The Essential Guide to Walk-In Cooler Doors

When it comes to preserving your perishable inventory, the humble walk in cooler door is your first line of defense. It's not just a barrier—it's the guardian of temperature control, energy efficiency, and ultimately, your bottom line.

Think of your walk in cooler door as the gatekeeper between two worlds: the precisely controlled environment you've created inside and the unpredictable temperatures outside. Every time that door opens and closes, you're either maintaining that delicate balance or disrupting it.

Walk-In Cooler Door Guide:

| Feature | Details |

|---|---|

| Common Types | Swinging, Sliding, Vertical-lift, Glass display |

| Standard Sizes | 34"×78", 36"×80", up to 60"×94" |

| Key Components | Gaskets, Hinges, Insulation (R-32 recommended), Latches |

| Lifespan | 15-20 years with proper maintenance |

| Energy Features | Magnetic seals, Anti-fog technology, Low-E glass |

Whether you're running a busy restaurant kitchen, a neighborhood floral shop, or a dignified funeral home, the right door makes all the difference. I've seen businesses save thousands in energy costs simply by upgrading to a properly fitted door with quality seals and insulation.

The best walk in cooler door does more than just swing open and closed. It creates a perfect seal when latched, prevents condensation from forming, and stands up to constant use in demanding environments. For specialized settings like mortuaries, where temperature stability is non-negotiable, selecting the right door becomes even more critical.

We at American Mortuary Coolers understand these challenges intimately. After years of helping funeral homes across the country, we've developed deep expertise in matching the right door to each unique cold storage need. From standard coolers to custom solutions, we've seen how the right door transforms operational efficiency.

Ready to explore your options further? We've compiled some helpful resources to deepen your understanding:

In the sections that follow, we'll dive deeper into walk in cooler doors—exploring everything from component construction to energy-saving innovations. Whether you're building new or replacing an aging door, we're here to help you make the most informed decision possible.

What Is a Walk-In Cooler Door & Why Does It Matter?

A walk in cooler door is much more than just an entry point—it's a sophisticated component engineered to maintain the critical thermal barrier between your controlled cold environment and the outside world. For businesses across industries—from restaurants and grocery stores to mortuaries and pharmaceutical facilities—these specialized doors serve as the gatekeepers of temperature integrity.

"The door is the most frequently used and abused component of any walk-in cooler system," explains our lead technician at American Mortuary Coolers. "It's opened and closed countless times daily, subjected to impacts, spills, and temperature fluctuations that test its durability and sealing capabilities."

In mortuary applications, the stakes are particularly high. A properly functioning walk in cooler door ensures dignified preservation while maintaining compliance with health regulations. The door must seal completely to prevent temperature fluctuations that could compromise the integrity of the remains in your care.

Beyond basic access, a quality walk in cooler door serves several critical functions. It maintains temperature by preventing cold air from escaping and warm air from entering. It boosts energy efficiency by reducing compressor runtime and lowering those monthly utility bills. It controls condensation, preventing moisture buildup that can lead to mold and dangerous slip hazards. For food service operations, it maintains the consistent temperatures required for safe food storage. And for all businesses, it allows quick, reliable access for staff while maintaining the cold environment.

Core Components of a Walk-In Cooler Door

Understanding what makes up a walk in cooler door helps you make smarter decisions about selection and maintenance. Heavy-duty, spring-loaded hinges ensure the door closes automatically and can withstand thousands of openings. Most quality doors feature three hinges with cam-lift design to create that tight seal when closed.

The positive-closing latch mechanism keeps the door securely shut. Modern latches include inside safety releases to prevent accidental entrapment—because no one wants to spend the night in the cooler! Many also include provisions for padlocks when security is a concern.

