Why Morgue Freezer - 16 Temperature Control Matters for Your Facility

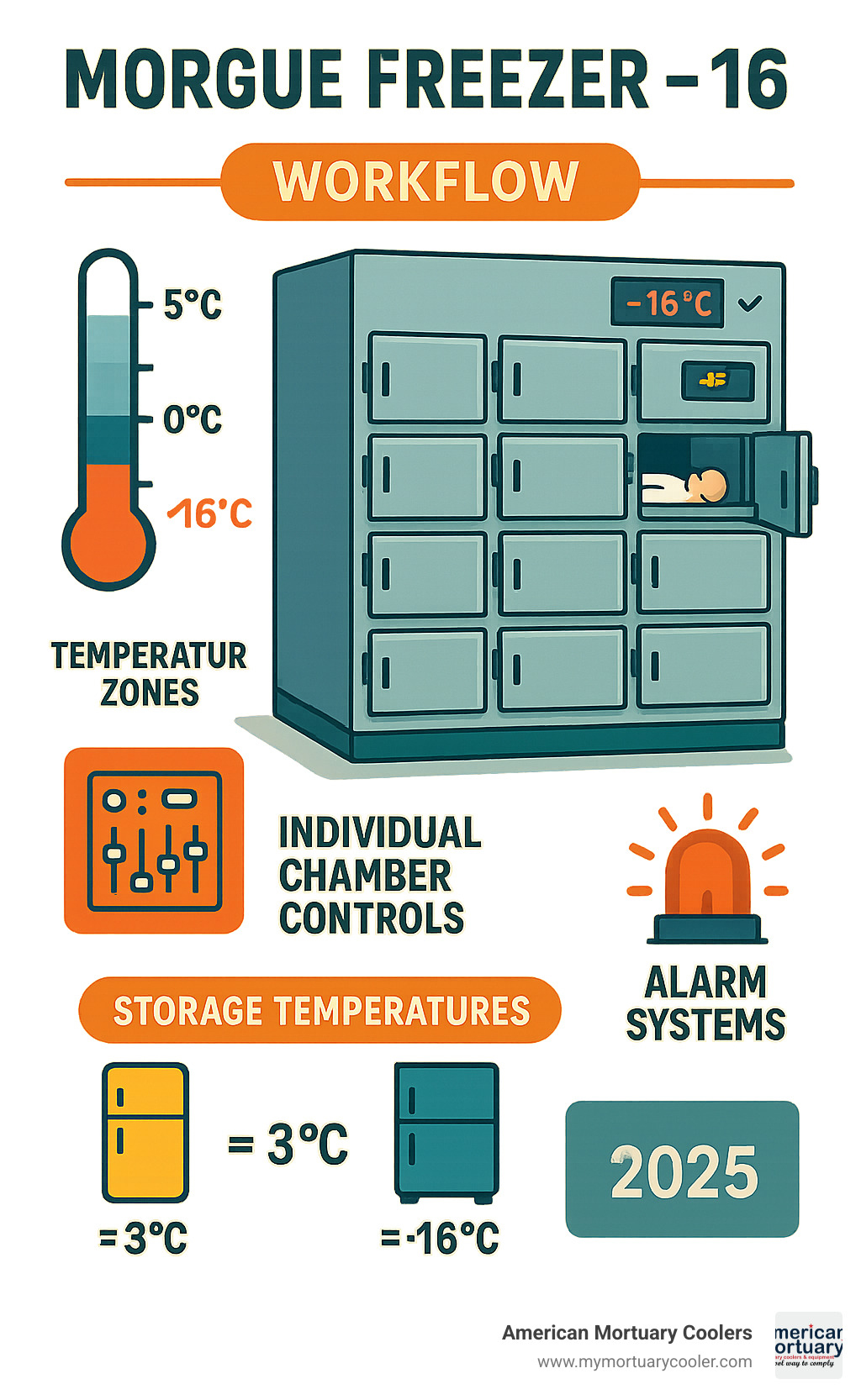

A morgue freezer - 16 refers to a specialized mortuary refrigeration unit designed to maintain precise temperature control at -16°C (3°F) for long-term body preservation. The "-16" specification indicates the unit's ability to operate at this critical temperature setpoint, essential for extended storage periods beyond standard mortuary refrigerators.

