Understanding Modern Embalming Equipment

When I first started working with funeral homes, I was amazed by how far embalming technology has come. The embalming machine – that unassuming yet vital piece of equipment – stands at the heart of modern preparation rooms across America.

At its core, an embalming machine is a specialized pump system designed to distribute preservation fluids throughout a deceased person's vascular system. But it's so much more than just a pump. It's the tool that helps funeral directors provide families with a meaningful final goodbye.

These machines serve multiple essential purposes. They deliver chemicals that preserve tissues, sanitize the body, and help create a natural, peaceful appearance for viewing. Modern units offer precise control over both pressure (typically ranging from 0-105 psi) and flow rate (up to 80 ounces per minute), allowing embalmers to tailor their approach to each individual case.

You'll find several types on the market today – from straightforward manual models to sophisticated automatic systems with digital controls. Portable options exist for those who provide home or remote services. Prices typically range from $2,849 for basic models to around $5,750 for premium digital consoles.

The difference between today's machines and the gravity-fed bottles of yesteryear is like comparing a smartphone to a rotary telephone. Modern embalming machines maintain consistent pressure and flow throughout the procedure, dramatically improving results while reducing the physical strain on the embalmer.

Most contemporary units feature durable glass or stainless steel tanks that hold about 3 gallons of fluid. The best models include safety features like backflow preventers and even self-cleaning cycles – innovations that protect both the embalmer and the integrity of the procedure.

Here at American Mortuary Coolers, I've spent years helping funeral professionals select equipment that matches their specific needs. I've seen how the right machine can transform a preparation room's efficiency and the quality of care provided to families.

For those exploring related funeral equipment, we've created helpful guides about american mortuary services, cremation oven technology, and mark iv table 2 specifications.

Why This Guide Matters

I remember speaking with a funeral director from a small-town operation in Missouri who had been using the same hand pump system for decades. "I just didn't know what I was missing," he told me after upgrading to a modern embalming machine. His preparation time was cut in half, and families noticed the difference in his results.

The funeral profession has transformed dramatically since the days of Civil War-era preservation techniques. Today's equipment offers levels of precision, safety, and efficiency that were unimaginable even a few decades ago. Whether you're establishing a new funeral home, replacing worn equipment, or simply exploring ways to improve your preparation room, choosing the right machine matters.

This guide draws from our experience serving funeral homes from coast to coast – from busy urban operations in New York and Los Angeles to small family businesses in rural communities. We've seen what works, what lasts, and what truly makes a difference in the care you provide.

We created this resource because we believe that funeral professionals deserve clear, honest information about the tools that are so central to their important work. In the following sections, we'll dive deeper into the specifics of different machine types, essential features, maintenance requirements, and how to select the perfect match for your unique needs.

Embalming Machine Basics: Purpose, Principles & Primary Function

Ever wonder what actually happens in a preparation room? At the heart of modern embalming is a remarkable device that transformed funeral care. An embalming machine does three essential jobs: it preserves the body, disinfects tissues, and helps restore natural appearance.

Think of it as the funeral professional's most trusted partner. This specialized device replaces blood with carefully formulated solutions containing formaldehyde (usually as formalin, which is 40% formaldehyde in water), along with preservatives, dyes, and other agents that work together.

As industry experts John A. Chew and Ray LaFramboise beautifully put it: "Embalming is the disinfecting, preserving and restoration of the dead human body to a natural form and color." The embalming machine makes this artful science possible with consistency and control that wasn't available to previous generations.

What makes these machines so effective is their ability to create just the right amount of pressure to move embalming fluid throughout the body's vascular network. This arterial injection process reaches tissues that would otherwise be inaccessible, allowing for thorough preservation while maintaining the natural dignity of the deceased.

How an embalming machine works

The beauty of an embalming machine lies in its straightforward operation paired with sophisticated technology. Here's what happens during a typical procedure:

First, the embalmer prepares a custom solution in the machine's tank, carefully mixing chemicals with water based on the specific needs of each case. Body weight, condition, and other factors all influence this formulation.

Next comes the pressure generation. Unlike older gravity methods, modern embalming machines create consistent, controlled pressure through a precision pump system. This reliability is what sets modern equipment apart.

