Understanding Manual Scissor Lifts: The Essential Guide

A manual scissor lift is a mechanical lifting device that uses crossed supports in a crisscross "X" pattern to raise and lower loads through manual force, typically via a foot pump or hand crank mechanism. These versatile tools are essential for material handling and ergonomic positioning across various industries.

| Manual Scissor Lift Quick Facts |

|---|

| Operation: Human-powered (foot pump or hand crank) |

| Typical Capacity: 700-2,200 lbs (317-998 kg) |

| Common Lift Heights: 14" to 53" (35.5-135 cm) |

| Best For: Intermittent use, areas without power, budget-conscious operations |

| Key Benefits: No electricity needed, lower cost, simpler maintenance |

Manual scissor lifts serve a critical role in reducing worker fatigue and preventing injuries by raising materials to a comfortable working height. Unlike their electric or hydraulic-powered counterparts, manual lifts don't require electrical outlets or battery charging, making them ideal for locations where power access is limited or for businesses looking for a more economical solution.

These lifts typically feature a platform mounted atop a set of crossed supports (the "scissors") that extend or collapse when force is applied. Most models use a hydraulic foot pump system that allows operators to raise heavy loads with minimal effort, while a hand-controlled release valve enables smooth, controlled lowering.

The simplicity of manual scissor lifts makes them particularly valuable in:

- Warehouses for loading, unloading, and positioning materials

- Manufacturing facilities for workstation height adjustment

- Retail environments for merchandise displays

- Funeral homes for casket and body positioning

- Maintenance operations for equipment access

While manual scissor lifts require more physical effort than powered models, they offer significant advantages in terms of cost, portability, and reliability—especially in environments where electrical hazards may be a concern.

I'm Mortuary Cooler, a national-level supplier of mortuary equipment including specialized manual scissor lifts designed for funeral home operations. With years of experience providing reliable lifting solutions for the mortuary industry, I understand how the right manual scissor lift can dramatically improve both safety and efficiency in your daily operations.

Basic manual scissor lift glossary:

How Manual Scissor Lifts Work & Key Components

Ever wonder how a simple foot pump can lift hundreds of pounds? The beauty of a manual scissor lift lies in its straightforward yet ingenious design. Understanding how these workhorse tools function will help you choose the right model and keep it running smoothly for years.

