Why Cremation-Lift Equipment is Essential for Modern Facilities

A cremation-lift is a specialized hydraulic or electric lifting system designed to safely transfer caskets, body trays, and cremation containers between different heights in crematory and mortuary facilities. Here's what you need to know:

Key Features:

- Weight Capacity: 1,000+ lbs to handle all body sizes

- Height Range: 20-80 inches for loading retorts and storage racks

- Power Options: Manual, hydraulic, electric, or battery-powered

- Loading Types: Side-loading or end-loading configurations

- Materials: Steel or lightweight aluminum construction

Primary Benefits:

- Reduces operator strain and back injuries

- Enables safe handling of bariatric cases

- Streamlines workflow from cooler to cremation chamber

- Improves dignity in body handling procedures

With cremation rates exceeding 50% nationwide, funeral homes face increasing demand for efficient body handling systems. Traditional manual lifting puts staff at risk for serious injury when moving heavy caskets and oversized remains. Modern cremation-lift systems solve this problem by providing smooth, controlled vertical transport.

The cremation-lift market has evolved significantly, with manufacturers serving the industry for over 50 years. Today's systems feature multi-directional rollers, digital weight scales, and battery power that eliminates the need for electrical connections near cremation chambers.

Quick cremation-lift definitions:

Understanding the Cremation-Lift Essentials

A cremation-lift transforms what used to be a back-breaking, potentially dangerous job into something that's both safe and dignified. Modern systems can handle over 1,000 pounds while reaching heights up to 80 inches. That's not just impressive engineering - it's peace of mind when handling everything from standard caskets to bariatric cases.

More info about lift efficiency

Primary Function & Range of Motion

The scissor mechanism provides rock-solid stability throughout the entire lifting cycle. Most professional units start at 13-22 inches and reach maximum heights of 69-80 inches. This range covers virtually every scenario in your facility.

The scissor design keeps the platform perfectly level throughout the entire lift. The roller platform features multi-directional capability, so remains can be smoothly transferred from either side or end, depending on facility layout.

Types of Cremation-Lift Systems

Manual hydraulic systems use hand-pump operation, perfect for facilities where electrical access is limited or budgets are tight. They're incredibly reliable and need minimal maintenance.

Electric hydraulic systems provide powered lifting convenience. Running on 12V DC power, these systems offer smooth, consistent operation with less operator fatigue.

Battery-powered systems offer complete independence from electrical connections. Modern battery technology means full-day operation on a single charge. Aluminum models weigh up to 50% less than steel versions.

Dual-power systems can run on battery or plug-in power, providing redundancy that keeps operations running smoothly during power outages.

Side-Loading vs. End-Loading Cremation-Lift

Side-loading systems allow transfers perpendicular to the lift's travel direction, working well in narrow corridors. End-loading systems facilitate transfers parallel to movement, creating straight-line workflows.

Systems with multi-directional rollers support both orientations, adapting to your facility's needs and layout changes.

Choosing the Right Cremation-Lift: Features, Specs & Integration

Selecting the perfect cremation-lift requires balancing durability, capacity, and facility requirements. Steel units offer maximum durability for demanding applications, while aluminum systems deliver the same lifting power at roughly half the weight.

Marine-grade aluminum provides heavy-duty performance without back-breaking weight. When staff needs to reposition the lift several times daily, that weight difference matters. Aluminum also resists corrosion better than steel.

Capacity ratings typically start at 1,000 pounds. Consider how the lift handles weight throughout its full range of motion. Double-scissor designs provide smoother travel and better load distribution.

Modern systems often include digital scales built into the platform - essential for documentation and staying within safe operating limits. Roller locks keep everything secure during transfers.

| Feature | Steel Construction | Aluminum Construction |

|---|---|---|

| Weight | 450-576 lbs | 395 lbs |

| Durability | Maximum | High |

| Maneuverability | Limited | Excellent |

| Corrosion Resistance | Good | Superior |

| Cost | Lower | Higher |

Key Specifications to Compare

Height range should be your first consideration. Look for systems traveling from 13-20 inches at lowest position up to 69-80 inches maximum. Platform size varies from 60-67 inches long and 18-27 inches wide.

