Elevating Workplace Efficiency with Modern Lifting Solutions

A battery powered lift table is a mobile hydraulic platform that uses rechargeable batteries to power a scissor mechanism for raising and lowering loads, eliminating the need for electrical cords or manual pumping.

What is a Battery Powered Lift Table?

- Definition: A self-contained hydraulic lifting platform powered by rechargeable batteries

- Capacity Range: 150 lbs to 6,000 lbs depending on model

- Lift Heights: Typically 18" to 63" vertical travel

- Battery Life: 7.5 to 22.5 hours per charge (depends on usage frequency)

- Key Benefit: Mobility without needing access to power outlets

In today's industrial environments, battery powered lift tables have become essential tools for enhancing workplace efficiency while prioritizing employee safety. These versatile platforms combine the convenience of cordless operation with the power of hydraulic lifting mechanisms, allowing workers to position heavy loads at ergonomically optimal heights without strain or injury risk.

Unlike their manual or plug-in counterparts, battery powered scissor lifts offer best mobility and can be deployed anywhere in your facility—even outdoors or in areas without convenient access to electrical outlets. With capacities ranging from lightweight 150-pound models ideal for trades work to heavy-duty 6,000-pound industrial workhorses, there's a solution for virtually every lifting challenge.

I'm Mortuary Cooler, a national-level mortuary equipment supplier with extensive experience implementing battery powered lift table solutions for funeral homes seeking to improve staff safety and operational efficiency. Having helped numerous facilities select the right lifting equipment for their specific needs, I understand how crucial reliable, mobile lifting capabilities are in sensitive environments.

Important battery powered lift table terms:

Why This Guide Matters

The market for ergonomic lifting equipment continues to grow as businesses increasingly recognize the impact of workplace injuries on both employee wellbeing and their bottom line. According to OSHA statistics, manual material handling is among the leading causes of workplace injuries, with back injuries accounting for nearly 20% of all workplace injuries and illnesses.

Battery powered lift tables directly address these concerns by eliminating the need for manual lifting and positioning of heavy objects. As demand grows, so does the variety of available models, making it increasingly important for buyers to understand the key differences between various options.

This comprehensive guide will help you steer the complex landscape of battery powered lift tables, ensuring you select the right equipment for your specific needs—whether you're operating a funeral home in Tennessee or a warehouse in California.

What Is a Battery Powered Lift Table & How It Works

Ever wondered how these incredible lifting machines work their magic? A battery powered lift table is basically a clever marriage of electrical and hydraulic systems that gives you safe, controlled lifting without the hassle of power cords or breaking your back with manual effort.

Here's the simple beauty of how it works: A rechargeable lead-acid battery (similar to what's in your car) powers a DC electric motor. This motor drives a hydraulic pump that pressurizes hydraulic fluid – typically ISO 32 oil – which then extends hydraulic cylinders connected to a scissor mechanism. As this scissor mechanism expands upward, your platform and whatever you're lifting rises smoothly. When it's time to come back down, a controlled release valve lets the hydraulic fluid return to its reservoir.

Most tables come with a handheld pendant featuring simple up/down buttons, though some fancier models offer foot pedals if you need to keep your hands free. The best part? Everything is self-contained within the base of the unit – no external power needed!

Scientific research on ergonomic lifting confirms what our funeral home clients already know – these systems dramatically reduce physical strain by letting you position loads at the perfect working height. No more bending, reaching, or twisting during those delicate handling moments.

