Why Roller Bed Technology is Revolutionizing Material Handling

A roller bed is a material handling system that uses a series of rollers installed in truck beds, trailers, or loading docks to allow heavy cargo to move smoothly with minimal manual effort. These systems dramatically reduce loading and unloading time while protecting both workers and equipment from injury and damage.

Quick Answer - Roller Bed Basics:

- What it is: Rolling floor system with multiple cylindrical rollers

- Main types: Permanent, drop-in, fold-up, and portable systems

- Key benefit: Single person can unload/reload in 10 minutes or less

- Primary users: Air cargo, trucking, military, postal service, mortuary operations

- Cost range: $150-$500+ depending on system type and customization

The challenge of moving heavy cargo efficiently has plagued industries for decades. Traditional loading methods often require multiple workers, create safety risks, and lead to damaged goods. Roller bed systems solve these problems by creating a low-friction surface that allows even heavy pallets and containers to glide smoothly.

According to KieTek's testing, their roller bed systems allow a single person to unload and reload a van in ten minutes or less - a dramatic improvement over conventional methods. The air cargo industry has been particularly demanding in testing these systems, with successful deployments across military branches including the Air National Guard, Marines, USPS, Army, and Air Force.

Industries from woodworking to mortuary operations are finding how roller beds reduce labor costs, prevent workplace injuries, and speed up operations. As American Mortuary Coolers, we've worked extensively with funeral homes to optimize their material handling processes, including the integration of roller bed systems for efficient transport of mortuary equipment and supplies.

Roller bed terms at a glance:

What You'll Learn

This comprehensive guide covers everything you need to know about roller bed systems. We'll explore the different types available, from permanent installations to portable solutions, and help you understand which option best fits your specific needs and budget.

You'll find the key components that make these systems work, learn about real-world applications across various industries, and get practical advice on installation and maintenance. Whether you're looking to improve efficiency in your mortuary operations, reduce labor costs, or make loading safer for your team, this guide will give you the knowledge to make an informed decision.

Understanding Roller Bed Technology

A roller bed transforms cargo handling by replacing friction with rolling motion. Think of pushing a heavy refrigerator across your kitchen floor versus rolling it on a dolly - that's essentially what a roller bed does for cargo handling.

Modern roller beds feature live floor technology that actively supports loads, gravity rollers that work without power, and specialized components like planks and cubes for custom loading solutions. The Step-Loc lock system uses foot-operated mechanisms to secure cargo at precise one-inch intervals without bending over.

The systems handle everything from standard warehouse pallets to specialized ULD pallets used in air cargo operations, with weight ratings from lightweight portable units handling hundreds of pounds to industrial installations supporting several tons.

How a Roller Bed Works

Each roller is a precision-engineered wheel mounted on high-quality bearings. When cargo is placed on top, weight spreads across multiple contact points, and rollers spin freely as you move the load.

Transfer boards serve as bridges between different systems. These heavy-duty polyethylene boards, typically 48" x 48", create smooth interfaces between roller systems and various cargo types, particularly useful with non-standard pallets or when connecting to ball decks.

The secret to smooth operation is perfect alignment. Every roller must be precisely parallel and level, which is why quality systems use side members that link multiple rollers together, maintaining perfect alignment even under heavy loads.

Main Components & Materials

Quality roller bed systems use carefully chosen materials. Rollers are typically crafted from aluminum or steel for optimal strength-to-weight balance. Bearings are usually sealed units designed to handle dust, moisture, and daily use.

Aluminum rails provide structural integrity while keeping weight manageable. Heavy-duty applications may use galvanized steel. HDPE boards serve as transfer surfaces, while steel rollers with precision bearings handle the heavy lifting. Many systems feature anti-skid coatings to keep cargo positioned during transport.

Main Types of Roller Bed Systems

Modern roller bed technology offers several distinct approaches, each designed to solve specific challenges. You can choose from permanent installations that become part of your vehicle, drop-in systems that move between trucks, or fold-up configurations that provide flexibility.

Permanent Roller Beds

Permanent roller bed installations are the heavy-duty workhorses of material handling. These systems become part of your trailer or truck bed, with every component precisely positioned and permanently secured.

The installation process involves cutting precise openings, installing mounting brackets, and securing roller assemblies with industrial-grade hardware. While requiring more upfront investment, the payoff is a system that handles maximum loads with minimal maintenance.

These permanent systems excel when dealing with the same cargo type repeatedly. Air cargo operations prefer them because they work perfectly with standardized containers and pallets, with optimal load distribution and smooth operation every time.

Drop-In / Portable Roller Beds

Drop-in roller bed systems offer maximum flexibility, installing quickly in any trailer or truck bed without permanent changes. The Portable Roller Bed System (PBS) uses individual sections that link together like building blocks to create full roller bed floors.