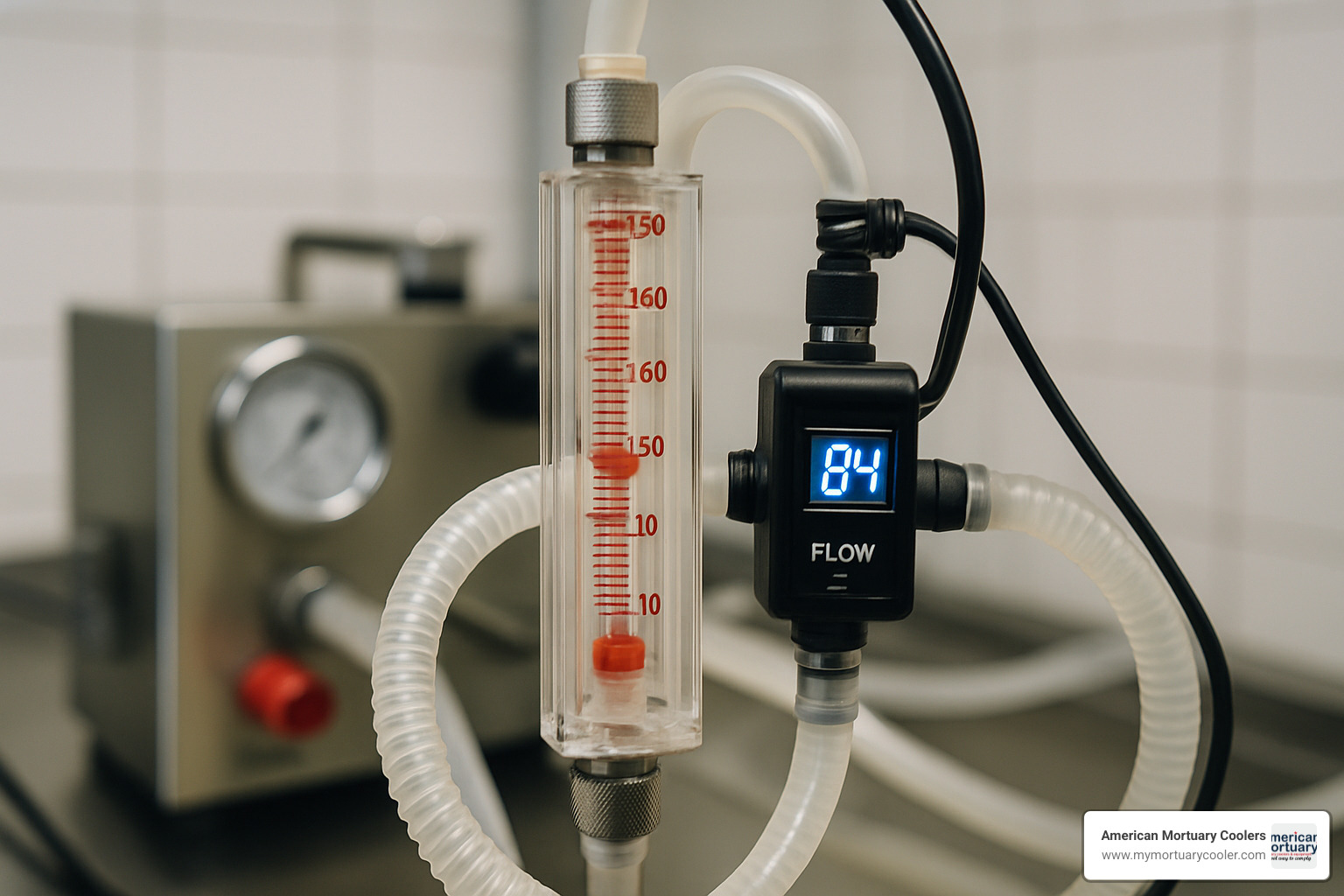

The embalmer then adjusts the flow rate, typically measured in ounces per minute, ensuring the fluid distributes properly without causing tissue distension or other complications.

As the solution enters through a selected artery (often the carotid, femoral, or brachial), it travels throughout the entire vascular system, eventually reaching capillary beds in all tissues. Meanwhile, blood and excess fluid drain from a corresponding vein, completing the circulation process.

