Understanding Lubricant Rings: The Key to Sealing System Reliability

Lubricant rings are specialized components designed to provide sealing, reduce friction, and extend the operational life of mechanical systems. Here's what you need to know:

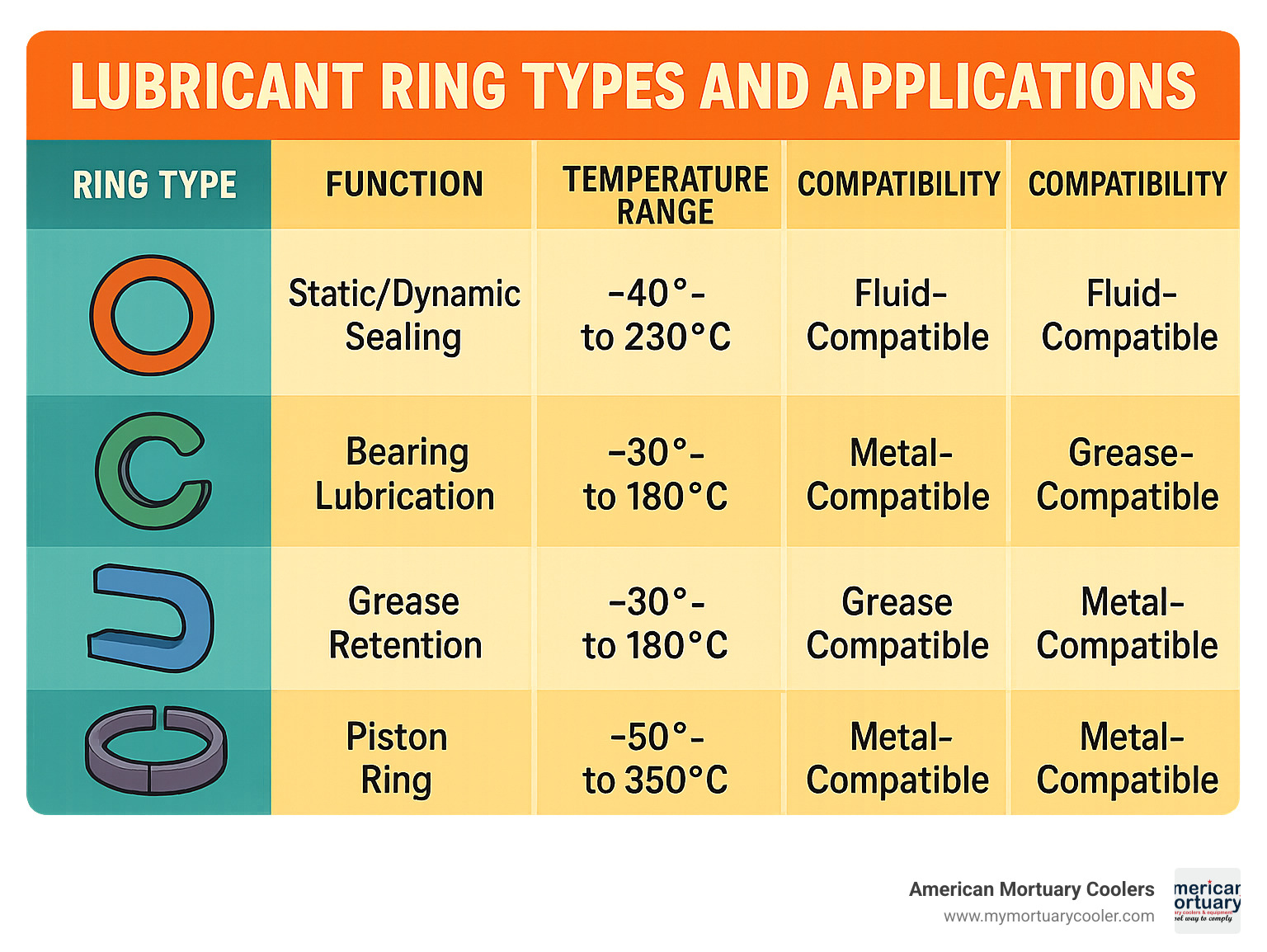

| Lubricant Ring Type | Primary Function | Common Applications | Key Benefits |

|---|---|---|---|

| O-rings | Static/dynamic sealing | Hydraulic systems, food equipment | Versatile, cost-effective |

