The Precision Behind Mortuary Excellence

Starrett bone saws are premium cutting tools manufactured by The L.S. Starrett Company, known for exceptional precision, durability, and specialized designs for various bone-cutting applications. For funeral directors and mortuary professionals seeking reliable equipment, here's what you need to know:

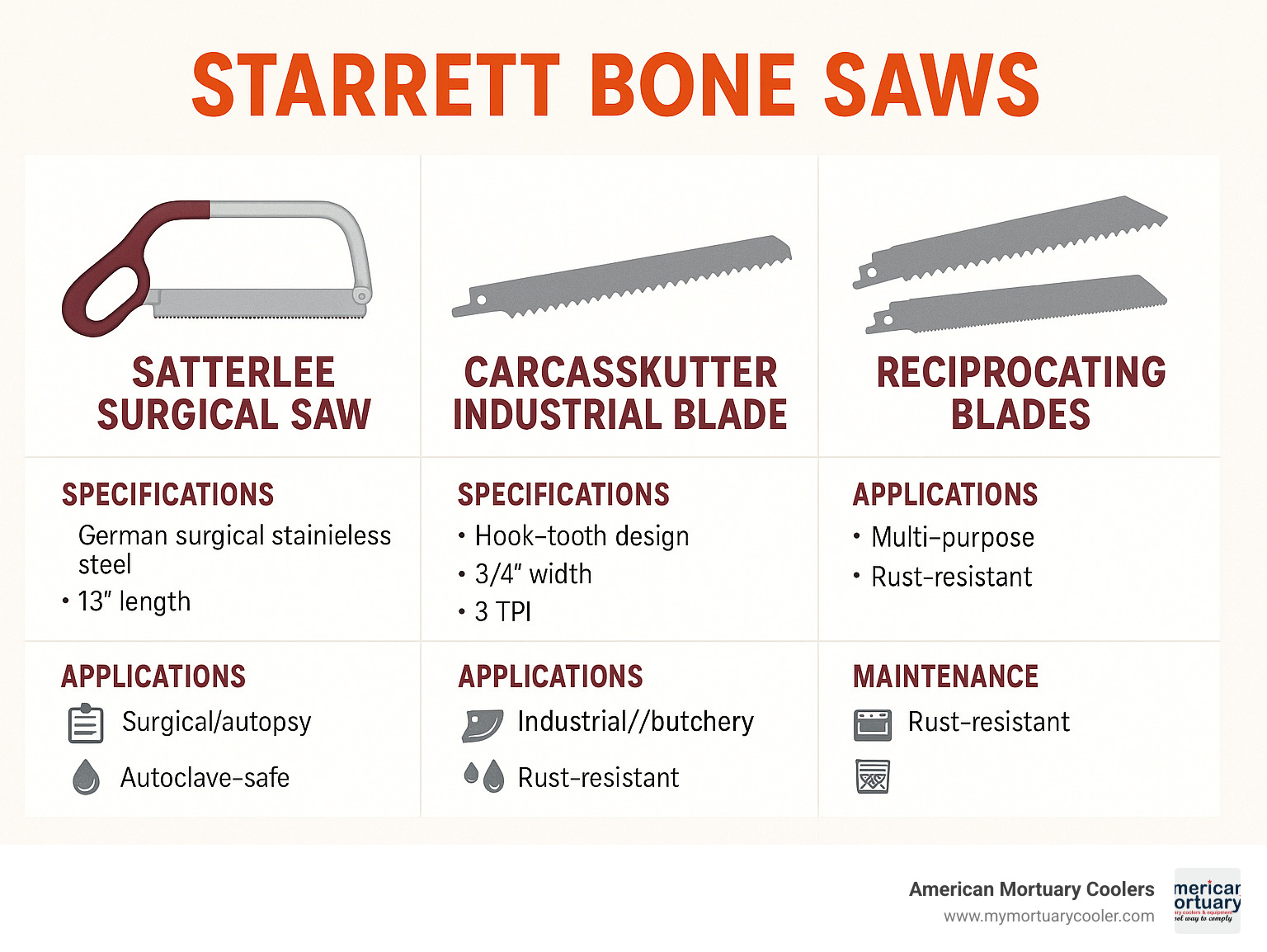

| Starrett Bone Saw Type | Best For | Key Features | Price Range |

|---|---|---|---|

| Satterlee Bone Saw | Surgical/Autopsy | German surgical stainless steel, 13" length | $110-280 |