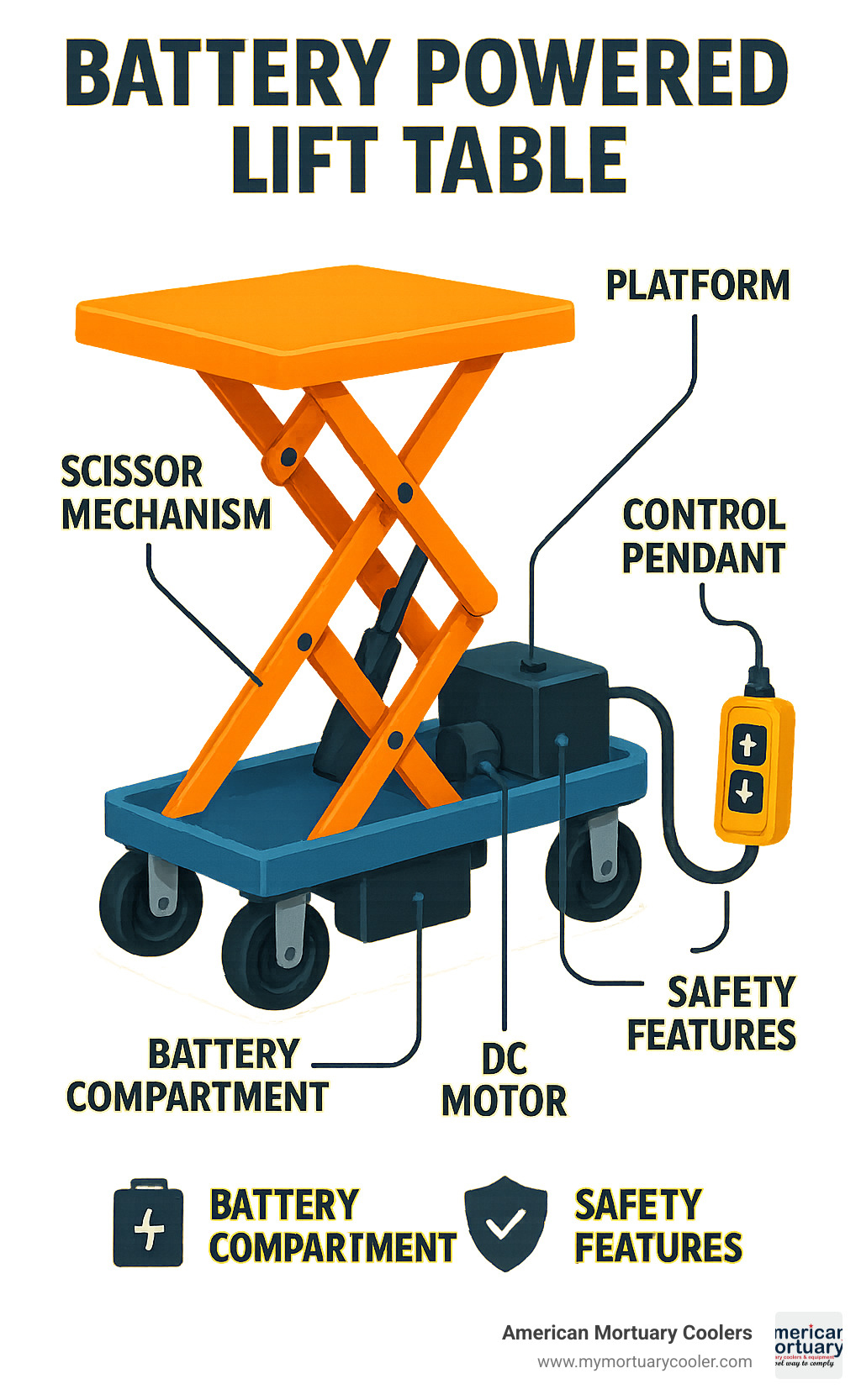

Core Components Explained

The heart of any battery powered lift table is its hydraulic system. Think of the pump as the heart, creating pressure that moves fluid through the system, while precision valves act as the brain, controlling flow direction and rate. This thoughtful design delivers smooth, controlled lifting even when you're handling heavier items like caskets or cremation equipment.

Every quality lift table includes an integrated safety relief valve – this is non-negotiable. This critical component prevents over-pressurization of the hydraulic system, ensuring the table can't be loaded beyond its rated capacity. In our business, where dignified handling is paramount, this safety feature prevents potential failures when you can least afford them.

The battery and charging system typically use sealed lead-acid batteries optimized for deep-cycle applications. These connect to an onboard charger that plugs into any standard 110V outlet when the table isn't being used – simple and convenient.

