Why Morgue Refrigeration Door Quality Matters for Your Facility

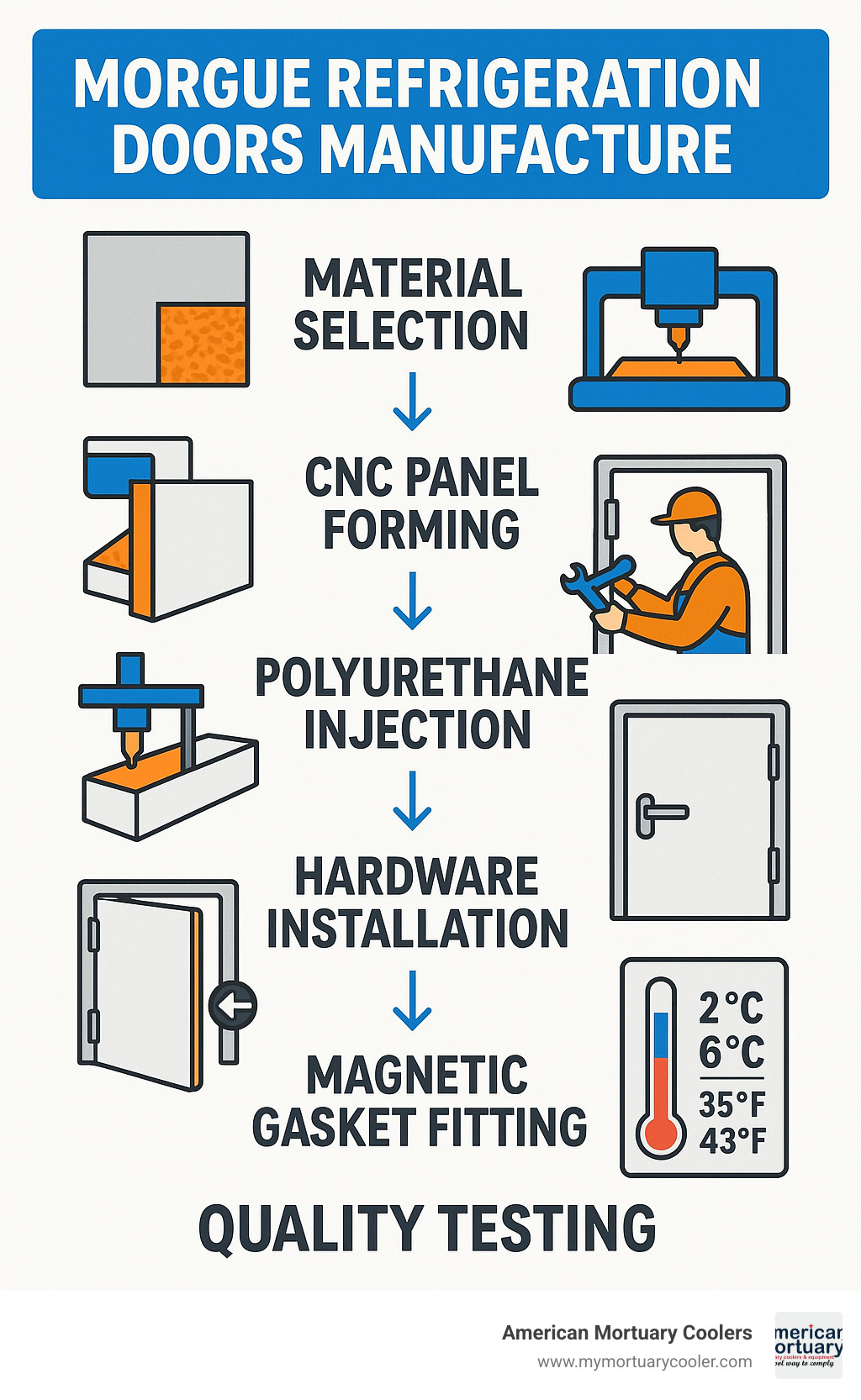

Morgue refiregeration doors manufacture involves creating specialized insulated doors that maintain critical temperature ranges between 2°C and 6°C (35°F to 42°F) for proper cadaver preservation. These doors serve as the primary barrier protecting your facility's cold chain integrity.

