Why Basket Stretchers Are Essential for Emergency Response

Basket stretchers are rigid, tub-shaped rescue devices designed to immobilize and transport patients safely across challenging terrain, from steep mountain rescues to industrial accident sites. These heavy-duty stretchers combine durability with patient protection, making them indispensable for search and rescue teams, emergency responders, and industrial safety crews.

Quick Answer for Basket Stretchers:

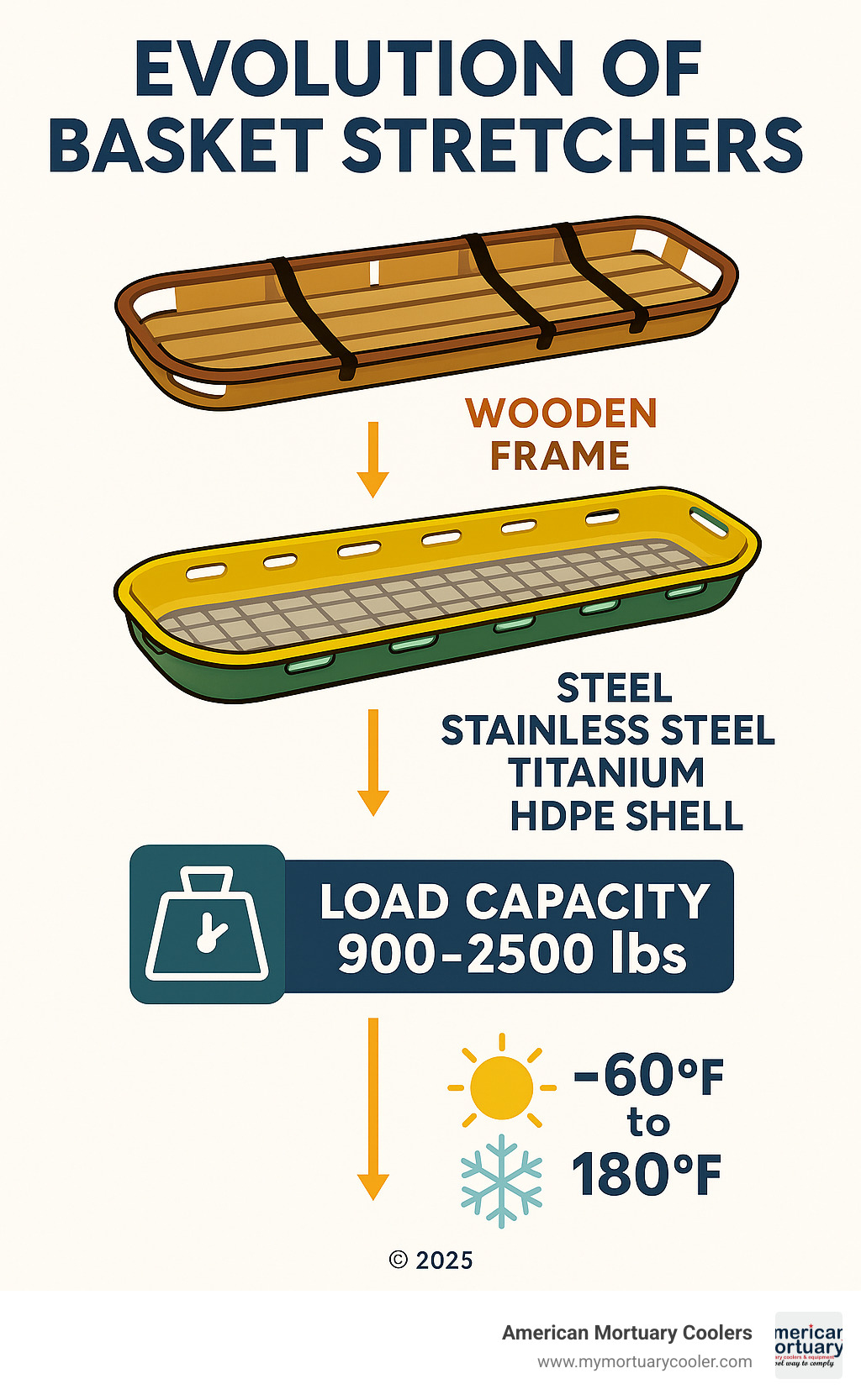

- Materials: Steel, stainless steel, titanium, or high-density polyethylene shells

- Weight Capacity: Typically 900-2,500 lbs static load capacity

- Key Uses: Wilderness rescue, water rescue, confined spaces, high-angle evacuations

- Standard Size: 80-85 inches long, 22-24 inches wide, weighing 27-45 lbs

- Temperature Range: -50°C to 82°C (-60°F to 180°F) for aluminum models

The history of basket stretchers traces back to World War II, when rescue teams used them to evacuate victims from bombed and collapsed structures. Modern basket stretchers feature Durathene netting that allows air and water to flow freely while supporting loads over 900 lbs. They accommodate essential accessories like lifting bridles, flotation collars, and patient restraint systems.

