Why Lifting Tables Are Essential for Modern Material Handling

Lifting tables are mechanical devices that use scissor mechanisms to raise and lower heavy loads, providing ergonomic work positioning and reducing workplace injuries. These versatile platforms serve industries from manufacturing to mortuary operations, handling capacities from 200 pounds to over 10,000 pounds.

Quick Overview of Lifting Tables:

- Primary Function: Raise and lower materials to optimal working heights

- Common Types: Hydraulic, electric, pneumatic, and manual operation

- Weight Capacities: Range from 550 lbs (compact models) to 6,000+ lbs (industrial units)

- Key Benefits: Reduce back injuries, improve productivity, improve workplace safety

- Typical Applications: Assembly lines, warehousing, pallet handling, machine feeding

- Expected Lifespan: 10-20 years with proper maintenance

- Safety Standards: ANSI MH29.1:2012 (North America), EN 1570-1:2011 (Europe)

Research shows that lift tables significantly reduce musculoskeletal disorders by positioning work at ergonomic heights. Standard lift tables typically handle 2,000-6,000 pound loads with 24-60 inches of vertical travel, while compact models offer 440-1,100 pound capacities in space-saving designs.

Industries ranging from automotive manufacturing to funeral homes rely on lifting tables for safe material handling. Whether you need a portable cart for warehouse operations or a heavy-duty stationary unit for production work, choosing the right lifting table involves matching capacity, platform size, and power source to your specific application.

I'm Mortuary Cooler, a national supplier of mortuary equipment with extensive experience helping funeral homes select the right lifting tables for their unique operational needs.

Related content about lifting tables:

How Do Lifting Tables Work?

Lifting tables use an ingenious scissor mechanism - two pairs of crossed arms that push outward against each other to create vertical lifting motion. When power is applied, these scissor legs extend smoothly, making heavy loads feel weightless.

Three main power sources drive these systems. Hydraulic cylinders use pressurized fluid for incredible force and control. Electric motors offer programmable positioning for precise height control. Pneumatic power uses compressed air, ideal for food processing where oil leaks could cause contamination.

Every lifting table has the same basic anatomy: a sturdy base frame, scissor legs that do the lifting, and a platform work surface. Safety isn't optional - ANSI MH29.1 sets North American standards while EN 1570 covers European requirements. Scientific research on workplace ergonomics shows proper lifting equipment can reduce musculoskeletal injuries by up to 40%.

What Is a Lifting Table?

A lifting table is a platform that moves up and down using scissor mechanisms, positioning materials at perfect working heights. The lift cycle travels from lowered position (typically 7-8 inches) to maximum height (24-60 inches depending on model). This vertical travel eliminates bending and reaching, creating ergonomic work zones.

Platforms range from compact 24" x 36" models for small parts to massive 48" x 96" surfaces handling full pallets. Materials vary from painted steel for general use to stainless steel for cleanroom applications.

Main Types of Lifting Tables

Hydraulic lifting tables dominate industrial settings with reliable power and smooth operation. Electric lifting tables provide precise positioning with programmable controls. Pneumatic systems use compressed air for contamination-free operation in food and pharmaceutical facilities. Manual lifting tables work via foot-pump or hand-crank for portable applications.

Design options include scissor configurations for stability, compact models for tight spaces, portable units with casters, and multi-stage systems for extreme heights.

Industries & Typical Applications for Lifting Tables

Manufacturing uses lifting tables for assembly work and component positioning. Warehousing operations rely on them for order picking and pallet handling. Mortuary operations benefit from ergonomic casket positioning that protects staff while maintaining dignity. Cleanroom environments require stainless steel construction for pharmaceutical and food processing. Outdoor dock operations need weather-resistant models for truck loading.

Key Benefits & Ergonomic Advantages of Lifting Tables

Lifting tables can slash back injuries by up to 50% while boosting productivity by 15-25%. The magic happens in the ergonomic sweet spot - that 28-36 inch height range where your body works most efficiently. Instead of bending and straining, workers position everything right where they need it.