The secret to effective embalming is what professionals call "differential pressure" – finding that sweet spot between the pressure applied by the machine and the natural resistance within the body's vascular system. Today's embalming machines give funeral professionals pinpoint control, typically operating between 3-12 psi for standard cases, though capable of reaching up to 105 psi when needed for challenging situations.

Following best practices, embalmers typically use about 1 gallon of solution per 50 pounds of body weight. Modern equipment can deliver fluid at impressive rates up to 80 oz/min (2.36 liters/minute), though most cases use gentler flow rates to ensure proper distribution without tissue distension.

Core Advantages Over Gravity Bottles

Remember those old-fashioned gravity-fed bottles that once dominated preparation rooms? While they served their purpose, modern embalming machines offer dramatic improvements that have transformed the profession.

The most significant advantage is consistent pressure. Gravity bottles naturally lose pressure as fluid levels drop, but today's machines maintain steady pressure from start to finish. This consistency leads to more thorough preservation and better results.

Modern machines also shine with their adjustable settings. Today's digital embalming machines give operators precise control over both pressure and flow, which can be fine-tuned during the procedure as conditions change.

Many current models feature pulsation capabilities that gently mimic natural heartbeats (typically around 24 pulses per minute), improving fluid distribution in challenging cases. Built-in safety valves prevent backflow, protecting both the equipment and the operator from contamination.

The efficiency gains are substantial too. Modern machines complete the arterial injection process more quickly and thoroughly than gravity systems ever could, saving valuable time while improving results.

There's also the professional image aspect. When families tour your facilities, contemporary embalming machines with their sleek designs make a statement about your commitment to dignity and excellence.

As one of our longtime customers told us, "Moving from gravity bottles to a digital embalming machine wasn't just an upgrade—it completely transformed how I work. The consistency and control make even difficult cases manageable."

Comparing Types & Specifications on Today's Market

Today's funeral directors face an important choice when it comes to embalming machines. The market offers everything from simple portable units to sophisticated digital systems, each designed for different needs and budgets. Let's explore your options so you can make the best choice for your funeral home.

Manual & Portable Options

If you're running a smaller operation or need flexibility, portable options might be your perfect match.

The beloved "Porti-Boy" style machines have been trusted companions in preparation rooms for decades. Priced between $2,849 and $3,500, these compact workhorses weigh under 40 pounds, making them perfect for funeral homes with limited space or those offering off-site embalming services. While they have smaller tanks and fewer bells and whistles than their larger cousins, their reliability has made models like the Mark IV and Mark V industry standards.

Some funeral directors still rely on hand pumps and fully manual systems in certain situations. These old-school options (ranging from $800-$1,500) don't need electricity, making them invaluable during power outages or in remote locations. They're a direct descendant of the equipment Dr. Thomas Holmes used during the Civil War when he embalmed over 4,000 soldiers. While they require more physical effort and offer less precise control, their simplicity makes them nearly foolproof in emergencies.

Automatic Digital Consoles

For funeral homes with dedicated preparation rooms, digital embalming machines represent today's gold standard.

Standard digital models fall in the $4,000-$5,000 range and offer the precision modern embalmers demand. With digital controls, clear pressure gauges, and reliable flow meters, these machines provide consistent performance case after case. Their 3-gallon tanks accommodate most standard embalming procedures with room to spare.

At the premium end ($5,450-$5,750), you'll find sophisticated systems like the Frigid Embalming Machine with touchscreen interfaces and features that would have seemed like science fiction just a decade ago. These top-tier units include patent-pending Mix/Self-Clean modes that handle internal cleaning automatically, saving you time and reducing chemical exposure. The laboratory-strength borosilicate glass tanks resist chemical damage, while Smart Lid technology manages pressure and sealing without manual adjustment.

With five distinct operating modes (Off/Gravity Embalm, Mix, Clean, Inject, and Pulse) and impressive specifications (pressure range of 0–105 psi and flow range up to 80 oz/min), these machines give you unprecedented control over the embalming process. The result? Better preservation outcomes and a more natural appearance for families' final viewing.

