Why Professional Mortuary Lifting Equipment is Essential for Modern Facilities

Mortuary Lift Company www.americanmortuarycoolers.com represents the gold standard in professional body handling equipment, serving funeral homes, hospitals, and morgues worldwide for over 50 years. When searching for reliable mortuary lifting solutions, here's what you need to know:

Key Products & Specifications:

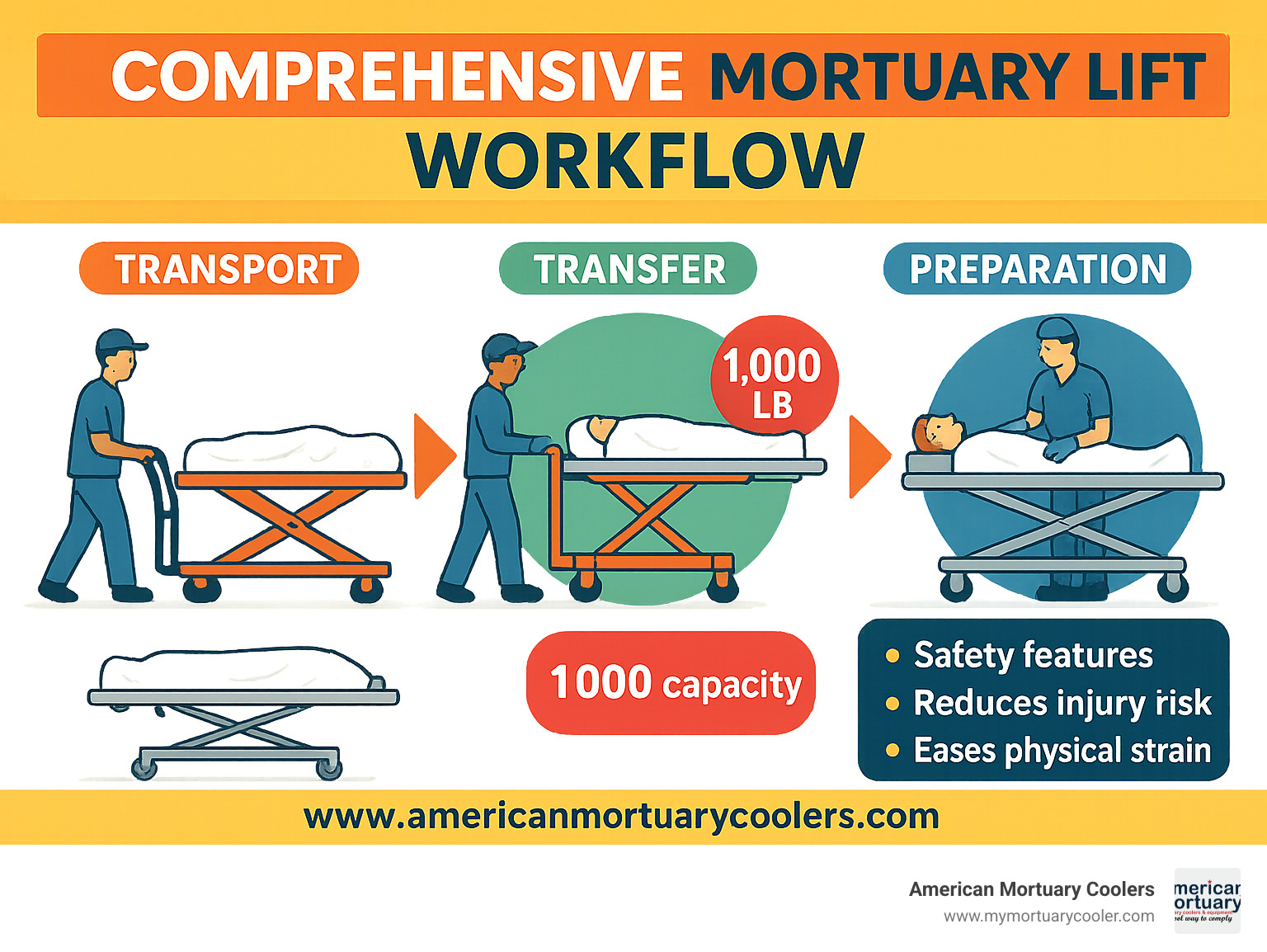

- Ultimate 1000 Lift™ - 1,000 lb capacity, wireless remote, All-in-One Lifting™ system

- HD1000-B-NS Electric Scissor Lift - 1,000+ lb capacity, 13" to 69" height range, 67" x 27" surface

- The Stepper™ - 375 lb electric stair climber for upright transport

- Tug-Along™ Winch - 1,000 lb pull capacity with wireless control

Contact Information:

- Website: www.americanmortuarycoolers.com

- Nationwide delivery and installation support

The mortuary industry faces serious challenges in 2024. Staff shortages and rising injury rates from manual lifting put enormous strain on funeral homes and hospital morgues. OSHA reports that back injuries from improper lifting techniques cost the healthcare industry millions annually.