The electronic control system manages power flow from battery to motor, ensuring smooth operation while incorporating important safety features like emergency stop functions and overload protection. At American Mortuary Coolers, we know these safety features aren't just nice-to-haves – they're essential when handling precious cargo.

Battery Runtime & Lift Cycles

When selecting a battery powered lift table for your funeral home, understanding its operational capacity on a single charge is crucial. Based on our extensive experience, a typical fully-charged battery provides:

- About 7.5 hours with frequent use (lifting something every 5-6 minutes)

- Around 15 hours with moderate use (lifting every 11-12 minutes)

- Up to 22.5 hours with light use (lifting every 17-18 minutes)

When fully depleted, a complete recharge takes about 8 hours connected to a standard outlet – perfect for overnight charging so you're ready for the next day's services.

Understanding your daily needs is straightforward. If you're handling multiple services and need to perform 100 lift cycles in a day, a table that can handle 1 cycle every 5.72 minutes for 7.5 hours will give you about 78 cycles before needing a recharge. This means you'd need one quick recharge during the day to complete all your transfers.

We've found that most funeral homes fall into the moderate use category, making a single overnight charge sufficient for daily operations. However, for busier locations, we often recommend having a backup battery or scheduling a midday recharge during lunch breaks to ensure continuous availability.

Key Benefits Over Manual or Plug-In Models

When it comes to versatility and efficiency in material handling, battery powered lift tables simply outshine their manual and corded counterparts. These self-contained workhorses bring freedom to your workflow that other lifting solutions just can't match.

Ergonomic Advantages

The heart of any lift table's purpose is improving workplace ergonomics, but battery powered lift tables take this benefit to new heights—literally. Your team can maintain neutral posture throughout their shifts, a game-changer for long-term health. No more unnecessary bending, stretching, or awkward twisting when accessing materials.

Unlike manual models that require physical pumping, battery-powered units eliminate that extra effort, saving energy for the tasks that really matter. Plus, they allow for precise positioning at just the right height for each worker—tall or short, everyone benefits from a custom work position.

These ergonomic improvements aren't just comfortable—they're financially smart too. Workplace safety studies show proper lifting equipment can slash back injuries by up to 30%. That translates to significant savings in workers' compensation costs and keeps your team productive rather than sidelined with injuries.

Productivity & ROI

Yes, you'll invest more upfront for a battery powered lift table compared to manual options, but the return comes quickly and consistently. We've seen cycle times up to three times faster compared to manual pumping—that's a lot of saved minutes that add up throughout the day.

Think about the hassles of corded models: constantly managing cables, unplugging and replugging when repositioning, and limiting your workspace to areas with available outlets. Battery-powered units eliminate these headaches entirely. With proper rotation, you can even maintain multi-shift operations without charging downtime.

The productivity gains are substantial. One warehouse manager we partnered with reported a 12% reduction in average order time after implementing battery powered lift tables. Even more impressive? Their reported back strain incidents dropped by over 40%. Happier, healthier workers and faster operations—that's a win-win for any business.

Portability & Terrain Limits

The true freedom of going cord-free comes from unrestricted mobility, though it's worth understanding practical limitations. Most models handle inclines up to 4° when loaded (about a 7% grade), making them suitable for most workplace environments including gentle ramps and slightly uneven surfaces.

Premium models often feature run-flat tires that keep you moving reliably even after unexpected punctures. If you need to cover distance, some self-propelled models can travel at speeds up to 2.8 mph—not exactly highway speeds, but efficiently quick for indoor operations.

Safety remains paramount, of course. Always engage floor locks or brakes during lifting operations, especially on anything but perfectly flat surfaces. While one PowerPusher ET-105 user reported their unit "climbed a 40-degree ramp smoothly under load," we should note this exceeds manufacturer recommendations and should be approached with extreme caution.

At American Mortuary Coolers, we've seen how these mobility benefits make a particular difference in funeral homes, where discrete, dignified movement of heavy items between preparation rooms, viewing areas, and vehicles requires both power and flexibility—without unsightly cords trailing behind.