Self-leveling models automatically adjust as you add or remove items, maintaining optimal work height. Tilt and rotate functions provide 360-degree access and angled positioning for complex tasks.

How Lifting Tables Improve Safety

Overload protection prevents operation beyond safe limits. Velocity fuses prevent sudden drops if hydraulic lines fail. Toe-guards protect feet from scissor mechanisms. Emergency stop buttons provide instant shutdown capability. Safety props lock platforms during maintenance.

Ergonomics vs Productivity

Better ergonomics speeds up work - tasks complete 20-30% faster when properly positioned. Fewer sick days from injuries mean consistent staffing. Cycle time improvements add significant productive hours over full shifts. Quality improves when workers aren't fighting fatigue and discomfort.

More info about mortuary lift ergonomics shows how proper positioning protects both staff and dignity of care.

The return on investment typically pays for itself within the first year through reduced workers' compensation claims and productivity gains.

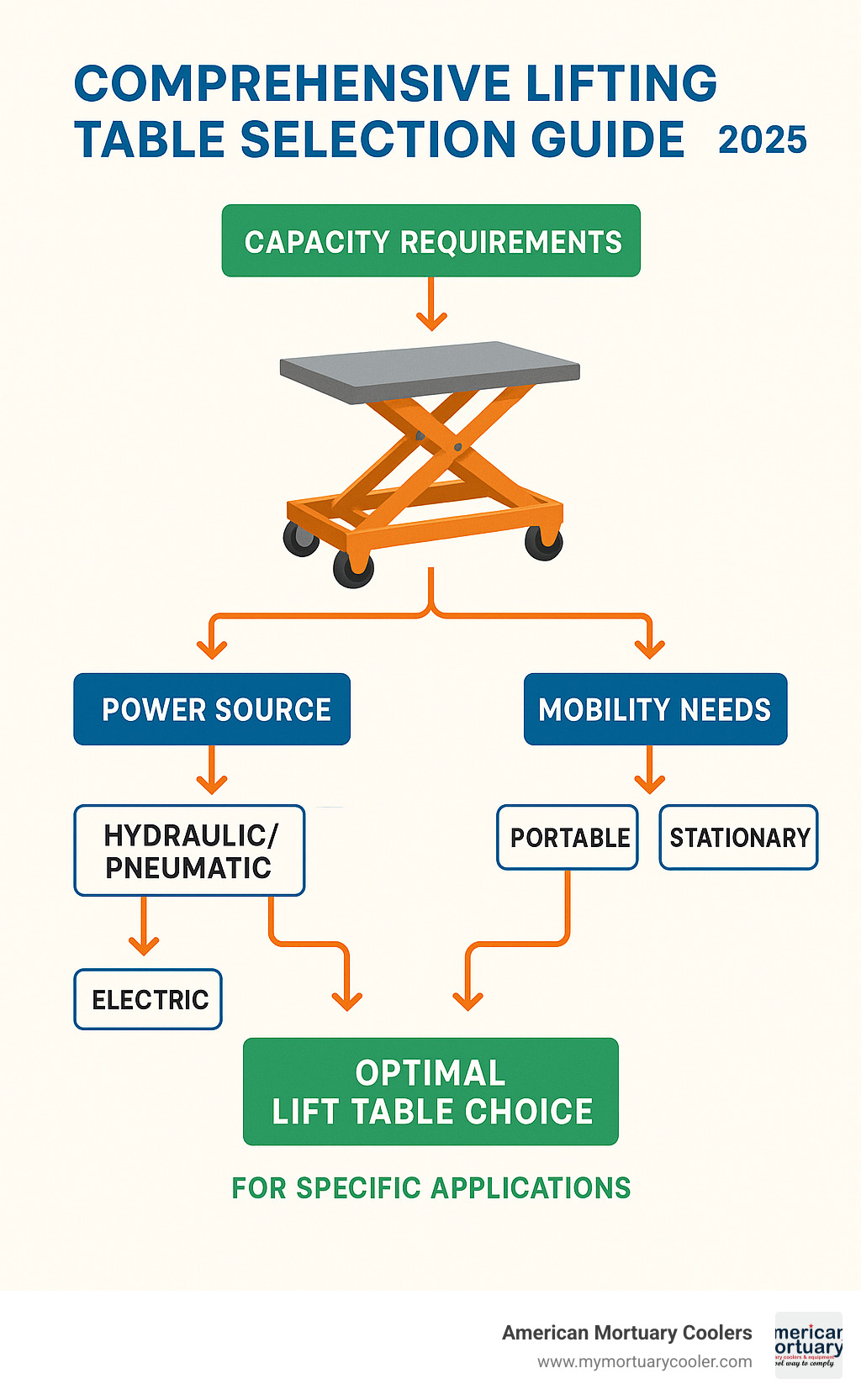

Selecting the Right Lifting Table for Your Needs

Finding the perfect lifting table requires considering weight requirements, space constraints, lift height needs, and power source options. Start with your heaviest load - this determines everything else about your selection.

Platform size should accommodate your largest items with breathing room. Lift height range should match the 28-36 inch ergonomic zone where people work most comfortably. Duty cycle - how often the table runs under load - affects which power system you'll need.

| Feature | Compact Lift Tables | Standard Lift Tables |

|---|---|---|

| Capacity | 440-1,100 lbs | 2,000-6,000 lbs |

| Platform Size | 24" x 36" typical | 36" x 48" to 48" x 96" |

| Lowered Height | 3-7 inches | 7-8 inches |

| Vertical Travel | 24-36 inches | 24-60 inches |

| Applications | Light assembly, parts handling | Heavy manufacturing, palletizing |

| Mobility | Often portable | Usually stationary |

| Power Options | Manual, electric | Hydraulic, electric-hydraulic |

Choosing by Capacity & Height

Lite-duty lifting tables handle 200-1,500 pounds for assembly work. Industrial-grade models manage 2,000-6,000 pounds for standard manufacturing. Heavy-duty systems lift 6,000+ pounds for automotive and steel operations. The stroke range determines working flexibility - standard models offer 24-60 inches of travel.