Specialty Hybrid Stations

For those looking to maximize efficiency in their preparation room, integrated systems combine embalming machines with other essential equipment.

Wall-mounted embalming stations ($5,000-$12,000) save valuable floor space while keeping everything within arm's reach. With integrated plumbing and often a built-in aspirator, these systems create a clean, professional workflow that reduces setup time between cases.

Center-sink embalming stations represent the ultimate all-in-one solution. Though priced between $15,000-$22,000, these complete workstations include a sink, aspirator, embalming machine, and storage in one cohesive unit. For high-volume funeral homes, this investment quickly pays for itself through improved efficiency and organization.

At American Mortuary Coolers, we've seen how the right equipment transforms a preparation room from merely functional to truly exceptional. Whether you're just starting out or upgrading a well-established funeral home, we're happy to help you steer these options to find the perfect embalming machine for your specific needs. Want to explore more equipment options? Check out our complete guide to buying embalming equipment.

Inside the Machine: Key Components, Safety Features & Tech Innovations

Ever wonder what's actually inside that embalming machine sitting in your prep room? Understanding the components and technology can help you make smarter purchasing decisions and keep your equipment running smoothly for years to come.

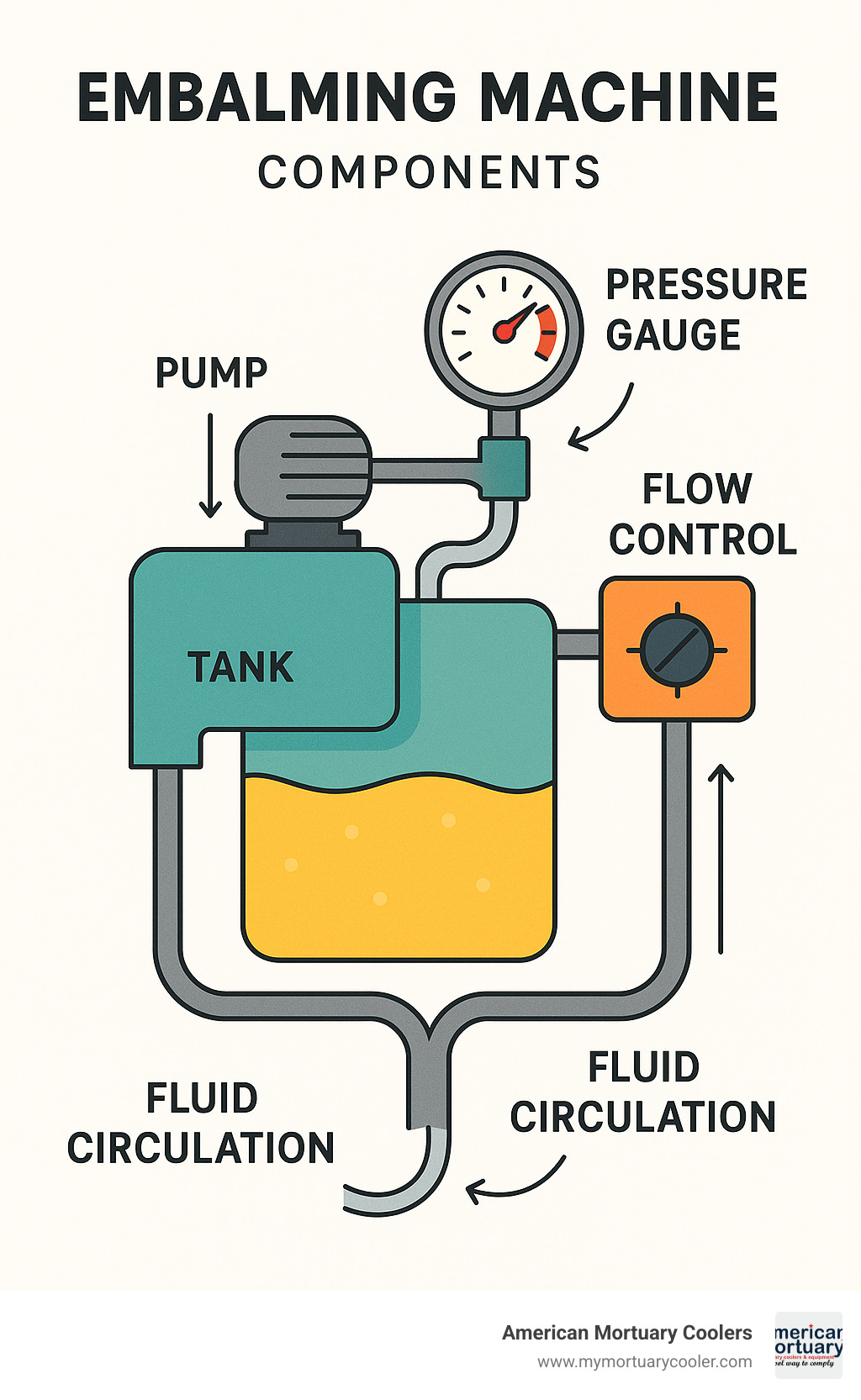

Key Components

The heart of any embalming machine is its pump head. Modern units typically use either centrifugal or positive displacement technology, with premium models like the Frigid featuring magnetic transmission pumps that require less maintenance and provide more reliable performance.

The tank is another critical component, typically holding about 3 gallons (12 liters) of fluid. While stainless steel tanks have been the industry standard for decades, premium models now offer laboratory-grade borosilicate glass tanks that resist the harsh chemicals used in embalming solutions. This might seem like a small detail, but when you're working with formaldehyde-based chemicals day after day, that chemical resistance really matters.

"I've had my glass-tank model for five years now, and it still looks brand new inside," one funeral director told us. "My old stainless tank was starting to pit after just two years."

Premium machines now feature Smart Lid technology that automatically manages pressure and sealing. These lids know when to seal tight and when to release, preventing those messy spills that used to be part of the job.

The digital displays on modern embalming machines show both pressure (PSI) and flow rate (oz/min) simultaneously, giving embalmers complete control over the process. Flow sensors provide real-time data that allows for precise adjustments during the procedure.

