Understanding the Essential Role of Body Bags in Modern Mortuary Operations

A body-bag- is a non-porous, sealable container designed to safely store and transport human remains while preventing fluid leakage and containing odors. These essential tools serve multiple purposes across healthcare, emergency response, and funeral service industries.

Key Body Bag Facts:

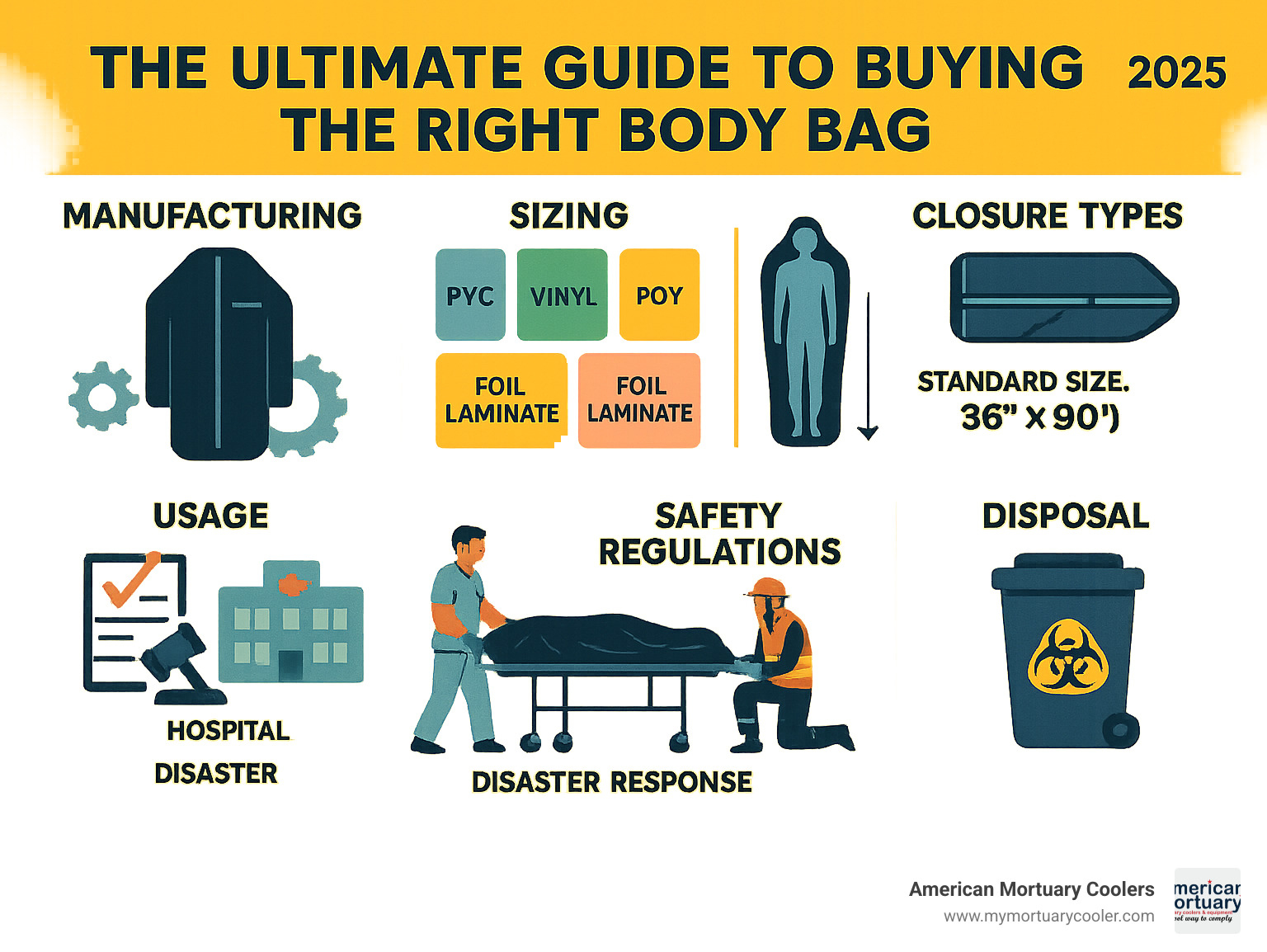

- Standard Size: 36" x 90" (91 cm x 229 cm) for adults

- Weight Capacity: 200-750 pounds depending on construction

- Materials: PVC, vinyl, polyethylene, or specialized foil laminates

- Thickness: 4-16 mil, with 16 mil being heavy-duty standard

- Closure Types: Center zipper, envelope zipper, or heat-sealed

- Colors: White, black, blue, red, yellow, and gray options

- Cost Range: $32-$86 for standard heavy-duty models

Body bags create an environmental barrier that protects both the deceased and those handling remains. They prevent contamination, preserve evidence in forensic cases, and maintain dignity during transport. Modern designs have evolved far beyond the cotton mattress covers used in World War II - today's plastic construction offers superior leak protection and durability.

Whether you're managing a hospital morgue, responding to mass casualties, or operating a funeral home, selecting the right body bag involves understanding materials, load capacities, closure systems, and regulatory requirements. The stakes are high - the wrong choice can lead to leaks, tears, or compliance issues during critical moments.

As American Mortuary Coolers with extensive experience as a national mortuary cooler supplier, we've worked closely with funeral directors and healthcare facilities to understand their body-bag- requirements alongside proper refrigeration storage solutions. This guide will help you steer the complex specifications and find the right containment solution for your specific needs.

Body-bag- vocab explained:

History and Evolution of Body Bags

The story of the body-bag- begins in one of America's darkest hours. During the Civil War, Dr. Thomas Holmes witnessed too many fallen soldiers being transported without dignity or proper containment. His solution? The first documented body bag patent, filed on July 21, 1863 - U.S. Patent No. 39,291. This wasn't just an invention; it was an act of compassion that laid the foundation for how we respectfully handle human remains today.

For decades after Dr. Holmes' innovation, military forces made do with whatever they could find. During World War II, cotton mattress covers became the standard makeshift solution. While these served a purpose, they had serious problems - they soaked up fluids like a sponge, were nearly impossible to clean properly, and offered little protection against contamination. Imagine trying to maintain dignity and safety with what was essentially a bedsheet.