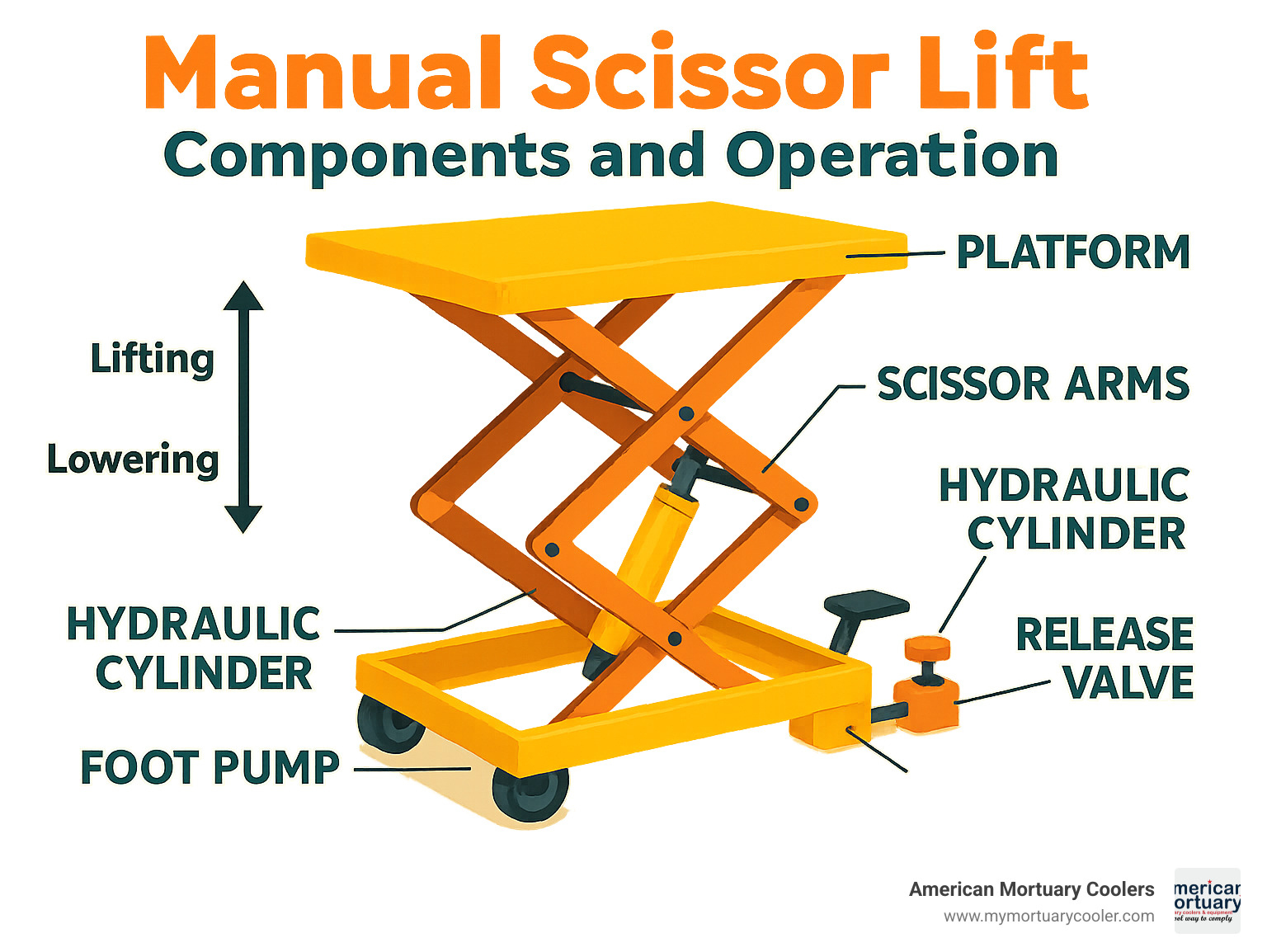

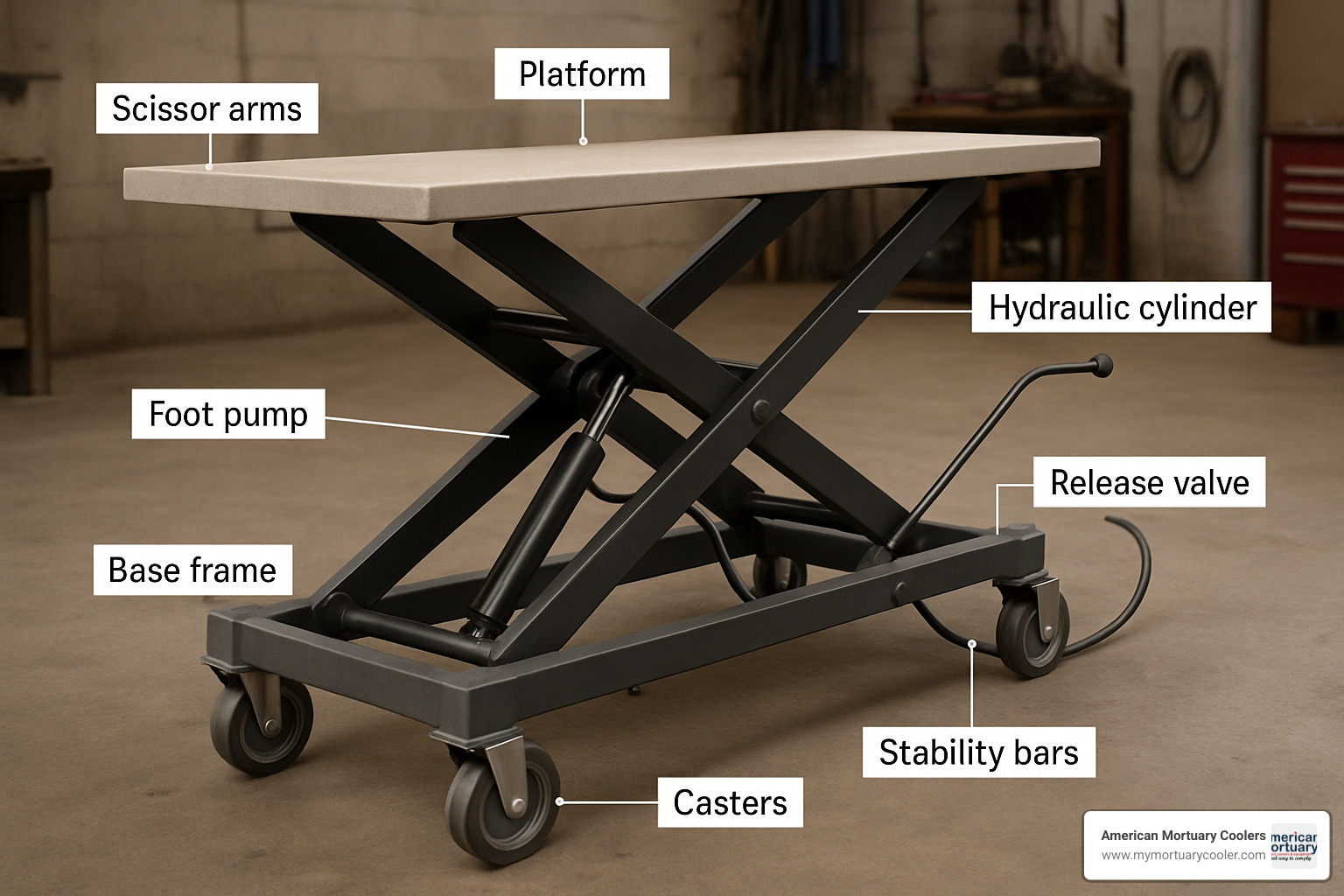

At the heart of every manual scissor lift is a collection of carefully engineered components working together:

The scissor arms form the distinctive X-shaped steel legs that give these lifts their name. Made from robust ½" to ¾" steel, these arms aren't just sturdy—they're designed to create a mechanical advantage that turns a modest input force into significant lifting power.

