slides in dusty environments knows how quickly performance can deteriorate. Thankfully, advancements in sealing technology have produced telescoping slides that maintain smooth operation even in extremely dirty conditions.

Modern sealed designs incorporate clever features like wipers, labyrinth seals, and specialized lubricants that keep contaminants away from critical bearing surfaces – dramatically extending service life in challenging conditions.

Smart Damping Systems

Remember the days of drawers slamming shut? That's becoming a thing of the past with sophisticated damping systems that adapt to both load and speed. Unlike simple friction dampers, these smart systems provide optimal closing action regardless of drawer weight or closing force. Whether you're gently pushing a heavy drawer or firmly closing a light one, the result is the same – smooth, controlled movement that protects both the contents and the hardware.

Clean-Room Compatible Designs

For industries like semiconductor manufacturing, pharmaceuticals, and medical applications, particle generation is a serious concern. New telescoping slide designs tackle this challenge head-on with specialized materials, non-outgassing lubricants, and manufacturing processes specifically developed for clean environments. These slides feature clever particle-capturing design elements that ensure they meet the stringent requirements of even the most demanding clean room applications.

Eco-Friendly Innovations

At American Mortuary Coolers, we've acceptd eco-friendly innovations in our slide-equipped coolers. Our 4" closed-cell ECO foam insulation combines exceptional thermal efficiency with environmental responsibility. The extruded aluminum telescoping slides with nylon rollers we use provide smooth, reliable operation while minimizing environmental impact.

As our product documentation notes, "The cooler is 100% self-contained with no drainage required. Slide rails are extruded aluminum with nylon rollers for smooth operation." This highlights how we're using modern slide technology to improve overall system performance while keeping sustainability in mind.

The future of telescoping slides looks brighter than ever, with innovations that continue to expand what's possible in linear motion. From extreme extension ratios to smart damping systems, these advancements ensure that whatever your application – from mortuary equipment to industrial machinery – there's a slide solution that perfectly fits your needs.

Installation, Maintenance & Common Mistakes to Avoid

Getting the most from your telescoping slides isn't just about choosing the right ones—it's also about installing and maintaining them properly. Even top-quality slides will let you down if they're not given the care they deserve.

Installation Fundamentals

Perfect alignment is absolutely critical when installing telescoping slides. Even a tiny misalignment of just 1mm can cause your slides to bind, wear unevenly, and fail long before their time. I've seen countless installations where everything looked right at a glance, but the drawer still didn't slide smoothly—and almost always, alignment was the culprit.

The surfaces you mount your slides to matter tremendously. They need to be flat, parallel, and sturdy enough to handle the load without flexing. Mounting slides to a warped cabinet side or a flimsy drawer is asking for trouble. As one technical guide puts it, "Ensure mounting surfaces are flat and parallel when installing paired guides."

Don't overlook your fasteners! They might seem like a small detail, but they're carrying all that weight. Choose screws that are right for both your slides and your mounting material. Those lightweight screws that came in the package might not cut it for your heavy-duty application.

When side-mounting your telescoping slides, the mounting screws experience twisting forces under load. For heavier applications, you might need extra support or reinforced mounting points to prevent the screws from working loose over time.

If you're mounting slides flat (on their minor axis), you'll likely need shims to provide additional clearance. Without this extra space, the slides can bind up as they deflect under load. One manufacturer specifically recommends to "Increase spacing with shims when mounting flat to avoid friction."

Mounting Configurations Explained

Side mounting is the most common way to install telescoping slides—and for good reason. This orientation aligns with the slides' major load axis, giving you the maximum load capacity. Think of it like carrying a board on its edge rather than flat—it's simply stronger that way.

Bottom mounting attaches the slides to the bottom of the drawer and the base of the cabinet. While this configuration can work in tight spaces, it dramatically reduces load capacity—often by 60-80%. I only recommend this approach when you absolutely can't side-mount.

For a cleaner look, under mounting conceals the slides beneath the drawer, hiding them from view. This gives your installation a sleek, professional appearance, but it requires specific slide designs and typically can't handle as much weight as side-mounted slides.