The Vietnam War brought us "transfer tubes" - a step up from mattress covers, but still far from ideal. These early designs taught us valuable lessons about what didn't work, paving the way for the breakthrough that would change everything.

The PVC revolution of the 1970s transformed body bag design completely. Suddenly, we had containers that actually contained - no more fluid leakage, no more absorption issues, and dramatically better tear resistance. This wasn't just an improvement; it was a complete game-changer for hospitals, morgues, and emergency responders worldwide.

During the Cold War's tense years, governments began stockpiling millions of body bags in disaster stockpiles, preparing for worst-case scenarios. This massive demand drove manufacturers to standardize designs and improve quality across the board. The development of white forensic bags emerged from this era too - investigators finded that the light color made it much easier to spot evidence that might otherwise be missed against darker materials.

Milestones From 1863 Patent to COVID-19 Response

Several key moments shaped the modern body-bag- into what we know today, each driven by real-world challenges that demanded better solutions.

Dr. Thomas Holmes' 1863 breakthrough established that fallen soldiers deserved better than being wrapped in whatever fabric was available. His patent created the template for dedicated human remains containment that we still follow today.

The 1982 Falklands War proved these containers could handle extreme conditions. British forces used body bags for temporary burials in harsh South Atlantic weather, then successfully exhumed remains months later for proper burial back home. This demonstrated durability that went far beyond anyone's expectations.

When Ebola outbreaks struck West Africa between 2014-2016, the stakes couldn't have been higher. The crisis drove rapid development of triple-layer containment systems with heat-sealed barriers, establishing new gold standards for infectious disease response that protect both the deceased and the living.

Military forces in Iraq and Afghanistan finded an unexpected use - repurposed supply drops. Body bags proved so durable that they became reliable containers for air-dropping supplies under 100 pounds to remote locations. Talk about versatility testing in the field.

The COVID-19 pandemic created unprecedented global demand, pushing manufacturers to innovate faster than ever before. Heat-sealed, hermetically sealed bags became the new standard, ensuring that infectious disease containment meets the highest possible safety requirements.