Key Morgue Refrigeration Door Manufacturing Elements:

- Materials: 20-gauge type 304 stainless steel fronts with stucco-embossed aluminum panels

- Insulation: 4-inch foamed-in-place polyurethane for optimal thermal performance

- Hardware: Chrome-plated components with OSHA-compliant safety release handles

- Sealing: Magnetic gaskets ensuring airtight closure and energy efficiency

- Certifications: NSF approval and ISO 9001:2015 compliance for quality assurance

The manufacturing process requires precision engineering to prevent thermal bridging, ensure proper airflow, and maintain consistent temperatures across units ranging from compact 2-body boxes to large walk-in systems accommodating up to 50 bodies.

Quality matters because door failures can compromise cadaver preservation, increase energy costs, and disrupt facility operations. Poor sealing leads to temperature fluctuations, while inadequate insulation drives up utility bills.

As Mortuary Cooler, I've spent years helping funeral homes steer the complexities of morgue refiregeration doors manufacture and equipment selection. My experience as a national-level mortuary cooler supplier has shown me how the right door specifications can make or break your facility's efficiency and reliability.

Core Functions & Door Configurations

When you're choosing morgue refrigeration doors, you're not just picking a simple barrier. These doors work overtime to keep temperatures stable, maintain workflow efficiency, and protect your staff—all while operating reliably in one of the most demanding environments imaginable.

The best morgue refiregeration doors manufacture processes focus on creating doors that handle multiple critical functions simultaneously. They need to provide secure access for authorized personnel while keeping unauthorized visitors out. They must support your facility's workflow efficiency by accommodating gurneys, transport equipment, and staff movement patterns. Most importantly, they ensure safety compliance with OSHA regulations while operating dependably for decades.

Modern morgue doors integrate safety systems including emergency release handles, magnetic gaskets for airtight sealing, and keyed locks for security. The manufacturing process must account for bariatric configurations that accommodate larger individuals, as well as pass-through designs that separate intake and release areas for better workflow management.

What Are Morgue Refrigeration Doors?

Think of morgue refrigeration doors as the guardians of your facility's cadaver preservation system. Unlike the refrigerator door in your break room, these engineered barriers must maintain precise temperature control while accommodating the unique challenges of human remains transport.

The primary function centers on preserving the deceased by maintaining that critical 2°C to 6°C temperature range. This isn't just about keeping things cold—it's about slowing decomposition while preventing freezing damage to tissues. When doors seal properly, facilities can reduce energy consumption by up to 30% compared to poorly fitted alternatives.

Every morgue door manufactured today must include OSHA-compliant safety release handles. These handles allow emergency exit from inside refrigerated compartments—a mandatory safety feature for any walk-in configuration where personnel might become accidentally trapped. It's one of those features you hope you'll never need, but you'll be grateful it's there.

Major Door Types Explained

Walk-in swing doors serve as the workhorses for large-capacity installations supporting 5 to 50 bodies. These doors require heavy-duty hinges and comprehensive sealing systems due to their size and frequent use. They're perfect for facilities that need maximum flexibility and storage capacity.

Sliding doors and vertical lift doors offer space-saving solutions when swing clearance becomes an issue. However, these configurations require more complex sealing mechanisms and regular maintenance of track systems. They're worth considering if your facility has tight space constraints.

Roll-up doors work well for specialized applications, though they're less common in morgue applications due to sealing challenges. Most facilities find that traditional swing or sliding options provide better long-term reliability.

Compartment "body box" doors provide individual access to stacked storage units, maximizing space efficiency in compact facilities. Each door operates independently with its own sealing system and temperature monitoring. Our research shows that front-loading configurations dominate the market with 204 available models compared to just 22 side-loading models.

Roll-in configurations accommodate gurneys and transport equipment, featuring wider openings and reinforced construction. These doors often include heated jambs to prevent condensation and ice buildup around sealing surfaces.