The unit's total weight affects daily usability. Units under 400 pounds can be repositioned by one person, while heavier systems might require two staff members.

Power source choice depends on facility layout and electrical access. Battery systems offer flexibility but need charging infrastructure. Electric models provide consistent power but require outlets.

Optional Accessories & Upgrades for a Cremation-Lift

LCD digital weight scales provide real-time load monitoring for safety and record-keeping. Remote control operation lets operators maintain safe distances during lifting.

Anti-drift brakes maintain precise positioning throughout transfers. Conveyor rollers reduce physical effort needed to position containers.

Track and gantry systems create permanent installations with guided movement along predetermined paths for high-volume facilities.

Integrating a Cremation-Lift with Existing Equipment

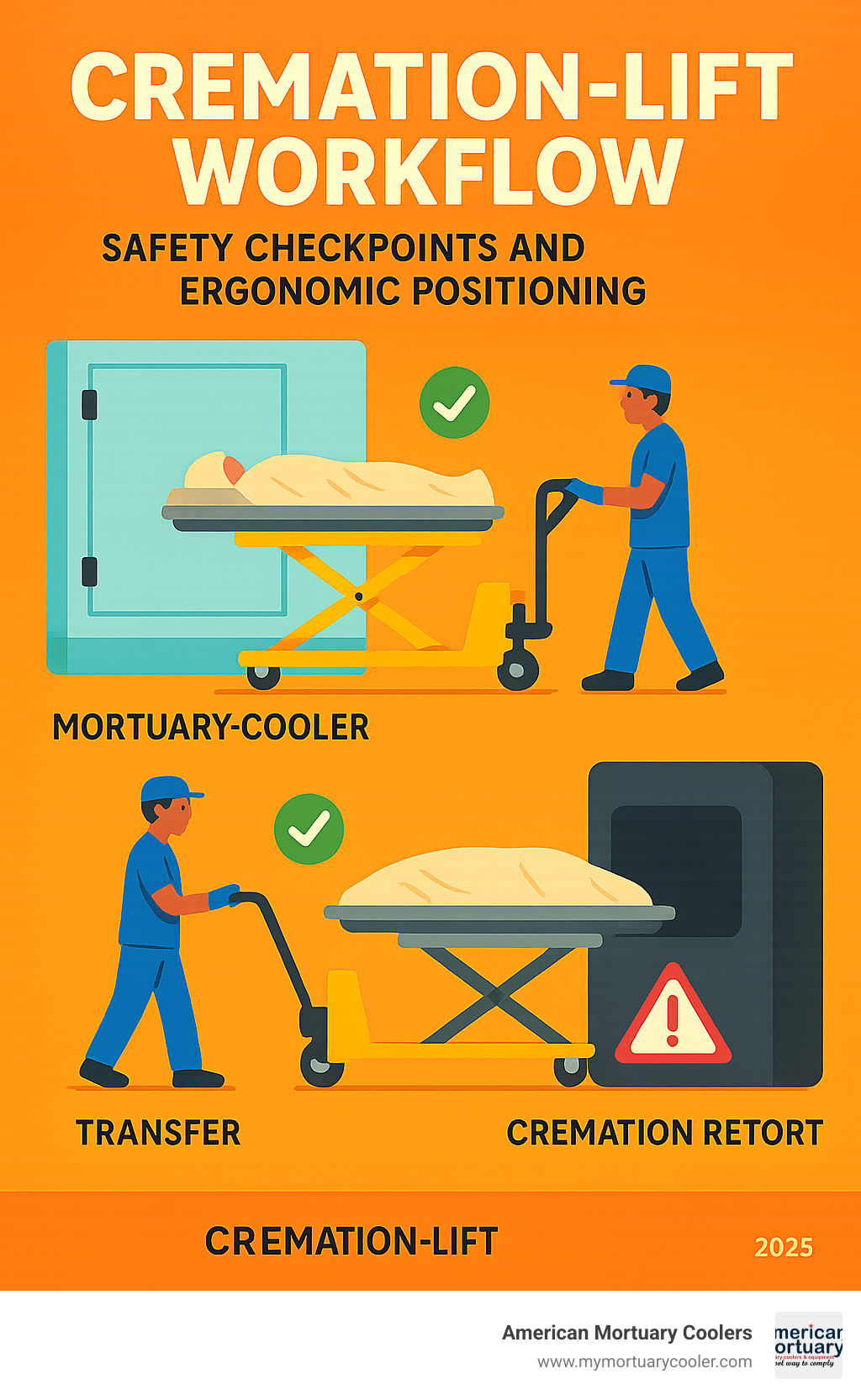

Mortuary cooler integration works best when platform heights match your cooler's discharge level, creating smooth transfer paths without manual adjustment.

Cremation chamber compatibility depends on retort loading height and available approach space. Measure both chamber opening and clearance needed for maneuvering.

Your lift can serve multiple functions - handling transfers between storage racks, preparation areas, and final processing with the same equipment.

Safety, Ergonomics & Compliance Benefits

Working in funeral service shouldn't cost you your back. Manually lifting a 300-pound casket plus remains puts enormous stress on your spine. A quality cremation-lift system eliminates this risk by handling all heavy lifting while operators focus on proper positioning and respectful care.