Each of these milestones taught us something crucial about what works, what doesn't, and what's possible when human dignity meets practical engineering.

Key Specifications to Compare When Buying a body-bag-

Shopping for a body-bag- might seem straightforward, but the devil's in the details. The wrong choice can lead to catastrophic failures at the worst possible moments - imagine a bag tearing during transport or leaking in a hospital corridor. That's why understanding key specifications isn't just helpful, it's essential.

The most critical factors that separate professional-grade bags from basic options include material composition, thickness ratings, and weight capacity. These three elements work together to determine whether your bag will perform reliably under pressure.

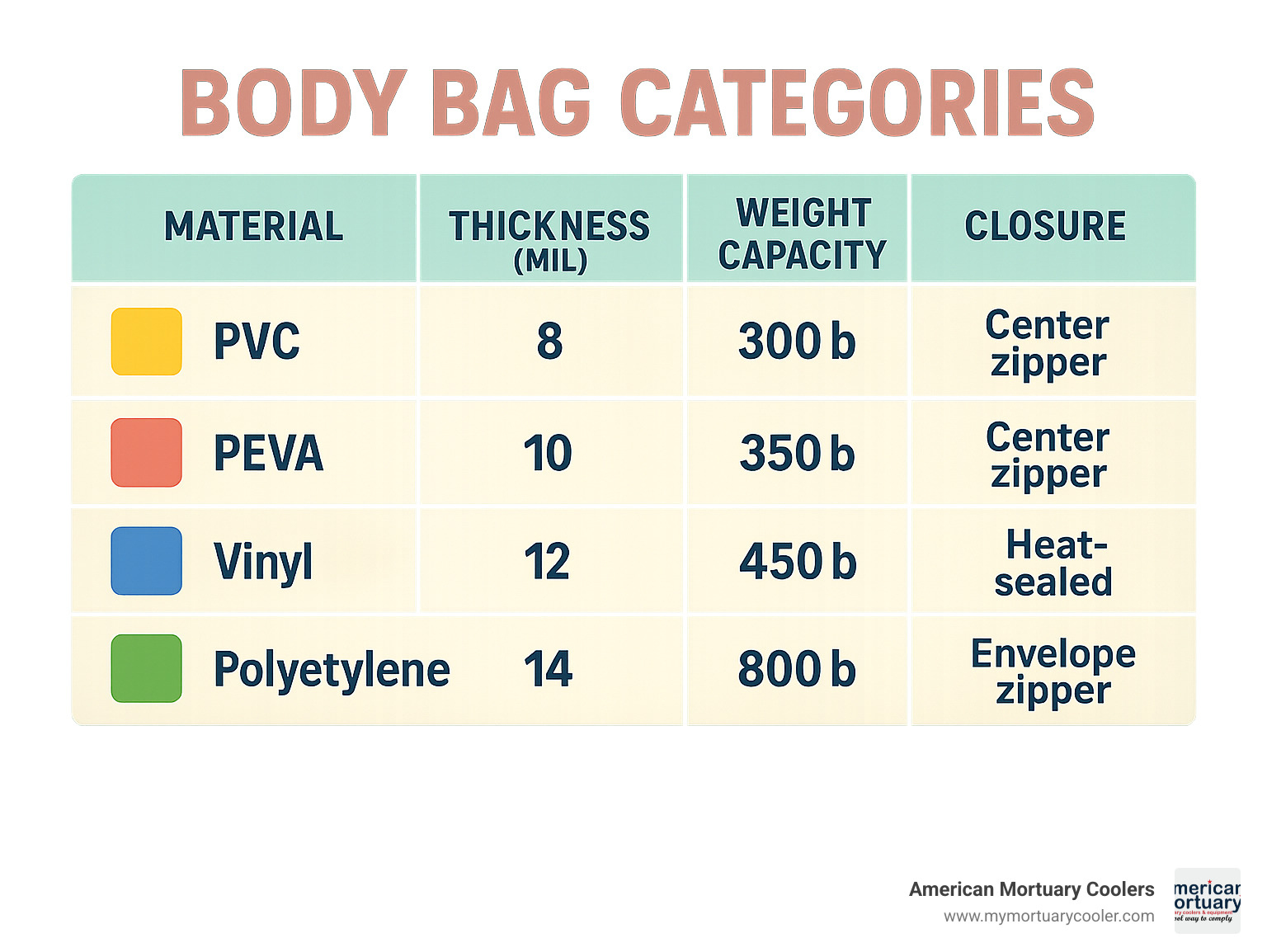

Thickness gets measured in mils (thousandths of an inch), and this number tells you everything about durability. A 4-mil bag might work for temporary storage, but disaster response teams rely on 16-mil construction for good reason. Dimensions matter too - standard adult sizing runs 36" x 90", but you'll need bariatric options for larger individuals.

The closure system can make or break your operation. Center zippers offer simplicity, while envelope designs provide better security. Heat-sealed options eliminate zippers entirely, creating hermetic containment that's becoming the gold standard for infectious disease protocols.

Handle configuration directly impacts safety during transport. Six handles allow three-person lifting, but heavy-duty applications often require eight to twelve handles for proper weight distribution. Each handle should support at least 200 pounds when the load is properly balanced.

Choosing the Right body-bag- Material

Material selection isn't just about cost - it's about matching the right plastic to your specific needs. After working with countless funeral homes and medical facilities, we've seen how the wrong material choice can create serious problems down the line.

PVC (Polyvinyl Chloride) remains the industry workhorse for most applications. High-density virgin PVC delivers excellent tear resistance and guaranteed leak-proof performance when heat-sealed on all four sides. The downside? You can't cremate PVC bags due to toxic gas emissions, which limits end-of-life options.

PEVA (Polyethylene Vinyl Acetate) solves the cremation problem beautifully. This chlorine-free alternative offers comparable durability while being completely cremation-safe. More facilities are switching to PEVA as environmental concerns grow and sustainability becomes a priority.

Vinyl construction typically means vinyl-coated polyester or PVC-supported vinyl with scrim backing. This reinforced approach dramatically improves puncture resistance, making these bags ideal when you're dealing with difficult handling conditions or potential sharp objects.