Pass-through systems enable separate loading and unloading areas, improving workflow efficiency and maintaining security protocols. These configurations require precise alignment and dual-door coordination systems, but they're invaluable for facilities with single vs double entry requirements.

Materials, Insulation & Performance Specs

When it comes to morgue refiregeration doors manufacture, the materials you choose today will determine whether your doors are still working perfectly in twenty years or giving you headaches next month. I've seen too many facilities cut corners on materials only to face costly replacements when cheap components fail. For a deeper dive into the science behind industrial cooling, the refrigeration entry on Wikipedia offers a helpful overview.

The foundation starts with understanding what your doors will face daily: frequent cleaning with harsh chemicals, temperature cycling, constant humidity changes, and the physical demands of moving bodies in and out. Your door materials need to handle all of this without breaking down.

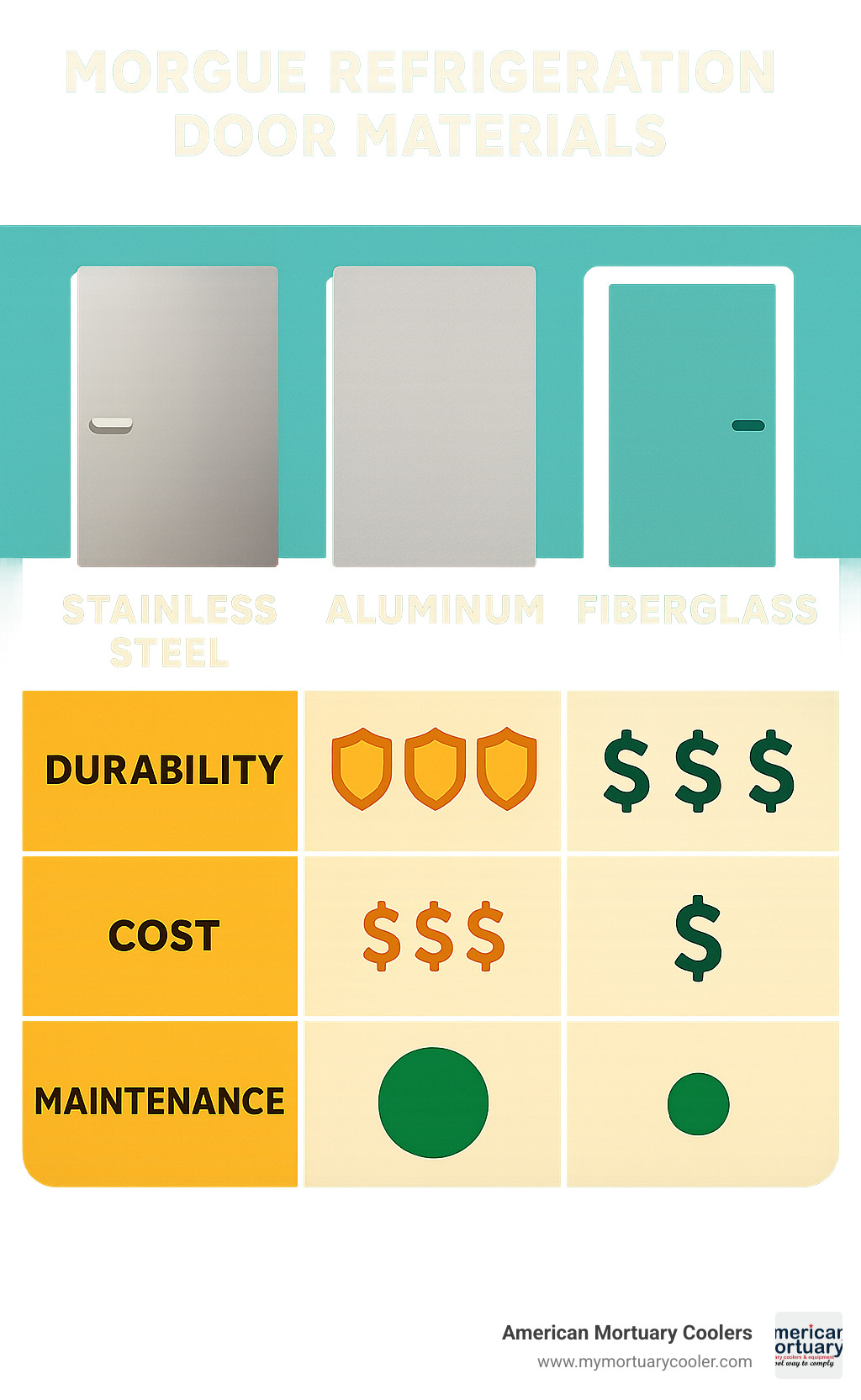

Choosing the Right Core Materials

Stainless steel remains the gold standard for morgue doors, and there's good reason why. Twenty-gauge type 304 stainless steel provides exceptional corrosion resistance that laughs at cleaning chemicals and moisture. The #4 finish strikes the perfect balance - it looks professional while hiding minor scratches that happen during daily use.

Yes, stainless steel costs more upfront. But when you're still cleaning it easily after fifteen years while aluminum doors show wear and corrosion, you'll appreciate the investment. The seamless appearance also helps maintain the dignified environment families expect.

Stucco-embossed aluminum offers a middle ground that many facilities find practical. At 0.032" thickness, it provides solid durability while keeping door weight manageable. This matters when your staff opens and closes doors hundreds of times each week.

Aluminum works well for backing materials and secondary panels where direct exposure is limited. The cost savings can be significant on larger installations, allowing you to invest more in critical components like insulation and hardware.

Fiberglass construction eliminates bacterial concerns that keep facility managers awake at night. Companies like Polar King have perfected seamless fiberglass interiors with anti-microbial finishes that meet strict NSF sanitation requirements.

The seamless construction means no joints, cracks, or crevices where bacteria can hide. For facilities handling infectious disease cases or maintaining the highest sanitation standards, fiberglass interiors provide best peace of mind.