| Carcasskutter™ Band Saw Blades | Industrial/Butchery | Hook-tooth design, 3/4" width, 3 TPI | Varies by length |

| Stainless Reciprocating Blades | Multi-purpose | Dishwasher safe, rust-resistant | $30-75 |

Founded in 1880 in Athol, Massachusetts, The L.S. Starrett Company has built a reputation for manufacturing precision tools that stand the test of time. Their bone saws represent over 140 years of American craftsmanship, with the company's first patent for a meat cutter dating back to 1865.

What sets Starrett bone saws apart from competitors like Biro Manufacturing, Butcher Boy, and Hobart is their specialized metallurgy. The surgical models feature high-carbon, low-chromium German stainless steel for superior corrosion resistance, while their industrial models use bi-metal construction optimized for durability and cutting performance.

For mortuary professionals, the right bone saw is essential for respectful and efficient preparation procedures. Starrett bone saws offer:

- Precision cutting with minimal drift

- Rust-resistance for hygienic applications

- Ergonomic designs to reduce fatigue

- Autoclave-safe materials for proper sterilization

I'm Mortuary Cooler, a national-level supplier of mortuary equipment with extensive experience recommending and providing Starrett bone saws to funeral homes across America. My expertise helps funeral directors select the right cutting tools that complement their cooler systems for complete mortuary operations.

Legacy of Precision: How L.S. Starrett Shaped Modern Bone Saws

Laroy S. Starrett was a Newburyport, Massachusetts farmer who, in 1865, patented a simple meat cutterha move that sparked what is now The L.S. Starrett Company2 an icon of American toolmaking. By 1880 he had opened a factory in Athol, MA, insisting that no product leave his floor unless it met his personal standard for excellence. That culture of precision still drives Starrett2 only now it happens on a global scale.

While Starrett2 headquarters remain in Athol, all saw production is centralized in the company2 500,0002plus1square1foot plant in Porto Alegre, Brazil2 the world2s largest dedicated saw facility. Concentrating output there guarantees uniform quality and year1round availability for mortuaries that can2t afford downtime.

What began as food1processing tools naturally evolved into surgical and mortuary saws2 the same accuracy that butchers needed turned out to be exactly what pathologists and funeral directors required.

Key Milestones in Starrett Saw Innovation

- 18772 Combination Square invented, proving precision was in the company2 DNA

- 1956 & 19582 First overseas factories (Brazil, then Scotland) standardize global production

- 20152 Launch of Carcasskutter2 hook1tooth band saw blades, now a mortuary favorite

- 20202 Creation of a single "super1plant" for all Starrett blades streamlines QC

- Ongoing2 Refinement of the German1steel Satterlee surgical saw for autopsy work

For a deeper dive into Starrett2 history, see the excellent Starrett, L.S. Company archive.

Today, whether you2re comparing Starrett to Biro, Butcher Boy, Hobart, Weston, or Mophorn, the company2s 1401year heritage of uncompromising accuracy remains its greatest competitive edge.

Choosing the Right Starrett Bone Saws for Your Application

When it comes to selecting the perfect Starrett bone saw for your funeral home or mortuary, understanding your specific needs is essential. Every cutting task has its own requirements, and Starrett's range of options ensures you'll find the right tool for your particular situation.

Types of Starrett Bone Saws You Can Buy

The world of Starrett bone saws offers more variety than most people realize. For mortuary professionals, this diversity means you can find tools perfectly matched to your specific procedures.