Professional lifting equipment isn't just convenient - it's essential. Modern facilities need reliable, ergonomic solutions that protect staff while maintaining dignity in body handling. Whether you're managing daily prep room operations or planning for surge capacity during emergencies, the right equipment makes all the difference.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral directors choose the right equipment for their facilities. Having worked with Mortuary Lift Company www.americanmortuarycoolers.com products across all 50 states, I understand the unique challenges funeral homes face when selecting lifting equipment. This guide will walk you through everything you need to know about their flagship products and how they can transform your operations.

Mortuary Lift Company www.americanmortuarycoolers.com further reading:

- A-Z Guide to www.embalmerssupplycompany.com Embalming Supplies

- Everything You Need to Know About Buying Morgue Carts

- The Definitive Guide to Buying Hydraulic Embalming Tables

Why Safe & Efficient Body Handling Matters

Picture this: It's Tuesday morning, and your most experienced embalmer calls in with a herniated disc from lifting yesterday. Your prep room schedule is packed, and now you're scrambling to cover the workload with already stretched staff. This scenario plays out in funeral homes across America every week.

Safe body handling isn't just about following rules - it's about protecting the people who make your business possible. When we talk about ergonomics and OSHA compliance, we're really talking about keeping your team healthy and your doors open. Back injuries from improper lifting don't just hurt the individual employee; they ripple through your entire operation.

The statistics are sobering. Funeral service workers face back injury rates that far exceed many other professions. These aren't minor aches and pains - they're career-ending injuries that can sideline experienced staff for months. In an industry already facing labor shortages, losing even one skilled employee to a preventable injury can be devastating.

Hospitals, morgues, and funeral homes all face the same challenge: how do you maintain safe handling practices when volume increases and staff decreases? The answer lies in professional lifting equipment that takes the physical strain off your team while maintaining the dignity every family deserves.

Modern facilities are also dealing with surge capacity planning - something that wasn't on most funeral directors' radar before 2020. Whether it's a pandemic, natural disaster, or other emergency, you need equipment that can handle sudden volume spikes without compromising safety.

More info about mortuary lifting equipment can help you understand which solutions work best for different facility sizes and needs.

Key Industry Challenges in 2024

This year has brought unique pressures that are reshaping how funeral homes operate. Labor shortages continue to be the biggest headache for most directors. Finding qualified embalmers and funeral directors was already challenging - now it's reached crisis levels in many markets.

When you're operating with a skeleton crew, every task becomes more critical. There's no room for injuries that could have been prevented with proper equipment. Staff safety has moved from "nice to have" to "business critical" faster than most of us expected.

Energy costs are hitting everyone hard, but they're particularly brutal for facilities running coolers and other equipment around the clock. Smart facility managers are looking at how efficient lifting equipment can reduce overall operational costs.

Regulatory audits are becoming more frequent and thorough. State inspectors and OSHA officials are paying closer attention to body handling procedures than ever before. Having compliant, well-maintained equipment isn't just good practice - it's essential insurance against costly violations.

Mortuary Lift Company www.americanmortuarycoolers.com: Flagship Solutions

After working with funeral homes for decades, I can tell you that Mortuary Lift Company www.americanmortuarycoolers.com has earned its reputation through consistent performance when it matters most. Their equipment doesn't just work on day one; it keeps working year after year, even under the demanding conditions of busy funeral homes.

What sets them apart isn't flashy marketing or the lowest price. It's their 50-year legacy of understanding exactly what funeral directors need. When you're dealing with grieving families and tight schedules, equipment failure isn't just inconvenient - it's devastating. That's why thousands of global installations rely on their proven systems.

Their flagship Ultimate 1000 Lift represents what they call All-in-One Lifting™ technology. This isn't just clever branding - it's a genuine approach to solving multiple lifting challenges with integrated solutions. The Stepper stair climber tackles one of the most dangerous aspects of our work, while the Tug-Along winch transforms vehicle operations from a multi-person struggle into a one-person task.

The track and gantry systems complete the picture by creating seamless workflow throughout your prep room. Instead of fighting equipment limitations, you can focus on what really matters - serving families with dignity and professionalism.

