Why Cooler Temperature Control Makes or Breaks Your Operation

Cooler temperature control is the system that maintains precise temperatures in walk-in coolers and freezers through sensors, thermostats, and automated controls. Here's what you need to know:

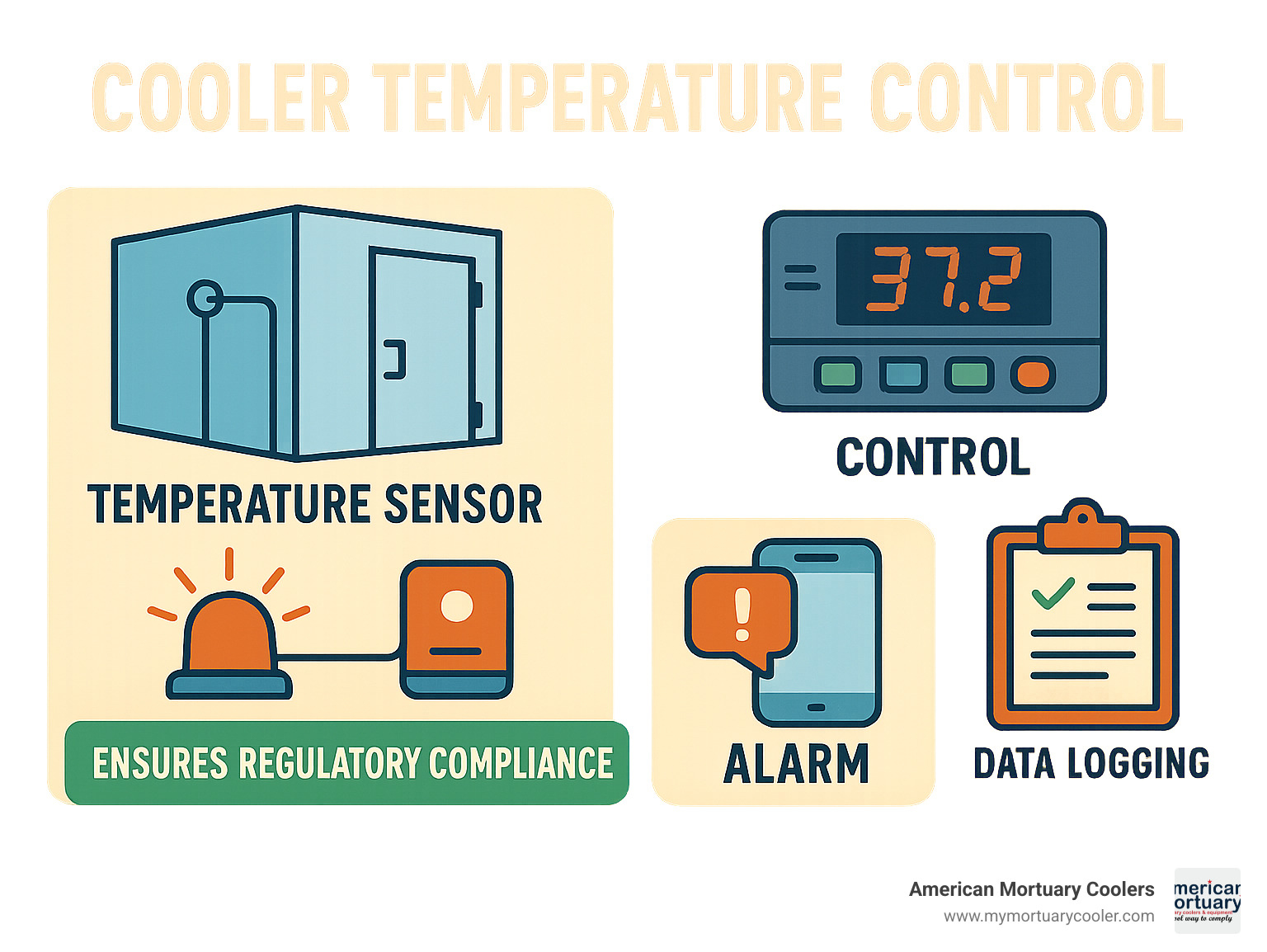

Essential Components:

- Temperature sensors - Monitor internal conditions

- Control systems - Mechanical thermostats or electronic controllers

- Monitoring devices - Digital displays, alarms, and data loggers

- Ideal ranges - 35°F-38°F for coolers, 0°F to -10°F for freezers

Key Benefits:

- Prevents product spoilage and contamination

- Reduces energy costs by 15-30%

- Ensures regulatory compliance

- Extends equipment lifespan

Walk-in coolers and freezers are the backbone of countless industries - from restaurants storing fresh produce to funeral homes preserving remains with dignity. Yet one small temperature fluctuation can mean thousands in lost inventory, failed health inspections, or worse.

The research shows that proper temperature control saves serious money. A well-maintained system can hold temperatures for 24-48 hours during power outages. Modern electronic controls offer precision within ±2°F, while older mechanical systems may drift by 5°F or more.

But here's what most operators miss: it's not just about setting the right temperature. The real challenge is maintaining consistent control through changing seasons, equipment wear, and daily use cycles.

I'm Mortuary Cooler, a national-level mortuary cooler supplier specializing in American-made refrigeration solutions. Over years of working with funeral homes nationwide, I've seen how proper cooler temperature control can transform operations - and how poor control creates costly headaches that could have been easily prevented.

Cooler temperature control terms at a glance:

Understanding Cooler Temperature Control

Cooler temperature control is like having a vigilant guardian watching over your refrigerated space 24/7. Think of it as an integrated system where temperature sensors act as the eyes, controllers serve as the brain, and your cooling equipment becomes the muscles that respond to keep everything at just the right temperature.

Modern temperature control systems use smart algorithms to prevent temperature swings that can wreak havoc on your operation. They're constantly learning and adjusting to minimize energy waste while extending your equipment's lifespan.

The real magic happens in that feedback loop. Your sensors continuously measure conditions, the controller compares those readings to your target temperature, and the cooling system responds instantly. It's this seamless coordination that separates professional-grade operations from those struggling with constant temperature headaches.

Why does this matter so much? Proper cooler temperature control delivers benefits that touch every corner of your business. Food safety compliance becomes automatic when your system prevents bacterial growth above 40°F. Energy efficiency improves dramatically - we're talking 15-30% reductions in utility costs through optimized cycling patterns.

Your product quality stays consistently high because temperatures don't fluctuate wildly. Equipment protection kicks in naturally since your compressor isn't constantly overworking. Regulatory compliance with FDA, HACCP, and health department requirements becomes effortless with proper documentation. And those cost savings from eliminated spoilage? They can easily reach thousands monthly.

Why Precision Cooler Temperature Control Saves Money

The biggest financial impact of precise temperature control often isn't the obvious spoilage prevention. It's all those hidden costs that add up when your system isn't running optimally.

Your utility bills take the biggest hit when temperatures start drifting. When your cooler temperature creeps above the setpoint, your compressor starts working overtime. We've measured energy consumption increases of 20-40% during these catch-up periods. A properly tuned electronic controller prevents this wasteful rapid cycling.

Compressor wear is the silent budget killer that most operators don't see coming. Every time your system struggles with temperature fluctuations, your compressor starts and stops more frequently. Each startup draws 3-5 times the normal operating current, creating mechanical stress. Systems with stable temperature control can extend compressor life by 2-3 years, translating to $3,000-$8,000 in avoided replacement costs.

Spoilage losses hit fast and hard when temperature control fails. Even brief excursions above safe temperatures can trigger contamination or product degradation. We've seen operations lose $10,000+ from a single temperature control failure. The FDA's 0°F requirement for frozen storage isn't just a guideline - exceed it, and entire inventories may need disposal.