Connected to these arms is the hydraulic cylinder—essentially a sealed tube containing fluid and a piston that extends when pressure builds up. This extension is what pushes the scissor arms apart, creating the lifting action.

How do you create that pressure? That's where the foot pump comes in. Each time you press down on this pedal, you're moving a small amount of hydraulic oil from a reservoir into the cylinder. It might not seem like much with each pump, but those small movements add up to impressive lifting power.

When it's time to lower your load, the hand-controlled release valve comes into play. This simple mechanism allows hydraulic fluid to flow back to the reservoir at a controlled rate, giving you precise control over the lowering speed.

The platform itself—where you place your materials—comes in various configurations depending on your needs. Some feature solid surfaces, others have roller tops for easy material handling, and specialized models (like our mortuary lifts) have custom designs for specific applications.

All of this sits atop a sturdy base frame that provides stability and houses the hydraulic components. Most mobile manual scissor lifts include high-quality casters that let you move the unit when it's not loaded. For extra stability when raised, many models also feature stability bars or outriggers that can be deployed.

Inside the Hydraulic Foot-Pump System

The hydraulic system is what makes these lifts so efficient despite being human-powered. When you push down on the foot pedal, you're activating a small piston inside the pump that compresses and forces hydraulic oil through a one-way check valve. This oil flows into the cylinder under pressure, pushing the main piston outward.

What makes this system so effective is how it multiplies force. The extending piston pushes against the scissor arms, and due to their geometry, a relatively small cylinder movement translates into significant platform elevation—that's mechanical advantage at work!

Every quality manual scissor lift includes a pressure relief valve that prevents over-pressurization. This is an important safety feature that protects both the equipment and the operator from potential damage or accidents.

For best performance, these systems need the right fluid—typically ISO VG32 hydraulic oil with a viscosity of 32 cSt at 40°C. Mixing different fluids is a big no-no as it can damage seals and compromise safety.

Premium models often feature chrome-plated ram cylinders that resist corrosion and ensure smooth operation throughout the lift's service life. These small details make a big difference in longevity and performance.

Manual Scissor Lift Safety Features You Must Know

When you're lifting hundreds of pounds, safety isn't optional—it's essential. Today's manual scissor lifts come equipped with several critical safety features:

Many models include a mechanical locking system that prevents accidental lowering when the platform is raised. Think of it as a safety net that keeps your load securely positioned even if something goes wrong with the hydraulic system.

The overload protection valve is another crucial safeguard. This clever hydraulic feature prevents the lift from raising if the load exceeds its rated capacity, helping avoid structural failure or dangerous tipping incidents.

Wheel brakes are simple but essential—these locking casters keep your lift firmly in place during loading, unloading, and while raised. No more worrying about unexpected movement at the worst possible moment.

For larger models, especially those designed for lifting personnel, guard rails provide an additional layer of protection by preventing falls. Spring-loaded levers ensure controlled operation and prevent sudden drops that could damage equipment or cause injuries.

Some advanced manual scissor lifts even include tilt sensors that alert operators if the lift is positioned on an unsafe slope—a small feature that can prevent major accidents.

At American Mortuary Coolers, we understand that in the funeral industry, stability and reliable operation aren't just about efficiency—they're about dignity and respect. That's why all our manual scissor lifts meet or exceed industry safety standards, giving you peace of mind when handling deceased individuals.

Comparing Manual Scissor Lift Types, Sizes, and Capacities

Shopping for a manual scissor lift can feel a bit overwhelming with all the options out there. Let me walk you through the different types, sizes, and capacities to help you find your perfect match without the headache.

Think of manual lifts as the reliable workhorses of the lifting world. They might not have all the bells and whistles of their electric cousins, but they make up for it in simplicity and dependability. Here's how they stack up against other lift types:

| Feature | Manual Scissor Lift | Electric Scissor Lift | Hydraulic Scissor Lift |

|---|---|---|---|

| Power Source | Human (foot pump/hand crank) | Battery/AC power | External hydraulic power unit |

| Cost | $300-$2,000 | $2,000-$15,000 | $1,500-$10,000 |

| Lift Capacity | 700-2,200 lbs | 500-4,000 lbs | 1,000-10,000+ lbs |

| Duty Cycle | Intermittent | Continuous | Continuous |

| Maintenance | Simple, minimal | Complex, regular | Moderate |

| Portability | High | Medium | Low |

| Best For | Occasional use, no power access | Regular use, indoor settings | Heavy-duty industrial applications |

| Typical Weight | 185-650 lbs | 500-3,000 lbs | 750-5,000+ lbs |

When it comes to manual scissor lifts, you've got several flavors to choose from. Table lifts are the all-purpose option with flat platforms perfect for most materials. These workhorses typically range from compact 24"×36" platforms up to spacious 48"×72" surfaces that can handle just about anything you throw at them.