Band saw blades form the backbone of Starrett's industrial cutting solutions. The Carcasskutter™ line stands out as their premier offering for bone-cutting applications. These continuous loop blades come in lengths up to 11 feet 1 inch, making them ideal for larger operations. With their 3/4-inch width and specialized 3 teeth per inch design, they make quick work of challenging cutting tasks.

The MeatKutter series, introduced in 2015, offers another excellent option for bone-cutting applications. While initially designed for meat processing, many mortuary professionals have found these blades perform admirably in their work as well.

For more versatile applications, Starrett's reciprocating saw blades deserve serious consideration. Their stainless steel options are particularly popular in mortuary settings because they're dishwasher safe and highly resistant to rust. Starrett also produces specialty autopsy blades, though they're less prominently advertised.

When precision matters most, nothing beats Starrett's hand bone saws. The Satterlee Bone Saw is a favorite among mortuary professionals, with its 13-inch overall length providing excellent control.

Materials & Geometry That Matter in Starrett Bone Saws

The exceptional performance of Starrett bone saws isn't just about the brand name—it's about thoughtful material selection and intelligent design geometry.

On the materials front, Starrett doesn't cut corners. Their industrial blades typically feature high-carbon steel, delivering excellent hardness and wear resistance. For surgical models like the Satterlee, they upgrade to German surgical stainless steel, which contains higher carbon and lower chromium than standard stainless.

Many Starrett blades use bi-metal construction, essentially giving you two metals in one blade. This clever approach optimizes both flexibility and cutting edge durability, extending the life of your investment.

The geometry of these saws is equally impressive. The Carcasskutter™ features a specialized hook-tooth design with just 3 teeth per inch, allowing it to efficiently pierce and slice through bone and frozen tissue with minimal effort.

Key Features & Benefits of Starrett Bone Saws vs Competitors

When we compare Starrett bone saws with competing products from companies like Biro, Butcher Boy, and Hobart, several advantages become apparent.

Starrett bone saws deliver superior precision thanks to their exceptional tooth-setting accuracy, which minimizes drift during cutting. This allows for more controlled, precise work—particularly important in mortuary settings where respect and care are paramount.

Durability is another area where Starrett bone saws shine brightly. Their bi-metal construction provides significantly longer life than single-material competitors, reducing your replacement costs over time. The German surgical stainless steel used in Satterlee models offers what many professionals describe as an "unrivaled level of strength and robustness" compared to standard stainless steel saws.

In mortuary environments, hygiene considerations are non-negotiable. Starrett's dishwasher-safe stainless reciprocating blades make cleaning and sanitization straightforward. The high-carbon, low-chromium composition of their surgical models resists corrosion better than standard stainless steel, maintaining both appearance and functionality through countless cleaning cycles.

While competing brands like Weston and Mophorn offer lower-priced alternatives, Starrett bone saws provide better value over time through their exceptional longevity and performance. At American Mortuary Coolers, we recommend Starrett bone saws because they align with our own philosophy—providing durable, high-quality equipment that performs reliably day after day.

Performance, Safety & Hygiene: What Sets Starrett Bone Saws Apart

In a mortuary, tools must work flawlessly, stay sanitary, and protect staff from injury. Starrett engineers for exactly that. The Carcasskutter2 hook1tooth profile chews through frozen tissue with less force, while oscillating reciprocating blades reduce "grab" that can lead to slips. German1steel Satterlee hand saws give surgeons fingertip control during delicate cuts.

Comparing Band, Reciprocating & Hand Starrett Bone Saws

| Feature | Band Saw Blades (Carcasskutter2) | Reciprocating Saw Blades | Hand Bone Saws (Satterlee) |

|---|---|---|---|

| Cut Capacity | Several inches, machine1dependent | 12 in. typical | Up to 1 in., very precise |

| Teeth Per Inch | 3 TPI | 618 TPI | Fine1tooth |

| Typical Length | To 11 ft 1 in | 612 in | 13 in overall |

| Primary Users | High1volume facilities | General mortuary work | Autopsy precision |

| Pros | Fast, consistent | Portable, versatile | Silent, no power needed |

| Cons | Needs band saw | Needs power source | Slower, manual |

Built1In Safety & Hygiene

- Welded blade joints rival base metal strength, reducing break risk.