Key specifications of a morgue freezer - 16:

- Temperature range: -16°C to 5°C with 0.1°C precision

- Individual chamber control: Each compartment operates independently

- Capacity options: 1 to 16+ body configurations available

- Construction: 304 stainless steel with polyurethane insulation

- Safety features: Multiple alarm systems with 72-hour battery backup

- Compliance: CE and ISO 9001 certified models

The primary difference between a morgue freezer - 16 and standard mortuary refrigerators lies in temperature capability. While morgue refrigerators operate between 2°C to 4°C for short-term storage, morgue freezers reach -16°C to -30°C for extended preservation periods.

Modern morgue freezer - 16 units feature individual temperature control for each chamber, ensuring one compartment's settings don't affect others. This is crucial for facilities handling multiple cases with different storage requirements simultaneously.

Find more about morgue freezer - 16:

Understanding Morgue Freezers and the "-16" Specification

When shopping for mortuary refrigeration, understanding temperature differences is crucial. A morgue freezer - 16 serves a completely different purpose than standard mortuary refrigerators, and knowing when you need which one can save both money and headaches.

The science behind body preservation is straightforward. Bacteria cause tissue breakdown, and these slow dramatically when temperatures drop. At normal refrigeration temperatures of 2°C to 4°C, you preserve bodies for several days to maybe a week. Drop that temperature to -16°C with a morgue freezer - 16, and you're talking about weeks or even months of preservation time.

| Feature | Morgue Refrigerator | Morgue Freezer - 16 |

|---|---|---|

| Temperature Range | 2°C to 4°C | -16°C to -30°C |

| Storage Duration | 3-7 days | Weeks to months |

| Primary Use | Short-term storage | Long-term preservation |

| Energy Consumption | Lower | Higher |

| Initial Cost | Lower | Higher |

For more detailed insights, check out our comparison guide between morgue refrigerators and freezers.

What Is a Morgue Freezer?

A morgue freezer is a specialized refrigeration system built specifically for preserving human remains at sub-zero temperatures. The cooling cycle works through a robust compressor system that circulates refrigerant through evaporator coils, constantly removing heat from storage chambers.

The insulation uses polyurethane foam with 40-45 kg/m³ density, providing excellent thermal performance while being CFC-free. Quality units feature 4 to 10 cm thick insulation depending on manufacturer specifications.

Decoding "morgue freezer - 16"

The "-16" designation refers to the temperature set-point capability of -16°C (3°F). Modern morgue freezer - 16 units typically offer a set-value range from -16°C to 5°C, with some models reaching -18°C to -30°C for extended preservation needs.

The calibration precision of 0.1°C ensures accurate temperature control through advanced digital microprocessor controls that continuously monitor and adjust the refrigeration system.

One of the most important features is independent chamber control. Each chamber has its own temperature control and refrigeration system, so temperature in one chamber doesn't affect others. This is particularly important when maintaining different storage conditions simultaneously.

For more technical information about cryogenic equipment, explore scientific research on cryogenic equipment.

Key Features & Specifications of a Morgue Freezer - 16

When shopping for a morgue freezer - 16, you'll want to understand what makes these units special. These aren't typical commercial freezers - they're precision-engineered systems designed specifically for mortuary facilities' unique demands.

The standout feature is the individual chamber control system. Each chamber operates completely independently with its own compressor and temperature controls. This means if one chamber needs -16°C for long-term storage while another requires 4°C for short-term needs, both can run simultaneously without interference.

Construction materials reflect the serious nature of this equipment. 304-grade stainless steel forms the foundation, covering both interior and exterior surfaces. This resists corrosion from harsh cleaning chemicals and maintains hygiene standards.

Polyurethane foam insulation provides the thermal barrier enabling precise temperature control. Quality units use foam with 40 kg/m³ density, creating an effective barrier against temperature fluctuations while being environmentally friendly.

Safety systems are comprehensive because there's no room for error. Multiple alarm systems include high and low temperature alerts, door-open warnings, sensor failure notifications, and power failure alarms. The 72-hour battery backup system maintains alarm functions and temperature displays for up to three days during power outages.

Temperature Range & Individual Chamber Control in a Morgue Freezer - 16

A morgue freezer - 16 offers impressive temperature flexibility, typically ranging from -30°C to 5°C. While standard operating range centers around -16°C to 5°C, this broad capability lets you adjust storage conditions based on specific needs.

Individual chamber control works through dual thermostats and chamber isolation systems. Each chamber gets its own temperature sensor and refrigeration circuit, meaning one chamber can maintain -16°C for long-term storage while another operates at 4°C for short-term needs.

Digital controllers feature LED displays showing real-time temperatures with ±1°C accuracy. Many models include password protection to prevent unauthorized temperature adjustments.