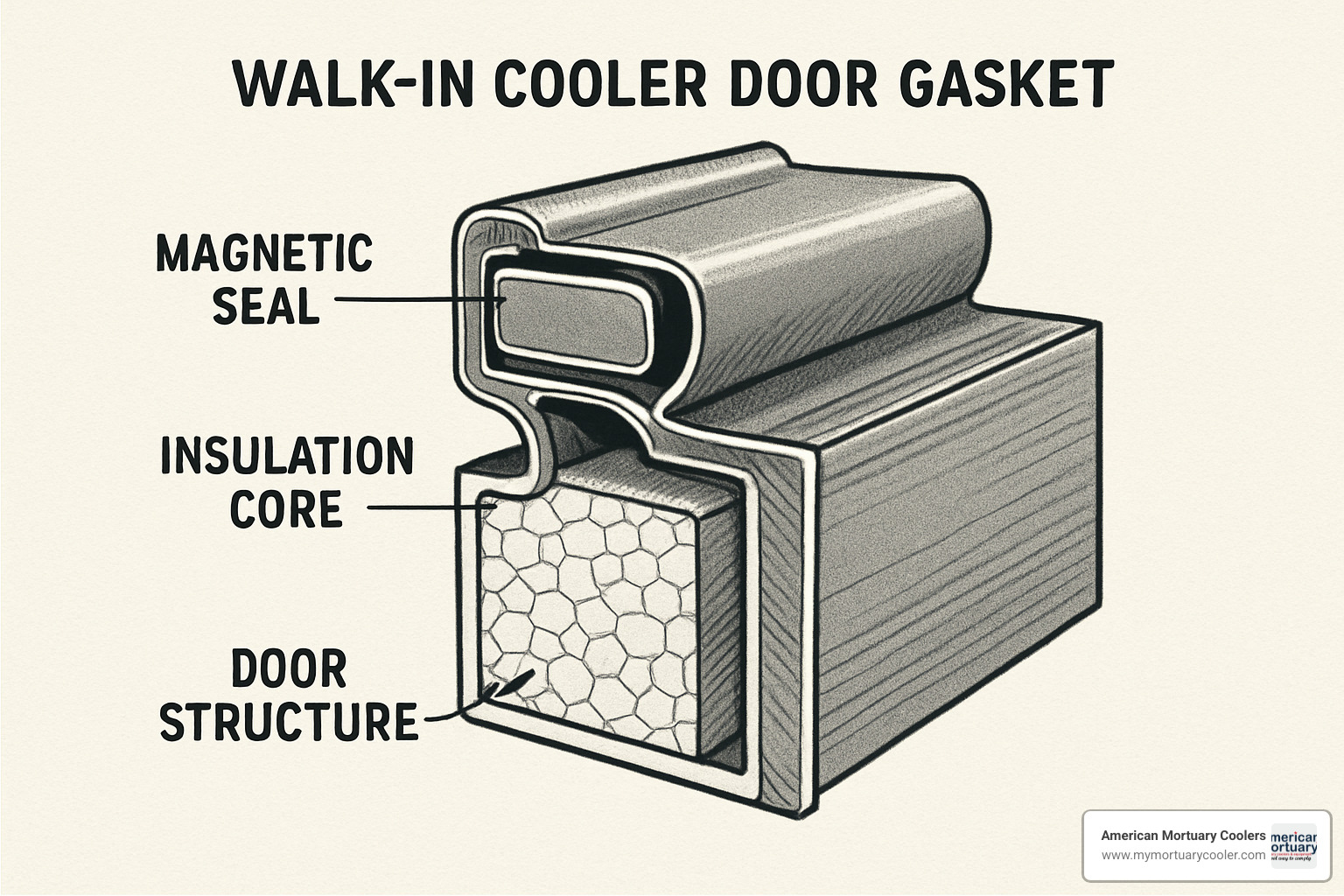

Perhaps the most critical component is the magnetic gasket—your primary defense against air infiltration. These flexible seals run along the perimeter of the door and create an airtight connection with the frame. Quality gaskets use magnetic material embedded in flexible vinyl for a consistent seal that maintains its grip year after year.

At the core of the door, you'll find foamed-in-place polyurethane insulation with an R-value of 25-32. This dense foam prevents heat transfer and supports the door's structural integrity. The door sweep at the bottom provides a flexible barrier that prevents air from escaping underneath—a common point of energy loss that's often overlooked.

Finally, hydraulic or spring-loaded closers ensure the door automatically returns to the closed position, preventing it from being accidentally left open after that midnight snack run.

As one customer from a Pittsburgh funeral home told us, "We never realized how much energy we were losing through our old door until we upgraded to a new one with proper gaskets and closers. The difference in our cooler's performance was immediate."

How a Walk-In Cooler Door Controls Energy & Temperature

The energy efficiency of your walk-in cooler system depends significantly on the quality and condition of your walk in cooler door. A well-designed door creates multiple barriers against heat transfer, working hard to keep your cooling costs down.

The industry standard for walk-in cooler doors is a minimum R-value of 25 for coolers and 32 for freezers. At American Mortuary Coolers, our doors exceed these standards with R-32 polyurethane foam that's foamed-in-place to eliminate air gaps and provide consistent insulation throughout the door panel. This isn't just about meeting standards—it's about creating a door that performs better and lasts longer.

The magnetic seal technology creates a continuous seal around the door perimeter. This clever design allows for a perfect fit even as the door frame and gasket age or experience slight warping. It's like having a door that adapts to changes over time, maintaining its seal integrity year after year.

Every time a walk in cooler door opens, cold air escapes and warm air enters. This air exchange forces your refrigeration system to work harder—like running your home air conditioner with the windows open. Quality doors with proper closers minimize the time the door remains open, while vinyl strip curtains can provide a secondary barrier during high-traffic periods.

The financial impact of an inefficient door is substantial. According to energy studies, air infiltration through poorly sealed doors can account for up to 30% of a walk-in cooler's energy consumption. By investing in a high-quality walk in cooler door with proper insulation and sealing, businesses can see a return on investment through reduced utility costs within just a few years.

This isn't just good for your bottom line—it's good for sustainability too. Energy-efficient doors reduce your carbon footprint and support environmentally responsible business practices. It's a win-win for your business and the planet.

The Main Types of Walk-In Cooler Doors

When it comes to selecting a walk in cooler door, you'll find several options that each serve different needs. Your choice should reflect your daily operations, available space, and budget considerations. Let's explore these options so you can make the best decision for your facility.