If you're handling pallets regularly, you might want to consider pallet truck lifts that combine the best of both worlds – they'll move your pallets around and lift them to working height. For those times when you need to reach a bit higher, high-lift models can extend up to 53" or more, perfect for accessing those top shelves or storage areas.

The difference between economy and premium models isn't just about price. Those higher-end manual scissor lifts typically feature thicker steel construction (½" to ¾" steel legs), chrome-plated cylinders that resist corrosion, and powder-coated finishes that won't chip at the first bump. Many also come with polyurethane wheels that won't mark up your nice floors – a small detail that your maintenance team will definitely appreciate.

Manual Scissor Lift Table Lifts vs Pallet Trucks

Let's talk about the difference between table lifts and pallet trucks, because they each have their sweet spots in the workplace.

Table lifts are the versatility champions. Their solid platforms handle odd-shaped items with ease, and their larger surfaces (up to 48"×72") give you plenty of workspace. They're perfect when you need to position items for assembly or detailed work. Many of our funeral home clients love the models with roller tops that let them smoothly transfer body trays without strain or awkward lifting.

Pallet trucks with scissor lifts, on the other hand, are the multitaskers of the warehouse. They'll not only lift your load but transport it too. Their narrower profile lets them steer tight spaces that would make a table lift blush, and they typically start from a lower minimum height (around 3"). The trade-off is height – they usually top out around 31"-33", while table lifts can reach 35"-39" or more.

For our mortuary clients, we typically recommend specialized table lifts that make transferring the deceased between different stations smooth and dignified – an important consideration in this line of work.

High-Lift Manual Scissor Lift Models for Extra Reach

Sometimes standard just doesn't cut it. When you need that extra reach, high-lift manual scissor lift models step up to the plate.

These impressive lifts can extend to heights of 53" or more while still starting from a reasonable 11.25" minimum height. Many feature surprisingly narrow frames – some as slim as 20" wide – that can steer tight spaces despite their impressive vertical reach.

What I really appreciate about these models is their versatility – many allow loading from both ends and sides, giving you flexibility in tight spaces. And don't worry about stability; manufacturers compensate for the increased height with wider bases or additional outriggers.

In mortuary settings, these high-lift models are absolutely essential for accessing upper tiers of body storage racks, which can reach up to 79" high with multiple levels. This allows funeral directors to work safely without straining to reach higher storage positions.

Typical Applications & Industries

The humble manual scissor lift shows up just about everywhere you look. Their versatility makes them valuable across countless industries.

In warehousing and distribution, they're the unsung heroes of order picking, helping workers position materials at comfortable heights and handling loading/unloading at dock areas. Manufacturing facilities use them for ergonomic workstation adjustment, ensuring workers can perform assembly tasks without back strain.

Funeral homes and mortuaries rely on specialized manual scissor lifts for respectful handling of the deceased – positioning bodies, transferring to and from cold storage, and loading into vehicles. The right lift in this setting isn't just about efficiency; it's about maintaining dignity in a difficult time.

Retail environments use these lifts for everything from setting up eye-catching merchandise displays to organizing stock rooms. Maintenance teams appreciate their portability for accessing HVAC systems, lighting, and other building maintenance tasks that require a boost.

In logistics and shipping operations, they help with package handling, loading containers, and cross-docking – all without requiring electrical outlets or battery charging.

At American Mortuary Coolers, we've spent years fine-tuning our manual scissor lifts specifically for funeral homes across Tennessee, Georgia, Illinois, and beyond. We understand that mortuary professionals have unique requirements, and our customized solutions reflect the special care needed in this industry.

Safe Operation, Safety Precautions & Regulations for Manual Scissor Lifts

Safety isn't just a buzzword when it comes to manual scissor lifts—it's what keeps you and your team going home in one piece at the end of the day. While these lifts might seem simpler than their powered cousins, they still demand respect and proper handling.

Pre-Operation Safety Checklist

Before you start pumping that foot pedal, take a moment to give your manual scissor lift a once-over. Think of it as a quick handshake with the equipment that's about to carry hundreds of pounds for you.

Start with a visual inspection by checking for any hydraulic leaks (those telltale puddles or drips) and looking for damaged components. A cracked weld or bent scissor arm isn't just an eyesore—it's a potential disaster waiting to happen.

Next, be honest about your load assessment. Every lift has its limits, and exceeding the rated capacity isn't being efficient—it's being dangerous. The weight rating isn't a suggestion; it's a hard limit determined by engineering.