When space constraints force you into flat mounting (with the broad face of the slide horizontal), be prepared for significantly reduced load capacity. This position puts stress on the slides in ways they weren't designed to handle. Always use appropriate load derating and add extra clearance to prevent binding.

In some specialized applications like lift systems, vertical mounting supports up-and-down motion. This unique orientation creates different stresses on your slides, so be sure to select models specifically rated for vertical use.

Routine Care for Long Life

Like any precision component, telescoping slides need regular TLC to perform their best. Most slides benefit from periodic relubrication, especially in high-use situations. Follow the manufacturer's recommendations for both lubricant type and how often to apply it.

At American Mortuary Coolers, we're particularly careful about lubricants in our mortuary equipment. We use specialized food-grade greases that meet the strict sanitary requirements of the funeral industry while still providing smooth, reliable operation.

Set up a regular inspection schedule to catch problems before they become serious. Look for excessive wear in the ball raceways, any deformation of slide components, fasteners that might have worked loose, buildup of dust or debris, and the condition of the lubricant.

Keeping your telescoping slides clean is simpler than you might think. For most applications, a clean, lint-free cloth does the job perfectly. Avoid harsh cleaning chemicals that could damage plastic components or wash away necessary lubrication.

Some high-quality slides allow you to replace worn ball cages or bearing components without replacing the entire slide. This can save you significant money over time, especially in high-value installations where complete replacement would be costly.

Common Mistakes to Avoid

The most frequent mistake I see is underestimating load requirements. Always include a safety margin of at least 25% above your calculated maximum load. That drawer might seem light now, but what happens when someone decides to store their bowling ball collection in it?

Telescoping slides are rated based on centered, evenly distributed loads. When the weight is offset or concentrated in one area (creating what engineers call "moment loads"), your slides' effective capacity drops dramatically. As one expert cautions, "Only partial-stroke versions typically withstand moment loads."

The environment matters more than you might think. Temperature extremes, humidity, corrosive conditions, and contamination can all significantly impact how your slides perform. Choose materials and finishes that suit your specific environment—stainless steel for damp areas, specialized coatings for corrosive environments, and so on.

Mounting slides in orientations they weren't designed for is asking for trouble. I've seen countless cases where perfectly good slides failed prematurely because they were installed flat when they should have been on their sides. Respect the design limitations of your hardware.

Even the finest telescoping slides need regular maintenance. Establish a maintenance schedule that makes sense for your application and stick to it. A little preventive care goes a long way toward extending the life of your slides.

At American Mortuary Coolers, we've learned through years of experience that proper installation and maintenance of telescoping slides is absolutely essential for reliable operation. Our technicians follow careful protocols to ensure optimal performance and longevity in our specialized mortuary equipment. When lives are on the line, we can't afford to cut corners—and neither should you.

Frequently Asked Questions about Telescoping Slides

How do I calculate the right load rating?

Figuring out the right load rating for your telescoping slides doesn't have to be complicated, though it does require a bit of honest assessment about what you'll be sliding in and out.

Start by adding up the total weight - both the drawer or platform itself plus whatever you'll be putting in it at maximum capacity. I always recommend being realistic here. If you're building a tool drawer, don't just weigh your current tools; think about what might get added over time.

Once you have that number, add a safety margin of at least 25%. This isn't just being cautious – it accounts for those times when items might shift to one side or when someone might lean on an extended drawer.

The way you mount your slides makes a huge difference too. Side-mounting gives you the maximum strength the slides were designed for. If you need to mount them flat (with the wide face horizontal), you'll need to multiply your weight calculation by 2.5-3 times because this orientation significantly reduces what the slides can handle.

Load ratings on product descriptions typically refer to a pair of slides with the weight evenly distributed. In our mortuary coolers, we're especially careful about these calculations since reliability is absolutely critical for our customers.

Can I mount telescoping slides flat?

Yes, you can mount telescoping slides flat, but I'd compare it to using a screwdriver as a chisel – it'll work in a pinch, but it's not what the tool was designed for.