Swinging vs. Sliding vs. Vertical-Lift

The classic swinging door remains the most popular choice for many businesses, and for good reason. These doors provide an excellent seal at a reasonable price point, making them ideal for standard-sized coolers in funeral homes, restaurants, and smaller facilities. One of our Tennessee clients recently told us, "We've had our swinging doors for nearly a decade with minimal maintenance—just a gasket replacement after year seven."

However, if floor space is at a premium, sliding doors might be your best bet. They glide smoothly along a track system, eliminating the need for swing clearance. This makes them perfect for narrow hallways or areas where a swinging door might create an obstacle. They're particularly helpful when staff need to maneuver carts or equipment through the doorway.

"The sliding door has transformed our workflow," shared a mortuary director from Atlanta who recently upgraded their facility. "Now we can move remains in and out of the cooler with dignity and efficiency, without worrying about door clearance issues."

For industrial settings or warehouses, vertical-lift doors offer a unique solution. These doors move upward rather than outward, preserving valuable floor space while accommodating wide openings. They're especially useful for facilities that use forklifts or need extra-wide access. While they typically cost more upfront, the operational benefits often justify the investment for high-volume operations.

Glass Display & Beer-Cave Doors

For retail environments where product visibility drives sales, glass display doors strike the perfect balance between temperature control and merchandising appeal. These specialized doors feature insulated glass panels that maintain your cooler's internal temperature while showcasing what's inside.

Modern glass display doors incorporate impressive technology, including Low-E glass that reflects heat while permitting visible light to pass through. Most models also feature anti-fog heaters that prevent condensation without significantly impacting energy consumption. We've seen convenience stores boost beverage sales by up to 15% simply by upgrading to high-visibility display doors.

Beer cave doors take this concept further with larger viewing areas and heavy-duty hardware designed to withstand constant use. These doors create an inviting entrance to beverage sections while maintaining proper cooling temperatures.

It's worth noting that all commercial glass display doors must comply with Department of Energy (DOE) regulations established under the Energy Independence and Security Act of 2007. These standards ensure energy efficiency through advanced features like pre-wired control systems and insulated frames. For the most current compliance information, you can check the DOE compliance database.

Vinyl strip curtains often serve as helpful secondary barriers behind any of these door types. They provide an additional layer of temperature control during busy periods when the main door might be opened frequently. While not a replacement for a proper walk in cooler door, these curtains can significantly reduce air exchange and energy costs.

At American Mortuary Coolers, we help funeral homes across the country select the right door configuration for their specific needs, whether that's a traditional swinging door for a standard mortuary cooler or a custom solution for unique facility requirements. The right door not only preserves temperature but also improves the dignity and efficiency of your operations.

Walk In Cooler Door Selection Guide

Choosing the perfect walk in cooler door is a bit like finding the right partner—it needs to match your specific needs, stand the test of time, and not break your budget! Let's explore the materials, insulation options, and features that will help you make a smart choice for your cold storage needs.

Materials Matter

When we talk with clients about door materials, we focus on matching their environment with the right surface. Each material has its own personality and strengths:

Stainless Steel doors shine in environments where cleanliness is paramount. In our mortuary installations, we often recommend stainless for its sleek appearance and incredible resistance to corrosion. It might cost a bit more upfront, but the peace of mind is worth every penny.

Galvanized Steel is the reliable workhorse of the walk-in world. With its distinctive stucco embossing and protective coating, these 26-gauge doors deliver durability without breaking the bank. One restaurant owner in Nashville told us, "It's been five years, and it still looks like new despite hundreds of daily openings."

Aluminum brings a lightweight touch to high-humidity settings. We've installed these in Florida mortuaries where the combination of heat and humidity would challenge lesser materials. The natural corrosion resistance means less maintenance headaches for you.

Fiberglass Reinforced Plastic (FRP) is the tough kid on the block. When a mortuary in Chicago needed doors that could withstand frequent cleaning with harsh chemicals, FRP was our go-to recommendation. Its non-porous surface cleans easily and stands up to impacts that would dent metal.

For insulation, modern walk in cooler doors primarily use polyurethane foam with impressive R-values of 25-32. These aren't your grandfather's insulation materials—today's formulations use environmentally friendly blowing agents that protect both your products and our planet.

How to Choose the Right Walk In Cooler Door for Your Business

After helping hundreds of businesses find their perfect walk in cooler door, we've developed a straightforward approach:

First, think about what you're storing. A mortuary cooler has very different requirements than a restaurant or floral shop. We once worked with a funeral home in rural Kentucky that needed extra-wide doors to accommodate bariatric cases—a detail they hadn't initially considered but proved essential for their community's needs.

Temperature requirements come next. Standard cooler doors work perfectly above 32°F, but step into freezer territory and you'll need specialized features like heated door frames and specialized gaskets to prevent freezing shut. As one Memphis customer put it, "There's nothing worse than trying to yank open a frozen door when you're in a hurry!"

Space constraints often dictate door style. A cozy New York City mortuary might need space-saving sliding doors, while a sprawling Texas facility might have plenty of room for traditional swinging models. Be honest about your space limitations—we can work with them!