The surface beneath your lift matters tremendously. That smooth concrete floor in your funeral home? Perfect. That soft lawn outside? Not so much. Manual scissor lifts need firm, flat ground that won't shift or sink under pressure.

Don't forget to look up! Overhead clearance is often overlooked until it's too late. Your lift will extend significantly higher than its resting position.

Before trusting your lift with a precious load, test those wheel locks. A rolling scissor lift is about as useful (and far more dangerous) than a unicycle in a hurricane.

Finally, run a quick no-load test of the hydraulic system. The raising and lowering should be smooth and controlled—no jerking, sticking, or unusual noises.

Critical Safety Precautions

When it comes to actually using your manual scissor lift, a few key practices will keep everyone safe and your equipment lasting longer.

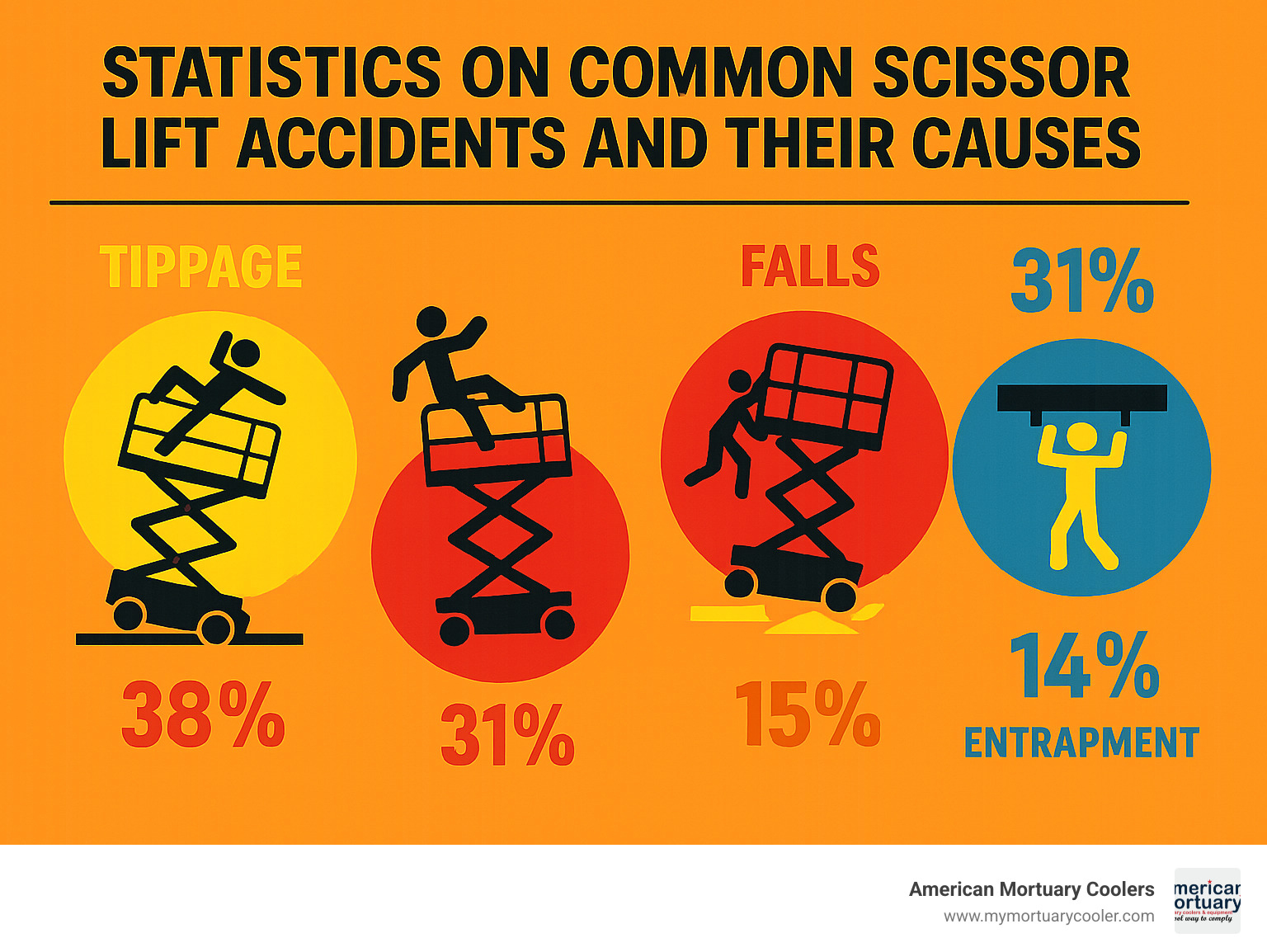

Load centering might seem obvious, but it's surprising how often this basic principle gets overlooked. An off-center load is like trying to sit on the edge of a chair—eventually, something's going to tip. Take the extra minute to position your load properly, especially when handling caskets or deceased individuals.