Many embalmers particularly value the pulse mode generator found in higher-end machines. This feature creates rhythmic pressure variations (typically 24 pulses per minute) that mimic natural heartbeats, helping fluid distribute more evenly through the vascular system – especially helpful in challenging cases.

Safety Features

Modern embalming machines aren't just more efficient – they're significantly safer than their predecessors. Backflow preventers are perhaps the most important safety feature, preventing contamination of the machine's tank with bodily fluids through one-way valve systems.

Anti-clog valves maintain consistent flow even when small tissue particles are present, while quick-release hoses allow for rapid disconnection if needed – a small feature that can make a big difference in certain situations.

Some premium models now incorporate HEPA filtration on tank vents, preventing the aerosolization of chemicals that can occur during the embalming process. This protection, combined with OSHA-compliant shields that guard against splashes, creates a significantly safer working environment.

"Safety features aren't just nice-to-haves," explains a 30-year industry veteran. "They're what keep us healthy throughout our careers. The shields and vents on newer machines have dramatically reduced my chemical exposure."

Mixing & Injection Science

The science behind effective embalming has evolved significantly over the years, with technology making the process more precise than ever.

Older machines relied on venturi systems that used water pressure to create vacuum, but modern embalming machines typically employ magnetic pumps offering better reliability and control. Premium models feature automatic mixing systems that precisely blend concentrated embalming chemicals with water to achieve the desired index (strength).

The pulsation technology found in advanced machines (typically operating at 24 pulses per minute) mimics natural heartbeat patterns. This rhythmic pressure prevents the "walling-off" effect that can occur with continuous pressure, allowing for better fluid distribution throughout the body.

As embalming experts John A. Chew and Ray LaFramboise note, proper fluid distribution requires varying formaldehyde indices depending on purpose: firming fluid needs a 25–35 index, medium preparations use 17–25, and low-index solutions range from 3–10. Modern embalming machines make achieving these precise formulations much easier and more consistent.

Recent Advancements You Should Know

The embalming machine market continues to evolve with several exciting innovations worth noting if you're considering an upgrade:

Self-clean cycles have revolutionized maintenance requirements. Advanced models like the Frigid incorporate automated cleaning cycles that flush the internal components with water, extending machine life and reducing the time you spend on maintenance.