- Low1friction coatings cut heat and operator fatigue.

- Dishwasher1safe stainless or autoclave1ready German steel simplifies sterilization.

These design choices mean fewer blade changes, faster procedures, and compliance with OSHA and FDA sanitation guidelines2 advantages that often outweigh the lower sticker price of alternatives from Weston, Mophorn, or other brands.

Maintenance, Cleaning & Authenticity Guide

Proper maintenance of Starrett bone saws ensures their longevity and optimal performance. A well-maintained saw not only cuts more efficiently but also maintains the hygiene standards necessary in mortuary environments.

Maintaining Starrett Bone Saws for Long Life

Taking care of your Starrett bone saws isn't complicated, but it does require attention to detail. Before each use, examine your blades for any signs of wear, chipping, or corrosion. These small inspections can prevent bigger problems down the road.

If you're using Carcasskutter™ band saw models, checking the blade tension is crucial. Proper tension not only extends the life of your blade but also ensures those precise cuts that mortuary work demands.

For band saw blades, a little food-grade lubricant goes a long way. Just a light application to the guide surfaces reduces friction and heat, which are the enemies of blade longevity. If you're using hand bone saws like the Satterlee, the occasional drop of medical-grade oil at pivot points keeps everything moving smoothly.

With proper care, band saw blades typically handle 600-800 uses per side before needing replacement. Hand saws like the Satterlee can be faithful companions for years, though they may need professional sharpening to maintain their edge.

When it comes to storage, treat your Starrett bone saws like the precision instruments they are. Store them in dry environments to prevent corrosion. Hand saws should rest flat or hang properly to prevent warping, while band saw blades should be coiled and kept in their original packaging when not in use.

Cleaning Protocols for Food & Medical Environments

Cleaning your Starrett bone saws properly is essential, especially in mortuary settings where hygiene is paramount. For dishwasher-safe models, start by thoroughly rinsing away tissue and debris. Place the blade in a commercial dishwasher, securing smaller blades in a utensil basket to prevent movement. Use a high-temperature wash cycle with appropriate detergent.

Here's the step many people miss: dry the blade completely and immediately after washing. Even stainless steel can develop oxidation if left wet for extended periods.

For surgical models that can handle autoclave sterilization, begin by removing all organic material. Wrap or package the saw according to standard autoclave protocols, then process at 270°F (132°C) for at least 4 minutes.

Sometimes manual cleaning is necessary or preferred. Use warm water and mild detergent with a soft brush for stubborn residue—never wire brushes, which can scratch and damage the blade surface. After thorough rinsing, sanitize with an appropriate medical-grade disinfectant and dry completely with clean, lint-free cloths.

When using chemical sanitizers, concentration matters. For quaternary ammonium compounds, aim for 200-400 ppm to effectively sanitize your Starrett bone saw blades without causing corrosion.

How to Spot & Verify Genuine Starrett Blades

With Starrett bone saws' stellar reputation, it's no surprise that counterfeits have emerged. Protecting your investment (and ensuring safety) starts with knowing what authentic Starrett products look like.

Genuine Starrett products arrive in branded packaging with clear, high-quality printing. Look for the distinctive Starrett logo and "The L.S. Starrett Company" marking. Authentic packages include a product code that you can verify on the Starrett website through their Product Details page.

The products themselves tell a story too. Authentic Starrett bone saws feature clear, permanent markings including the Starrett name and model number. Most Starrett tools proudly display the "S-Circle" logo, while hand tools like the Satterlee bone saw should have "The L.S. Starrett Co." clearly marked.

Where you purchase matters tremendously. Buy only from authorized Starrett distributors, which you can find using the company's distributor lookup tool. If shopping online, verify the seller's authorization status before clicking "buy." Be suspicious of significantly discounted prices—if it seems too good to be true, it probably is.