Specifications & Options: Comparing Top Brands & Models

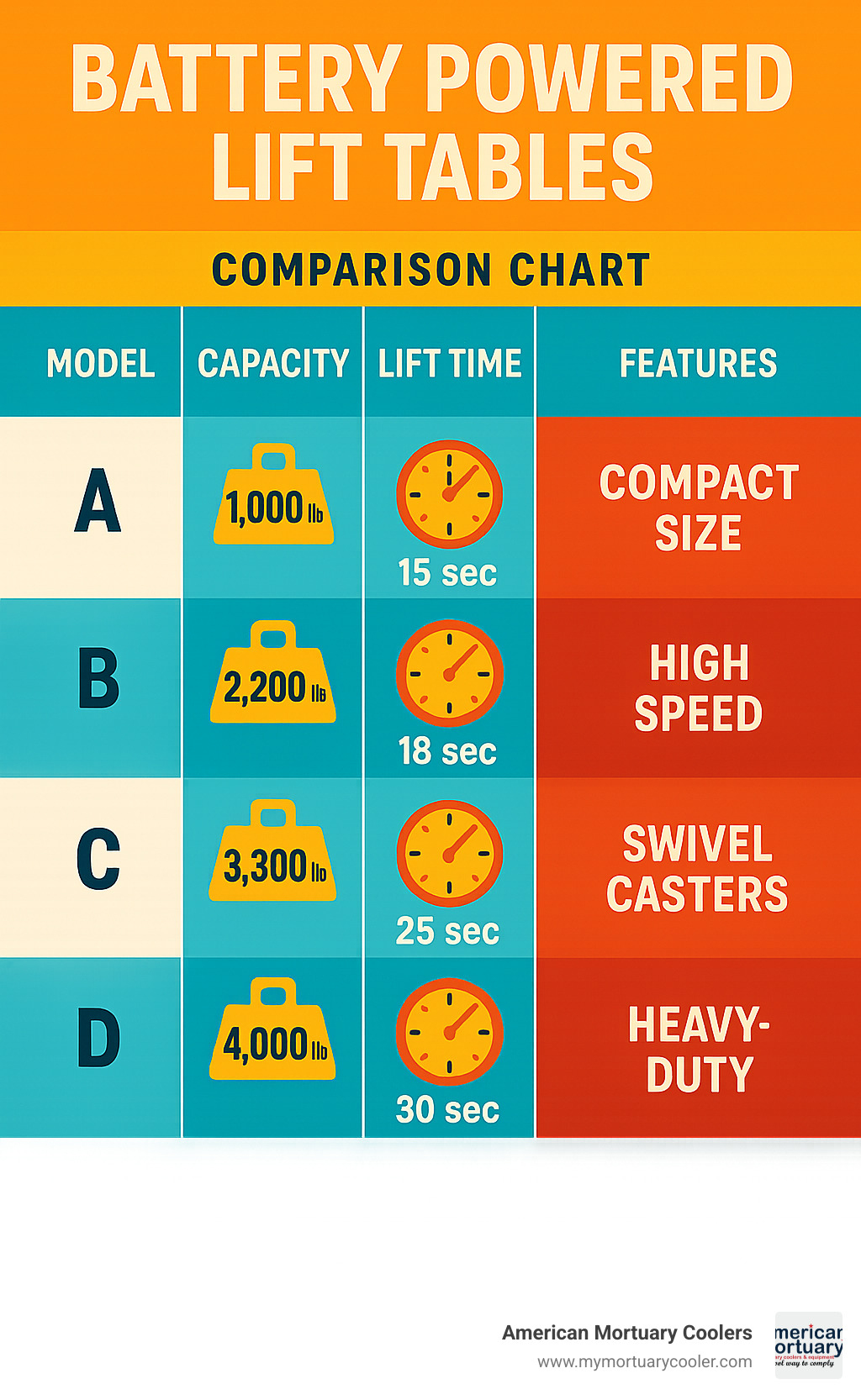

The world of battery powered lift tables is wonderfully diverse, with options ranging from compact units perfect for a single technician to industrial behemoths capable of hoisting thousands of pounds. Let's take a friendly tour through what's available on the market today.