More info about top mortuary lift company provides detailed insights into why these solutions consistently outperform alternatives.

ULTIMATE 1000 Lift™ – Workhorse of Prep Rooms

The Ultimate 1000 Lift™ earned its name through decades of proving itself in the most demanding environments. With its 1,000 lb capacity, this system handles any situation you'll encounter, from the smallest individual to the most challenging cases that would strain lesser equipment.

The wireless remote isn't just about convenience - it's about safety and precision. You can position yourself where you have the best view and control while maintaining safe distances from the lifting operation. No more awkward reaching or compromised positions just to operate your equipment.

Anti-tip technology provides the confidence you need during critical operations. The Ultimate 1000's engineering incorporates real-world feedback from thousands of installations to eliminate these risks.

Custom rails adapt to your specific prep room layout rather than forcing you to work around equipment limitations. Whether you're dealing with tight spaces or complex room configurations, the system flexes to match your needs.

The Stepper™ Electric Stair Climber

Stairs have always been the nemesis of safe body handling. The Stepper™ with its 375 lb capacity transforms this dangerous necessity into a manageable, one-person operation. Instead of requiring your entire staff for stair navigation, one trained operator can handle the task safely and efficiently.

Upright posture during operation protects your most valuable asset - your back. Traditional manual methods force operators into positions that virtually guarantee injury over time. The Stepper allows natural, ergonomic positioning that you can maintain throughout your career.

Built-in brakes provide security and control on any incline. Whether you're navigating steep basement stairs or gentle ramps, the braking system ensures smooth, controlled movement.

The vehicle loading aid functionality extends the Stepper's usefulness beyond stair climbing. Loading and unloading removal vehicles becomes a controlled, safe process instead of the back-breaking ordeal that has sidelined too many good funeral directors.

Tug-Along™ Casket & Gurney Winch

The Tug-Along™ represents a breakthrough in funeral service efficiency with its 1,000 lb pull capacity. This system eliminates the dangerous dance of multiple staff members trying to coordinate heavy lifting in cramped vehicle spaces.

Wireless control lets you position yourself where you can see everything clearly while maintaining complete control over the operation. No more shouting instructions over vehicle noise or trying to coordinate movements you can't properly supervise.

Vehicle mounts are designed for real-world use - quick to install when you need them, easy to remove when you don't. The system works with virtually any funeral service vehicle, making it a versatile addition that pays dividends across your entire fleet.

Manpower reduction isn't just about cutting costs - it's about protecting your team. When you can accomplish with one person what previously required three or four, you're dramatically reducing the chance of injury to your most experienced staff.

Mortuary Lift Company www.americanmortuarycoolers.com Track & Gantry Systems

Overhead rails revolutionize prep room workflow by creating smooth pathways throughout your facility. Instead of multiple awkward transfers between different pieces of equipment, the track system enables continuous, dignified movement from arrival through final preparation.

Ceiling hoist configurations maximize your valuable floor space while providing superior lifting capacity. When every square foot of prep room space costs money, overhead systems deliver full functionality without cluttering your work areas.

Retrofit kits make modernization possible without major construction headaches. We've helped countless funeral homes upgrade their operations by adding track systems to existing prep rooms, often completing installations over weekends to minimize disruption.

Space optimization through thoughtful track design can effectively double your prep room efficiency. By eliminating unnecessary transfers and reducing the footprint required for equipment operation, you can handle more cases in the same facility.

Deep Dive: HD1000-B-NS Electric Crematory Scissor Lift

When you're running a crematory, you need equipment that works every single time. The HD1000-B-NS Electric Mortuary Crematory Scissor Lift from Mortuary Lift Company www.americanmortuarycoolers.com delivers exactly that kind of reliability.

This isn't your typical scissor lift. It's been engineered specifically for the brutal conditions inside crematories - the heat, the constant use, the demanding weight requirements. The heavy-duty welded steel construction stands up to decades of daily operation without breaking down when you need it most.

The numbers tell the story of its capability. With a 1,000+ pound load capacity, this lift handles any case you'll encounter. The 13-inch low start height makes loading from gurneys effortless, while the 69-inch maximum height aligns perfectly with crematory retorts and prep tables.

What makes the HD1000-B-NS special is its multi-directional rollers. The "NS" stands for "No Shelf," which gives you incredible flexibility for different loading situations. Whether you're working with cardboard trays, wooden boards, or other crematory containers, this system adapts to your needs.