Traffic patterns matter too. High-traffic areas benefit from automatic doors or strip curtains that minimize temperature loss. One busy Chicago funeral home reduced their energy bills by 17% after adding strip curtains behind their main walk in cooler door.

Budget considerations shouldn't mean compromising quality. We can often suggest creative solutions that meet both performance needs and financial constraints. Remember—a quality door is an investment that pays dividends through energy savings and reduced maintenance.

For more detailed information about complete refrigeration systems, check out our guide on walk-in refrigeration units.

Standard vs. Custom Walk In Cooler Door Sizes

While we pride ourselves on custom solutions, most facilities find their needs met by standard walk in cooler door dimensions:

Our 34"×78" Blue Line Series doors serve well in tight spaces. The industry-standard 36"×80" door handles most personnel access needs beautifully. When you need to move larger items, our 48"×80" doors provide generous clearance without requiring custom fabrication.

For conventional plug doors, we can go up to 60"×94" before entering true custom territory. But don't worry if your needs fall outside these ranges—we've created custom solutions for everything from historic buildings with unusual openings to specialized industrial applications requiring extra-large access.

When measuring for replacement, always measure the actual door rather than just the opening. Also note whether you need a flush mount plug door with frame or an overlap door with face case frame. This small detail makes a huge difference in proper fit and function.

Safety & Compliance Features

Modern walk in cooler door design isn't just about keeping cold air in—it's about keeping people safe and meeting regulatory requirements.

Every door we manufacture includes inside safety release mechanisms—a feature one grateful customer called "a literal lifesaver" after an employee was accidentally locked inside. Padlock provisions give security when needed, while illuminated switches ensure visibility even when the lights are dim.

We ensure all our doors meet critical standards including NSF/ANSI-7 certification, EISA 2007 energy requirements, UL compliance for electrical components, and ADA guidelines where applicable. These aren't just bureaucratic checkboxes—they're safeguards that protect your business, your employees, and the people you serve.

As one funeral director in Atlanta told us, "Having a door that meets all the safety standards gives me one less thing to worry about during inspections." We couldn't agree more—peace of mind is part of what you're buying when you choose American Mortuary Coolers.

Installation, Maintenance & Lifespan

When you invest in a quality walk in cooler door, you're looking at 15-20 years of reliable service—but only with proper installation and regular TLC. Think of your cooler door like a car: regular maintenance prevents breakdowns and extends its useful life.

Installation Options

Most facilities choose between two main installation approaches:

Pre-hung Frames arrive as complete assemblies with the door already mounted in its frame. They're the "plug and play" option of the cooler door world. Our customers love them because they simplify installation and virtually guarantee proper alignment from day one.

When it comes to mounting styles, you've got choices:

Flush Mount Plug Doors sit perfectly flush with your cooler wall, creating that clean, streamlined look that many modern facilities prefer. These typically require a specific frame designed for your cooler.

Overlap Doors do exactly what the name suggests—they overlap the opening with a face case frame. This style is the chameleon of cooler doors, adapting to many existing walk-in brands and making them ideal for replacement projects.

One of our mortuary clients in Columbia, SC shared a story that made us smile: "When our original cooler door started failing after 18 years, we were worried about downtime during replacement. The pre-hung overlap door from American Mortuary Coolers installed in just a few hours, and we were back in operation the same day. No drama, no extended downtime."

Maintenance Essentials

The secret to a long-lasting walk in cooler door isn't really a secret at all—it's consistent care. Here's what works:

On a monthly basis, take five minutes to inspect your gaskets for tears or hardening. Check that your door still aligns properly, and give those gasket surfaces a gentle cleaning with mild detergent. While you're at it, make sure the door closer is doing its job.

Quarterly, show your door some deeper love. Lubricate hinges and latches with food-grade lubricant (never use WD-40 or household oils!). Check and adjust door sweeps to make sure they're still making good contact with the floor. If you have a freezer door, verify those anti-condensate heaters are working as they should.

Once a year, consider bringing in a pro for a thorough checkup. They'll inspect all components, adjust spring tension in those self-closing hinges, verify your thermal seal is still doing its job, and test all safety features.

Signs Your Walk-In Cooler Door Needs Replacement

Even the best-maintained doors eventually reach retirement age. Here's how to tell when that time has come:

Ice buildup around the door frame is like your cooler waving a white flag. Those failing gaskets or deteriorating insulation are letting warm, moist air in where it doesn't belong.

Feel the surface of your door. Warm spots suggest the insulation inside is breaking down in those areas—and that means energy dollars floating right out of your cooler.

When your door starts to sag and no longer aligns properly with its frame, you're looking at seal gaps that create energy loss. This is especially common in high-traffic installations.

Visible damage like cracked insulation on the door's surface often points to bigger problems hiding inside. And if your energy bills are creeping up without explanation, your door might be the silent culprit.

A Chicago customer told us a story we hear too often: "We ignored the warning signs for months—the slight condensation, having to push harder to close it properly. By the time we replaced it, our electricity bills had jumped 30%. The new door paid for itself within a year just in energy savings."