| Oil rings | Bearing lubrication | Motors, industrial machinery | Self-lubricating, reduces maintenance |

| NILOS-rings | Grease retention | Roller bearings, heavy machinery | Creates labyrinth seal, prevents contamination |

| Piston rings | Combustion sealing | Engines, compressors | Regulates oil, transfers heat |

Lubricant rings serve as the unsung heroes of mechanical reliability across industries. These specialized components create effective seals while maintaining proper lubrication at critical interfaces. When properly selected and maintained, they significantly extend equipment life and reduce downtime.

The term "lubricant ring" encompasses several distinct components that either contain lubricant themselves or require lubrication to function optimally. From elastomeric O-rings that need proper greasing to metallic oil rings that actively distribute lubricant, these components play a vital role in everything from small hydraulic systems to massive industrial machinery.

"Lubricant rings are critical sealing components across automotive, aerospace, and industrial manufacturing sectors," notes industry research, highlighting their importance in maintaining system integrity.

Proper lubrication of rings is essential—studies show that appropriate lubricant selection can extend O-ring life significantly, reducing maintenance costs and preventing expensive downtime.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience working with lubricant ring applications in refrigeration systems and mortuary equipment.

Lubricant Ring Basics: Definition, Anatomy, Primary Functions

Ever wondered what keeps your car engine from leaking oil or your refrigerator cooling properly? The unsung hero might just be a lubricant ring. These small but mighty components are the crucial middlemen between moving and stationary parts in almost any mechanical system.

Think of lubricant rings as the peacekeepers of the mechanical world. They perform three essential jobs that keep everything running smoothly:

- They create reliable seals that prevent fluids from leaking out and keep dirt and contaminants from sneaking in

- They maintain a thin film of lubricant that dramatically reduces friction between moving parts

- They help carry heat away from high-friction areas, preventing overheating and extending the life of your equipment

The shape and design of a lubricant ring depends on its specific job. O-rings have that familiar donut shape with a circular cross-section. When compressed, they squish just enough to create a perfect seal. Oil rings often have a circular or C-shaped design with special grooves that help distribute lubricant where it's needed most.

"O-rings are the sealing device par excellence," notes industry research. At American Mortuary Coolers, we've seen how these seemingly simple components make all the difference in our refrigeration systems.