More info about portable systems

KieTek's drop-in systems use gates that lay flat on trailer floors and secure with spreader bars and nose pieces. When handling containers, the system is ready; for standard freight, components can be removed for a completely clear floor.

This flexibility makes drop-in systems ideal for mixed-use fleets or operations requiring frequent reconfiguration, with lower initial investment and ability to use equipment across multiple vehicles.

Fold-Up & Retrofit Options

Fold-up roller bed systems offer a brilliant compromise using hinged gates that fold up against trailer walls when not needed, providing maximum clear floor space for conventional loading.

When roller bed operation is needed, gates fold down to create the smooth rolling surface. This design has become popular for van conversions and mixed-use vehicles handling different load types.

Retrofit solutions like the RollBedder system use low-profile rollers placed on existing cargo floors with secondary Bi-Liner floors installed on top, adding roller bed functionality without major modifications.

Applications, Benefits & Real-World Performance

Roller bed systems have revolutionized material handling across unexpected industries. The air cargo industry pushed these systems to their limits first, earning deployments across the Air National Guard, Marines, USPS, Army, and Air Force.

Trucking companies found that roller beds could transform operations overnight. What used to require a crew of workers can now be handled by a single person, providing not just labor cost savings but scheduling flexibility.

Scientific research on material handling efficiency

In mortuary operations, we've seen how roller beds make a real difference. Moving heavy mortuary equipment used to be backbreaking work that put funeral home staff at risk. Now, equipment glides smoothly with minimal effort while protecting sensitive equipment during transport.

Key Benefits Over Traditional Methods

KieTek's testing shows that a single person can unload and reload a van in ten minutes or less using roller bed systems. Compare that to traditional methods requiring multiple workers and significantly more time.

Labor cost savings represent the most immediate benefit. When you reduce a three-person job to one person, the math is straightforward. Time savings compound throughout the day - extra minutes saved on each load add up to hours over a full shift.

Safety improvements might be the most important benefit. Back injuries from lifting heavy cargo are expensive and painful. Roller bed systems eliminate most heavy lifting, dramatically reducing injury risk.

Floor protection is often overlooked. Traditional loading methods damage truck beds through constant dragging. Roller beds distribute weight evenly and eliminate friction that causes floor damage, extending vehicle life.

Safety & Compliance Considerations

Load securement becomes critical with roller beds. The same low-friction surface that makes moving cargo effortless can allow loads to shift during transport if not properly secured. Cargo straps must secure freight firmly against fixed points.

M1 testing standards require roller bed systems to withstand pull tests of 10.5 tons, ensuring systems can handle forces during normal operation and meet commercial transportation requirements.

Proper training makes all the difference in safe operation. Operators need to understand correct loading techniques, securement procedures, and system limitations.

Installation, Maintenance & Customization

Getting your roller bed system installed properly makes the difference between smooth operations and constant headaches. Most installations are surprisingly straightforward, especially drop-in systems that don't require permanent vehicle modifications.

Basic hand tools, measuring tape, and a level handle most drop-in systems. Permanent installations might need cutting and drilling equipment. For portable systems, forklift access makes the job easier.

Modern roller bed technology is highly customizable. Manufacturers can create custom lengths and configurations to match your exact needs, whether for specific trailer dimensions or unique cargo like mortuary equipment.

Step-by-Step Installation

Measure everything twice before starting. Trailer dimensions need to be spot-on, and existing floor damage should be fixed beforehand.

For permanent installations, mark exactly where each roller goes, then cut precise openings. Mounting brackets are critical - even tiny misalignments cause problems later.

Drop-in systems are more forgiving. Position gates or modules on your floor and secure with provided hardware. Spreader bars and nose pieces maintain proper spacing and alignment.

Always test with actual cargo. Load something representative of your typical cargo and ensure everything works smoothly before putting the system into regular service.

Ongoing Maintenance Tips

Roller bed systems are low-maintenance compared to hydraulic alternatives. The bearings are your main concern since they do the heavy lifting. Keep them clean and check regularly for smooth operation.

Regular cleaning is your best maintenance practice. Dirt and debris are enemies of smooth operation. In harsh environments, more frequent cleaning pays dividends.

Lubrication needs vary by system. Some sealed bearing systems never need additional lubrication, while others benefit from periodic attention. Check manufacturer recommendations.

Keep spare parts on hand. Bearings, rollers, and mounting hardware are most likely to need replacement. Having them in stock means handling maintenance during scheduled downtime.