Extending Door Life: Pro Tips

Want to get the absolute most from your walk in cooler door? Our service techs swear by these strategies:

Install strip curtains as a second line of defense. These vinyl strips reduce air exchange during door openings, taking pressure off both your door and your refrigeration system. They're especially valuable in high-traffic environments.

Develop a regular cleaning schedule and stick to it. Food acids and harsh sanitizing chemicals can deteriorate gaskets over time, but gentle, consistent cleaning prevents premature breakdown.

Keep a small spare parts kit on hand with basics like gaskets and hinges. When something minor fails, you'll be ready to fix it immediately rather than waiting for parts to arrive while your energy bills climb.

Train your staff properly on door operation. It sounds simple, but we've seen countless doors damaged by improper use. Make sure everyone confirms full closure and avoids propping doors open unnecessarily.

Finally, don't skip those annual professional inspections. Our technicians can spot developing issues before they become expensive problems. It's like preventive medicine for your cooler door.

For more information about replacement hardware and maintenance supplies that can extend your door's life, visit Walk In Cooler Parts.

Innovations & Future Trends in Walk-In Cooler Doors

The world of walk in cooler door technology is evolving faster than a cold front in winter! Today's innovations aren't just impressive—they're revolutionizing how businesses maintain temperature control while saving energy and improving operations.

When I visit customers across the country, they're always amazed by how far cooler door technology has come from the heavy, inefficient models of the past. Let me walk you through some of the exciting developments that are changing the game.

Cutting-Edge Technologies

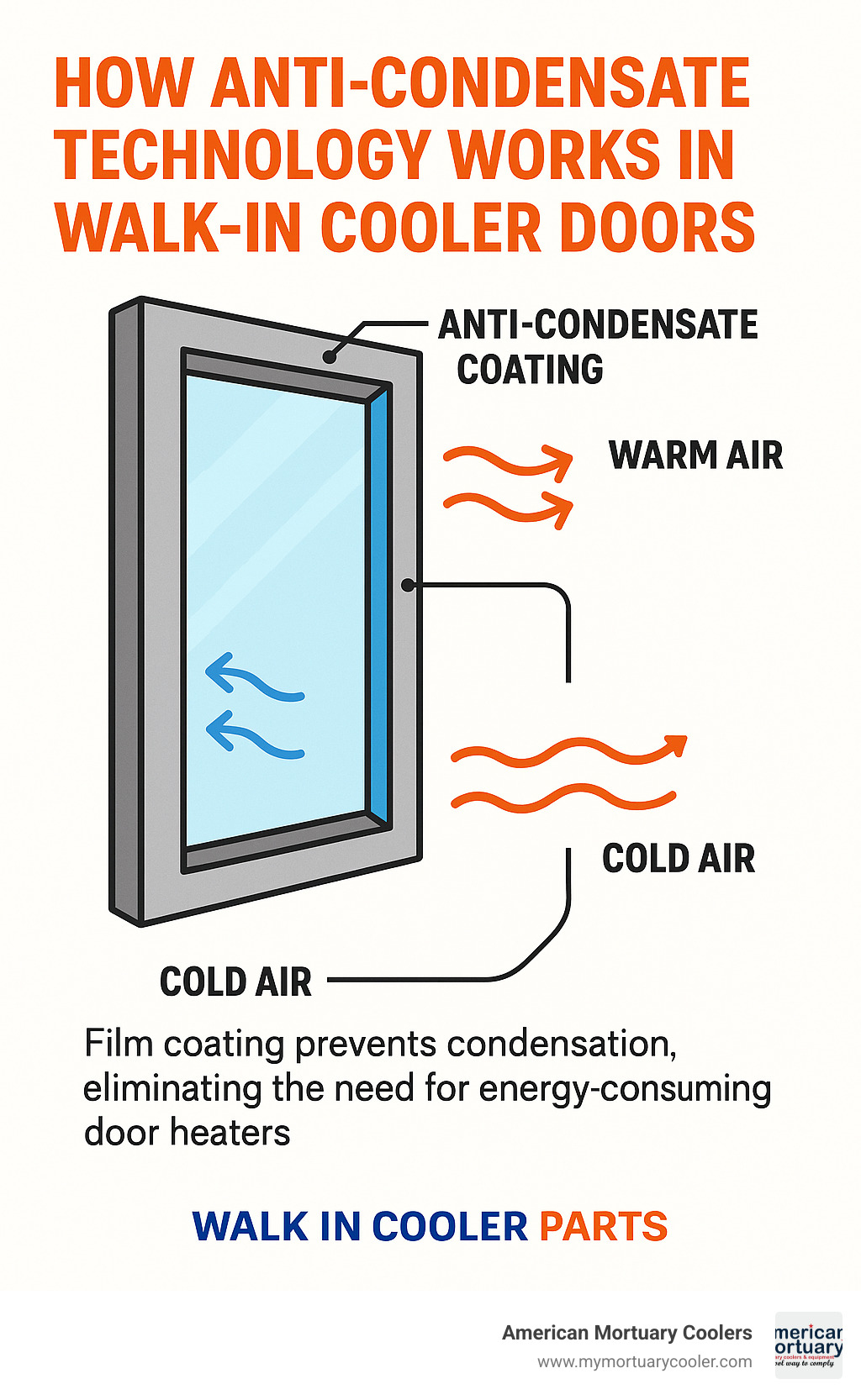

Remember when glass doors always fogged up? Those days are fading into history thanks to anti-fog film technology. These permanent coatings eliminate condensation without needing energy-hungry heaters. One restaurant owner in Nashville told me, "It's like having an invisible windshield wiper running 24/7—our customers can always see our beverages clearly."