Spotlight on Light-Duty Models

If you're looking for something nimble and portable, Airsled's LiftCart series might be just the ticket. These lightweight champions start at just $439.99 for the ASLC-150 with its 150-pound capacity. Need a bit more muscle? The ASLC-275 handles 275 pounds for $629.99, while the brawnier ASLC-400 can lift 400 pounds for $759.99.

These compact helpers have become favorites among tradespeople who need to position equipment without breaking their backs. I recently spoke with an appliance installer who called his LiftCart "a game-changer for wall oven installations." What used to require two people can now be handled solo—talk about working smarter, not harder!

Mid-Range Workhorses

Moving up to the middle weight class, we find versatile tables that handle the daily grind of warehouses and manufacturing floors with ease.

The Southworth Dandy Lift line has earned its stripes over more than three decades of reliable service. These sturdy tables offer capacities from 550 to 1,500 pounds while maintaining a surprisingly compact footprint—perfect when floor space is at a premium. Many users love the optional self-leveling platforms that automatically adjust as items are added or removed, keeping work at that perfect ergonomic height.

Meanwhile, the Vestil PST Series has built a loyal following with its practical approach to portable lifting. These workhorses deliver approximately one lift cycle every 5.72 minutes for 7.5 hours on a single charge—enough to handle a full shift's worth of lifting. Their open bearing design makes maintenance a breeze, and they use standard ISO 32 hydraulic fluid that's readily available when service time comes around. Just remember to keep them on relatively flat surfaces—the maximum safe incline is 4 degrees.

Heavy-Duty & Self-Propelled Units

When the going gets tough, these heavy-duty battery powered lift tables get going. For environments where the loads are serious and the work never stops, these industrial-strength options deliver impressive performance.

The PowerPusher ET-105 is something special—it's not just a lift table but a self-propelled workhorse that can travel at speeds up to 2.8 mph. With an 800-pound lift capacity and 1,100-pound drive capacity, it can reach impressive heights of 63 inches. The front-wheel transaxle drive offers variable speed control for precise positioning, while automatic brakes and emergency stop features keep things safe when the unexpected happens.

For truly massive loads, Wesco's Heavy-Duty Models (261106/261107) are the giants of the industry, handling up to 6,000 pounds with confidence. Their robust construction stands up to punishing industrial environments, and extended battery life means they can keep working through multiple shifts. These models come with comprehensive safety documentation, including the Hydraulic Oil SDS Sheet needed for workplace compliance.

At American Mortuary Coolers, we've seen how the right battery powered lift table can transform operations in funeral homes across Tennessee and beyond. The dignity of your work deserves equipment that's both powerful and reliable—something we understand deeply in our own custom solutions for the funeral industry.

Choosing the Right Battery Powered Lift Table: Buyer Checklist

Selecting the perfect battery powered lift table for your workplace isn't just about finding the strongest lift—it's about finding the right fit for your specific needs. I've helped countless businesses steer this decision, and I've learned that a thoughtful approach saves both money and headaches down the road.

Essential Factors to Consider

When evaluating options, always start with your load weight requirements. I recommend choosing a model with at least 20% more capacity than your heaviest anticipated load. This buffer gives you peace of mind and extends the life of your equipment.

Your lift height needs are equally important—consider both ends of the spectrum. A lower minimum height makes pallet jack access easier, while the maximum height should allow comfortable working without anyone having to reach or strain.

Think about your duty cycle realistically. Will your team use the lift once an hour or once a minute? More frequent use demands more robust battery capacity, faster charging systems, and more durable hydraulic components. One client initially underestimated their usage and found themselves with constant downtime until upgrading to a heavier-duty model.

Your floor surface plays a huge role in performance. Smooth concrete is ideal, but if you're working outdoors, you'll need pneumatic tires. Carpeted areas increase rolling resistance, and remember that most models limit inclines to about 4 degrees—steeper than that and you're asking for trouble!

Don't compromise on safety features. At minimum, insist on emergency stop functionality, overload protection, and descent speed control valves. If you're looking at self-propelled models, dead-man brakes are non-negotiable.