Four-inch foamed-in-place polyurethane insulation forms the thermal heart of quality doors. This isn't the cheap foam you see in basic coolers - it's engineered insulation that maintains its R-value for decades while preventing thermal bridging.

The foaming process creates a complete seal within door panels, eliminating air gaps that destroy insulation performance. Quality manufacturers inject this foam under controlled conditions, ensuring consistent density and thermal properties throughout each door.

Critical Hardware & Safety Features

Magnetic gasket systems work like magic - they create perfect seals without mechanical latches that break or need constant adjustment. The magnetic force pulls gaskets tight against door frames, maintaining consistent pressure around the entire perimeter.

This consistent sealing pressure ensures temperature stability while reducing energy costs. Unlike compression gaskets that lose their "squeeze" over time, magnetic systems maintain their sealing force for years of reliable operation.

Chrome-plated hardware withstands the daily punishment that morgue doors endure. Quality manufacturers specify heavy-duty components designed for thousands of open-close cycles without loosening or corroding.

The chrome plating isn't just for looks - it provides a hard, corrosion-resistant surface that cleans easily and maintains its appearance. Cheap hardware fails quickly in morgue environments, creating safety hazards and operational disruptions.

OSHA safety release handles save lives in walk-in configurations where staff might become accidentally trapped. These handles must operate without tools and work reliably even in freezing conditions.

The safety release mechanism bypasses all locking systems, allowing immediate exit from inside refrigerated spaces. This isn't optional equipment - it's mandatory for compliance and essential for worker safety.

Heated door frames prevent the ice buildup that destroys sealing performance and creates operational headaches. Strategic heating elements warm frame surfaces just enough to prevent condensation and ice formation.

This feature becomes critical in high-humidity environments or facilities with frequent door operation. Without heated frames, ice buildup can prevent doors from closing properly, compromising temperature control and increasing energy costs.

Digital temperature monitoring integrates seamlessly with modern door systems, providing continuous tracking with 0.16 precision. Advanced systems include alarm functions and data logging capabilities that satisfy compliance requirements while protecting your facility's reputation.