Polyethylene bags provide basic containment at lower cost points. They work well for lighter applications or temporary storage, but don't expect the same durability as heavier-duty materials. Think of them as the economy option when budget constraints are tight.

Scrim reinforcement changes everything about bag performance. This fabric mesh layer between plastic sheets transforms tear resistance and handle strength. Disaster response teams swear by scrim-reinforced bags because they can handle rough treatment that would destroy standard construction.

Foil laminates represent the premium tier - three-layer constructions with metal foil barriers for maximum containment. These specialized materials allow X-ray imaging while maintaining hermetic sealing. They're compatible with both cremation and burial, making them incredibly versatile for forensic applications.

For deeper technical details on material properties, Types of Plastic Body Bags provides comprehensive comparisons.

Size, Load & Closure Options

Getting the size right seems obvious until you encounter your first oversized individual or need to handle pediatric cases. Standard adult sizing runs 36" x 90" to 38" x 94" with weight capacities between 200-400 pounds. This works for most situations, but "most" isn't always enough.

Pediatric options require completely different dimensions, typically around 24" x 48" for children and even smaller for infants. Some manufacturers offer preemie sizes for the smallest cases. Having the right size maintains dignity and prevents the unsettling appearance of oversized bags.

Bariatric sizing can reach 54" x 108" with weight capacities up to 750 pounds. These heavy-duty bags feature additional handles and reinforced construction because physics doesn't care about your regular procedures - more weight demands stronger materials and better weight distribution.

Closure systems create different trade-offs between convenience and security. Center zippers offer simplicity and speed but create a single point of failure. Envelope zippers use U-shaped or curved designs that provide more secure closure and easier loading access. Heat-sealed options eliminate zippers entirely, using handheld heat sealers to create maximum containment.

Thickness considerations directly impact performance expectations. 4-8 mil construction handles light-duty applications and temporary storage. 10-12 mil thickness covers standard hospital use and routine transport. 16 mil construction represents the heavy-duty standard for disaster response and extended storage. 18+ mil options provide maximum durability for extreme conditions where failure isn't an option.