Consider whether you need customization options like special platform sizes, industry-specific attachments, or integrated scales. These features might cost more upfront but can dramatically improve efficiency over the life of the equipment.

Finally, balance your price and warranty considerations. A quality lift table should last 5-10 years with proper maintenance, so look for at least a 1-year parts and labor warranty and check the availability of local service support.

For specialized applications like funeral services, industry-specific solutions often provide better value than adapting general-purpose equipment. We've seen this at American Mortuary Coolers. Learn more about Top Mortuary Lift Company: Lift Your Funeral Home's Efficiency with Durable Lifts.

Essential Safety Features

I can't stress enough how critical safety features are when selecting a battery powered lift table. An emergency stop button should be prominently positioned for immediate access when needed. I once visited a warehouse where this button prevented a serious accident when a load shifted unexpectedly—these features aren't just regulatory checkboxes, they save lives.

Self-propelled models should include dead-man brakes that engage automatically when the operator releases the control. This prevents the nightmare scenario of a heavy lift rolling unattended across your facility.

Quality lifts incorporate pressure relief valves to prevent operation when loaded beyond capacity. Toe guards block access to the scissor mechanism during operation, preventing pinch injuries that can be devastating. And don't overlook mechanical maintenance locks that secure the table in a raised position during maintenance—a feature that has prevented countless injuries.

Maintenance & Service Needs

Taking care of your battery powered lift table isn't complicated, but it is essential. Battery care makes the biggest difference in long-term reliability. Follow the manufacturer's charging recommendations, check water levels monthly in non-sealed batteries, and keep those terminals clean. Most batteries need replacement every 2-3 years, depending on how heavily you use them.

The hydraulic system requires monthly fluid checks and annual oil replacement. I recommend creating a simple calendar reminder for these tasks—they take minutes but can prevent thousands in repair costs. Keep an eye on hoses and fittings for leaks or damage, especially if your environment includes chemicals or extreme temperatures.

Don't forget the mechanical components. Lubricate pivot points and bearings regularly, inspect the scissor mechanism for wear, and verify all safety features work correctly. One of our funeral home clients has a 15-year-old lift that still performs flawlessly because they've been religious about maintenance.

Custom Attachments & Industry-Specific Add-Ons

The right attachments can transform a standard battery powered lift table into a specialized tool perfectly suited to your needs. Roller decks with integrated balls or cylinders make transferring heavy loads smooth and effortless. 360° rotating platforms allow operators to access all sides of a load without awkward repositioning.

Integrated scales have been game-changers for shipping departments, eliminating extra handling steps. Tilt tops improve ergonomics for assembly and inspection tasks, reducing worker fatigue and increasing accuracy.

In our work with funeral homes, we've seen tremendous success with specialized attachments like multi-directional ball tops that allow for dignified, smooth transfer of caskets from any angle. These thoughtful customizations not only improve efficiency but also improve the level of service you can provide to families during difficult times.

The right battery powered lift table with appropriate customizations isn't just equipment—it's an investment in your team's health, safety, and productivity. Take the time to choose wisely, and it will serve you well for years to come.

Real-World Applications & Case Studies

Battery powered lift tables have found their way into countless industries, proving just how versatile these handy tools really are. Let's take a peek at how they're making work easier and safer across different fields.

Manufacturing & Warehousing

Walk into any modern manufacturing facility, and you'll likely spot battery powered lift tables hard at work. These unsung heroes make assembly lines more efficient by providing adjustable work surfaces that can be perfectly positioned for each task.

One electronics manufacturer shared with us that they saw a remarkable 15% boost in productivity after introducing these tables. The secret? Each worker could position components at their own perfect height - no more hunching over or awkward reaching.

In warehouses, these tables shine when building or breaking down pallets. The mobility factor is huge too - need a workstation in a different spot? Just wheel it over, no hunting for power outlets needed.

Automotive & EV Service

The electric vehicle revolution has created exciting new uses for battery powered lift tables. EV batteries are hefty beasts, and getting them in and out of vehicles safely is no small feat.

"Our ET-105 lift table has completely transformed our EV battery service process," one shop owner told us with obvious pride. "What used to require three technicians can now be safely handled by one."