The optional LCD digital scale integration adds precise weight measurement - something many crematories require for proper documentation and compliance.

| Feature | HD1000-B-NS Electric | Manual Hydraulic |

|---|---|---|

| Power Source | Electric 12V DC | Manual Pump |

| Weight Capacity | 1,000+ lbs | 1,000 lbs |

| Height Range | 13" - 69" | 14" - 68" |

| Operation | Push Button | Manual Pump |

| Precision | Exact positioning | Good positioning |

| Operator Fatigue | Minimal | Moderate to High |

| Speed | Consistent | Variable |

The difference between electric and manual operation becomes obvious after your first busy week. Electric operation means consistent, smooth lifting every single time. No more pumping handles when you're already exhausted from a long day.

More info about AMC Pro Series Body Lift provides detailed technical specifications and helps you understand why this system outperforms the competition.

Scientific research on powered patient lifts demonstrates the significant reduction in workplace injuries when facilities switch from manual to powered lifting systems.

Features & Benefits at a Glance

The ergonomic controls are positioned where your hands naturally fall during operation. After 50 years of feedback from crematory operators, every button and switch is exactly where you expect it to be.

The non-slip diamond-plate aluminum surface provides secure footing even when conditions get wet or slippery. It's tough enough to handle daily abuse but smooth enough to clean easily between uses.

Roller locks prevent unexpected movement during loading and unloading - the kind of movement that can cause serious injuries. When the locks are engaged, the lift stays exactly where you put it.

The electric 12V DC operation delivers the kind of precise control you need for delicate positioning. Unlike hydraulic systems that can be jerky or unpredictable, electric power gives you smooth, controlled movement at the touch of a button.

US-made quality means something important when you're buying equipment that needs to last decades. When you need parts or service, you're dealing with American suppliers who understand your urgency.

Installation & Maintenance Essentials

Getting the HD1000-B-NS up and running is refreshingly simple. Plug-and-play 110V operation means you connect it to any standard wall outlet and start working. No special electrical installation, no contractor delays, no unexpected costs.

The PDF installation manual walks you through setup step by step with clear diagrams and plain English instructions. Most facilities have their lift assembled and operational within an hour using basic tools.

Routine lubrication keeps everything running smoothly for years. The maintenance schedule is straightforward - a few lubrication points checked monthly, nothing complicated or time-consuming.

Annual inspection protocols ensure your equipment stays compliant with safety standards and continues operating reliably. We recommend establishing a maintenance calendar that includes both routine care and professional inspection.

More info about support includes detailed maintenance schedules, troubleshooting guides, and direct contact information for technical support when you need help fast.

Customization, Ordering & Lifetime Support

What sets Mortuary Lift Company www.americanmortuarycoolers.com apart isn't just their equipment - it's how they take care of you after the sale. I've worked with countless suppliers over the years, and few match their commitment to long-term customer relationships.

Their 0% down financing option has been a game-changer for many facilities. You shouldn't have to compromise on staff safety because of cash flow concerns. I've seen funeral homes transform their operations by spreading equipment costs over manageable monthly payments.

Their custom cooler quotes process is refreshingly thorough. Whether you need a compact 2-body unit tucked into a tight space or a large walk-in facility, their engineering team actually listens to your specific needs.

Summer surge planning has become critical since 2020. High temperatures combined with increased case volume can overwhelm inadequate systems. Their compressor upgrades ensure reliable operation even when ambient temperatures exceed 95°F.

The warranty coverage speaks volumes about their confidence in the equipment. 15-year panel warranties and 5-year mechanical coverage aren't marketing gimmicks - they reflect genuine quality. When equipment fails at 2 AM on a Sunday, their 24/7 tech service means you get real help, not an answering machine.

For emergency situations, rental overflow units and portable containers provide immediate surge capacity. These solutions have proven invaluable during pandemic surges and natural disasters when permanent facilities are overwhelmed.

More info about custom cooler quotes walks you through their detailed specification process.