Handling and Labeling a body-bag- Safely

Safe handling prevents injuries and maintains dignity during what's already a difficult situation. Modern body-bag- designs incorporate multiple safety features, but they only work when used properly.

Handle configurations vary based on intended use. Six handles provide standard adult bag lifting with three-person teams. Eight handles offer heavy-duty capability for larger remains or challenging terrain. Ten to twelve handles appear on disaster bags designed for maximum lifting capacity and load distribution.

Each handle should support at least 200 pounds when weight is properly distributed. Never exceed the bag's total rating, and always maintain horizontal lifting to avoid stressing handles or seams. Vertical lifting or dragging can cause catastrophic failures.

Identification systems have evolved far beyond simple toe tags. ID pockets use clear vinyl windows (typically 6" x 8") for identification cards that remain visible and protected. Barcode and RFID systems enable modern tracking for chain of custody requirements. Color coding provides instant visual identification - white for forensics, yellow for infectious disease, black for standard use.

Safety protocols protect both handlers and dignity. Always wear appropriate PPE when handling any body-bag-. Inspect bags for damage before use - small tears become big problems under stress. Never drag bags regardless of surface conditions. Document any damage or unusual circumstances according to your facility's procedures.

Proper preparation techniques, especially for specialized applications like underwater recovery, require specific training. Prepare a Body Bag | ucidiver offers detailed guidance for these challenging situations.

The bottom line? Specification details matter because failure isn't just inconvenient - it's unacceptable when dealing with human remains. Take time to match your requirements with the right combination of materials, sizing, and features.

Usage Contexts and Best Practices

Body-bag- applications span multiple industries, each with unique requirements and challenges. From hospital morgues to disaster zones, understanding these different contexts helps you make smarter purchasing decisions and follow proper protocols.

Hospitals & Morgues

Healthcare facilities face unique pressures when it comes to handling deceased patients. Speed, safety, and dignity all matter when families are grieving and hospital operations need to continue smoothly.

Rapid transfer is often the biggest priority in busy hospitals. Emergency departments and ICUs can't afford delays, so body-bag- selection needs to prioritize quick loading and secure closure. Standard PVC bags with envelope zippers work well here - they're easy to operate under pressure and provide reliable containment for transport to funeral homes or medical examiners.

Cooler storage compatibility matters more than many people realize. Through our years of installing mortuary coolers across the country, we've learned that bags with minimal air pockets store much more efficiently. They also maintain better temperature control, which is crucial for preservation and regulatory compliance.

Leak prevention protects both hospital staff and expensive equipment. Nobody wants to deal with contaminated floors or damaged transport equipment. Heat-sealed bags with 16 mil thickness provide excellent security against leaks during transport through hospital corridors and elevators.

Infection control follows standard precautions in most cases, but some situations require improved containment. PEVA bags offer a chlorine-free option that won't interfere with hospital disinfection protocols - a small detail that can prevent bigger headaches later.

For more information on proper storage duration and temperature management, see Body Refrigeration Explained: How Long is Too Long.

Military & Mass-Fatality Response

Military and disaster response applications push body-bag- designs to their limits. These environments demand maximum durability and functionality because failure isn't an option.

DoD disaster pouches meeting MIL-PRF-131K standards have proven themselves in extreme conditions worldwide. These government-specification bags feature reinforced construction that can handle rough treatment, extreme temperatures, and extended field deployment.

Multi-handle systems become essential when dealing with difficult terrain or coordinated operations. Bags with 8-12 handles allow multiple personnel to lift safely and efficiently. Each handle must support at least 200 pounds when weight is properly distributed - a critical safety requirement when working in challenging conditions.

Color coding systems help maintain organization during chaotic situations. Military operations typically use black for standard cases, white when forensic evidence is involved, and yellow for infectious disease situations. Simple visual cues prevent costly mistakes when everyone is working under pressure.

Temporary burial protocols sometimes require body bags to maintain integrity during extended ground storage. This is particularly challenging because the bags must withstand soil conditions, moisture, and temperature variations while preserving remains for later exhumation and proper burial.

Field deployment conditions test every aspect of bag construction. Scrim-reinforced materials provide the durability needed when bags might be dragged across rough terrain, loaded onto helicopters, or stored in harsh environments for extended periods.