The switch to laboratory-grade borosilicate glass tanks offers superior chemical resistance compared to traditional stainless steel – particularly important when using harsh chemicals like phenols and high-index cavity fluids.

Some newer models now incorporate RFID technology to track chemical usage and automatically adjust dilution rates based on the specific chemicals being used. Similarly, Bluetooth logging capabilities allow for automatic recording of embalming parameters (pressure, flow, duration) for quality control and documentation.

Even the aesthetics have improved, with companies like American Mortuary Coolers offering customizable exterior colors using the RAL color system. This allows funeral homes to match their preparation room aesthetic or brand colors for a more cohesive, professional environment.

These technological advancements aren't just about making machines look nicer – they're about creating tools that help funeral professionals provide better service to families while making the preparation process safer, more efficient, and more reliable. For more detailed information about the latest technologies, you might want to check out the latest research on aspirator safety.

Ownership Guide: Maintenance, Accessories, Pricing & Compliance

Buying an embalming machine is just the beginning of your relationship with this essential piece of equipment. Like any good partnership, it requires care, the right supporting accessories, and understanding of both financial and regulatory aspects. Let's walk through what you need to know to get the most from your investment.

Maintenance Requirements

Taking good care of your embalming machine isn't complicated, but it does require consistency. Think of it like caring for a car – regular attention prevents major problems down the road.

After each use, take a few minutes to run clean water through the system. This simple step washes away chemical residues that could otherwise corrode internal components. A quick wipe-down of exterior surfaces with an appropriate disinfectant keeps everything clean and professional-looking.

Monthly, set aside time for a more thorough cleaning. Descaling is particularly important, as mineral buildup from water can affect performance over time. Check those filters too – both the tank filter and port filter can collect debris that restricts flow.

"I've seen $5,000 machines fail after a year due to poor maintenance, and I've seen $3,000 machines last for decades with proper care," one experienced embalmer told us. That annual maintenance check is worth its weight in gold – replace gaskets and seals before they fail, and consider having the machine professionally inspected and calibrated to keep it running at its best.

Essential Accessories

Your embalming machine works best with supporting players. Think of these accessories as the team that helps your star performer shine:

Rubber and clear plastic tubing are daily essentials, with clear tubing offering the advantage of visual confirmation that fluid is flowing properly. For cavity embalming, a quality hypo trocar shaft and valve are must-haves.

Protection is important too. A magnetic filter for your tank catches tiny metal particles before they can damage the pump, while a mix/clean port filter prevents clogging during cleaning cycles. These small investments pay big dividends in extending machine life.

For convenience, consider hose holders – both suction cup and magnetic versions make your preparation room more organized and efficient. And if you want to visually confirm fluid flow at higher pressures, a high-pressure hose with window is worth considering.

Pricing & Investment Considerations

Embalming machines come in several price tiers, each offering different features and capabilities. Entry-level portable models start around $2,849, while mid-range digital models typically run $4,000-$5,000. Premium digital models with advanced features like self-cleaning cycles and touch-screen interfaces range from $5,450-$5,750.

For those looking at complete solutions, integrated stations that combine an embalming machine with other preparation room equipment can range from $5,000 to $22,000 depending on included features.

When budgeting, look beyond the price tag. Operating costs are minimal for electricity, but you'll want to factor in maintenance supplies and occasional replacement parts. Check warranty coverage – premium models typically offer 2-year protection, while basic models may only include 1 year.

Many suppliers, including us at American Mortuary Coolers, offer financing options to help distribute the investment over time. While it might be tempting to choose the lowest-priced option, higher-end machines typically offer longer service lives and reduced maintenance headaches – potentially providing better value despite the higher initial cost.