As Mortuary Cooler, a national-level mortuary cooler supplier, I've worked extensively with emergency transport equipment including basket stretchers across various rescue and medical transport scenarios. My experience spans both mortuary applications and emergency response equipment, giving me insight into the durability and reliability requirements these critical tools must meet.

Basic basket stretchers- terms:

What Is a Basket Stretcher? Core Components & Key Specs

Basket stretchers are rigid, tub-shaped patient protection systems built around tubular steel or aluminum frames. Modern models use Durathene netting that lets air and water flow freely while supporting incredible loads, replacing old-fashioned wire that rusts and breaks.

The frame construction determines durability. Most basket stretchers use either wire mesh netting or high-density polyethylene (HDPE) shells that handle extreme conditions. These stretchers typically measure 80-85 inches long and 22-24 inches wide, weighing between 27-45 pounds depending on materials.

Load capacity varies dramatically by model. Standard basket stretchers like the Traverse Rescue Gazelle Series are tested beyond their 900 lb (408 kg) static threshold. Premium models like the Titan-Ti reach 1,134 kg (2,500 lbs) capacity.

The temperature range for aluminum frame models spans -50°C to 82°C (-60°F to 180°F). Whether extracting someone from an icy river or blazing industrial site, these stretchers keep working when other equipment fails.

Basket stretchers work as complete systems with lifting bridles, mattresses, backboards, and straps. The drainage capability becomes crucial during water rescues, while rigid construction protects patients navigating debris-filled environments. For insights into effective patient transport, check out this Scientific research on patient-transport ergonomics.

Anatomy of Strength

The tubular frame forms the backbone. Quality models like the Gazelle series use 19mm diameter tubing providing greater strength and longer service life than flat-steel competitors.

Rails run along sides as mounting points for accessories and lifting hardware. Cross-braces connect side rails and distribute load forces across the entire frame structure using 3/16" x 3/4" flat steel. Molded-in runners on the bottom allow smooth dragging across rough terrain without damaging the frame.

The footrest integrates with position regulators for patient stability. Handholds are strategically placed around the perimeter - either molded into HDPE shells or integrated into wire frame designs. Many models include nylon rope perimeter providing additional grip points while protecting handlers' hands.

Standard Ratings & Certifications

Professional basket stretchers prove durability through rigorous testing. NFPA 1983 sets minimum requirements including 600 lb working load for rescue rope. Smart manufacturers exceed these minimums by wide margins.

Breaking strength for hardware snaps often meets CSA standards at 5,000 lbs, while lifting bridle webbing handles 2,955 kg (6,500 lbs). CE marking indicates European safety compliance, while ISO 9001 certification ensures manufacturing quality control meets international standards.

Types of Basket Stretchers: Materials, Designs & Leading Models

Steel models like the Gazelle series are rescue workhorses. Weighing around 33 lbs (15 kg), these stretchers offer the sweet spot between durability and affordability. The Durathene netting lets water and air flow freely while supporting substantial loads.

Stainless steel versions excel in marine environments or situations requiring frequent deep cleaning. The Titan SS series uses TIG welding for maximum frame strength, making these stretchers practically bulletproof against corrosion.

Titanium models like the Titan-Ti weigh more than half less than comparable stainless steel stretchers while maintaining impressive 2,500 lb traverse ratings. For helicopter operations or long-distance carries, every pound matters.

Plastic shell designs combine high-density polyethylene construction with internal aluminum or stainless steel frames. These models often feature spring-suspended support systems for smoother patient rides.

Specialty designs address specific challenges. Split-apart models are lifesavers for confined spaces where you assemble the stretcher around the patient. Roll-up stretchers fold for compact storage. Tapered designs steer tight spaces better, while extra-wide models accommodate larger patients.

Leading brands include Traverse Rescue with their Titan and Gazelle series, Junkin Safety with solid JSA models, Skedco with innovative Sked systems, and Ferno offering comprehensive rescue lines.