Infectious-Disease Containment

The COVID-19 pandemic reminded everyone how quickly infectious disease situations can escalate. Proper containment protects healthcare workers, families, and communities from exposure.

Triple-layer systems represent the gold standard for high-risk pathogens like Ebola. CDC-approved kits use three separate containment layers - an outer bag, heat-sealed middle barrier, and inner bag. This redundant system provides maximum protection for healthcare workers handling dangerous remains.

Heat-sealed barriers create hermetically sealed environments that eliminate the need for refrigeration. These specialized bags trap all gases and liquids inside, withstanding up to 4000 PSI pressure without failure. They're particularly valuable in remote locations where refrigeration isn't available.

BSL-4 rating represents Bio Safety Level 4 - the highest standard for infectious disease control. Body-bag- designs meeting this specification can safely contain the most dangerous pathogens known to medical science.

PPE requirements for personnel handling infectious remains are extensive and expensive. Smart bag design minimizes handling time and complexity, reducing exposure risk for everyone involved. Every second saved during containment procedures matters.

Transport compliance follows strict IATA guidelines for air transport of infectious remains. Approved bags must meet specific construction standards and labeling requirements - non-compliance can ground flights and delay critical operations.

For detailed guidance on infectious disease protocols, consult CDC Ebola Mortuary Guidance.

Regulations, Safety, and Environmental Considerations

When it comes to body-bag- selection and use, you're dealing with multiple regulatory frameworks that aren't just suggestions - they're legal requirements. Getting compliance wrong can shut down operations and put people at risk.

The regulatory landscape covers everything from worker safety to environmental protection. OSHA Regulation 3130 sets strict standards for occupational exposure to bloodborne pathogens, which directly impacts how you handle and store body bags. Meanwhile, CDC guidelines provide the roadmap for infectious disease protocols, especially after lessons learned during COVID-19 and Ebola outbreaks.

If you're transporting remains by air, IATA regulations become your bible. These international standards govern everything from packaging materials to labeling requirements. Miss these details, and your shipment gets rejected at the airport - not a conversation you want to have with grieving families.

Compliance & Standards Checklist

Military operations follow their own playbook with MIL-PRF-131K specifications. This military standard defines exactly what materials can be used in government-issued body bags. The testing is rigorous - bags must pass ASTM leak tests and meet specific material property requirements under extreme conditions.

State and local health departments add another layer of complexity. Each jurisdiction has its own rules about chain of custody documentation for forensic cases. Some states require specific labeling, while others mandate particular disposal methods. It's worth building relationships with your local health officials - they can save you headaches down the road.

Documentation requirements vary, but the basics remain consistent: proper identification and labeling, complete chain of custody forms for legal cases, and disposal tracking for infectious materials. We've seen facilities get cited for missing paperwork even when their actual handling procedures were perfect.

For a deeper dive into different containment options and their regulatory implications, check out Disaster Pouch vs Body Bags Explained.

Hygiene, Disposal & Environmental Impact

Here's something that surprises newcomers: body bags are strictly single-use. You might think heavy-duty bags could be cleaned and reused, but that creates unacceptable contamination risks and violates health regulations in most jurisdictions. Once used, proper disposal becomes the next challenge.

Incineration remains the most common disposal method because it completely destroys both biological material and the bag itself. Some facilities use autoclaving as a pre-treatment step, essentially sterilizing bags before final incineration. Landfill disposal is generally discouraged due to potential groundwater contamination concerns.

The environmental impact varies dramatically based on material choice. Traditional PVC bags release hydrochloric acid when incinerated, requiring specialized scrubbing equipment to meet air quality standards. That's why many facilities are switching to PEVA alternatives, which burn cleaner and don't release toxic gases.

Chlorine-free PEVA bags represent a significant environmental improvement. They provide the same leak protection and durability as PVC but incinerate without harmful emissions. The cost difference is minimal, but the environmental benefit is substantial.

Some manufacturers are experimenting with biodegradable films for specific applications, though these remain in pilot stages. Recycling programs exist for unused bags in some areas, but contaminated bags obviously can't be recycled.