Argon-filled glass has been a game-changer for display doors. This invisible gas sits between glass panes, providing superior insulation while maintaining crystal-clear visibility. The difference is remarkable—like upgrading from standard to high-definition TV.

I'm particularly excited about the integration of smart sensors and IoT technology. Modern walk in cooler doors now serve as data collection points that can:

- Alert you when doors stay open too long

- Track temperature fluctuations in real-time

- Monitor usage patterns to optimize workflows

- Integrate with building management systems

"The integration of smart technology with our mortuary cooler doors has transformed our operation," a funeral director from Boston recently shared with me. "We receive immediate alerts if a door hasn't sealed properly, preventing any potential issues before they affect temperature stability."

Perhaps most impressive are the new energy-free frame designs. These plastic frames with thermal breaks can slash energy consumption by a whopping 68-80% compared to traditional heated frames. That's not just good for the planet—it's great for your utility bills too.

Sustainability Focus

The future of walk in cooler door design isn't just about efficiency—it's about responsibility toward our planet. I've been watching several exciting developments in this space:

3D-printed custom gaskets are changing how we approach replacements. Instead of mass-produced options that might not quite fit, we can now create perfect-fit gaskets that reduce waste and improve sealing. When a funeral home in Memphis needed an unusual-sized gasket for their vintage cooler, we printed one that fit like it was made for it—because it was!

Recyclable insulation materials maintain impressive R-values while being more environmentally friendly at end-of-life. The foam insulation in older doors could last centuries in landfills, but newer formulations break down much more readily when properly processed.

Some forward-thinking facilities are even incorporating solar-powered components for door heaters and sensor systems. A mortuary in Arizona installed a small solar array that powers all their cooler door electronics—a perfect match for their sunny climate.

I'm fascinated by the emerging field of biomimetic sealing technology—designs inspired by nature's own sealing mechanisms. Some new gasket designs mimic how certain plants and animals create waterproof seals, resulting in more effective barriers against air infiltration.

At American Mortuary Coolers, we're not just watching these trends—we're actively incorporating them into our products. When you choose one of our walk in cooler doors, you're getting technology that keeps you ahead of the curve while reducing operational costs and environmental impact.

As one of our customers wisely put it: "The cheapest energy is the energy you don't use." Modern cooler door innovations help you use less energy while maintaining perfect preservation conditions—a win-win that's hard to beat.

Buying, Quotes & Direct-From-Manufacturer Benefits

When it comes to purchasing a walk in cooler door, working directly with a manufacturer like American Mortuary Coolers gives you significant advantages that just make sense for your bottom line and peace of mind.

Think about it—why pay more for the same product? Distributors typically add a 15-30% markup to the base price of doors. When you buy direct from us, that margin stays right where it belongs—in your business account. It's like getting a built-in discount simply by cutting out the middleman.

But the benefits go well beyond just dollars and cents. Our team lives and breathes walk in cooler doors every day. We don't just sell them—we design and build them. This means you're getting advice from people who understand every gasket, hinge, and insulation panel in intimate detail.

I remember talking with a funeral director from Colorado who called us after getting quotes that made his eyes water. "After getting quotes from local suppliers that seemed excessive, we contacted American Mortuary Coolers directly," he told me later. "Not only did we save nearly 22% on the price, but they were able to customize the door height to fit our unique opening without charging a premium." Stories like this are why we love what we do.

How to Order or Replace a Walk-In Cooler Door

Getting your new walk in cooler door doesn't have to be complicated. Here's how we make it simple:

Start by measuring your existing door carefully—not just the rough opening. We'll need the width and height of the door panel itself, the thickness, which side the hinges are on (left or right when facing from outside), and whether it's a flush or overlap mounting style.

Next, think about what you really need. Based on your specific situation, you'll want to consider whether a swinging, sliding, or vertical-lift door makes the most sense. What material finish would work best in your environment? Stainless steel looks beautiful and resists corrosion, while galvanized or aluminum options might be more budget-friendly.

Once you've got your specifications ready, just complete our online quote form or give us a call. We'll help confirm any regulatory requirements for your industry and location, and then we can coordinate delivery timing that minimizes disruption to your operations.

We're proud to ship directly to all locations across the 48 contiguous states, and we include shipping costs right in our quotes—no surprise fees when you get the final bill.

Manufacturer vs. Distributor: What You Gain

Working with us directly creates a relationship that a distributor simply can't match. When you call with a question about your walk in cooler door, you're talking to the people who actually build it—not someone reading from a catalog who represents a dozen different manufacturers.