One-Piece vs Two-Piece Frames

One-piece basket stretchers offer maximum rigidity and structural integrity with no connection points to fail. They're ideal for helicopter hoisting operations or high-load scenarios where continuous frame construction provides superior strength.

Two-piece or split-apart designs excel in confined spaces where assembling the stretcher around the patient is necessary. Models like the Spartan feature LocSafe connections for tool-free assembly with visual confirmation of proper locking.

Storage considerations often favor two-piece designs that nest or stack more efficiently than one-piece counterparts.

Basket Stretchers vs Scoop Stretchers

Basket stretchers excel at patient transport across challenging terrain, providing rigid protection and multiple carrying options. They're built for extended transport scenarios where environmental hazards and rough terrain are major concerns.

Scoop stretchers prioritize spinal immobilization and rapid patient loading without log-rolling. They split lengthwise to slide under patients with minimal movement but lack protective shells and rugged transport capabilities.

Smart teams often use both systems in sequence - scoop stretchers for initial patient packaging, then basket stretchers for transport across difficult terrain. For emergency stretcher selection strategies, check out More info about comparing emergency stretcher options.

Specialty Add-Ons & Accessories

Lifting bridles are essential for safe operations, distributing load forces across multiple attachment points with forged steel O-rings rated to CSA standards. Four-point bridle systems are gold standard for helicopter and high-angle operations.