OSHA guidelines recommend mechanical lifting aids to prevent musculoskeletal injuries. Installing a cremation-lift demonstrates workplace safety commitment, often translating to lower workers' compensation costs and reduced insurance premiums.

Modern systems include CE and UL safety marks, non-slip deck surfaces, and roller locks for additional protection. Most manufacturers provide comprehensive training modules for safe, confident operation.

How a Cremation-Lift Improves Workplace Safety

Instead of multiple people straining to lift heavy caskets to retort height, one operator positions the container and lets the machine handle vertical movement safely. The ergonomic design keeps everyone in proper body position.

Bariatric cases present special challenges that manual lifting can't address safely. Modern cremation-lift systems with 1,000+ pound capacity handle these situations with the same ease as standard cases.

Roller brake systems prevent containers from shifting unexpectedly during loading. Emergency stop features and automatic safety locks ensure the system fails safely if problems occur.

Regulatory Standards for Cremation-Lift Operation

NFDA best practices emphasize regular equipment inspection and documented maintenance procedures. Local health codes often specify requirements for equipment handling human remains.

Maintenance logs keep equipment running safely while providing documentation inspectors require. Operator training requirements vary by location, but proper training prevents accidents and ensures compliance.

Environmental & Energy Efficiency Considerations

Today's cremation-lift systems feature improved battery efficiency - many units provide full-day operation on single charges. Low-noise pump systems minimize disruption in facilities where quiet operation matters.

The shift toward recyclable materials supports environmental responsibility. Emissions reduction happens through improved operational efficiency and reduced transfer times.