Ground conditions can make or break your lifting operation. Manual scissor lifts are at their best on solid, level surfaces. When the ground isn't ideal, consider alternatives rather than risking a tip-over.

Pay attention to slope limits. Most manufacturers specify a maximum gradient of around 3 degrees—which is barely noticeable to the human eye but critical to lift stability. When in doubt, find a flatter spot.

The golden rule of scissor lifts: don't move while raised unless your specific model is designed for it (and most manual ones aren't). This isn't being overly cautious—it's preventing one of the most common causes of lift accidents.

Manual Scissor Lift Operating Checklist

Daily operation of your manual scissor lift becomes second nature with practice, but even veterans should follow a consistent routine.

Start each day with quick checks of the basics: look for leaks, test those wheel locks (again), make sure hydraulic fluid isn't low, and verify all safety mechanisms work as designed. These take just minutes but can prevent hours of trouble.

When you're actually using the lift, engage those wheel locks before any raising or lowering operations. Use smooth, steady pumping motions rather than erratic ones—this helps maintain control and reduces wear on components. Always keep an eye on your load as it rises, and most importantly, keep hands and feet clear of the scissor mechanism—those pinch points don't care how experienced you are.

After you're done, lower the platform completely for storage. This reduces stress on the hydraulic system and makes the unit more stable. Take a moment to clean any debris from the platform and document any issues you noticed for maintenance follow-up.

Certification & Legal Requirements

The regulatory landscape for manual scissor lifts is less intensive than for powered lifts, but that doesn't mean it's a free-for-all.

While formal certification may not be mandatory, OSHA still requires operator training specific to the equipment being used. This isn't just checking a box—proper training prevents accidents and improves efficiency.

Regular inspections by a designated "competent person" aren't just good practice; they're required by OSHA. This person should understand the equipment thoroughly and have authority to address any issues found.

Keep solid records of all training, inspections, and maintenance. In the unfortunate event of an incident, documentation showing your diligence can make a significant difference.

Every lift must display clear Safe Working Load (SWL) labels showing maximum capacity. These aren't just for new operators—they remind everyone of critical limits.

Be aware that some states and municipalities may have additional requirements beyond federal standards. It's worth checking local regulations, especially in facilities like funeral homes where public safety is paramount.

For more comprehensive guidance, check out the OSHA scissor lift safety guide which, while focused on powered lifts, contains many principles applicable to manual models as well.

Built-in Safety Features That Reduce Risk

Modern manual scissor lifts come equipped with engineered safety features that work silently in the background to protect you.

Overload protection systems use hydraulic pressure relief valves to prevent lifting when you've exceeded the maximum capacity. This isn't the manufacturer being difficult—it's preventing structural failure.

Mechanical locks act like insurance against unexpected lowering. Once engaged, these locks physically prevent the platform from descending until intentionally released.

Some models include stabilizers and outriggers that can be deployed to improve stability during operation—especially valuable in mortuary settings where absolute stability during body transfers is essential.

More advanced models might include tilt sensors that warn when the lift is on an unsafe slope, and virtually all quality lifts include emergency lowering systems that allow controlled descent even if the primary mechanism fails.

At American Mortuary Coolers, we understand that in funeral home settings, safety isn't just about preventing damage or injury—it's about maintaining dignity and respect throughout all handling procedures. That's why our manual scissor lifts are designed with the specific needs of mortuary professionals in mind, prioritizing stable, reliable operation when it matters most.

Buying Guide: Selecting, Assembling & Maintaining Your Manual Scissor Lift

Finding the perfect manual scissor lift is a bit like shopping for a good pair of work boots – you need something reliable, suited to your specific needs, and built to last. Let's walk through everything you need to know to make a smart purchase decision.

Key Selection Criteria

When I talk with funeral directors about choosing the right manual scissor lift, I always start by asking about their daily needs. Think about what you'll actually be lifting and how often. The heaviest items you'll handle should determine your capacity needs – and always add about 25% as a safety buffer. Most standard models handle between 700 and 2,200 pounds, which covers most mortuary and general warehouse needs.

Platform size matters tremendously for stability and usability. Too small and you'll struggle with larger items; too large and you might not fit through doorways or tight spaces. Standard platforms typically range from 24"×36" to 48"×72", but custom sizes are available for specific applications.

Height range is another critical factor that often gets overlooked. Consider both the minimum height (how low it goes for easy loading) and maximum height (how high it reaches). For mortuary applications, you'll want to match the height of your preparation tables, storage racks, and transport vehicles for smooth transfers.

Think about where and how you'll use your lift. Will you need to move it while loaded? Will it operate on smooth concrete or across thresholds? Caster quality and size become especially important if you're rolling over uneven surfaces. For narrow hallways or tight corners common in older funeral homes, a narrower frame might be essential even if it means a slightly smaller platform.