How a Lubricant Ring Works in a Sealing System

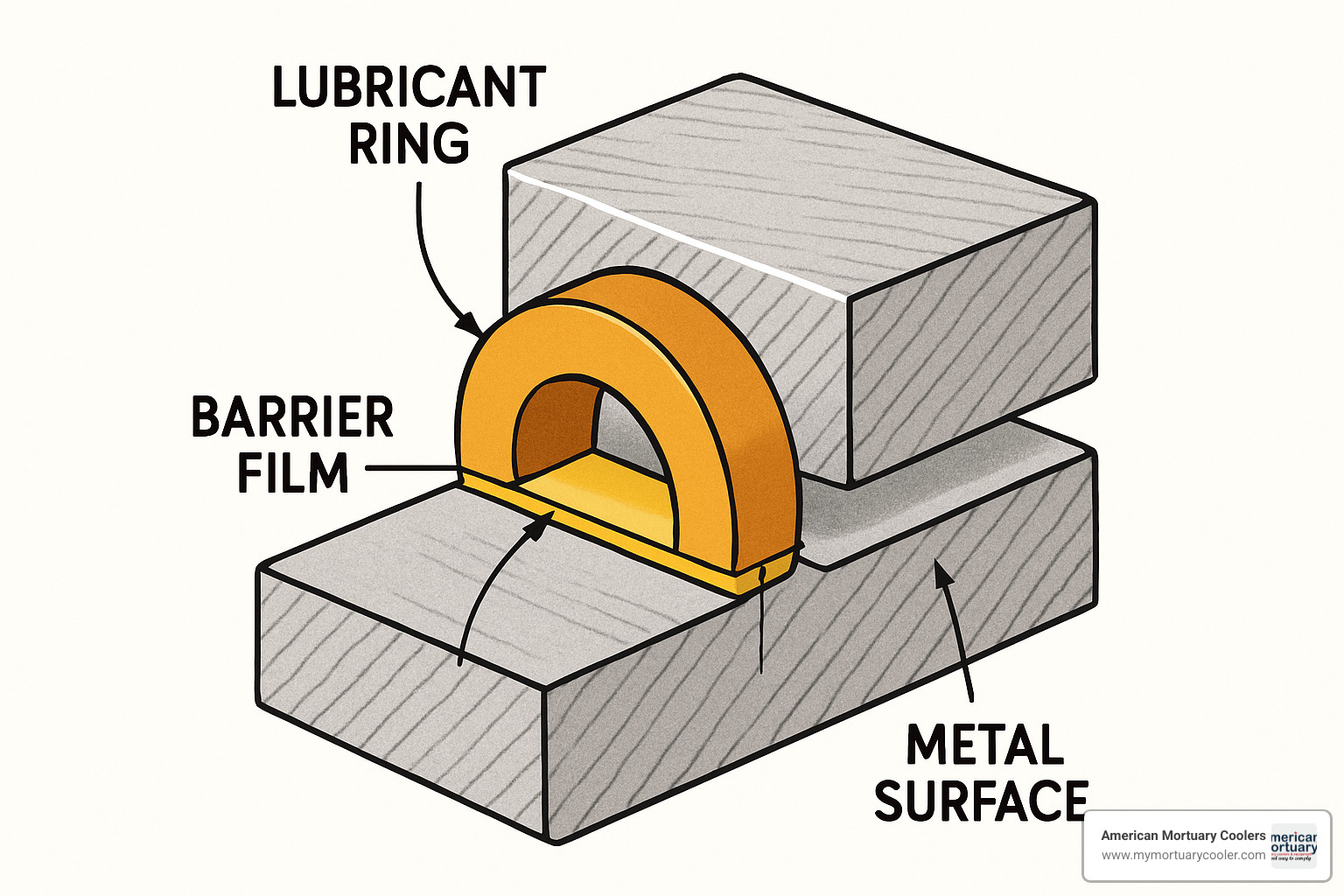

The magic of a lubricant ring comes down to a few key principles that engineers have perfected over decades.

When we install a lubricant ring, we're looking for the perfect "squeeze" – typically about 10-30% compression for O-rings. This creates just the right contact pressure against the sealing surfaces. The ring material needs good "compression set" properties too, meaning it can be squished repeatedly without losing its shape.

Groove design is another crucial factor. The housing that holds the lubricant ring must have precise dimensions to ensure the ring doesn't twist, roll, or get pinched during operation.

When everything comes together correctly, the lubricant ring creates what engineers call a "barrier film" – a microscopic layer that fills in all the tiny imperfections on metal surfaces.

The Term "Lubricant Ring" vs "Lubricated Ring"

I've noticed some confusion when people talk about lubricant rings versus "lubricated rings." Let me clear that up:

A true lubricant ring (like an oil ring) actively helps distribute lubricant throughout a system. These components are designed specifically to move oil or grease to where it's needed.

A "lubricated ring," on the other hand, is any sealing ring that needs lubrication to work properly. Your basic O-ring falls into this category – it needs a bit of grease during installation, but it doesn't actively move lubricant around.

This distinction matters when you're selecting components or planning maintenance. True lubricant rings often have different design requirements and maintenance schedules than rings that simply need lubrication during installation.