Unlike some competitors who outsource production to multiple facilities, Starrett's centralized manufacturing helps maintain consistent quality. This makes authentic Starrett products easier to identify through their uniform finishing with no rough edges, precisely applied markings, and materials with a uniform appearance.

Buying, Customization & Support Options

Finding and purchasing the right Starrett bone saws for your mortuary needs shouldn't be complicated. Whether you're looking to replace a worn blade or equip your entire preparation room, there are several convenient options available.

Where to Purchase Starrett Bone Saws & Blades Online

When it's time to buy Starrett bone saws, you'll want to ensure you're getting authentic products from reliable sources. Starrett's comprehensive "Find-a-Distributor" tool on their website makes it easy to locate authorized sellers near you. These trusted partners not only provide genuine products but often offer valuable advice about which saw best suits your specific applications.

Since 2022, Starrett has maintained an official Amazon Brand Page, creating a convenient shopping experience with the assurance of product authenticity. This is particularly helpful for smaller funeral homes that may not have established relationships with industrial suppliers.

For those who prefer traditional industrial suppliers, companies like MSC, Grainger, and McMaster-Carr carry extensive selections of Starrett bone saws and related products. These vendors typically offer next-day shipping and volume discounts for larger orders.

One of the most valuable services Starrett offers is custom-length cutting for their band saw blades. If your existing equipment requires a specific blade length, authorized distributors can provide precisely cut blades to match your needs. This customization ensures optimal performance and extends the life of your equipment.

Here at American Mortuary Coolers, we understand that Starrett bone saws are an essential component of a well-equipped preparation room. That's why we often include these premium tools in our complete mortuary setup packages alongside our custom cooling solutions.

Resources & Training for Users

Getting the most from your Starrett bone saws means understanding how to use and maintain them properly. Starrett provides comprehensive PDF catalogs detailing specifications for all their bone saw products, making it easy to identify the right replacement parts when needed.

Their website features detailed technical data sheets that outline materials, dimensions, and optimal applications for each saw type. These resources are invaluable when training new staff or troubleshooting issues with existing equipment.

For visual learners, Starrett's YouTube channel offers video tutorials demonstrating proper use and maintenance techniques. These clear, step-by-step guides cover everything from blade installation to proper tensioning for band saw applications.

When questions arise that aren't covered in their documentation, Starrett maintains a responsive technical hotline for product questions and troubleshooting. Their newer DataSure 4.0 wireless platform even enables remote monitoring for some powered equipment.

Most Starrett bone saws include manufacturer warranties against defects, though terms vary by product type. We always recommend registering your products promptly to ensure warranty validation should issues arise.

While competitors like Biro Manufacturing and Hobart offer their own training resources, many professionals find Starrett's materials more comprehensive and user-friendly. At American Mortuary Coolers, we complement these resources with our own practical expertise in mortuary operations, helping funeral directors integrate Starrett bone saws into their overall preparation room workflow.

Frequently Asked Questions about Starrett Bone Saws

What applications are Starrett bone saws best suited for?

When funeral directors ask me about Starrett bone saws, I always emphasize that different models shine in different settings.

The Satterlee Bone Saws are the precision instruments of the mortuary world. With their German surgical stainless steel construction, they give you incredible control during detailed autopsy procedures. The craftsmanship really shows when you need to make those careful, dignified cuts.

For larger operations, the Carcasskutter™ Band Saw Blades are workhorses. Their hook-tooth design makes quick work of challenging situations, including bone-in tissue and even frozen specimens. One medical examiner I work with switched to these from a competing Biro model and immediately noticed cleaner, more efficient cutting with less physical strain.

The Stainless Reciprocating Blades are what I call the "Swiss Army knife" of mortuary tools. They're perfect when you need versatility and portability. Many of our smaller funeral home clients appreciate that they're dishwasher-safe, which simplifies their cleaning protocols when specialized sterilization equipment isn't available.

What ties all these Starrett bone saws together is their precision engineering. In our line of work, where respect for the deceased is paramount, these tools help ensure preparation procedures are performed with appropriate dignity and care.

How often should I replace a Starrett bone saw blade?