Your working environment affects durability too. Indoor units can be built with standard finishes, but if you're using the lift outdoors or in areas with frequent washing (like preparation rooms), you'll want corrosion-resistant finishes and sealed components.

Frequency of use should guide your quality investment. For daily use in a busy facility, spending more upfront for a premium manual scissor lift with better components and smoother operation will save money and frustration in the long run. For occasional use, a mid-range model might be perfectly adequate.

While budget is always a consideration, quality differences are substantial between entry-level ($300-500) and professional-grade ($1,000-2,000) manual scissor lifts. The professional models offer better stability, smoother operation, longer service life, and improved safety features – crucial when handling deceased loved ones with dignity and care.

Assembling and Adjusting a Manual Scissor Lift on Delivery

Most manual scissor lifts arrive partially assembled to prevent shipping damage. Don't worry – assembly is straightforward if you follow these steps.

Start with the handle installation, which typically involves inserting the draw-bar onto the piston rod and securing it with the included hardware. Pay special attention to the orientation of the handle – it should move smoothly between pumping and release positions.

One crucial step many people skip is bleeding air from the hydraulic system. Air bubbles cause jerky, unpredictable movement – definitely not what you want when handling delicate loads. Loosen the deflation screw (often labeled 303N) while slowly pumping the handle. You'll know you're done when the operation becomes smooth and consistent.

Fine-tuning the control mechanism ensures proper function in all positions. This usually involves adjusting a control nut (typically labeled 104) or bolt (318) that determines the relationship between pumping, neutral, and lowering functions.

Before putting your new lift into service, verify all fasteners are properly tightened and test the operation through its full range of motion with no load. The platform should rise smoothly with consistent pumping and lower in a controlled manner when the release valve is opened.

Routine Maintenance to Extend Service Life

A well-maintained manual scissor lift can provide decades of reliable service. The good news is that maintenance is straightforward and doesn't require specialized tools.

Lubrication is your first line of defense against wear and tear. Apply a quality lithium-based grease to all pivot points weekly – this includes the scissor arm joints, axles, and wheel bearings. A light spray of silicone lubricant on the wheel swivels keeps them turning freely and prevents squeaking.

Your hydraulic system needs regular attention too. Check fluid levels monthly and top up with ISO VG32 hydraulic oil as needed. This specific viscosity ensures proper function across a range of temperatures. I recommend replacing the hydraulic fluid annually or after 500 cycles, whichever comes first, to remove contaminants that can damage seals and valves.

Take a few minutes each month to inspect the structure of your lift. Look for any cracks in welds, bending in the scissor arms, or loose fasteners. Catching small issues early prevents costly failures later. Pay special attention to the pivot points where scissor arms connect – these experience the most stress during operation.

The wheels and casters on your manual scissor lift deserve special attention, especially if you move the lift frequently. Clean debris from wheels weekly, check for flat spots or damage monthly, and lubricate the swivel mechanisms quarterly. Quality casters make a world of difference in maneuverability and longevity.

Troubleshooting Common Manual Scissor Lift Problems

Even the best manual scissor lift might occasionally need some troubleshooting. Here's how to handle the most common issues:

If your lift won't raise, first check that you're not exceeding the rated capacity. Then check hydraulic fluid levels – low fluid is a common culprit. Air in the system can also prevent proper lifting, so try bleeding the system as described earlier. If these steps don't resolve the issue, inspect the pump components for damage.

Slow lifting usually indicates air in the hydraulic system or contaminated fluid. Bleeding the system often resolves this, but if the problem persists, you may need to drain and replace the hydraulic fluid. Worn pump seals can also cause slow lifting and may require replacement.

Uneven lowering is typically caused by debris in the release valve or damaged cylinder seals. Clean the release valve according to your manual's instructions, and if that doesn't help, you may need to replace the seals. In rare cases, bent scissor arms can cause uneven movement and require professional repair.

If your platform drifts down under load, you're likely dealing with leaking hydraulic seals or contaminated fluid affecting valve seating. This requires replacing the seals or draining and replacing the hydraulic fluid.

Difficult pumping usually means there's air in the system, worn pump components, or an improperly adjusted handle mechanism. Start with bleeding the air, then check for proper handle adjustment, and finally inspect for worn components.

For a comprehensive guide to common scissor lift problems and solutions, we recommend reviewing the FieldEx troubleshooting guide, which covers both manual and powered models.

Storage & Long-Term Care

Proper storage significantly extends the life of your manual scissor lift. Always store your lift indoors in a clean, dry environment when possible. Lower the platform completely before storage to reduce stress on the hydraulic components and scissor mechanism.

Before storing, take a few minutes to clean any debris, especially anything that might cause corrosion. For extended storage periods, consider applying a light coat of rust preventative to exposed metal surfaces. Taking these simple steps can add years to your lift's service life.