Main Categories of Lubricant Rings and Where They Excel

The world of lubricant rings is surprisingly diverse, with several distinct types designed to solve specific mechanical challenges. Let's get to know the main family members and where they shine brightest:

Lubricant Ring Essentials: O-Ring Edition

O-rings are the workhorses of the lubricant ring world. You'll find these simple but effective circular rings practically everywhere – from your kitchen faucet to spacecraft components.

The personality of an O-ring comes from its material. FKM (Fluorocarbon) O-rings handle heat like champions (up to 400°F) and shrug off harsh chemicals. NBR (Nitrile) rings are the budget-friendly option that still stands up well to petroleum products. Meanwhile, EPDM rings are the outdoor specialists, resisting weather, ozone, and steam with ease.

In our mortuary coolers, we're particularly careful about using FDA-compliant materials wherever there might be incidental food contact.

For more on specialized equipment components, check out our guide on forceps types and uses.

Lubricant Ring Roles: Oil Rings & Loose Oil Rings for Bearings

Oil rings and loose oil rings are the true delivery specialists of the lubricant ring family. Unlike O-rings that need lubrication, these rings actively transport and distribute oil themselves.

You'll typically find these helpful rings keeping journal bearings happy inside electric motors, industrial machinery with splash lubrication systems, and heavy equipment where self-lubrication is essential.

The loose oil rings made by RENK are particularly clever. Crafted from copper-zinc alloys, they feature a design that maintains consistent oil immersion even when the bearing housing tilts. According to specs, they can zip along at speeds up to 20 m/s normally.

What makes the Loose oil ring design special? Its symmetrical shape prevents oil from spraying where it shouldn't, and those little grooves help technicians quickly identify the ring dimensions.

Lubricant Ring Labyrinths: NILOS-Ring Advantages

NILOS-rings are the specialized guardians of the lubricant ring world. Designed specifically for roller bearings, they create an ingenious labyrinth seal that keeps grease in and contaminants out.

What makes them special? Their labyrinth edge creates a fine sealing interface by gently rubbing against the hardened bearing ring. Many models feature a built-in grease chamber that serves as a tiny reservoir, keeping lubrication right where it's needed.

According to The 10 points to be noted for proper installation, you should always fill NILOS-rings with grease before first use to reduce friction.

We've found NILOS-ring technology particularly valuable in our mortuary cooler refrigeration systems, especially those installed in humid environments.

Lubrication Science: Why the Right Lubricant Matters for Every Ring

Have you ever wondered why some mechanical systems run smoothly for years while others fail after just a few months? The secret often lies in something seemingly simple: how we lubricate our lubricant rings.

According to Scientific research on O-ring lubrication, "Lubricating an O-ring is an important part of the assembly line process as it can help protect an application from abrasion or scuffing damage." When properly applied, lubricant creates a microscopic barrier film that fills tiny surface imperfections, dramatically improving how well the ring seals. It also significantly reduces friction between moving surfaces and prevents premature wear.

At American Mortuary Coolers, we've seen how proper lubrication can transform lubricant ring performance. In our mortuary refrigeration systems, where stable temperatures are absolutely critical, the difference between a well-lubricated ring and a poorly lubricated one can mean the difference between years of trouble-free operation and costly breakdowns.

Common Lubricant Chemistries for Rings

Choosing the right lubricant for your lubricant ring is a bit like picking the perfect pair of shoes – what works beautifully in one situation might be terrible in another.

Silicone-based lubricants are wonderful all-rounders. They handle extreme temperatures like a champ (from -70°F all the way up to 400°F!), shrug off water exposure, and generally play nice with most materials.

PTFE-infused lubricants (think Teflon) offer incredibly low friction and resist almost any chemical you throw at them. They cost more and might need more frequent application, but for heavy-duty applications, they're hard to beat.

For truly extreme environments, PFPE lubricants shine. They're practically indestructible chemically, work in ridiculous temperature ranges, and they're non-toxic.

For our mortuary cooler systems, we typically reach for NSF H1-rated silicone or PTFE-infused lubricants. These give us the performance we need while meeting regulatory requirements.