These tables provide the stability needed for delicate battery work and can be easily positioned under vehicles on lifts - a perfect match for the evolving automotive service industry.

Construction & Installation

Construction sites are rarely finished environments, which makes the cord-free nature of battery powered lift tables particularly valuable. Without needing to hunt for power outlets (which might not even exist yet), workers can position HVAC equipment during installation or lift materials to just the right height.

Window and door installations become much more manageable, and some crews even use these tables as temporary work platforms for ceiling work. The versatility on job sites is truly impressive - one tool solving multiple challenges.

Mortuary & Funeral Industry Use

In the funeral industry, where dignity and respect are paramount, specialized battery powered lift tables play a crucial but often unseen role. At American Mortuary Coolers, we've worked closely with funeral homes to understand their unique needs.

Cadaver lifts help transfer deceased individuals between surfaces with minimal physical strain on staff. The right equipment ensures these transfers happen smoothly and respectfully.

Adjustable embalming tables allow professionals to work at the perfect height for their stature, reducing back strain during lengthy preparation procedures. This ergonomic benefit is invaluable in a profession that already carries significant physical demands.

Casket handling has been revolutionized by mobile lift tables. Heavy caskets that once required multiple staff members can now be moved and positioned by a single person, improving both safety and operational efficiency.

Our custom solutions at American Mortuary Coolers, like the Efficient Mortuary Cadaver Lift, feature multi-directional ball tops that allow smooth transfers from any angle. This innovation is particularly valuable in preparation rooms where space is often limited.

User Testimonials & Performance Stories

The true test of any equipment is how it performs in the real world, and battery powered lift tables have some impressive stories to tell.

Remarkable longevity is a common theme. "We've been using the same PowerPusher daily since 1994 with only minor part replacements," one manufacturing facility manager shared. That's nearly three decades of reliable service!

While manufacturers typically recommend keeping inclines under 4°, some users have pushed the limits. One adventurous soul reported: "The unit climbed a 40-degree ramp smoothly under load." (Though we should note - we don't recommend exceeding manufacturer specifications!)

A funeral director in Tennessee told us about the transformative impact on their daily operations: "Before our battery-powered mortuary lift, transferring remains required at least two staff members. Now, a single person can safely manage transfers while maintaining dignity and respect for the deceased."

Battery life often exceeds expectations too. "The battery life is insane—up to a week on a full charge in our application," a warehouse supervisor noted with obvious delight.

These real-world experiences tell the story better than specifications ever could - battery powered lift tables aren't just practical tools, they're workplace game-changers that boost efficiency, improve safety, and reduce physical strain across countless industries.

Frequently Asked Questions About Battery Powered Lift Tables

After helping countless funeral homes and other businesses find the perfect lift table solutions, I've noticed some questions pop up time and again. Let me share the most common questions about battery powered lift tables that customers ask us:

How long does a full battery charge last?

This is probably the question I hear most often! The answer really depends on how frequently you're using your lift table throughout the day.

If you're constantly raising and lowering loads (about 1 cycle every 5.72 minutes), expect around 7.5 hours of runtime. For moderate use (a cycle approximately every 11.44 minutes), you'll get about 15 hours. And if you're only using it occasionally (a cycle every 17.16 minutes or so), the battery can last up to 22.5 hours.

Most of our funeral home clients find they can easily complete a full day's work on a single charge. Just plug it in overnight, and you're ready for another full day of reliable service.

What capacities and lift heights are most common?

When it comes to capacity ranges, I typically recommend thinking about your needs in these categories:

Light-duty tables (150-500 lbs) are perfect for service technicians and lighter tasks. Medium-duty options (500-2,000 lbs) handle most warehouse and manufacturing needs, while heavy-duty models (2,000-6,000 lbs) tackle those industrial-strength challenges.

For lift heights, most tables offer a minimum height between 3" and 27" when fully lowered, and can extend to maximum heights of 30" to 63". That gives you anywhere from 18" to 40" of vertical travel.