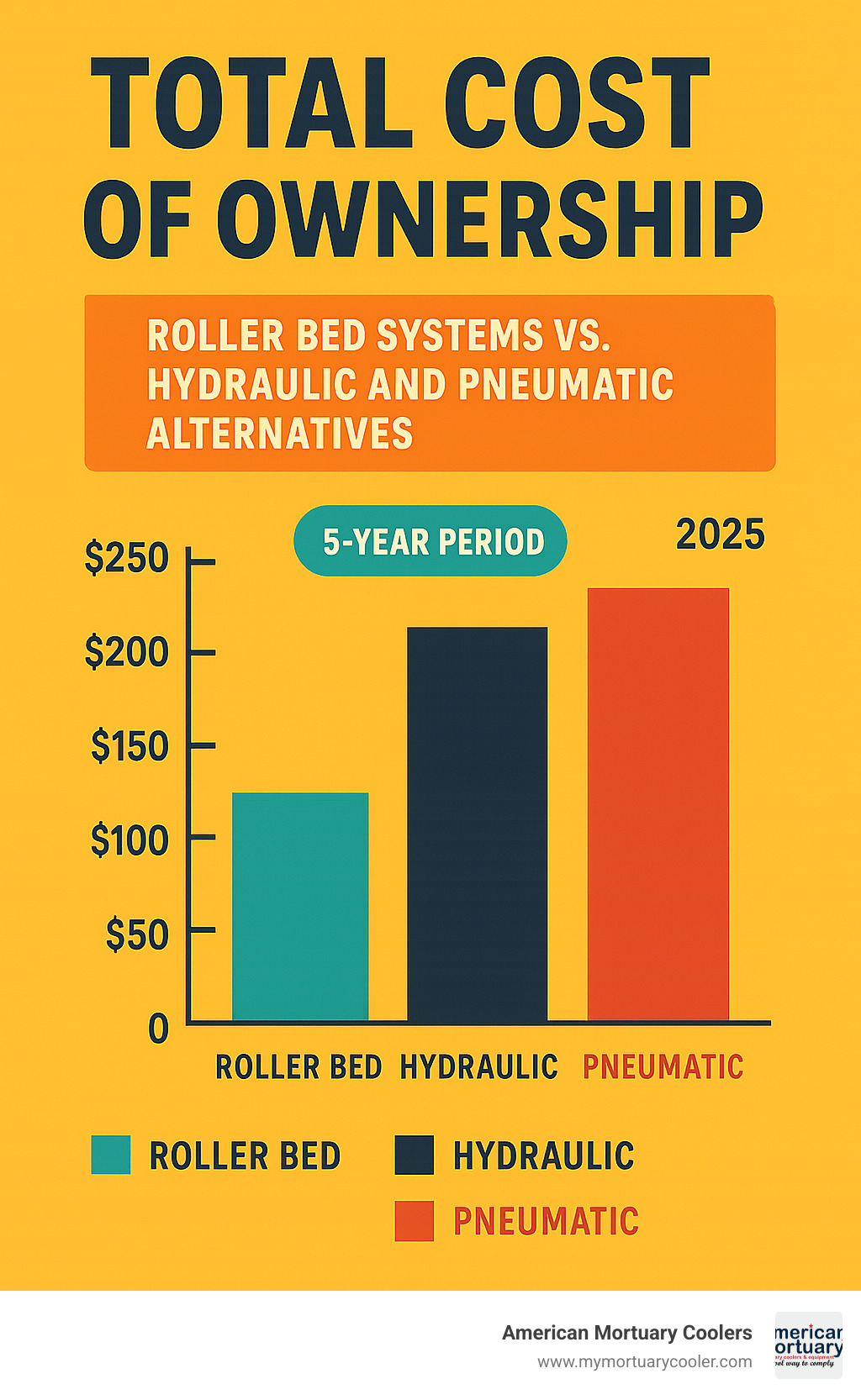

Calculating ROI & Cost of Ownership

Roller bed systems deliver impressive returns when factoring in all benefits. Labor cost savings alone often justify investment, but there's more to consider.

Labor cost reduction is usually the biggest factor. If your system lets one person handle what required two people, savings add up quickly. Don't forget indirect benefits like improved scheduling flexibility.

Time savings translate to money in most operations. Faster loading means vehicles spend more time generating revenue. For commercial operations, improved asset utilization significantly impacts bottom line.

Damage reduction adds real value. Roller beds are gentler on cargo and vehicle floors. Less damaged freight means fewer claims and happier customers. Less floor damage means lower vehicle maintenance costs.

Roller Beds vs. Alternative Material-Handling Solutions

When considering a roller bed system, it's worth understanding how it compares to other material handling options. Each technology has its place, but differences in cost, complexity, and performance can be significant.

Hydraulic conveyor systems are heavy-duty champions that can move extremely heavy loads with powered assistance. However, they need hydraulic pumps, cylinders, hoses, and control systems - all requiring expensive repairs. For funeral homes and smaller operations, complexity often outweighs benefits.