These monitoring systems alert staff immediately when temperatures drift outside acceptable ranges, allowing quick corrective action before problems develop. The data logging also provides documentation needed for regulatory compliance and insurance requirements.

For comprehensive guidance on maximizing door performance and extending component life, review our detailed maintenance best practices that cover everything from gasket care to hardware lubrication.

Morgue Refiregeration Doors Manufacture: Process, Standards & Quality Control

Creating quality morgue doors isn't something you can rush. Morgue refiregeration doors manufacture demands precision at every step, from the first CAD drawing to the final temperature test. One small mistake during production can mean the difference between a door that works flawlessly for decades and one that fails when you need it most.

The manufacturing process has evolved significantly over the past few decades. What once relied heavily on manual craftsmanship now combines CNC precision with traditional techniques to achieve results that meet today's strict standards. Companies like Frank Door Company have perfected this balance over 35 years, using their 60,000 square foot facility to blend automated cutting with skilled hand finishing.

Modern manufacturers must steer complex regulations including DOE/EISA compliance for energy efficiency and UL-NSF lighting requirements. These standards ensure that every door meets both performance and safety expectations right out of the gate.

Key Stages in Morgue Refiregeration Doors Manufacture

Design and CAD engineering sets the foundation for everything that follows. Engineers don't just measure your space - they analyze your workflow, consider how staff will move through the facility, and optimize door placement for maximum efficiency. This planning stage prevents costly mistakes later.

Material preparation starts with CNC-controlled cutting and forming. The precision here matters enormously because even small variations can create problems during assembly. Quality manufacturers invest in advanced equipment that maintains tolerances measured in thousandths of an inch.

The insulation injection process represents the most critical stage of production. Foamed-in-place polyurethane requires exact temperature and pressure control to achieve uniform density throughout the door panel. The tongue-and-groove panel design ensures tight seals between sections, but only if the insulation cures properly.

Hardware installation demands careful attention to alignment and torque specifications. Chrome-plated components receive individual inspection because even tiny flaws can lead to premature failure. The hardware must operate smoothly thousands of times while maintaining its appearance and corrosion resistance.

Gasket fitting involves more than just pressing rubber into place. Magnetic gaskets must provide consistent compression across the entire door perimeter while remaining flexible in near-freezing conditions. This balance requires careful material selection and precise installation techniques.

Quality testing includes comprehensive leak testing and temperature performance validation. ISO 9001:2015 certified manufacturers like Mortech Manufacturing perform multiple test cycles before any door leaves their facility. This testing catches problems that might not show up until months after installation.

Common Pitfalls in Morgue Refiregeration Doors Manufacture

Thermal bridging remains one of the most common manufacturing defects. This happens when heat finds a path through structural elements, bypassing the insulation entirely. Poor manufacturers often overlook thermal breaks, creating cold spots that lead to condensation and energy waste.

Warping and dimensional instability typically result from rushing the curing process. When insulation doesn't cure at the proper temperature or for adequate time, doors can twist or bow as they age. This seemingly minor issue can make proper sealing impossible.

Gasket failure often traces back to poor material choices or installation errors. Cheap gaskets might work initially but lose flexibility over time. Quality manufacturers specify materials that maintain their sealing properties across temperature ranges while providing consistent pressure.

Manufacturing challenges extend beyond the factory floor. Shipping knock-down systems reduce costs and damage risk, but they require skilled technicians for on-site assembly. The Guidelines for walk-in coolers and freezers provide important context for these installation requirements.

At American Mortuary Coolers, we understand these manufacturing complexities because we've seen what happens when shortcuts are taken. Our Tennessee-based operation focuses on getting every detail right the first time, ensuring your doors perform reliably for years to come.

Innovations, Integration & Customization Options

Today's morgue refiregeration doors manufacture has evolved far beyond basic insulated barriers. Modern facilities demand smart technology, seamless integration, and custom solutions that adapt to unique operational needs.

The most exciting development? Dual-mechanical backup systems that automatically switch over when primary systems fail. This redundancy ensures your facility never loses temperature control, even during equipment emergencies.