Health & Safety Impacts of Cooler Temperature Control

Temperature control becomes a life-and-death matter in many applications. The FDA's requirement for frozen food storage at 0°F (-18°C) or lower isn't arbitrary - it's the scientifically proven threshold for inhibiting dangerous microbial growth.

HACCP compliance requires more than just setting the right temperature. Your system needs continuous monitoring with documented corrective actions. Walk-in freezers must maintain temperatures below critical limits, with monitoring frequency varying by application.

Microbial growth prevention is where the science gets serious. Bacteria multiply exponentially in the danger zone between 40°F and 140°F. Even brief temperature excursions can trigger contamination that persists after temperatures return to safe levels. This is why modern systems include immediate alarm functions.

The bottom line? Cooler temperature control isn't just about maintaining cold temperatures - it's about creating a reliable, documented system that protects both your products and the people who depend on them.

Control Technologies & Ideal Settings

The heart of any cooler temperature control system lies in choosing the right technology for your specific needs. Modern systems range from simple mechanical thermostats to sophisticated electronic controllers with IoT connectivity, and each has its sweet spot.

Mechanical controls use a gas expansion and contraction system in a bulb-and-capillary setup. When temperatures climb, the gas expands and flips a switch to activate cooling. They're beautifully simple - no fancy electronics needed. The trade-off? They typically work within a ±5°F range with limited fine-tuning options.

Electronic controls bring modern precision to temperature management. These systems use thermistor probes that change electrical resistance as temperatures shift. A smart control board reads these changes and makes split-second decisions. You're looking at accuracy within ±2°F, plus features like programmable setpoints, defrost controls, and alarm systems.

Integrated refrigeration controls are the premium option. These systems manage temperature sensing, defrost cycle management, fan controls, and energy optimization simultaneously. They can slash energy consumption by 15-25% compared to basic mechanical controls.

| Control Type | Accuracy | Features | Best Applications |

|---|---|---|---|

| Mechanical | ±5°F | Simple, reliable | Basic coolers, backup systems |

| Electronic | ±2°F | Digital display, alarms | Commercial applications |

| Integrated | ±1°F | Full automation, energy optimization | High-volume operations |

Getting your temperature ranges right is crucial. Walk-in coolers perform best at 35°F-38°F for general food storage, though floral applications prefer 33°F-35°F. Walk-in freezers need to stay between 0°F to -10°F for most frozen goods, dropping below -20°F for pharmaceuticals.

Don't forget about humidity control - aim for 50-60% relative humidity to prevent mold growth while keeping products from drying out.

Check out our Product store Electronic temperature control for professional-grade options.

Mechanical vs. Electronic: Which Fits Your Operation?

Choosing between mechanical and electronic controls isn't just about budget - it's about finding the right fit for how you actually operate.

Mechanical thermostats use a remote bulb filled with gas, connected by a capillary tube to a switch mechanism. As temperature climbs, the gas expands and physically triggers the switch. No computer chips, no digital displays - just physics doing its thing reliably.

The beauty of mechanical systems is their simplicity and reliability. They don't need electrical power for basic operation, have fewer parts that can break, cost less upfront, and any decent technician can service them.

Electronic controllers use thermistor probes where electrical resistance changes predictably with temperature. The control board constantly reads these changes and calculates exact temperatures, making precise adjustments that mechanical systems can't match.

Electronic controls shine with their superior accuracy - ±2°F versus ±5°F for mechanical systems. You get digital displays, programmable setpoints, built-in alarms, data logging for compliance, and compatibility with remote monitoring systems.

For most commercial operations, electronic controls pay for themselves through improved efficiency and compliance capabilities.

Setting the Sweet Spot for Walk-In Coolers

Finding that perfect temperature setpoint requires balancing food safety, energy efficiency, and product quality. The FDA says keep food below 40°F, but most walk-in coolers hit their stride in the 35°F-38°F range.

For general food storage, set your cooler to 35°F-38°F. This gives you a safety margin above freezing while staying well below that critical 40°F danger zone. Most commercial operations find their sweet spot at 37°F.