In my experience, funeral homes and most industrial users typically prefer a 1,000-2,000 lb capacity table with about 30" of lift range – this sweet spot handles most common tasks while remaining maneuverable.

Can the table be used on uneven outdoor surfaces?

Yes, but with some important limitations to keep in mind. Battery powered lift tables can handle outdoor use and moderately uneven surfaces, but safety should always be your priority.

Most manufacturers recommend a maximum incline of 4° (about a 7% grade) when loaded. If you'll be regularly working outdoors, look for models with pneumatic tires rather than solid rubber casters – they'll perform much better on rough terrain.

Uneven surfaces reduce stability, so you might need to keep loads at lower lift heights for safety. And while the battery power works great outdoors, you'll want to consider weather protection for the electrical components if this will be a regular work environment.

One last tip from experience – floor locks and brakes may not grip as effectively on soft or uneven ground, so take extra precautions when working on these surfaces.

How difficult is maintenance on a battery powered lift table?

Honestly, it's pretty straightforward! Think of it like maintaining a car – regular attention prevents bigger problems down the road.

Daily checks are simple visual inspections and making sure the battery is charged. Weekly, you'll want to wipe down exposed surfaces and check for any hydraulic leaks. Monthly maintenance involves lubricating pivot points and inspecting wheels.

Every quarter, check hydraulic fluid levels and test all safety features. And once a year, schedule a complete inspection, replace hydraulic fluid, and test the battery's performance.

I always tell our funeral home clients that following the manufacturer's maintenance schedule is the best way to protect your investment. A well-maintained lift table can provide reliable service for many years.

Are custom modifications available for specific industries?

Absolutely! This is actually where we shine at American Mortuary Coolers. Most major manufacturers offer various customization options, but working with a specialist who understands your industry makes all the difference.

For funeral homes, we frequently customize battery powered lift tables with mortuary-specific features like multi-directional ball tops that make casket transfers smooth from any angle. We can also modify platform dimensions to perfectly accommodate standard mortuary containers.

Beyond our specialty, you can find customizations including specialized platform shapes, roller tops, V-cradles, clamps, custom control systems (like foot pedals or extended pendants), and even integrated measurement tools.

The key is working with someone who understands both the equipment and your specific industry needs. That's why at American Mortuary Coolers, we focus specifically on the funeral industry – we understand the unique challenges funeral directors face and how to address them with the right equipment modifications.

Conclusion

When it comes to making your workplace safer and more efficient, battery powered lift tables truly shine as game-changers in material handling. These versatile tools have revolutionized how businesses handle heavy loads across countless settings – from busy warehouses to quiet funeral homes.

The freedom to move without being tethered to power outlets, the ability to position loads at just the right height, and the significant reduction in workplace injuries all combine to create tangible benefits you'll notice right away:

Battery powered lift tables help you save money by reducing workplace injuries and their associated costs. Your employees will thank you too – proper lifting equipment means less fatigue and more satisfaction at the end of each workday. Plus, your team will accomplish more with optimized workflows that eliminate unnecessary strain and wasted movement.

When you're shopping for your own battery powered lift table, take your time to consider what matters most for your specific situation. Think about how much weight you'll typically lift, how high you need items raised, where you'll use the table, and how frequently it'll be in operation. Investing in quality equipment might cost more upfront, but you'll be rewarded with years of reliable service and improved efficiency.

Here at American Mortuary Coolers, we've seen how different industries face unique challenges when it comes to lifting and positioning. Our team in Tennessee specializes in creating custom solutions specifically for funeral homes, where handling must be done with the utmost sensitivity, reliability, and dignity. Whether you need a standard lift table or something specially designed for mortuary transfers, we deliver durable, thoughtfully crafted equipment directly to funeral homes throughout the contiguous 48 states.

If you're in the funeral industry and looking for custom lifting solutions that address your specific needs, I encourage you to learn more about becoming part of your one-stop mortuary cooler shop.

Choosing the right battery powered lift table isn't just about buying a piece of equipment – it's about investing in your team's wellbeing, improving your daily operations, and boosting your long-term productivity. The right lifting solution doesn't just move products; it lifts your entire business.