Compact vs Standard Lifting Tables

Low-profile lifting tables collapse to just 3 inches, allowing pallet jacks to roll over them. Pit-mounted installations integrate flush with floor level for maximum height while eliminating ramps.

Stationary vs Lift Table Carts

Mobile lift table carts add wheels and push handles for portable lifting power. Battery-powered versions eliminate cord constraints. Stationary installations provide maximum stability and capacity for repetitive operations.

Power Sources & Performance

Hydraulic pump systems deliver maximum power and reliability. Electric-hydraulic combinations add precise positioning. Pneumatic systems use compressed air for cleanroom applications. Manual options work via foot-pump for portable use. Battery-powered DC systems provide cordless operation with 8-12 hour runtime.

Safety, Compliance & Maintenance Essentials for Lifting Tables

Lifting tables handling thousands of pounds require proper safety measures and maintenance. Operator training covers loading procedures, weight distribution, emergency responses, and daily inspections. Many facilities require formal certification before operation.

Daily inspections check hydraulic fluid levels, test emergency stops, verify safety devices, and examine platforms for damage. Preventive maintenance includes weekly lubrication, monthly system checks, and annual professional service. Following this routine ensures 10-20 year lifespans.

Safety Requirements for Industrial Scissors Lifts spell out mandatory requirements for North American installations.

Mandatory Safety Features on Lifting Tables

Toe-guards prevent foot injuries from scissor mechanisms. Safety skirts block access to moving parts while maintaining visibility. Velocity fuses prevent uncontrolled drops if hydraulic lines fail. Limit switches prevent over-travel. Emergency stop buttons provide immediate shutdown. Safety bellows protect cylinders while keeping operators away from pressurized components.

Best Maintenance Practices

Weekly maintenance includes lubricating grease fittings, inspecting hydraulic lines, testing safety devices, and cleaning platforms. Annual professional service ensures safety compliance and catches wear components before failure. Smart operators maintain spare parts inventory for critical components. Properly maintained units achieve 10-20 year lifespans.