"We've built our business on direct relationships with funeral homes and mortuaries across the country," explains our Johnson City headquarters manager. "When you call us about your walk in cooler door, you're talking to the people who make the decisions and stand behind the product—not a middleman juggling multiple brands."

This direct connection gives you access to our engineers and technicians when you need technical support. We have the flexibility to accommodate rush orders when emergencies happen (and in your business, they sometimes do). If you're updating multiple facilities, we can offer volume pricing that distributors typically can't match.

Perhaps most importantly, we have a vested interest in our reputation. Every walk in cooler door that leaves our facility represents our commitment to quality. We stand firmly behind our products because our name is on them—and that means everything to us as a family-owned American manufacturer.

From customization options to financing flexibility, working directly with American Mortuary Coolers gives you a partner who understands your business needs—not just another vendor looking to make a quick sale.

Frequently Asked Questions about Walk In Cooler Doors

What's the difference between a cooler door and a freezer door?

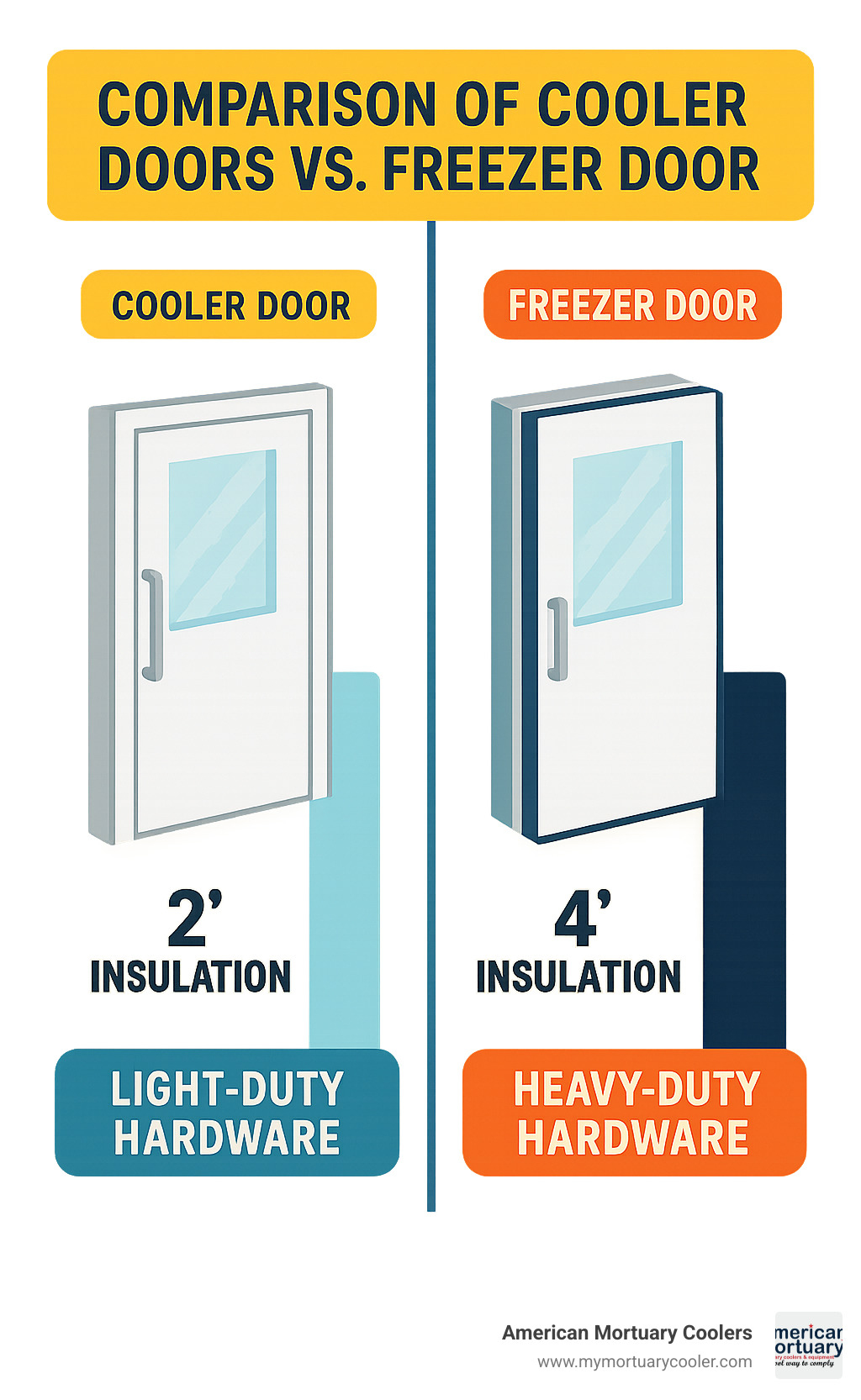

While they might look similar at first glance, walk in cooler doors and freezer doors have important differences that affect performance and efficiency.

Freezer doors are the heavy-duty siblings in the cold storage family. They come with thicker insulation—typically 4 inches compared to the 3.5 inches you'll find in standard cooler doors. They also feature heated door frames and thresholds that prevent freezing and sticking. The gaskets are specially designed to stay flexible even when temperatures plummet below freezing, and they include anti-sweat heaters around the perimeter to prevent moisture buildup. The insulation values are typically higher too, with R-32 or greater to keep those sub-zero temperatures stable.