At American Mortuary Coolers, we take pride in providing manual scissor lifts specifically designed for the unique needs of funeral homes. Our models feature improved stability, smooth operation, and specialized platforms that integrate seamlessly with our mortuary coolers and rack systems. For more information about our specialized mortuary equipment, including custom lifts for your facility, check out our guide to Scissor Lifts for Sale Near You & Specialized Mortuary Lifts.

Frequently Asked Questions about Manual Scissor Lifts

What load capacities are available?

When shopping for a manual scissor lift, one of the first questions that comes to mind is how much weight it can handle. These workhorses come in a range of capacities to suit different needs.

Most manual scissor lifts fall somewhere between 700 lbs and 2,200 lbs capacity. If you're handling lighter materials, a light-duty lift (770-1,000 lbs) might be perfect for your needs. For more substantial loads, medium-duty models at around 1,500 lbs offer a good balance of capacity and cost. When you're moving truly heavy items, heavy-duty lifts rated for 2,000-2,200 lbs provide the muscle you need.

For our funeral home customers, we typically recommend models with at least 1,000 lbs capacity. This ensures you can safely handle caskets and body trays with enough margin for additional accessories or equipment. Safety always comes first when handling precious cargo.

Do I need certification to operate a manual scissor lift?

Good news! Unlike their powered cousins, manual scissor lifts generally don't require formal operator certification. This makes them more accessible for businesses without extensive training programs.

That said, OSHA still expects employers to provide proper training. This should cover equipment inspection procedures, safe operation practices, hazard recognition, and the manufacturer's specific instructions and limitations.

Even though formal certification isn't mandatory, we strongly recommend keeping records of all operator training. This documentation can be invaluable in case of workplace inspections or, heaven forbid, accidents. A simple training log with dates and topics covered provides peace of mind and demonstrates your commitment to workplace safety.

How often should hydraulic oil be changed?

Think of hydraulic oil as the lifeblood of your manual scissor lift. Keeping it clean and fresh ensures smooth operation and extends the life of your equipment.

For new equipment, it's best to change the oil after the first 50 hours of operation. This initial change removes any manufacturing debris or contaminants that might be lurking in the system. After that, plan on annual changes for regularly used equipment, or every 500 operational cycles – whichever comes first.

If you notice the fluid looking milky or contaminated, don't wait for the scheduled change – replace it immediately. Contaminated fluid can damage seals and valves, leading to expensive repairs down the road.

Always use ISO VG32 hydraulic oil or whatever specific fluid your manufacturer recommends. And here's an important tip: never mix different types of hydraulic fluids! This can damage the seals and valves, potentially causing leaks or system failure. When in doubt, a complete flush and refill is the safest approach.

At American Mortuary Coolers, we've seen how proper maintenance extends equipment life. A little attention to your hydraulic system today can prevent headaches tomorrow, especially when you need your lift to perform flawlessly during sensitive funeral home operations.

Conclusion & Next Steps

After diving into manual scissor lifts, it's clear why these reliable workhorses continue to be valued across so many industries. Their straightforward design, lack of electrical components, and budget-friendly price point make them the perfect solution when you need dependable lifting power without the bells and whistles.

I've seen how the right lift can transform daily operations, especially in funeral homes where dignity and precision matter most. There's something reassuring about equipment that just works, day in and day out, without complicated maintenance schedules or unexpected downtime.

At American Mortuary Coolers, we've spent years refining our manual scissor lift designs specifically for funeral professionals. We understand that in a mortuary setting, you need equipment that performs flawlessly when handling the deceased. That's why our lifts feature:

- Heavy-duty construction built to withstand the demands of daily mortuary use

- Specialized roller tops that make transferring body trays smooth and effortless

- Precision height ranges carefully calibrated to align perfectly with standard mortuary coolers and preparation tables

- Thoughtful design touches that reflect our deep understanding of funeral home workflows

What sets us apart is our commitment to customization. No two funeral homes are identical, and your equipment shouldn't be either. Whether you're working in a century-old building with unique space constraints or a modern facility with specific workflow needs, we'll help you find the perfect manual scissor lift solution.

We deliver directly to funeral homes across all 48 contiguous states from our facilities in Tennessee, Georgia, Illinois, and other strategic locations. This means whether you're in Johnson City, Atlanta, Chicago, or anywhere in between, we can get your custom lift to you efficiently and without the markup of a middleman.

Choosing the right equipment partner matters. When you work with American Mortuary Coolers, you're not just buying a piece of equipment – you're gaining a team that understands the unique challenges of funeral service. We're just a phone call away when you have questions or need support.

Ready to find the perfect manual scissor lift for your funeral home? Our friendly experts are here to help you assess your specific needs and recommend the ideal solution. For more information about our complete line of mortuary equipment, including specialized lifts, coolers, and preparation room solutions, reach out today through our website at More info about mortuary cooler solutions.

We look forward to helping you create a safer, more efficient workplace with the perfect lifting solution for your unique needs.