IoT data loggers now track every temperature fluctuation with precision monitoring. These smart systems send alerts directly to your phone when temperatures drift outside safe ranges. No more middle-of-the-night surprises or compromised preservation.

Antimicrobial coatings represent the cutting edge of hygiene technology. These specialized finishes go beyond standard stainless steel, actively preventing bacterial growth while maintaining easy cleaning protocols.

Color-matching options have transformed morgue aesthetics. Frank Door Company pioneered this innovation, allowing facilities to coordinate with existing décor or implement color-coding systems for improved workflow efficiency.

RFID access control integration provides secure, trackable entry to refrigerated areas. Staff credentials automatically log access times and durations, supporting compliance documentation and security protocols.

How Doors Integrate with Full Refrigeration Systems

Smart door design starts with understanding airflow patterns. Evaporator placement must coordinate perfectly with door locations to maintain uniform cooling throughout storage areas. Finned-tube evaporators work best in forced-air circulation systems that account for door opening patterns.

Rack compatibility drives door sizing decisions. Cantilever storage systems supporting multiple bodies require wider openings and reinforced construction. Roll-in configurations need precise measurements to accommodate gurney maneuvering space without compromising seal integrity.

Workflow efficiency improves dramatically with strategic door placement. Pass-through configurations enable separate loading and unloading areas, reducing cross-contamination risks while improving operational flow during busy periods.

Modern doors integrate seamlessly with building management systems, alarm networks, and access control platforms. This system integration provides centralized monitoring and control from a single dashboard.

For detailed guidance on coordinating doors with complete refrigeration systems, our comprehensive equipment options guide covers system-wide integration strategies.

Custom Projects & Large-Scale Installations

Walk-in systems accommodating up to 50 bodies require custom engineering solutions that balance accessibility with thermal performance. Mortech Manufacturing, America's largest morgue refrigeration manufacturer, specializes in modular panel systems that facilitate easy assembly, disassembly, and relocation as needs change.

Large facilities benefit from modular expansion capability that grows with demand. Prefabricated panels with precision-formed insulation enable reconfiguration without complete system replacement. This flexibility proves invaluable for expanding funeral homes and medical facilities.

Specialized applications push manufacturing boundaries. Bariatric storage units require reinforced construction and oversized openings. Disaster response systems need rapid deployment capability. Mobile installations demand compact, efficient designs that maintain full functionality.

Field hospitals and emergency response scenarios require rapid deployment systems with simplified installation procedures. These custom solutions maintain full temperature control while enabling quick setup in challenging environments.

The ongoing scientific research on energy-efficient refrigeration continues driving innovations in door design and building system integration, promising even more efficient solutions in the coming years.

Advanced automation systems now handle routine monitoring tasks, freeing staff for more critical responsibilities. These automation features include automatic defrost cycles, predictive maintenance alerts, and energy optimization protocols that reduce operational costs while improving reliability.

Frequently Asked Questions about Morgue Refrigeration Doors

When you're investing in morgue refiregeration doors manufacture, you naturally have questions about how these specialized systems work. Let me address the most common concerns I hear from funeral directors and facility managers across the country.

How do magnetic gaskets maintain temperature stability?

Think of magnetic gaskets as the unsung heroes of temperature control. Unlike the old-style mechanical latches that can work loose over time, magnetic gaskets create consistent sealing pressure around your entire door perimeter without any fiddling or adjustment needed.

Here's what makes them so effective: the magnetic force automatically adjusts as materials expand and contract with temperature changes. When your facility moves from ambient temperature to that critical 2°C to 6°C range, the gasket maintains perfect contact.

The gasket material stays flexible even in cold conditions, which means it keeps doing its job year after year. I've seen quality magnetic gaskets maintain seal integrity for years without replacement - though I always recommend regular inspection to catch any issues early.

The magnetic force also makes daily operations smoother. Your staff gets easy door operation with positive closure indication, so they know immediately when the door is properly sealed.

Which certifications should a morgue door meet?

This is where things get serious - certifications aren't just paperwork, they're your protection against costly problems down the road.