The reality is that material selection directly impacts environmental compliance. Facilities with older incineration equipment may struggle with PVC emissions, while newer systems can handle various materials. Foil laminates require the most sophisticated incineration equipment but offer superior containment for infectious cases.

As mortuary equipment specialists, we've seen facilities face unexpected compliance issues when their bag choice didn't match their disposal capabilities. It's worth having that conversation with your waste management provider before making large purchases.

Innovations and Future Trends in body-bag Technology

The funeral industry is experiencing a quiet revolution in body-bag- technology. What started as simple containment has evolved into sophisticated systems that solve real-world problems for funeral directors, hospitals, and emergency responders.

These innovations aren't just about fancy gadgets - they're addressing genuine pain points we've heard about from our customers over the years. Long transport times without refrigeration, tracking challenges during mass casualties, and environmental concerns are all driving meaningful improvements.

Heat-Sealed & No-Refrigeration Models

The game-changer in modern body-bag- design is hermetic sealing technology. These aren't your grandfather's body bags - they create completely airtight containment that eliminates the need for refrigeration entirely. Once sealed, nothing gets in or out.

Foil-laminate construction represents the cutting edge of materials science. These three-layer systems include actual metal foil barriers sandwiched between protective layers. The result? Superior containment that still allows X-ray imaging when needed and remains safe for cremation.

We've seen these bags tested to 4000 PSI pressure resistance - that's enough to handle just about anything you can throw at them. This durability makes them perfect for air transport, rough handling during emergencies, and extended storage in challenging conditions.

The field deployment advantages are huge. No more worrying about generator failures or refrigeration logistics during disaster response. Military operations particularly benefit since they can store remains safely without the massive logistical headache of maintaining cold storage in remote locations.

Airport compliance has become much simpler too. These heat-sealed bags meet strict IATA guidelines for air transport of human remains. That means easier international repatriation and significant cost savings compared to traditional zinc-lined coffins.

For funeral directors evaluating these newer options, Step-by-Step Guide to Evaluating BioSeal Body Bags provides detailed criteria to consider.

Digital Tracking & Smart Identification

Technology is finally catching up to the funeral industry's tracking needs. RFID integration embedded directly in body-bag- construction enables automated tracking through facilities. No more clipboard errors or lost paperwork - the system knows exactly where each bag is located.

QR code systems offer an neat solution for smaller operations. These codes link directly to cloud databases containing comprehensive information about remains, chain of custody, and special handling instructions. Any smartphone can instantly access this information, making handoffs between facilities seamless.

Cloud database integration supports the most challenging scenarios - mass casualties and disaster victim identification efforts. Modern tracking systems maintain comprehensive records that multiple agencies can access simultaneously, dramatically improving coordination during emergencies.

Some forward-thinking facilities are exploring blockchain applications for truly immutable chain of custody records. While still emerging, this technology shows promise for legal proceedings where evidence integrity is paramount.

Temperature monitoring through smart tags provides another layer of quality assurance. These systems track temperature exposure during transport and storage, automatically flagging any deviations from proper handling protocols.

The combination of improved materials and smart tracking represents the future of mortuary operations - more reliable, more efficient, and ultimately more respectful of the families we serve.

Frequently Asked Questions about Body Bags

When it comes to body-bag- selection and use, we hear the same questions repeatedly from funeral directors and healthcare facilities across the country. After years of working with mortuary professionals, we've compiled the most common concerns and their practical answers.

How much weight can a standard body bag hold?

The weight capacity of a body-bag- varies significantly based on construction and intended use. Most standard adult bags handle 200-400 pounds comfortably, while heavy-duty models can support up to 750 pounds when properly handled.

Several factors determine actual weight capacity. Material thickness plays a huge role - those sturdy 16 mil bags will carry much more than thinner 8 mil versions. The handle configuration matters too, since more handles mean better weight distribution across the bag's structure.

Construction method makes a real difference in strength. Heat-sealed seams consistently outperform sewn seams when it comes to supporting heavy loads. If you're dealing with bariatric cases regularly, look for scrim-reinforced materials - that fabric mesh layer dramatically increases the bag's load capacity.

Here's the critical point: never exceed the manufacturer's rated capacity. We've seen bags fail catastrophically during transport when overloaded, creating dangerous situations for staff and compromising dignity for families. Always check those specifications before use.