Floral storage likes it cooler at 33°F-35°F with high humidity (90%+). Beverage coolers work well at 35°F with moderate 60-75% humidity. Mortuary applications typically run 35°F-40°F depending on requirements, while pharmaceutical storage demands manufacturer specifications - often requiring ±2°F control.

Humidity matters just as much as temperature. Too high and you're dealing with condensation and mold. Too low and products dry out. The sweet spot for most applications is 50-60% relative humidity.

For detailed specifications on cooler room requirements: More info about cooler room specs.

Monitoring, Alarms & Data Logging

Modern cooler temperature control monitoring systems are like having a dedicated technician watching your equipment 24/7. Gone are the days of clipboard checks and hoping everything was okay.

Today's sensor technologies work around the clock, tracking temperature, humidity, door openings, and power consumption. These digital sensors detect patterns and spot problems before they become disasters.

Data logging creates a permanent digital paper trail that makes health inspectors smile. Instead of searching for handwritten logs, you can pull up months of detailed records with a few clicks. The system automatically stores every temperature reading, creating charts and reports.

The real game-changer is cloud-based monitoring. Your phone buzzes with an alert if your cooler runs warm. You can check the exact temperature, see how long it's been climbing, and call your service technician with specific information. No more finding problems Monday morning when it's too late.

IoT integration connects your coolers to your building's other systems. Smart systems automatically adjust temperatures based on door activity, outdoor weather, or electricity rates.

Our guide How to Control Temperature in 5 Simple Steps breaks everything down into manageable pieces.

For tech-savvy users who want maximum control, CoolerControl offers open-source monitoring solutions.

Common Cooler Temperature Control Devices

Basic digital thermostats show exact temperatures on clear displays and remember the highest and lowest temperatures reached. This min/max memory feature tells you if temperatures spiked overnight even if everything looks normal in the morning.

Programmable Logic Controllers are the heavy-duty workhorses of temperature control. PLCs handle complex operations like managing multiple cooler zones and coordinating with your building's HVAC system. They're essential for larger facilities.

Wireless temperature probes solve the biggest headache of traditional monitoring - running wires everywhere. These battery-powered sensors operate for years and beam temperature data to receivers or directly to cloud platforms.

Gateway devices act like translators between your local sensors and internet-based monitoring systems. They collect data from multiple sensors, store it locally as backup, and upload everything to the cloud.

Smart controllers combine thermostat reliability with modern connectivity features. Most include smartphone apps that let you check temperatures, adjust settings, and receive alerts from anywhere.

Remote Alerts That Prevent Costly Spoilage

The right alert system catches problems before they become expensive disasters. It's like having a vigilant watchman who never gets tired.

SMS text alerts are the gold standard for critical notifications. They work even when internet connections fail, and they're impossible to ignore. Most systems can send alerts to multiple phone numbers. I recommend setting up a call chain - primary contact, backup contact, and emergency service number.

Email notifications work perfectly for detailed information and less urgent alerts. When a temperature excursion happens, email alerts can include complete data - duration, peak reading, and suggested corrective actions.

Push notifications through smartphone apps provide the fastest response times. Modern apps show real-time temperatures, historical trends, and system status instantly.

Getting threshold settings right prevents alert fatigue from too many minor notifications and missed emergencies from thresholds set too high. Most systems allow multiple alert levels - maybe a warning at 40°F and a critical alert at 45°F for a cooler normally set at 37°F.

Dashboard integration gives you the big picture at a glance. Web-based dashboards display multiple locations, trend data, and alert status from any internet-connected device.

The key is finding the right balance. You want enough alerts to catch problems early, but not so many that you start ignoring them.

Maintenance, Calibration & Compliance

Think of cooler temperature control maintenance like caring for a reliable old friend - treat it well, and it'll serve you faithfully for decades. Most temperature control failures happen gradually, then suddenly. The good news? Most problems are completely preventable with simple, regular care.