Using Lifting Tables in Specialized Environments

Outdoor installations need weather-resistant construction with sealed hydraulics and corrosion-resistant finishes. ATEX-certified models meet explosive atmosphere requirements. Cleanroom applications require stainless steel construction with sanitizable surfaces. Temperature extremes require special hydraulic fluids and seal materials.

Cost, Customization & ROI

Basic manual lifting tables start around $2,000, while heavy-duty electric-hydraulic systems exceed $15,000. Consider total cost of ownership including installation, energy consumption, maintenance, and replacement costs over the typical 10-20 year lifespan.

Many suppliers offer financing options and lease programs. Heavy-duty mortuary lifts justify premium costs through improved safety and efficiency.

Custom Accessories & Add-Ons

Tilt modules angle platforms 5-90 degrees for better access. Rotary tables provide 360-degree positioning. Integral scales weigh loads during lifting. Photocell controls automate height adjustments. Remote controls enable safe-distance operation. Accordion skirts provide full scissor mechanism enclosure.

Calculating Return on Investment

Labor savings from improved productivity typically pay for equipment within 12-24 months. Injury claim reductions can save thousands annually - a single back injury claim can exceed $50,000. Downtime reduction keeps production schedules on track. Throughput increases boost capacity without adding labor costs.

Expected Lifespan & Durability Factors

Steel grade and construction quality determine longevity. Cycle ratings indicate operational life expectations. Corrosion resistance from proper finishes extends equipment life. Maintenance history has the biggest impact - well-maintained units regularly exceed specifications by years.

Frequently Asked Questions about Lifting Tables

What certification is required to operate lifting tables?

You don't need a special license to operate lifting tables in most situations, but employers should provide proper training covering safety procedures, loading techniques, and emergency responses. OSHA requires adequate training for powered industrial equipment. Most facilities create internal training programs covering weight distribution, limits, and recognizing malfunctions.

Can lifting tables be used outdoors or in cleanrooms?

Yes, with the right models. Outdoor units need sealed hydraulic systems and corrosion-resistant finishes for weather protection. Cleanroom applications require stainless steel construction with sanitizable surfaces for food-grade and pharmaceutical use. ATEX-certified versions handle explosive atmospheres in chemical processing. Match equipment to your environment - standard indoor models fail quickly outdoors.

How often should lifting tables be inspected?

Daily visual checks for hydraulic leaks, platform damage, and safety device function take just minutes but catch most problems early. Weekly maintenance includes lubricating pivot points and testing emergency stops. Monthly inspections check fluid levels and structural components. Annual professional inspections ensure safety compliance and catch wear before failure. Well-maintained units operate safely for 10-20 years.

Conclusion

Lifting tables have become indispensable for modern material handling, adapting to virtually any situation requiring safe vertical movement. The key to maximizing your investment is matching capacity, platform size, lift height, power source, and environmental conditions to your actual needs.

Safety through ANSI and EN standards compliance, proper training, and regular maintenance ensures years of reliable service. With 10-20 year lifespans and measurable injury reductions, quality lifting equipment pays for itself through improved productivity and fewer compensation claims.

At American Mortuary Coolers, we've seen how the right lifting equipment transforms funeral home operations. Our Tennessee-based team understands mortuary work's unique challenges - from casket handling demands to preparation room sensitivity. Lifting tables designed for funeral service create safer workflows while respecting both staff and families.

Every funeral home has different needs, which is where custom solutions excel. Whether you need compact lifts for tight spaces or heavy-duty systems for oversized caskets, we design equipment fitting your specific requirements. Our direct delivery across the contiguous 48 states provides professional-grade equipment without vendor complications.

Ready to explore how lifting tables can improve your facility's safety and efficiency? More info about AMC product lineup shows our complete mortuary equipment range and custom solutions helping funeral homes nationwide work more safely and efficiently.

Contact us today - let's discuss your needs and how we can make your facility safer and more productive.