Impact of Lubricant Choice on Performance & Life Span

The lubricant you choose for your lubricant ring doesn't just affect how it works today – it determines how long your entire system will last.

A well-matched lubricant can cut friction by up to 50% compared to running dry. That's not just about efficiency; it's about preventing the heat buildup that leads to premature failure. Temperature range matters too – Dow 111 O-ring Lubricant, for example, maintains its consistency from a frigid -70°F all the way to a scorching 400°F.

Chemical compatibility is another crucial factor. When we select lubricants like Krytox™ for certain applications, we're choosing something that won't break down when exposed to harsh cleaners, steam, or moisture.

Additives & Fillers That Transform Ring Behavior

Modern science has given us some amazing ways to improve lubricant ring performance through special additives and fillers.

The Tribological Characteristic study revealed something fascinating – adding just 4% graphite powder to NBR and FKM O-ring materials significantly reduced friction during operation.

Carbon black is another wonder additive, improving how elastomers resist wear and UV damage. PTFE (Teflon) particles create a slicker surface that dramatically extends component life.

In our mortuary cooler systems, we sometimes specify lubricant rings with integrated graphite or PTFE for components buried deep inside the cooling system.

Selecting, Applying, and Maintaining Lubricant Rings

Choosing and caring for the right lubricant ring isn't just a technical decision—it's the foundation of your system's reliability.

When selecting a lubricant ring, consider your system's temperature range, pressure requirements, the media your ring will contact, the speed of movement, and the environment where your equipment operates.

With lubricant rings, less is often more. A thin, even film typically outperforms a thick, gloppy application. Excess lubricant doesn't just waste money—it can become a magnet for dust and debris.

Step-by-Step Guide to Proper Lubrication of a Lubricant Ring

Properly lubricating a lubricant ring isn't complicated, but it does require attention to detail:

Start with preparation—gather your lubricant, clean cloths, and any application tools you'll need. Create a clean workspace free of contaminants.

Cleaning is next and absolutely crucial. If possible, remove the ring completely. Gently clean it with an appropriate solvent to remove old lubricant and any contaminants. Let it dry thoroughly before proceeding.

For lubricant application, less is definitely more. Apply a small amount to your gloved finger or application tool, then spread a thin, even film around the entire circumference.

During installation, gentle handling prevents scraping off that carefully applied lubricant. With O-rings, avoid rolling or twisting them during installation.

Finally, verify your work. Confirm the ring is properly seated and aligned, remove any excess lubricant that might attract contaminants, and document your maintenance for future reference.

Common Failure Modes & How Lubrication Prevents Them

In our decades servicing mortuary coolers nationwide, we've seen every possible way a lubricant ring can fail. The good news? Proper lubrication prevents most of these issues.