Coil cleaning tops every maintenance priority list. When evaporator and condenser coils get clogged with dust and debris, your system has to work much harder to move heat. Clean your coils monthly using soft brushes and a vacuum cleaner. Be gentle with those delicate fins.

Gasket inspection prevents sneaky air leaks that drive energy bills through the roof. Check door gaskets monthly for tears, warping, or gaps when the door closes. A worn gasket is like leaving a window cracked open in winter.

Calibration keeps everything honest. Even the best temperature sensors can drift over time. Calibrate your sensors and displays annually using certified reference thermometers. Document every calibration for regulatory compliance.

Defrost controls need special attention in freezer applications. Ice buildup on evaporator coils acts like insulation, forcing your system to work harder while delivering less cooling. Modern electronic defrost controls run only when needed, but older systems might need seasonal adjustments.

Power outage planning can save thousands in spoiled inventory. A well-insulated walk-in cooler maintains safe temperatures for 24-48 hours without power - but only if you keep those doors closed. Consider backup generators for critical applications.

For detailed information on defrost controls: Read the full article.

Many problems stem from simple mistakes that are easy to avoid: Beginner Freezer Temperature Mistakes and How to Avoid Them.

Scheduled Service Keeps Cooler Temperature Control Reliable

The secret to reliable cooler temperature control is consistency. Establishing regular maintenance schedules prevents small issues from becoming expensive emergencies.

Monthly maintenance takes about 30 minutes but saves hours of headaches later. Clean condenser and evaporator coils, inspect door gaskets and hinges, and verify temperature accuracy with a backup thermometer. Look for unusual ice buildup or frost patterns that might indicate airflow problems.

Test your alarm functions monthly. The best monitoring system won't help if the alerts aren't working when you need them.

Quarterly inspections go deeper into system health. Calibrate temperature sensors, inspect electrical connections, and have a qualified technician check refrigerant levels. Review your temperature logs for concerning trends - gradual temperature creep often signals developing problems.

Annual service by a certified technician catches problems before they become failures. This comprehensive inspection includes replacing worn components, updating control software, and thorough calibration of all sensors.

Record keeping proves essential for warranty claims, insurance coverage, and regulatory compliance. Maintain detailed logs of all maintenance activities, temperature readings, and system modifications.

Regulatory Records & Audit Readiness

Compliance documentation protects your business and ensures you're ready for inspections. The key is establishing systems that make record-keeping automatic rather than burdensome.

HACCP logs require continuous temperature monitoring with documented corrective actions for any deviations. Most food safety regulations require temperature checks at least daily, though some applications need hourly or continuous monitoring.

Healthcare guidelines often mandate stricter temperature ranges and documentation requirements. Pharmaceutical storage typically requires calibrated sensors with certificates traceable to national standards.

Calibration certificates provide legal proof that your monitoring equipment meets accuracy requirements. Keep certificates for all temperature monitoring devices and ensure calibration occurs within required timeframes.

Audit preparation becomes much easier when you maintain organized documentation year-round. Regular self-audits help identify compliance gaps before official inspections.

The goal isn't just passing inspections - it's creating systems that protect your business, your customers, and your reputation through consistent, reliable temperature control.

Frequently Asked Questions about Cooler Temperature Control

Let's tackle the most common questions we hear from funeral directors and facility managers about cooler temperature control. These are the real-world concerns that keep you up at night - and the answers that help you sleep better.

What is the ideal temperature range for a walk-in cooler and freezer?

Here's where precision matters most. Walk-in coolers perform best between 35°F-38°F for general storage needs. This sweet spot keeps your contents safe while avoiding the freezing damage that can ruin sensitive items.

But not every application is the same. If you're storing floral arrangements, aim for 33°F-35°F with high humidity. For mortuary applications, 35°F-40°F often works perfectly, depending on your specific requirements and local regulations.

Walk-in freezers need to stay between 0°F to -10°F for most applications. The FDA doesn't mess around here - they require frozen storage at 0°F (-18°C) or lower to stop harmful bacteria in their tracks. Some pharmaceutical storage demands even colder temperatures, dropping below -20°F for certain medications.