For comprehensive information about optimal temperatures, visit our guide on Morgue Freezer Temperature 101: How Cold is a Morgue Freezer?

Construction Materials & Thermal Insulation

Construction prioritizes both durability and hygiene. Type 304 stainless steel serves as the industry standard for all surfaces contacting bodies or cleaning agents, providing excellent corrosion resistance.

The thermal insulation system uses polyurethane foam with 40 kg/m³ density, injected at high pressure to eliminate air pockets. Insulation thickness varies from 80mm to 100mm depending on the model.

Safety, Alarm & Backup Systems

Safety systems create multiple protection layers: high and low temperature alarms, door-open alarms, sensor failure alarms, and power failure alarms. The 72-hour battery backup system maintains alarm functions during extended power failures.

Password protection prevents unauthorized access to temperature controls, while buzzer and light alerts provide both audible and visual warnings. CE and ISO compliance ensures units meet international safety and quality standards.

Sizing, Capacity Options & Configuration Choices

Choosing the right size for your morgue freezer - 16 means finding the perfect fit for your facility's needs. Whether you're running a small funeral home or managing a large medical facility, there's a configuration that works.

Modern morgue freezer systems offer impressive flexibility. Start with a compact single-body cabinet or go with a walk-in system handling 16 to 20 bodies. It's about matching capacity needs with available space and budget.

Cabinet configurations typically range from 1-body units up to 9-body models. Side-loading models are great for limited space, while end-loading models make stretcher operations easier since you can roll right up to the unit.

For facilities needing serious storage capacity, walk-in systems are game-changers. These modular systems use tongue-and-groove panels that lock together, creating custom storage rooms that can grow with your needs.

The telescopic rack system extends three-quarters of the way out, giving safe access for cadaver lifts and making loading easier on staff. For bariatric cases, extra-wide doors and reinforced assemblies handle additional weight safely.

From 1-Body Cabinets to 16-Body Walk-Ins

A single-cabinet morgue freezer - 16 still provides all essential features - individual temperature control, comprehensive alarm systems, and battery backup. These units typically measure around 240cm x 210cm x 204cm, perfect for smaller funeral homes.

When you need more capacity without endless floor space, double-stack and triple-tier configurations are brilliant solutions. A triple-tier system can store up to 6 bodies in roughly the same footprint as a two-body horizontal unit.

For high-volume facilities, walk-in systems can be configured for 16 to 50+ bodies, with layouts completely customized to your facility's workflow. The scalability means you can start smaller and add modules as needs grow.

Customization, Ergonomics & User-Friendly Design

Modern morgue freezer - 16 units are designed with staff's daily experience in mind. Mobility features like casters on cabinet models mean you can reposition units for cleaning. For fixed installations, integrated ramps make stretcher access smooth and safe.

LED lighting systems provide excellent visibility while being energy-efficient. Stretcher compatibility is carefully designed, with most models accommodating standard mortuary stretchers.

Pass-through units offer unique advantages for facilities with adjoining rooms. One refrigeration system can serve two separate areas, maximizing efficiency while maintaining separate access points.

For detailed guidance on storage accessories, check out our Complete Guide to Choosing Cadaver Storage Racks.

Installation, Maintenance & Compliance Best Practices

Getting your morgue freezer - 16 running properly requires careful preparation and ongoing maintenance. Think of it as setting up a high-tech guardian that needs the right environment and care to perform effectively.

Installation starts with site preparation. You'll need adequate space, proper ventilation, and correct electrical supply. Power requirements vary significantly - single-body units typically run on standard 220-240V, 50/60Hz power, while larger walk-in systems often demand 380V three-phase power.

Ventilation deserves special attention because it directly impacts equipment performance and facility air quality. Poor airflow around condensing units can lead to overheating and reduced efficiency.

Compliance isn't just paperwork - it's assurance that your morgue freezer - 16 meets essential safety and quality standards. Most units should carry CE certification, ISO 9001 quality standards, and meet local electrical codes.

Site Preparation, Power & Ventilation

Before your morgue freezer - 16 arrives, verify your floor can handle the weight. A fully loaded 16-body walk-in system can weigh several thousand pounds.

Electrical planning requires careful consideration of your facility's power infrastructure. Voltage options typically include 220V/50Hz, 110V/60Hz, and 220V/60Hz configurations. If your area experiences frequent power outages, integrating UPS backup systems can maintain operation during interruptions.