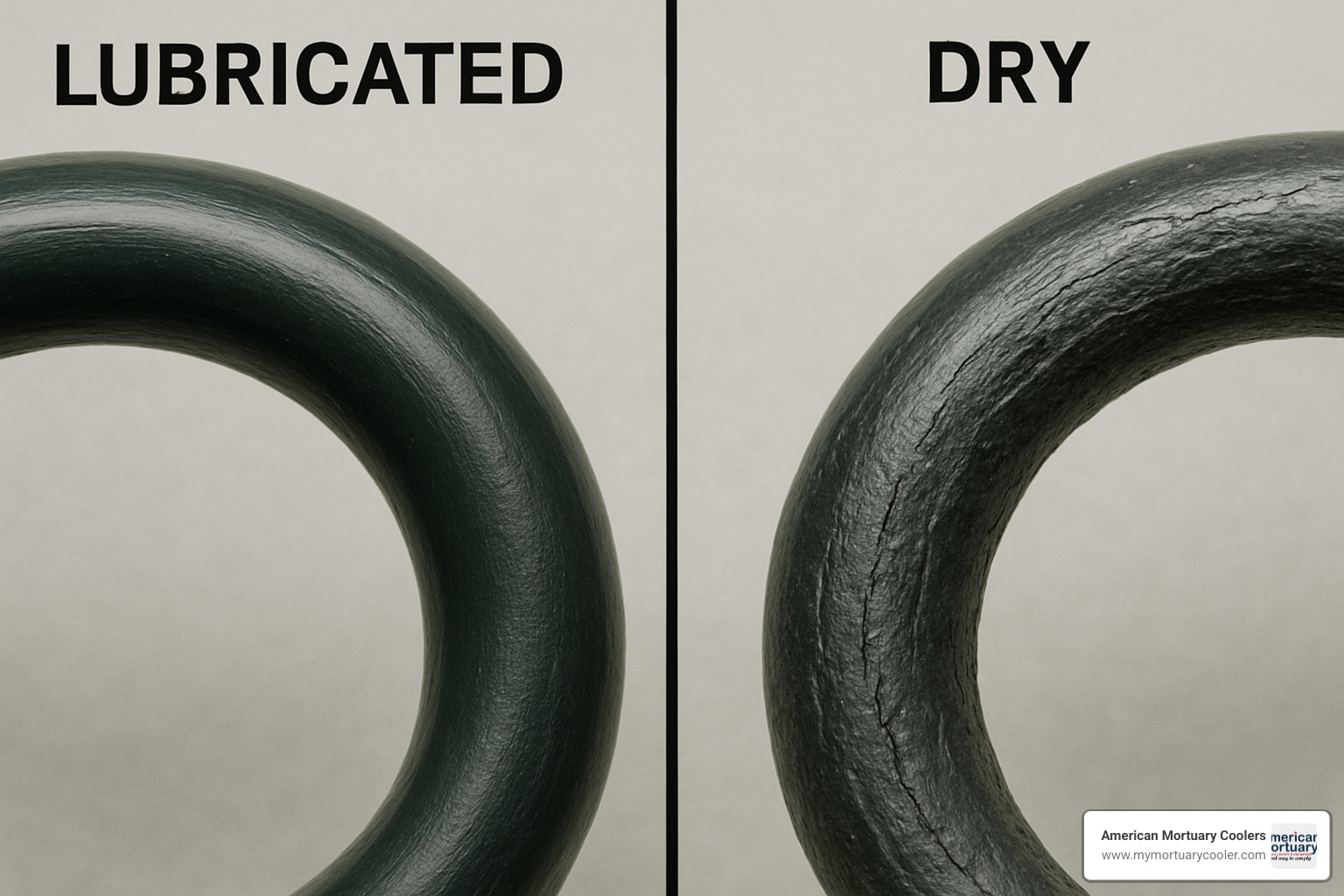

Abrasion is perhaps the most common failure—those tiny scratches and wear marks that eventually compromise the seal. The right lubricant creates a protective barrier film that keeps surfaces from directly contacting each other.

Extrusion happens when pressure forces ring material into clearance gaps. It's particularly common in high-pressure applications. The right lubricant with appropriate viscosity helps support the ring structure against this pressure.

Thermal cracking occurs when heat breaks down the ring material over time. A good lubricant dissipates heat and reduces friction-generated temperature spikes.

Chemical swelling is the silent killer of many lubricant rings. When exposed to incompatible fluids, rings can expand, soften, and lose their sealing properties.

Contamination ingress is particularly relevant in mortuary environments, where cleanliness is paramount. Foreign particles can cause wear or compromise seals.

Standards, Certifications & Compliance for Lubricant Rings

When it comes to lubricant rings in sensitive applications like mortuary equipment, compliance isn't just paperwork—it's peace of mind. Several important standards may apply:

NSF H1 certification is crucial for lubricants with potential incidental food contact. Similarly, FDA 21 CFR 178.3570 compliance covers lubricants that might occasionally contact food or food-adjacent environments.

For hygiene-critical applications, look for ISO 21469 certification. ASTM D2000 provides a standard classification system for rubber materials.

Products like the O-Ring Silicone Lubricant from Super Lube® offer multiple certifications—it's NSF H1 registered, meets USDA 1998 H1 guidelines, and is even Kosher certified.