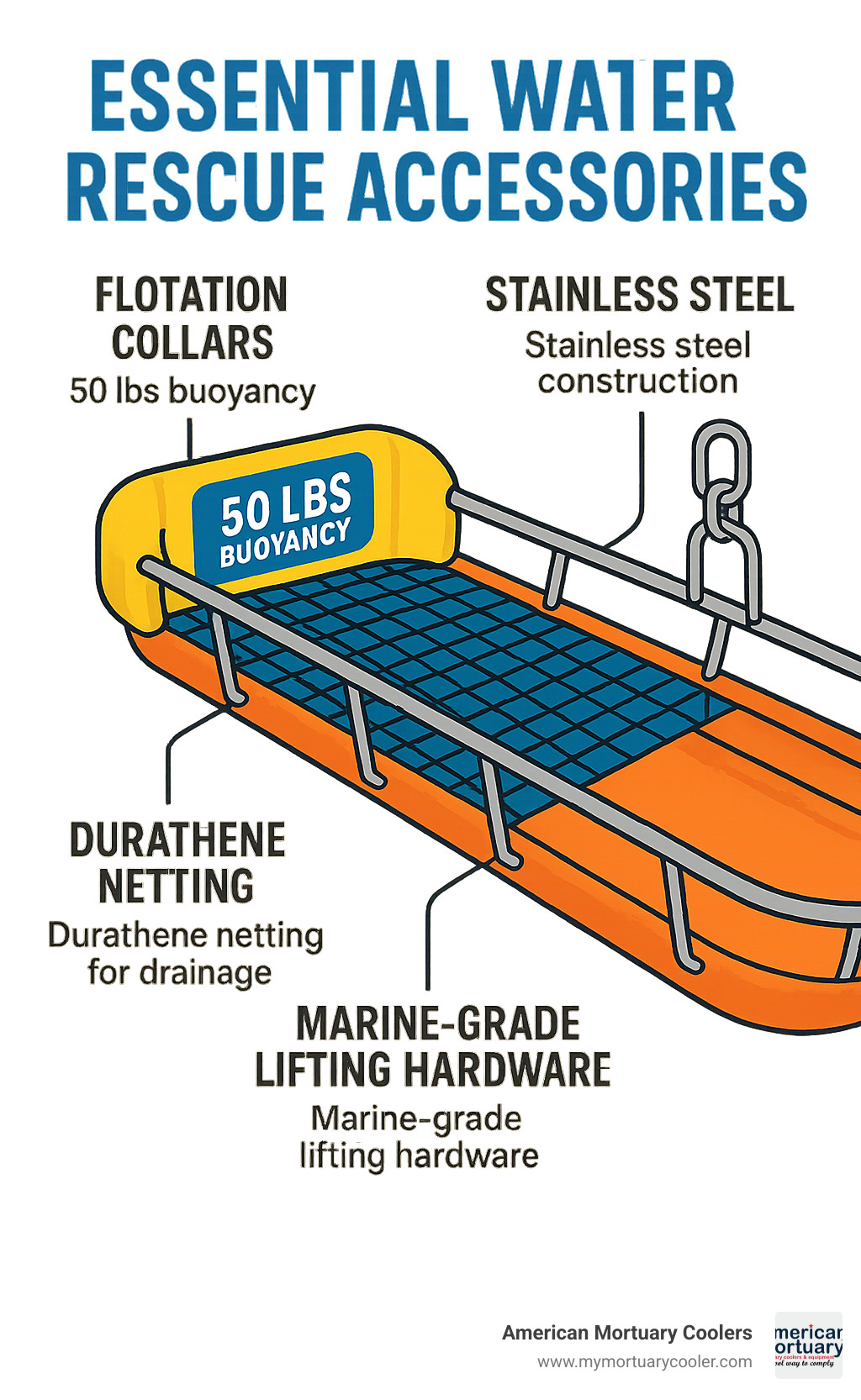

Flotation collars attach to outer rails providing approximately 50 lbs buoyancy for water rescues, supporting victims up to 900 lbs in water scenarios.

Patient comfort systems include vinyl-covered foam mattresses and spring-suspended support systems minimizing shock during rough terrain transport. Patient restraint systems keep everyone secure with quick-release straps, full-body harnesses, and head immobilizers.

Comparing Basket Stretchers to Other Rescue Stretchers

Basket stretchers offer versatility that other stretcher types can't match. Pole stretchers require multiple carriers and leave patients exposed. Spine boards excel at immobilization but become liabilities for transport over rough ground. Stair chairs need smooth surfaces and only work for upright transport. Wheeled stretchers are useless in sand, mud, or rocky terrain.

Basket stretchers shine with their versatility - you can drag, carry, lift, or hoist them. The rigid shell protects patients from environmental hazards.

| Stretcher Type | Terrain Versatility | Patient Protection | Lifting Capability | Weather Resistance |

|---|---|---|---|---|

| Basket Stretchers | Excellent | Excellent | Excellent | Excellent |

| Scoop Stretchers | Good | Fair | Good | Good |

| Pole Stretchers | Fair | Poor | Fair | Poor |

| Wheeled Stretchers | Poor | Fair | Poor | Fair |

Advantages in Rugged, Water & Industrial Environments

Basket stretchers prove their worth in tough conditions. In snow and ice, smooth bottom runners turn stretchers into sleds. The Durathene netting design lets water flow through while keeping patients secure. Add flotation collars for patient transport systems that double as life rafts.

Confined spaces benefit from the protective shell keeping patients safe from debris and hazards. Industrial sites with chemicals and extreme temperatures favor stainless steel and titanium models that resist corrosion.

High-angle rescues demand equipment with multiple attachment points and 2,500 lb load ratings providing necessary safety margins. For specialized training, check out rescue training courses.

Securing Patients in Basket Stretchers-

The shoelace lacing method using 35-foot tubular webbing is the gold standard. Start with a girth hitch at the foot end, split webbing to both sides, then work up the patient wrapping around side rails in crisscross pattern. This distributes pressure evenly while providing multiple contact points with the stretcher frame.

Quick-release straps allow rapid patient release in emergencies but never rely on them alone for vertical lifts. Always supplement with webbing techniques providing redundant securing points. Two experienced rescuers can complete full lacing in under three minutes.

How to Use, Maintain & Clean Basket Stretchers-

Proper maintenance ensures your basket stretchers are ready when lives depend on them. Inspection should be routine before every deployment. Check all welds, joints, and connection points for cracks or rough spots. Examine grommets and runners for sharp edges that could injure patients or rescuers.

Corrosion is the silent enemy, especially near salt water or industrial environments. Look for rust, pitting, or discoloration, particularly at weld joints where corrosion often starts.

Cleaning starts with soap and water to remove debris and contaminants. For disinfecting, use manufacturer-recommended chemicals - some can weaken materials or compromise structural integrity. Storage covers protect against UV rays, moisture, and debris. Store in dry, well-ventilated areas without heavy equipment stacked on top.

For comprehensive stretcher care guidance, check out More info about Stretcher 101 guide.

Safety Best Practices

Load limits aren't suggestions - they're the difference between successful rescue and catastrophic failure. Those 900-2,500 lb ratings assume perfect conditions, but age, wear, and harsh environments can reduce actual capacity.