Floor drains should be positioned strategically to handle defrost water and cleaning runoff without creating standing water issues.

Cleaning, Calibration & Routine Service

Maintaining your morgue freezer - 16 properly extends its lifespan and ensures reliable performance. Regular cleaning protocols are essential for both hygiene and equipment performance. Stainless steel surfaces are designed for easy cleaning with appropriate cleaners.

Calibration should be performed quarterly to maintain precise 0.1°C accuracy. This involves checking sensor readings against calibrated reference thermometers and making adjustments as necessary.

Condenser coil maintenance is crucial for efficient operation. Dirty coils force the system to work harder and consume more energy. Establishing regular cleaning schedules prevents costly efficiency losses and premature equipment failure.

Certifications & Standards to Verify

When selecting your morgue freezer - 16, verifying certifications protects your investment and ensures regulatory compliance. The CE mark indicates compliance with European safety standards. ISO 9001 certification demonstrates quality management systems throughout production.

FDA compliance may be required for certain applications. ASTM E84 testing verifies insulation materials meet fire safety requirements. EISA 2007 compliance is mandatory for walk-in coolers and freezers, establishing minimum energy efficiency standards.

These certifications represent more than paperwork - they're assurance that your morgue freezer - 16 will perform reliably when families are counting on you most.

Buying Guide: How to Choose the Right Morgue Freezer - 16 for Your Facility

Choosing the right morgue freezer - 16 doesn't have to be overwhelming. At American Mortuary Coolers, we've guided hundreds of facilities through this decision, and the best choices come from understanding your specific needs first, then finding equipment that matches them perfectly.

A morgue freezer - 16 represents one of your facility's most critical investments. These units need to work flawlessly, protecting the dignity of those in your care while supporting daily operations. That's why we tell customers to think beyond just the sticker price.

Budget planning starts with understanding the full picture. Basic single-body units begin around $6,000, while multi-body cabinets typically range from $10,000 to $25,000. Walk-in systems designed for 16 or more bodies usually fall between $30,000 and $60,000.

Lifecycle costs can dwarf the purchase price. A unit costing $5,000 less upfront might consume $10,000 more in energy over its lifetime. Similarly, choosing a supplier without strong service support can lead to costly downtime exceeding any initial savings.

Energy consumption varies dramatically between models. Units with premium insulation and high-efficiency compressors might cost 20-30% more initially, but save thousands in utility bills over their 10-15 year lifespan.

Supplier reputation matters more than you might think. When your morgue freezer - 16 has an issue at 2 AM on a weekend, you need a supplier who answers the phone and has parts readily available.

For a deeper dive into mortuary freezer selection, check out our comprehensive guide: Morgue Freezers 101: Everything You Need to Know.

Cost Factors & Return on Investment

The initial price tells only part of the story. Smart buyers look at total cost of ownership, including energy consumption, maintenance, and potential downtime costs over the equipment's lifetime.

Insulation quality makes the biggest difference in operating costs. Units with 4-inch polyurethane insulation can save $5,000 to $10,000 in energy costs over a decade compared to basic units.

Maintenance contracts deserve serious consideration for critical equipment. These typically cost 8-12% of equipment value annually but provide predictable maintenance budgets and priority service response.

Quick Evaluation Checklist for morgue freezer - 16

When evaluating morgue freezer - 16 options, focus on these key areas:

Capacity planning requires honest assessment of current needs and future growth. Consider typical daily census, peak capacity requirements, and planned facility expansions.

Temperature specifications matter more than many realize. Verify your chosen unit can maintain required temperature range with needed precision. Individual chamber control is essential if you handle cases with different storage requirements simultaneously.

Construction quality directly impacts longevity and hygiene. Insist on 304-grade stainless steel construction and high-density polyurethane insulation.

Compliance documentation protects your facility. Verify CE certification, ISO 9001 quality standards, and local code compliance.

Service and support capabilities often determine long-term satisfaction. Evaluate the supplier's service network, parts availability, warranty terms, and training programs.

The right morgue freezer - 16 will serve your facility reliably for many years. Taking time to evaluate these factors thoroughly ensures you'll make a choice supporting both immediate needs and long-term success.

Frequently Asked Questions about Morgue Freezer - 16

What temperature should a morgue freezer - 16 run at?

The optimal temperature for your morgue freezer - 16 depends on how long you need to preserve bodies and your facility's specific protocols. For standard long-term preservation, -16°C (3°F) is the sweet spot - it's where the name comes from, after all.