This is one of the most common questions I hear from funeral directors, and the answer really depends on which Starrett bone saw you're using and how busy your facility is.

For the Carcasskutter™ and other band saw blades, you'll typically get 600-800 uses per side before replacement becomes necessary. You'll know it's time when cuts start wandering or when you notice yourself applying more pressure than usual. The teeth will also show visible wear when examined closely.

With reciprocating saw blades, replacement is more about feel and performance. In busier facilities where these tools see daily use, monthly replacement might be necessary. Smaller operations might stretch that to quarterly.

Hand bone saws like the Satterlee are built to last for years. Rather than replacement, these quality tools often just need professional sharpening when they begin to lose their edge. I have customers who've been using the same Satterlee for a decade, with occasional maintenance.

Compared to competitors like Weston and Mophorn, Starrett bone saws typically require less frequent replacement, which offsets their higher initial cost.

Are Starrett bone saws compliant with food & medical regulations?

Yes, and this is why so many professionals trust them. Starrett bone saws meet regulatory standards that matter in our industry.

Their surgical models feature high-carbon, low-chromium stainless steel compositions that achieve two critical goals: they resist corrosion (essential for hygiene) while maintaining the strength needed for bone cutting. This specialized metallurgy meets the materials standards for medical devices.

What's interesting is that many of the same properties that make these tools suitable for food processing also make them ideal for mortuary work. The stainless steel blades meet FDA guidelines for food-contact surfaces, which translates well to our field's hygiene requirements.

I particularly appreciate the dishwasher-safe properties of their stainless reciprocating blades. This feature makes compliance with sanitization protocols straightforward for funeral homes of all sizes. For facilities with autoclaves, many Starrett models are compatible with standard sterilization cycles.

While competitors like Butcher Boy and Hobart also meet basic regulatory requirements, Starrett bone saws often exceed minimum standards, providing an extra margin of safety and compliance that many mortuary professionals value.

Conclusion

As we've journeyed through precision cutting tools, it's clear why Starrett bone saws have earned their reputation as the gold standard for mortuary professionals. From the surgical precision of the Satterlee model to the powerful efficiency of the Carcasskutter™ band saw blades, these tools represent more than just cutting equipment—they embody a 140-year legacy of American craftsmanship.

At American Mortuary Coolers, we believe that quality preparation tools deserve to stand alongside reliable refrigeration systems. That's why we often find ourselves recommending Starrett bone saws to complement our custom mortuary coolers. Both share a commitment to excellence that honors the dignity of the deceased while supporting the important work of funeral professionals.

While competitors like Biro, Butcher Boy, Hobart, Weston, and Mophorn offer alternatives at various price points, Starrett bone saws consistently deliver superior performance and longevity that justify their investment. Their precision, durability, and hygienic design make them particularly well-suited to the demanding environment of mortuary preparation rooms.

What began with Laroy Starrett's innovative spirit in 1865 continues today in tools that blend traditional quality with modern engineering. The precision that made Starrett's first measuring tools famous now extends to their bone saws, offering funeral directors the reliability they need when performing their most sensitive tasks.

I've seen how the right equipment makes all the difference in a preparation room. A Starrett bone saw isn't just a tool—it's peace of mind knowing that you have equipment that won't let you down when families are counting on you to create a meaningful final goodbye.

For those considering an upgrade to their preparation room, think about how Starrett bone saws might integrate with your existing workflow. When you're ready to discuss complete mortuary solutions—from coolers to cutting tools—our team at American Mortuary Coolers is here to help with honest, practical advice based on real-world experience.

Based in Tennessee but proudly serving funeral homes across the lower 48 states, we specialize in durable, custom solutions with direct delivery to your door. Our expertise goes beyond just refrigeration—we understand the complete ecosystem of mortuary equipment and can help you select the right tools for your specific needs.

For more information about our full range of mortuary equipment and services, please explore our refrigeration solutions or reach out directly. We're always happy to share our experience and help you find the perfect balance of quality, functionality, and value for your funeral home.