Frequently Asked Questions about Lubricant Rings

What happens if I run a lubricant ring dry?

When lubricant rings run without proper lubrication, they start to suffer almost immediately. Research comparing lubricated and dry O-rings shows friction can jump by up to 50% when lubricant is absent. This extra friction is like sandpaper slowly wearing away at the ring material.

Without that protective film of lubricant, direct surface-to-surface contact creates heat - lots of it. This localized heating causes the ring material to degrade much faster than normal. You might also notice a jerky, stuttering motion (what engineers call "stick-slip") that damages both the ring and whatever it's touching.

"I've seen refrigeration systems completely fail because of a single dry lubricant ring," shares one of our technicians at American Mortuary Coolers. "What started as a simple maintenance oversight ended with a $3,000 compressor replacement."

The bottom line? A dry lubricant ring might last only 20% as long as a properly lubricated one.

Which lubricant is safest for food-contact O-rings?

When it comes to lubricant rings that might come into contact with food, safety isn't just important—it's non-negotiable.

The gold standard for food safety is NSF H1 certification, which means a lubricant is approved for incidental food contact. Several excellent options meet this standard:

Super Lube® O-Ring Silicone Lubricant stands out with its NSF H1 registration, USDA H1 compliance, and even Kosher certification. For applications involving drinking water, Dow 111 O-ring Lubricant with its NSF 51 and NSF 61 approvals is often our go-to choice.

At American Mortuary Coolers, we exclusively use NSF H1-certified lubricants for all lubricant ring applications in our refrigeration systems.

How often should I re-lubricate a dynamic seal?

"How often should I add more lubricant?" might be the most common question we get about lubricant rings, and unfortunately, there's no one-size-fits-all answer.

For light-duty applications with low speeds and clean environments, you might get away with relubrication every 6-12 months or every 1,000-2,000 operating hours. Medium-duty applications typically need attention every 3-6 months or 500-1,000 hours. If your lubricant rings are working hard in harsh conditions, you're looking at more frequent maintenance - possibly every 1-3 months or 200-500 operating hours.

"We've found that synthetic lubricants generally last 2-3 times longer than conventional ones," notes our lead service technician.

For our mortuary cooler customers, we typically recommend relubrication of dynamic lubricant rings during our scheduled maintenance visits. These happen every 6-12 months depending on usage patterns and local conditions.

Conclusion

Lubricant rings might seem like small, unremarkable components, but they're actually the unsung heroes of mechanical systems everywhere. From the O-rings in your kitchen faucet to specialized NILOS-rings in heavy industrial equipment, these humble parts make a world of difference in how machines perform day after day.

I've seen how the right lubricant ring properly maintained can transform equipment reliability. Research backs this up, showing that well-lubricated rings can withstand hundreds of thousands of cycles without failing. This translates directly to your bottom line through fewer repairs, less downtime, and longer-lasting equipment.

Here at American Mortuary Coolers, we take lubricant rings seriously because we understand what's at stake. Our funeral home customers depend on consistent, reliable cooling to maintain dignity and safety in their operations. That's why we train all our technicians to be experts in selecting the right lubricants and applying them correctly.

Whether you're maintaining equipment you already have or designing something new, the humble lubricant ring often stands between smooth operation and frustrating, expensive breakdowns. Think of it this way: investing a little time and money in quality components and proper maintenance now saves a lot more of both later on.

I've worked with mortuary equipment across the country, from Johnson City to Los Angeles, and I've learned that paying attention to these "little things" like lubricant rings is what separates equipment that lasts from equipment that disappoints. When systems fail, it's often these small components that caused the problem.

For more information about specialized equipment for the funeral industry, take a look at our guide on Mobi Medical equipment.

With locations throughout the United States including Johnson City TN, Atlanta GA, Chicago IL, and Los Angeles, American Mortuary Coolers is your nationwide partner for dependable refrigeration solutions backed by real technical expertise.