But here's the thing: these units are more flexible than you might think. You can adjust the temperature anywhere from -16°C to 5°C depending on what you're dealing with. Need to store a body for several weeks? Set it to -16°C or even -18°C. Got a case that only needs a few days? You can bump it up to regular refrigeration temperatures around 4°C.

Some facilities push it even further to -30°C for very long-term storage - think months rather than weeks. The beauty of modern morgue freezer - 16 systems is that 0.1°C precision control lets you dial in exactly what you need. No guesswork, no "close enough" - just precise temperature management that matches your facility's protocols.

How do individual chambers stay independent?

This is where morgue freezer - 16 technology really shines. Each chamber operates like its own mini-freezer, completely separate from its neighbors. Think of it as having multiple standalone units built into one cabinet - because that's essentially what it is.

Each chamber gets its own compressor system and temperature control setup. There's a dedicated refrigeration circuit for every compartment, along with its own temperature sensor (usually a PT-100 for accuracy). This means chamber one can be humming along at -16°C while chamber two sits comfortably at 4°C, and they won't interfere with each other.

The isolation system prevents temperature cross-contamination between chambers, which is absolutely crucial when you're juggling different storage requirements. If one chamber has a mechanical issue or needs maintenance, the others keep running normally. It's like having a backup plan built right into your equipment.

This independence is a game-changer for busy facilities. You're not stuck with one-size-fits-all storage anymore - you can customize each chamber's environment based on what's actually needed.

What maintenance does a morgue freezer - 16 require annually?

Let's be honest - a morgue freezer - 16 is a workhorse that needs regular attention to keep performing at its best. The good news is that most maintenance tasks are straightforward, and staying on top of them prevents bigger headaches down the road.

Temperature calibration should happen quarterly to maintain that crucial 0.1°C precision. This involves checking your sensors against calibrated reference thermometers and making adjustments as needed. It's not complicated, but it's essential for accurate temperature control.

Monthly condenser coil cleaning keeps your system running efficiently. Dirty coils make your compressor work harder, which means higher energy bills and more wear on components. A simple cleaning routine can save you thousands in energy costs over the equipment's lifetime.

Your electrical system needs annual inspection, including thorough alarm testing. Don't forget about the battery backup system - test it monthly and plan to replace batteries every 2-3 years. There's nothing worse than finding your backup failed during an actual power outage.

Door seals deserve attention too - inspect them quarterly and replace when they show wear. Good seals keep your temperatures stable and your energy costs down. And of course, regular interior cleaning with appropriate stainless steel cleaners keeps everything hygienic and looking professional.

The smart move is having professional service performed annually by technicians who understand mortuary equipment. They'll catch issues you might miss and keep your morgue freezer - 16 running reliably for years to come.

Conclusion

Choosing the right morgue freezer - 16 is one of the most important decisions you'll make for your facility. It's about providing dignified care while ensuring your operations run smoothly day after day.

We've covered essential ground in this guide, from understanding why -16°C precision matters to exploring safety features that keep your facility running during power outages. Key takeaways are clear: individual chamber control gives you flexibility, quality construction materials ensure longevity, and comprehensive alarm systems provide peace of mind.

At American Mortuary Coolers, we've seen how the right equipment makes all the difference. A small funeral home might need a compact single-body unit, while a busy medical examiner's office requires a 16-body walk-in system with multiple temperature zones. That's why we build custom solutions custom to your exact needs.

The investment in a morgue freezer - 16 goes beyond the initial price tag. When you choose equipment with 304 stainless steel construction, polyurethane insulation, and 72-hour battery backup, you're investing in reliability that lasts for decades. The difference between basic and quality equipment often pays for itself through lower energy bills and fewer service calls.

Would you rather deal with a temperature alarm at 2 AM because your equipment failed, or sleep soundly knowing your morgue freezer - 16 has redundant safety systems and proven reliability? The choice is clear.

Proper installation and maintenance are just as important as choosing the right equipment. Those quarterly calibration checks and monthly condenser cleanings might seem like small details, but they keep your system running at peak performance. Facilities that follow these guidelines are the ones calling us to say their equipment is still running perfectly after 15 years.

Our direct delivery service across the contiguous 48 states means you get quality equipment with the support you need, right when you need it. Whether you're upgrading an existing facility or planning a new one, we're here to help you steer the choices and find the perfect morgue freezer - 16 solution.

For more information about our complete range of mortuary refrigeration solutions, visit our main website. Our team is ready to help you select the right system for your facility's specific needs, ensuring reliable operation and respectful care for years to come.