Team communication prevents disasters. Establish who's calling shots and what verbal commands mean before lifting. PPE provides necessary grip and stability when conditions are wet and slippery. Training drills should feel routine - practice until procedures become muscle memory.

Routine & Annual Maintenance Schedule

Pre-use checklists catch problems before they become disasters. Document everything - small scratches today might be stress fractures tomorrow. Post-incident cleaning removes contaminants while providing close inspection of equipment condition.

Record keeping tracks equipment life and usage patterns. Annual professional inspections by qualified technicians spot wear patterns and potential failures not obvious during routine checks.

Buying Guide: Choosing the Right Basket Stretcher

Choosing the right basket stretcher starts with your mission profile. Wilderness rescues across rocky terrain, marine environments with saltwater corrosion, or industrial sites with tight spaces and chemical hazards each demand different features.

Budget range varies significantly. Basic steel models start around $900, while premium titanium versions can exceed $3,900. Factor in accessories like lifting bridles, flotation systems, and patient restraints that can double initial costs.

Weight capacity depends on typical patients and equipment carried. Most basket stretchers handle 900 lbs for standard rescues, but industrial scenarios or bariatric patients might require 2,500 lb rated systems.

Patient comfort becomes crucial for long transports. Spring-suspended support systems and quality mattresses make significant differences in patient stability and comfort.

Top Questions to Ask Vendors

Warranty coverage should be your first question - not just duration, but what's actually covered. Accessory bundles can save money compared to separate purchases. Replacement parts availability separates serious manufacturers from fly-by-night operations. Training availability from manufacturers dramatically improves team effectiveness and safety.

Budgeting & Cost Factors

Material premiums reflect real performance differences. Titanium costs more than steel, but weight savings become essential for helicopter operations. Accessory packages can represent half your total system cost. Shipping costs for bulky, heavy items often require freight shipping. Bulk discounts often apply for department purchases or multi-unit orders.

Frequently Asked Questions About Basket Stretchers

How much weight can a standard basket stretcher hold?

Most basket stretchers handle between 900 to 1,500 pounds of static load. The Traverse Rescue Gazelle Series is tested beyond its 900-pound threshold (408 kilograms). The Titan-Ti model handles up to 1,134 kilograms (2,500 pounds). Always stick to manufacturer specifications and never exceed rated capacity, as environmental factors can reduce safe capacity.

Can basket stretchers be used for helicopter hoists?

Absolutely! Basket stretchers are designed for helicopter operations with proper lifting bridles - specifically four-point bridle systems spreading load across multiple attachment points. Models like the Titan series are traverse-rated for helicopter hoisting. Lighter titanium versions are popular with flight crews for improved aircraft performance and fuel efficiency.

What accessories are essential for water rescue?

Water rescue requires specific gear. Flotation collars attaching to outer rails provide around 50 pounds buoyancy supporting victims up to 900 pounds. Stainless steel or titanium construction resists saltwater corrosion. Durathene netting allows water drainage instead of creating bathtub effects. You'll also need marine-grade lifting bridles, waterproof patient restraints, and quick-drain mattresses.

Conclusion

When rescue teams face impossible terrain and lives hang in the balance, basket stretchers stand as the unsung heroes of emergency response. From windswept mountain peaks to industrial accident sites, these remarkable tools have evolved from simple World War II wooden frames into sophisticated rescue systems that literally carry hope across the most challenging landscapes.

Modern basket stretchers aren't just tools; they're lifelines engineered with scientific precision. Whether you need steel for budget-conscious operations, stainless steel for marine environments, titanium for helicopter hoisting, or HDPE shells for chemical resistance, there's a solution for your specific rescue challenges.

Here at American Mortuary Coolers, we've witnessed how quality equipment makes the difference between success and tragedy. Our work across Tennessee, Atlanta, Chicago, Columbia, Dallas, Los Angeles, New York, Pittsburgh, and throughout every region of the country has taught us that when seconds count, you need equipment you can trust absolutely.

The investment in professional-grade basket stretchers goes beyond initial purchase price. It's an investment in safety of both patients and rescue teams, in confidence that your equipment won't fail when everything depends on it. Training matters just as much as equipment - the best basket stretcher won't save lives if teams don't know proper usage, maintenance, and load limits.

For those ready to take the next step in emergency preparedness, our comprehensive More info about choosing EMS stretchers resource provides detailed guidance on selecting the right equipment for your specific needs. Because being prepared isn't just about having the right tools - it's about having the right tools, training, and mindset to bring everyone home safely.