Ownership Essentials: Costs, Brands & Customization

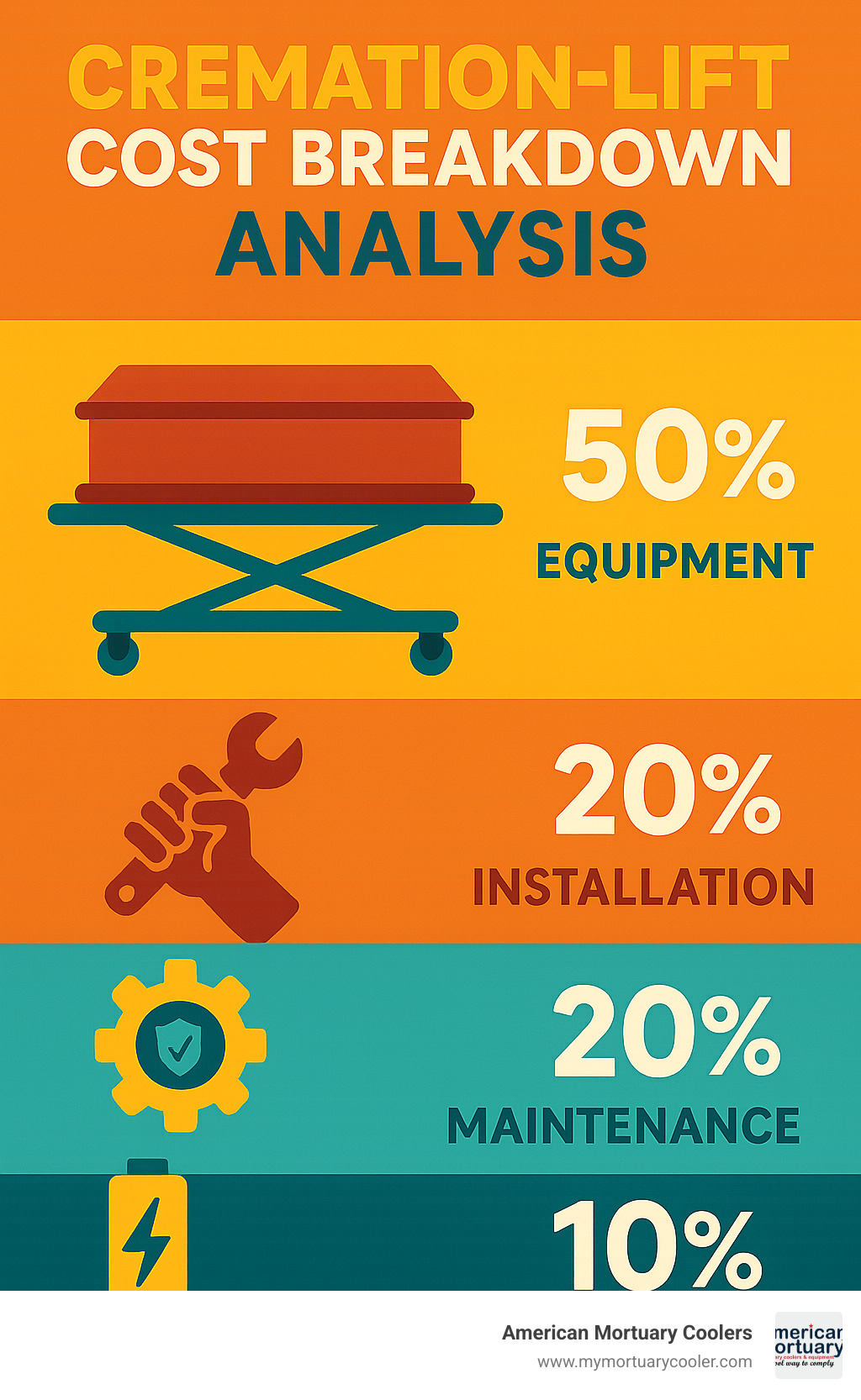

Expect to budget $4,000 to $12,000 for a professional-grade system. Manual units start at the lower end, while fully-loaded battery-powered systems reach the higher end. Consider alternative costs of staff injuries and liability issues.

Financing options make systems accessible to facilities of all sizes. Most manufacturers offer flexible payment plans, and lease-to-own arrangements align monthly payments with operational cash flow.

Warranty coverage varies dramatically between brands. Premium manufacturers provide comprehensive service support and extended coverage periods for equipment serving 15-20 years.

Cremation.com industry trends show facilities investing in quality equipment experience better staff retention and fewer operational disruptions.

Budgeting for Your First Cremation-Lift

Total cost of ownership extends beyond initial price. Factor in installation, training, maintenance, and operational benefits over 15-20 years of service life.

Manual versus powered systems present interesting trade-offs. Manual systems cost less upfront but require more operator effort. Electric systems cost more initially but reduce fatigue and speed workflows.

Installation requirements vary by facility needs. Portable units need minimal setup, while permanent installations may require electrical work and floor modifications.