Are body bags reusable or single-use?

This question comes up more often than you'd expect, but the answer is absolutely clear: body bags are strictly single-use items. There's no safe way to reuse them, period.

Contamination risk tops the list of concerns. Even after thorough cleaning, biological materials can harbor dangerous pathogens that standard disinfection can't eliminate. Health regulations mandate single-use specifically for infection control - it's not just a recommendation, it's the law in most jurisdictions.

Beyond safety concerns, used bags may have microscopic damage that compromises containment. A tiny puncture invisible to the naked eye can lead to leaks during the worst possible moment. From an ethical standpoint, reusing bags violates basic dignity standards for human remains.

After use, body bags must be incinerated or disposed of according to your local regulations. Yes, single-use means higher ongoing costs, but the expense is minimal compared to the catastrophic risks of reuse.

Can a body bag be cremated with the body inside?

Yes, but material selection is absolutely critical for safe cremation. This is where understanding your body-bag- composition really matters.

PEVA bags are the gold standard for cremation - they burn cleanly without releasing toxic emissions. Most modern crematories prefer PEVA specifically because it doesn't create harmful gases during the cremation process. Polyethylene bags are generally acceptable too, though you should always verify with your crematory operator.

Foil laminates represent the premium option, designed specifically for cremation compatibility while providing maximum containment during transport and storage.

Never use PVC bags for cremation. PVC releases hydrochloric acid and other dangerous gases that can damage crematory equipment and create safety hazards for operators. The same warning applies to vinyl bags containing PVC components.

If you're unsure about a bag's composition, don't guess. Contact the manufacturer or your crematory operator before proceeding. Most crematory professionals have specific requirements and can guide you toward appropriate materials for their equipment.

The bottom line: when in doubt, choose PEVA bags for cremation cases. They're designed for clean burning and won't create problems during the cremation process.

Conclusion

Choosing the right body-bag- isn't just about picking the cheapest option - it's about protecting dignity, ensuring safety, and meeting legal requirements when it matters most. After working with funeral homes and medical facilities across the country, we've seen how the right choice makes all the difference during difficult moments.

The perfect body bag for your facility depends on your specific needs. Hospital morgues typically need reliable PVC bags with envelope zippers for quick patient transfers. Disaster response teams require heavy-duty, multi-handle bags that can withstand rough conditions. Funeral homes often prefer PEVA bags that work with both burial and cremation. Military operations need bags meeting strict government specifications.

Your material choice affects everything from safety to environmental impact. PVC offers maximum durability but can't be cremated safely. PEVA provides the best balance - it's strong, leak-proof, and burns cleanly during cremation. Foil laminates work when you need hermetic sealing without refrigeration. Always verify your material is compatible with your final disposal method.

Weight capacity matters more than you might think. A 200-pound bag works fine for most situations, but bariatric cases need 750-pound ratings to prevent dangerous failures during transport. The extra cost is minimal compared to the safety risks and dignity issues if a bag fails.

Never compromise on safety basics. Always wear proper protective equipment, use enough people for lifting, and inspect bags before use. Body bags are single-use only - reusing them creates serious health risks and violates most regulations. When in doubt, choose a heavier-duty option rather than risking failure.

At American Mortuary Coolers, we've learned that proper body-bag- selection works best when paired with appropriate storage systems. Our custom mortuary coolers complement quality body bags to create complete deceased care solutions. Whether you're in Tennessee, Georgia, Illinois, or anywhere in the contiguous 48 states, we design refrigeration systems that work with your body bag protocols.

We serve funeral homes, hospitals, and medical facilities with direct delivery and ongoing support. Our decades of experience help facilities integrate proper storage with safe handling procedures. The right body bag protects everyone involved, but it's most effective when part of a complete system.

Quality matters when dignity and safety are on the line. Choose your body-bag- based on your specific needs, not just price. Handle every situation with respect and never cut corners on safety standards. For comprehensive guidance on selecting the right equipment for your facility, check out A Practical Guide to Buying Body Bags for Dead Bodies.

Remember - the families you serve deserve your best efforts, and your staff deserves to work safely. The right body bag helps you deliver both.