NSF Certification tops the list because it ensures your doors meet strict sanitation requirements for mortuary applications. This covers everything from material safety to cleanability and bacterial resistance standards. Without NSF approval, you could face compliance issues during inspections.

ISO 9001:2015 Compliance tells you the manufacturer has quality management systems in place. Leading companies like Mortech Manufacturing maintain this certification because it demonstrates ongoing commitment to consistent manufacturing standards.

OSHA Compliance isn't optional - it's the law for safety release handles and emergency exit capabilities in walk-in configurations. These requirements protect your staff who might accidentally become trapped inside refrigerated spaces.

For electrical components, UL Approval covers lighting systems and control panels. Those vapor-proof lighting fixtures must meet UL standards for safe operation in high-humidity morgue environments.

DOE/EISA Compliance ensures energy efficiency standards, particularly important for walk-in installations. The Federal Energy Independence & Security Act of 2007 establishes minimum insulation requirements that can significantly impact your utility bills.

What maintenance schedule maximizes gasket life?

Smart maintenance saves money - it's that simple. I recommend a straightforward schedule that prevents expensive emergency repairs.

Monthly visual inspections should become routine. Check for tears, deformation, or debris buildup that could compromise sealing. Clean gaskets with mild detergent and inspect magnetic strips for damage or foreign material. This takes just a few minutes but prevents major headaches.

Quarterly deep cleaning involves removing gaskets for thorough cleaning and inspection. Check mounting surfaces for corrosion or damage that could affect gasket performance. This deeper look often catches problems before they become costly failures.

Annual replacement assessment evaluates overall gasket condition and sealing effectiveness. Your temperature monitoring system can indicate declining seal performance before you see visible gasket failure - rising energy costs often signal seal problems.

Watch for immediate replacement indicators including visible cracking, permanent deformation, loss of magnetic attraction, or temperature monitoring showing increased energy consumption. Don't wait when you see these warning signs.

With proper maintenance, quality gaskets last 3-5 years in normal service. Neglected gaskets may fail within months of installation - a costly mistake that's easily prevented with regular attention.

Conclusion

After years of helping funeral homes across the country, I've learned that quality morgue refiregeration doors manufacture isn't just about meeting specifications—it's about protecting your facility's most important responsibility. Every door we manufacture carries the weight of families' trust and your professional reputation.

The difference between a properly manufactured door and a cheap alternative becomes clear within the first year of operation. Quality doors maintain consistent temperatures, reduce energy costs by up to 30%, and operate reliably for decades. Poor doors fail when you need them most, compromising preservation and disrupting operations during already difficult times.

What makes the difference in door quality? It starts with 4-inch polyurethane insulation that prevents thermal bridging and maintains stable temperatures. 20-gauge type 304 stainless steel construction provides the durability needed for daily operation while meeting strict hygiene standards. OSHA-compliant safety features protect your staff, while NSF certification ensures you meet all regulatory requirements.

The magnetic gasket systems we specify aren't just about sealing—they're about peace of mind. When a family entrusts their loved one to your care, that door needs to work perfectly every single time. No exceptions, no failures, no compromises.

At American Mortuary Coolers, we've built our Tennessee-based operation around one simple principle: every facility deserves equipment that works as hard as they do. Whether you're installing a compact 2-body unit in a small funeral home or designing a large walk-in system for a busy medical examiner's office, the manufacturing quality determines everything that follows.

Our direct delivery model across the contiguous 48 states means you're working directly with the people who build your equipment. No middleman markups, no communication gaps, no excuses. When you call with questions or need support, you're talking to someone who understands both the technical details and the human side of what you do.

The mortuary industry doesn't offer second chances when equipment fails. Families depend on you, and you need to depend on your equipment. That's why we focus on proven manufacturing techniques, comprehensive testing, and the kind of customer support that treats your success as our success.

Ready to discuss what your facility needs? Our team provides personalized consultation because we know that no two facilities are exactly alike. From custom design through installation and ongoing support, we're here to ensure your equipment performs flawlessly for years to come.

For complete information about our custom mortuary cooler solutions and door options, visit More info about custom mortuary coolers.