Recommended Cremation-Lift Brands & Models

The Ultimate 1000 LIFT™ has earned reputation through over 50 years of service in funeral homes, morgues, and hospitals worldwide. The All-in-One Lifting™ design provides exceptional versatility.

VersaLift 2 systems feature heavy-duty welded steel construction with industrial-grade finishes. Their ergonomic design and multi-directional rollers excel in facilities prioritizing maximum durability.

The HD1000-B-NS Electric Mortuary Scissor Lift features No-Shelf design maximizing compatibility with various trays and caskets. 12V DC operation supports both side and end loading.

MOBI Aluminum Series lifts revolutionize portability without sacrificing capacity. Marine-grade aluminum reduces weight by 50% while maintaining full 1,000-pound ratings.

Customizing a Cremation-Lift for Unique Facilities

Narrow hallways often require compact designs with reduced platform widths. Modular platform designs can be configured for tight spaces without compromising functionality.

Integrated scale systems provide weight monitoring for documentation and safety compliance. Color coding systems help differentiate equipment for different purposes.

Pet cremation facilities often need smaller platforms and specialized handling features. Hospital and medical examiner facilities may require improved weighing systems and contamination control measures.

Frequently Asked Questions about Cremation-Lift Technology

What training is required to operate a cremation-lift safely?

Operating a cremation-lift safely requires proper training beyond basic controls. Most manufacturers provide comprehensive packages including operation manuals, safety checklists, and video demonstrations.

Basic operator training covers pre-operation inspection, weight limit awareness, and proper loading techniques. Advanced training includes troubleshooting, battery maintenance, and equipment integration.

Keep records of all training completion as part of facility safety documentation. Refresher sessions help maintain consistent safety standards when adding new staff.

How often should a cremation-lift be serviced and cleaned?

Maintenance schedules depend on usage frequency and facility conditions. Daily cleaning should include sanitizing surfaces, checking roller movement, and testing safety systems.

Weekly maintenance involves lubricating moving parts, checking battery condition, and inspecting hydraulic components. Annual professional service ensures complex systems receive expert attention including hydraulic testing and scale calibration.

Regular maintenance extends equipment life, reduces downtime, and ensures continued safe operation.

What common mistakes should operators avoid with a cremation-lift?

The biggest mistake is exceeding weight capacity limits. Always verify load weights before lifting, especially with bariatric cases or heavy caskets.

Improper loading techniques cause problems when containers aren't centered properly. Neglecting safety systems like roller locks creates unnecessary risks.

Operating defective equipment and inadequate training underlie most operational mistakes. Stop using equipment immediately if something doesn't work properly, and ensure every operator receives comprehensive training.

Conclusion

The future of crematory operations clearly points toward cremation-lift technology as an essential investment. As cremation rates continue climbing past 50% nationwide, funeral homes prioritizing safety and efficiency find that quality lifting equipment transforms their daily operations.

At American Mortuary Coolers, we've seen this change working with facilities from small family funeral homes to large corporate operations. The difference is immediate - staff members go home without aching backs, operations run smoother, and families receive dignified service without compromise.

Your facility's unique needs matter. Whether you're working with narrow hallways in older buildings or designing new crematories, the right cremation-lift system integrates seamlessly with mortuary coolers and existing workflows. We've helped funeral directors solve challenges in historic downtown buildings and modern suburban facilities.

The investment in quality cremation-lift systems pays for itself through reduced workers' compensation claims, improved staff retention, and peace of mind knowing your team can handle any case safely. These systems typically provide 15-20 years of reliable service, making the daily cost surprisingly reasonable.

Streamlined ordering and direct delivery across the contiguous United States means quick installation and operation without multiple vendors or complicated logistics. Our Tennessee-based team understands the funeral industry's unique challenges and timeline pressures.

Ready to see how a cremation-lift system can transform your operations? We're here to discuss your specific requirements and help you select the perfect combination of lifting equipment and mortuary cooling solutions.