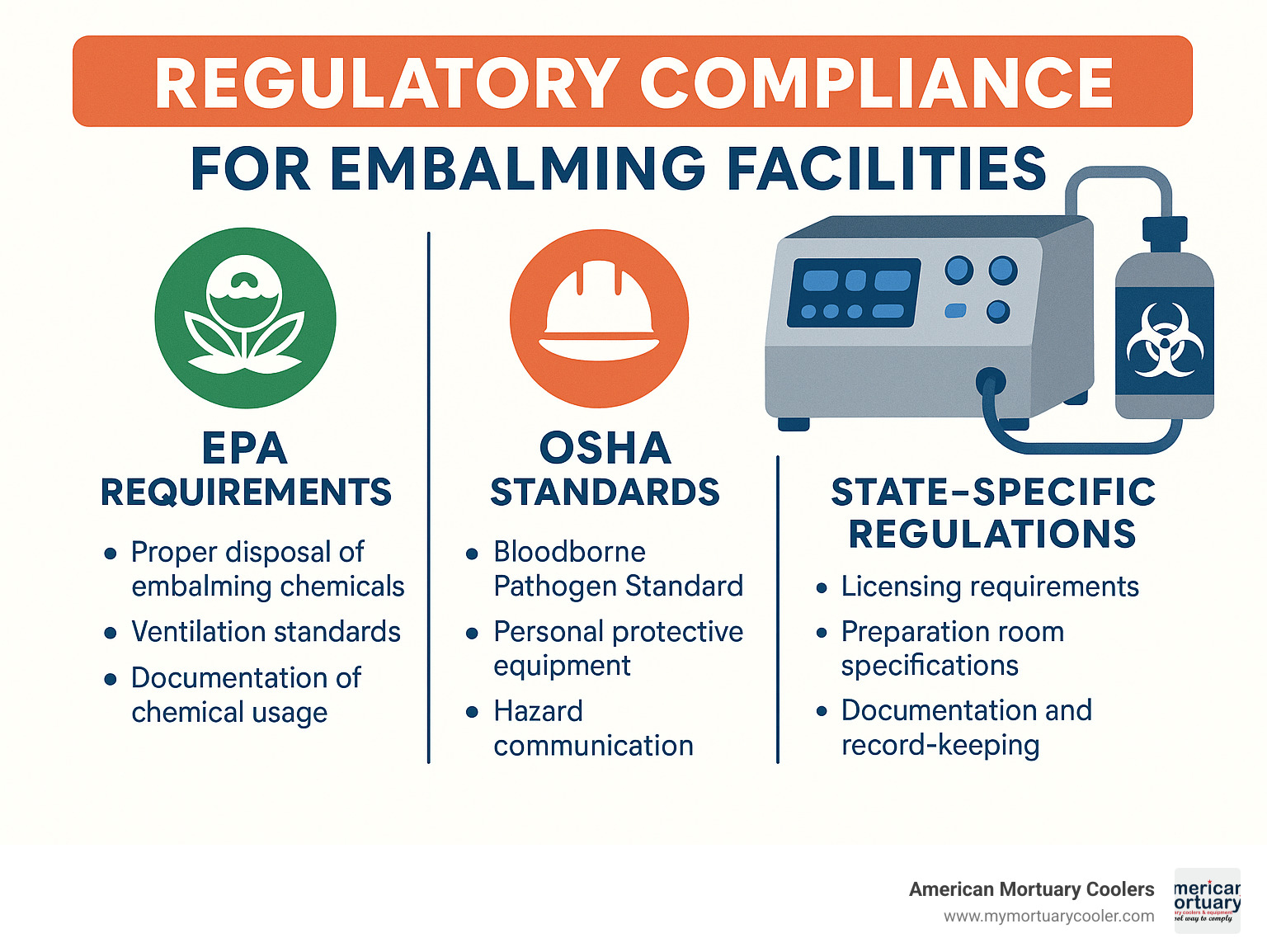

Regulatory Compliance

Operating an embalming machine means navigating a sea of regulations from multiple agencies. The EPA has specific requirements for chemical disposal, ventilation standards, and documentation. OSHA oversees workplace safety with standards for bloodborne pathogens, personal protective equipment, and hazard communication.

Don't forget state-specific regulations, which can include licensing requirements for embalmers, preparation room specifications, and record-keeping mandates. These rules aren't just bureaucratic hoops – they protect you, your staff, and the environment.

Troubleshooting your embalming machine

Even the best embalming machine occasionally needs a little troubleshooting. When pressure drops unexpectedly, check for air in the system, leaking connections, or clogged filters. Flow surges often indicate a partially blocked arterial tube or vascular obstruction – check and clear the tube, adjust pressure settings, or consider alternative injection sites.