Pneumatic lifts and conveyors use compressed air and are generally more reliable than hydraulic systems. However, you still need air compressors, control systems, and regular maintenance. Operating costs add up quickly.

Belt conveyor systems work well for moving lots of small items but aren't ideal for mixed loads. For palletized loads or equipment varying in size and weight, they lack flexibility.

Simple alternatives like dollies and hand trucks are budget-friendly but require significant physical effort and don't eliminate manual handling safety risks.

Weight considerations matter more than expected. Hydraulic and pneumatic systems add substantial vehicle weight, reducing payload capacity. Roller bed systems are relatively lightweight while providing excellent load capacity, translating to fuel savings.

Cost comparisons reveal significant differences. While hydraulic systems might cost $15,000-30,000 installed, roller bed systems typically range from $3,000-8,000. Maintenance costs are even more dramatic - roller beds need occasional bearing replacement, while hydraulic systems require regular fluid changes and pump maintenance.

Flexibility is where roller beds shine. You can use them with pallets, containers, mortuary equipment, or loose cargo. Hydraulic systems are typically designed for specific cargo types. For funeral homes transporting everything from caskets to refrigeration equipment, this versatility is invaluable.

Frequently Asked Questions about Roller Bed Systems

When we talk with funeral directors and mortuary professionals about roller bed systems, we hear the same practical questions repeatedly.

What load capacities can a roller bed handle?

Roller bed systems range from basic units handling 500-1000 pounds to heavy-duty installations supporting several thousand pounds. The difference comes down to roller construction, bearing quality, and mounting system strength.

KieTek's systems are designed for standard air cargo loads using M1 testing, which requires systems to withstand 10.5-ton pull tests. There's a difference between what a system can hold stationary versus what it handles when moving cargo with acceleration and braking forces.

How do I secure cargo on a roller bed during transit?

The low-friction surface that makes a roller bed easy to load requires careful cargo securement during transport. Cargo straps are essential - use them to secure freight tightly against fixed points like rear doors or trailer walls.

Position straps to handle forces in both directions - preventing backward sliding during braking and forward movement during acceleration. Many modern roller bed systems include Step-Loc locking mechanisms with foot-operated locks that secure cargo at one-inch increments.

Can I retrofit my existing trailer or truck with a roller bed?

Absolutely. Drop-in systems require zero permanent modifications - just install them in any trailer with a decent floor. The RollBedder system uses low-profile rollers on existing floors with secondary surfaces on top.

For maximum performance, full retrofit installations involve cutting openings and installing mounting hardware. The Portable Roller Bed System (PBS) uses modular sections that convert regular trailers into partial or full roller beds.

For mortuary operations, we often recommend starting with drop-in systems to test the concept, then upgrading to permanent installations once you've seen the benefits.

Conclusion & Next Steps

After exploring roller bed technology, it's clear these systems offer game-changing solutions for heavy cargo handling. Whether moving mortuary equipment, handling air cargo, or managing palletized freight, the right roller bed system transforms operations from multi-person struggles into smooth, single-operator processes.

The beauty of roller bed systems lies in their simplicity and versatility. You don't need complex hydraulics or expensive pneumatic systems to achieve dramatic improvements in efficiency and safety.

At American Mortuary Coolers, we've seen how proper material handling solutions make real differences in funeral home operations. From our Tennessee headquarters, we've helped funeral directors across the country - whether in Atlanta with high-volume operations, Chicago facing tight schedules, Dallas managing large facilities, or Los Angeles handling specialized transport.

The key to success is honest evaluation of your specific situation. If you handle the same cargo daily, permanent installation serves best. For flexibility between cargo types, drop-in or fold-up systems might be perfect. For frequently changing operations, portable systems provide needed options.

Don't focus only on sticker prices. Real value comes from labor savings, reduced injuries, faster operations, and better cargo protection. These benefits often pay for premium systems quickly.

What matters most: Load capacity should match your heaviest regular cargo with safety margin. Installation flexibility becomes crucial for multiple vehicles. Maintenance requirements affect long-term satisfaction. Safety features like Step-Loc systems protect cargo and people.

The funeral industry has unique challenges we understand completely. Moving heavy mortuary equipment safely while maintaining dignity and efficiency requires the right tools. Roller bed systems have proven themselves in our industry, just as in military, postal, and commercial applications.

More info about our custom solutions

Ready for the next step? Our team understands material handling challenges inside and out. We can walk you through options, help calculate real ROI, and ensure you get a system that fits your operation.

The technology is proven, benefits are real, and options are more flexible than ever. Whether you choose simple drop-in systems or full permanent installations, you're looking at solutions that will make work easier, safer, and more profitable for years to come.