When mounted flat (with the wide face horizontal), slides typically lose 60-80% of their load capacity compared to side mounting. This happens because the slides are engineered to handle forces perpendicular to their major axis.

If you absolutely need to mount your slides flat, here's how to make it work:

First, choose slides with much higher load ratings than you think you need. Second, use shims or spacers to provide additional clearance – this prevents binding when the slides inevitably flex under load. Third, make absolutely sure your mounting surfaces are flat and parallel.

One of our technicians likes to say, "Flat-mounted slides are like wearing shoes on the wrong feet – they'll work, but you won't be happy with the results." If possible, look for slides specifically designed for flat mounting, as they'll have design features that compensate for this orientation.

What locking options exist for safety?

When it comes to keeping telescoping slides securely positioned, you've got several helpful options that go beyond just "locked" and "open uped."

Lock-in mechanisms keep your slides securely closed until you want them open. These range from simple friction detents that provide a gentle "hold" to positive mechanical locks that require a deliberate action to release. These are especially important in mobile applications – nobody wants drawers flying open during transport!

On the flip side, lock-out systems hold slides in the extended position, preventing accidental closure. This is particularly important for safety when you're accessing heavy equipment or working with the extended drawer. Some lock automatically at full extension, while others require manually engaging a lever or latch.

Some of our customers really appreciate slides with intermediate position locks that can secure the drawer at multiple points throughout its travel. This provides flexibility for specific work requirements.

While not strictly locking mechanisms, many modern slides include integrated damping systems that prevent drawers from slamming shut, controlling the closing speed and adding an element of safety.

In our mortuary coolers, we're particularly careful about selecting the right locking features. The last thing a funeral director needs is a tray that won't stay extended when needed or one that closes unexpectedly. The right locking mechanism ensures safe, dignified access while maintaining the critical environmental conditions inside the cooler.

Conclusion

Choosing the right telescoping slides isn't just about picking hardware—it's about ensuring the success of your entire project. Throughout this guide, we've walked through the essential knowledge you need to make informed decisions that will directly impact how well your sliding systems perform day after day, year after year.

At American Mortuary Coolers, we've taken these principles to heart. Our specialized cooling systems represent the perfect marriage between smooth, reliable access and the precise temperature control that funeral homes and mortuaries demand. When we developed our 4-body and 8-body telescoping slide rail coolers, we didn't just grab whatever slides were available—we carefully selected extruded aluminum slides with nylon rollers because we know this combination delivers exceptional durability and buttery-smooth operation in the demanding environment our customers work in.

"Telescoping slide rails are extruded aluminum with nylon rollers for smooth operation," you'll see in our product documentation. This isn't just technical jargon—it reflects our deep understanding that the right materials make all the difference between equipment that works and equipment that works brilliantly.

We've been in your shoes, facing the challenge of selecting components that need to perform flawlessly for years. That's why we've distilled the selection process into our 5-step blueprint: measure your space, determine your extension needs, verify your load requirements, match materials to your environment, and add the functional options that make your life easier. This systematic approach takes the guesswork out of the process, giving you confidence in your decisions.

Our commitment to quality doesn't stop at our Tennessee workshop doors. We proudly deliver our expertise nationwide across the contiguous 48 states. With locations in Johnson City TN, Atlanta GA, Chicago IL, Columbia SC, Dallas TX, Los Angeles, New York NY, Pittsburgh PA, and comprehensive regional coverage of the Midwest, Northeast, Rocky Mountain, Southeast, Southwest, and Pacific regions, we ensure that our knowledge of telescoping slides and mortuary equipment reaches you wherever you are.

Whether you're outfitting a custom mortuary cooler, industrial equipment, or specialized cabinetry, the fundamentals remain unchanged: match your slides to your specific needs, install them with care, and maintain them regularly. Follow these principles, and your sliding systems will reward you with years of trouble-free service.

For more information about our custom mortuary coolers and how we leverage telescoping slide technology to create exceptional mortuary equipment, visit our website or reach out to our team. We're real people who understand your challenges, and we're here to help you find solutions that truly work for your specific situation.