Air locks can occur when air gets trapped in the pump or lines. Running the machine in purge mode usually resolves this issue, but also check for loose connections that might be drawing air. Modern machines often have sensors that trigger alarms for abnormal conditions – keep your manufacturer's guide handy to interpret these helpful warnings.

As one experienced preparation room technician shared with a smile: "The most common issue I see is people panicking when there's a simple fix. About 80% of embalming machine problems can be solved by checking connections and cleaning filters."

Frequently Asked Questions

What pressure and flow rate should I start with?

For standard adult cases, begin with pressures between 3-12 psi and flow rates of 8-16 oz/min. These settings aren't one-size-fits-all, though – adjust based on body weight, time since death, vascular condition, and preservation needs.

The golden rule is to start lower and increase gradually as needed. Your goal is thorough distribution without causing tissue distension. With experience, you'll develop a feel for what works best in different situations.

How do I prevent cavity fluid backflow?

Cavity fluid backflow isn't just messy – it can damage your embalming machine and compromise your work. Always use dedicated cavity instruments rather than arterial tubes, and ensure proper trocar button placement after cavity embalming.

Consider specialized hypo valves that prevent backflow, and whenever possible, keep cavity and arterial processes separate. While modern machines often include backflow prevention valves, think of these as your backup plan rather than your primary protection.

Which accessories extend machine life the most?

Based on our experience serving funeral homes from coast to coast, four accessories stand out for extending embalming machine longevity:

A good tank filter prevents debris from entering and damaging the pump system. Port filters protect internal valves and channels from contamination. High-quality tubing reduces the risk of leaks and failures. And don't overlook regular cleaning supplies like descaling solutions and system cleaners.

These modest investments can add years to your machine's service life – a return that's hard to beat in any business.

Conclusion & Next Steps

Choosing the right embalming machine isn't just a purchase—it's an investment in your funeral home's ability to provide dignified, professional care. As we've explored throughout this guide, today's technology offers everything from portable units perfect for smaller facilities to premium digital models with features our predecessors could only dream about.

The funeral profession has always balanced tradition with innovation, and embalming machines perfectly exemplify this evolution. While the fundamental purpose remains unchanged—preserving and restoring the deceased with dignity—how we accomplish this has transformed dramatically.

Environmental Stewardship

Modern funeral service increasingly emphasizes environmental responsibility. Today's premium embalming machines support this commitment through features like:

- Self-cleaning cycles that minimize chemical waste

- Precise fluid control that reduces excess usage

- Filtration systems that ensure proper disposal

At American Mortuary Coolers, we're proud to offer equipment that helps funeral professionals balance effective preservation with environmental consciousness. After all, caring for families means caring for the world they live in too.

Investment Planning

When budgeting for your next embalming machine, consider the complete picture beyond just the sticker price:

Expected lifespan (typically 10-15 years for quality models) Maintenance requirements and costs Training time for staff to learn new systems Potential efficiency improvements and chemical savings

Think of your embalming machine as an extension of your professional skill. The right equipment improves your abilities while the wrong choice can frustrate even the most experienced embalmer. This perspective helps justify investing in quality equipment that will serve your business reliably for years.

American Mortuary Coolers Custom Solutions

We understand that funeral homes across America face different challenges. The needs of a high-volume urban facility in New York differ dramatically from a rural funeral home in Tennessee. That's why we've built our business on customization and personal service.

Our team serves funeral professionals nationwide from our multiple locations, including Tennessee, Georgia, Illinois, South Carolina, Texas, California, New York, and Pennsylvania. This national presence means we understand the regional variations in funeral practice while offering consistent support wherever you're located.

When you're ready to explore options for your preparation room, our experts can help match your specific requirements with the ideal equipment solution. We consider your case volume, preparation room layout, staff preferences, and budget constraints to recommend embalming machines that will truly work for your unique situation.

For a complete look at how we can support your mortuary equipment needs beyond just embalming machines, take a moment to explore our mortuary cooler solutions. Our custom-crafted coolers complement our embalming equipment to create complete preparation room solutions.

The right equipment doesn't just make your job easier—it helps you provide better service to families during their most difficult moments. That's something worth investing in.