Cooler doors, on the other hand, are designed for the more moderate temperatures above 32°F. They use standard gaskets without the need for heating elements and typically measure about 3.5 inches thick with an R-value of 25 or higher—plenty for keeping your refrigerated products at the perfect temperature.

"Using the wrong door type is like wearing a light jacket in a snowstorm," explains our service manager. "If you install a standard cooler door in a freezer, you'll soon see frost buildup, door sticking, and your energy bills will skyrocket. And while you could use a freezer door for a cooler, you'd be paying extra for features you don't need."

How often should I replace gaskets or hinges?

Gaskets are the unsung heroes of your walk in cooler door—they create that all-important seal that keeps the cold air in and the warm air out. With normal use, you'll typically need to replace them every 2-3 years, though this can vary based on how often the door is opened and how well it's maintained.

Keep an eye out for warning signs that your gaskets need attention: visible cracking or tearing, hardening of the once-flexible material, gaps you can see when the door is closed, or condensation forming around the edges. Any of these symptoms means it's time for a replacement.

Hinges tend to be more durable, usually lasting 5-7 years before needing replacement. However, they may require periodic adjustment to maintain proper door alignment. You'll know your hinges need attention when the door starts sagging, you have trouble getting a good seal when closed, you hear unusual noises during operation, or you notice visible wear or corrosion.

"One of the best tips we give our funeral home clients is to keep spare gaskets on hand," shares our customer service director. "When a gasket fails, your energy efficiency takes an immediate hit. Having replacements ready means you can fix the problem right away instead of waiting for parts to arrive while your cooling system works overtime."

Can I retrofit a glass door into my existing walk-in?

Yes, you can transform your solid walk in cooler door into a glass display door in many situations—and the results can be dramatic for retail environments. However, there are several important factors to consider before making the switch.

First, check the structural requirements. Your existing frame needs to be sturdy enough to support the weight of a glass door unit, which is typically heavier than a solid door. The opening dimensions need to match available glass door sizes, and your wall thickness must accommodate the frame depth of the new door system.

Electrical considerations are also important. Glass display doors usually require power for anti-condensate heaters and lighting. This wiring should be installed by qualified professionals, and you may need to add controls for the lighting and heating elements.

Be aware of the performance implications too. Glass doors generally have lower insulation values than solid doors, which means your energy consumption might increase. Your cooler may also take longer to recover its temperature after the door has been opened.

Despite these considerations, the benefits can be substantial for retail businesses. A convenience store owner in Arizona who worked with us shared: "Converting to glass doors was the best decision we made for our beverage section. Our customers can now see everything we offer without opening the door, and our drink sales jumped by 35% in just the first month. The slight increase in our electric bill is nothing compared to the sales boost we've seen."

For mortuaries, while glass doors aren't typically needed for body storage areas, they can be beneficial in flower storage sections where visibility helps staff quickly locate specific arrangements without prolonged door openings.

Conclusion

The walk in cooler door is the unsung hero of your refrigeration system – not just a simple entry point, but the critical component that balances thermal efficiency, durability, and accessibility. Choosing the right door isn't just a practical decision; it's an investment that affects your operation's efficiency and bottom line for years to come.

At American Mortuary Coolers, we've seen how the right door transforms a good cooling system into an exceptional one. Whether you're running a busy restaurant kitchen, managing a funeral home, showcasing delicate flowers, or storing temperature-sensitive pharmaceuticals, your walk in cooler door needs to meet specific demands unique to your business.

We're proud to serve customers nationwide from our home base in Johnson City, Tennessee, with regional support across the country. From Chicago to Los Angeles, New York to Dallas, our team understands the local challenges and requirements you face.

What makes our approach different? It's simple – we believe in direct relationships. When you work with us, you're getting:

Custom solutions custom to your specific challenges, not one-size-fits-all products. A mortuary in Minnesota has very different needs than a florist in Florida, and we honor those differences.

Factory-direct pricing that eliminates the middleman markup, putting those savings back into your business where they belong.

Expert guidance from people who design and build these systems every day, not just sell them. We'll help you steer options and avoid costly mistakes.

Comprehensive support from initial consultation through installation and beyond, ensuring your system performs at its best for years.

Industry-leading warranty protection that gives you peace of mind and protects your investment.

One funeral director in Pennsylvania told us, "I never thought I'd be excited about a cooler door, but the difference in our daily operations since upgrading has been remarkable. The door closes with a gentle click, seals perfectly, and our cooling system runs half as often as before."

That's the kind of practical difference a quality walk in cooler door makes – not just preserving what's inside, but contributing to a quieter, more efficient, and more economical operation overall.

For businesses looking to explore custom options that perfectly match their unique requirements, we invite you to learn more about our approach to customization in our guide on customization power.

The door you choose today will be opened and closed thousands of times in the years ahead. Make it count by selecting a solution that combines quality, efficiency, and durability – your future self (and your utility bills) will thank you.