The key is matching your temperature range to your specific needs. When you're unsure, check with your local health department or industry guidelines. It's always better to ask than to guess wrong.

How often should cooler/freezer temperatures be monitored and recorded?

The answer depends on what you're storing and who's watching. Food service operations typically check temperatures daily at minimum, with busy facilities checking twice daily during peak seasons. Some critical applications demand hourly monitoring.

Healthcare and pharmaceutical storage plays by stricter rules. Continuous monitoring with automatic data logging is often required, with some medications needing temperature verification every 15-30 minutes. No exceptions.

For general commercial use, daily checks usually suffice. But here's the thing - modern automated monitoring systems eliminate the guesswork while providing better protection. They're watching 24/7 so you don't have to.

Modern monitoring systems with continuous tracking and automatic data logging take the burden off your shoulders. They provide superior protection against temperature excursions while creating the documentation you need for compliance.

How long will a walk-in hold temperature during a power outage?

This is the question that makes everyone nervous, and for good reason. A properly insulated walk-in cooler can maintain safe temperatures for 24-48 hours during power outages - but only if you keep those doors closed.

Several factors determine how long your unit will hold temperature. Insulation quality makes a huge difference - newer units with high-quality insulation far outperform older units with degraded insulation. Door sealing is equally critical. Tight-fitting doors with good gaskets prevent warm air from sneaking in.

Your internal load affects holding time too. Fuller units retain temperature longer thanks to thermal mass, but don't overload to the point where air can't circulate properly. Ambient temperature plays a role - hot summer days reduce holding time while cold weather extends it.

Here's the most important factor: usage during the outage. Every time someone opens that door, warm air rushes in and your holding time drops significantly. Train your staff to minimize door openings during emergencies.

For critical applications, consider backup generators or dry ice supplementation during extended outages. It's a small investment compared to losing valuable contents or facing regulatory issues.

Conclusion

Getting cooler temperature control right transforms your entire operation. It's not just about avoiding spoiled products - it's about creating a system that works quietly in the background, protecting your investment while keeping costs under control.

The right control technology makes all the difference between constant headaches and smooth operations. Whether you choose simple mechanical controls or sophisticated electronic systems, matching the technology to your specific needs prevents both overspending and underperforming.

Setting those optimal temperature ranges isn't guesswork anymore. You know that 35°F-38°F keeps most products safe in coolers, while 0°F to -10°F handles freezer needs. But more importantly, you understand why these ranges matter and how they protect both your products and your bottom line.

Modern monitoring and alerting systems have become game-changers. No more finding problems after they've already cost you thousands. Smart alerts catch issues early, often before they become real problems.

Regular maintenance keeps everything humming along smoothly. Clean coils, good gaskets, and calibrated sensors prevent those middle-of-the-night emergency calls. Documentation isn't just paperwork - it's your protection during inspections and proof that you're doing things right.

Here's what I've learned after years in this business: the facilities that invest in proper cooler temperature control sleep better at night. They spend less on energy bills, throw away less spoiled inventory, and pass inspections with confidence.

At American Mortuary Coolers, we've seen how the right refrigeration system changes everything for funeral homes. Our custom-built solutions deliver the precision and reliability that sensitive applications demand. From our Tennessee facility, we ship durable, American-made equipment across all 48 contiguous states.

Every funeral home has unique needs, and cookie-cutter solutions rarely work perfectly. That's why we focus on custom designs that fit your specific space, capacity, and operational requirements.

Ready to upgrade your temperature control system? Browse our complete selection of custom mortuary coolers at mymortuarycooler.com collections. Our experienced team helps you design systems that provide reliable temperature control for decades, not just years.

Remember this simple truth: proper cooler temperature control pays for itself. The money you invest upfront comes back through lower energy bills, reduced spoilage, and equipment that lasts longer. Most importantly, you get peace of mind knowing your system works when it matters most.