Step-by-Step Ordering Process

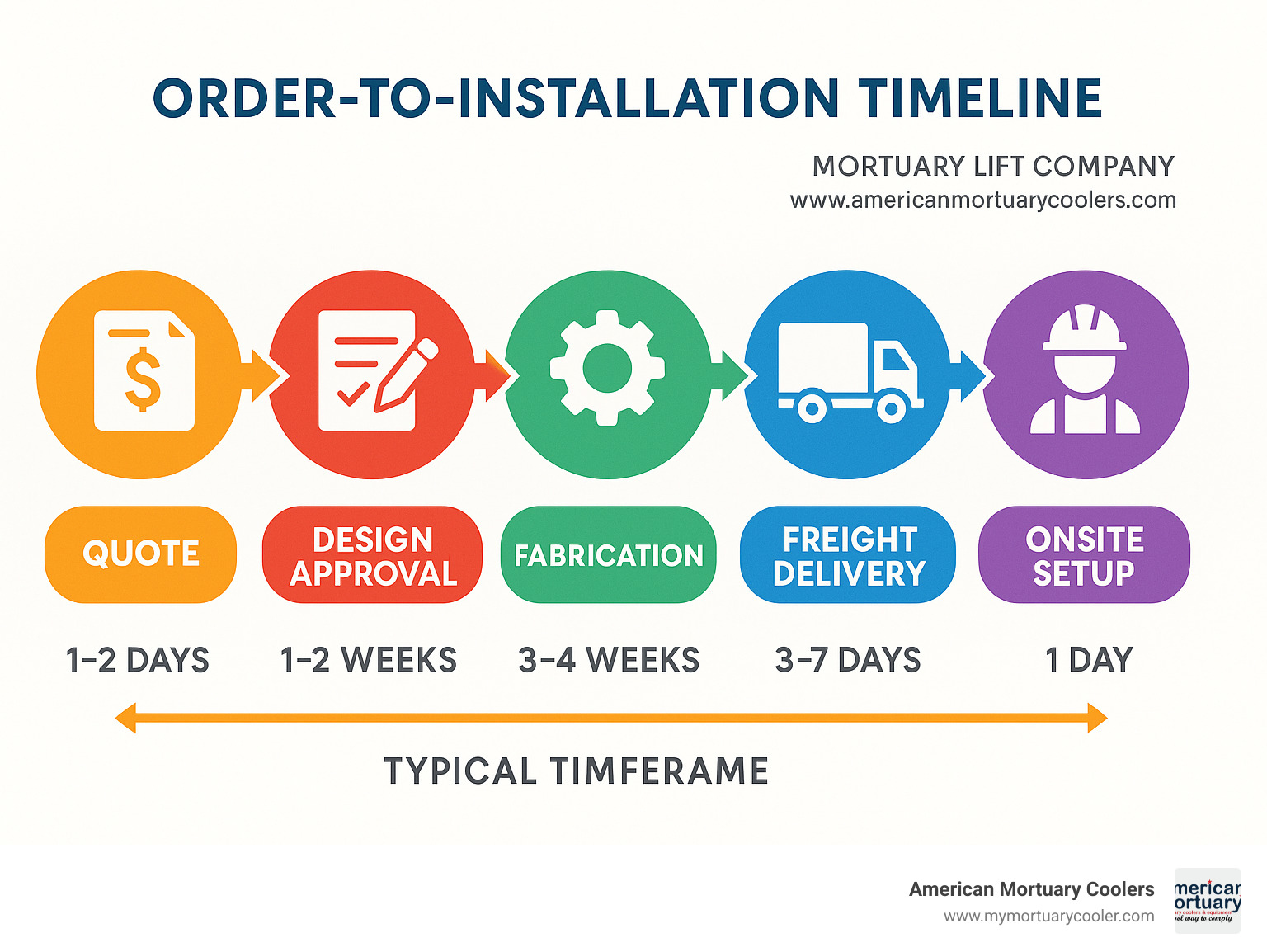

The quote process starts with a real conversation about your needs. This isn't a cookie-cutter approach where they try to sell you whatever's in stock. Every facility faces unique challenges, and their team takes time to understand yours.

Design approval happens before any fabrication begins. You'll review detailed drawings and specifications, making changes while they're still simple and cost-effective.

Fabrication typically takes 4-6 weeks for standard units, longer for complex installations. Everything is made in the USA, which means quality control and parts availability you can count on.

Freight delivery gets coordinated around your schedule. They offer lift-gate service if you don't have dock access. Just remember to note any freight damage on delivery paperwork - it protects your warranty claims.

Onsite setup is available for complex installations, though most units are designed for straightforward assembly with basic tools.

Compliance & Certification Checklist

EISA 2007 compliance ensures your equipment meets federal energy efficiency standards. This matters for utility rebates and tax incentives that can offset equipment costs.

UL-NSF approval provides the safety and sanitation certifications that health departments and insurance companies increasingly require.

ASTM E84 testing verifies fire safety characteristics - critical for building codes and insurance policies.

Local health rules vary dramatically between states and counties. Their engineering team helps steer these requirements so your installation passes inspection the first time.

Financing & High-Demand Solutions

0% financing for qualified buyers makes professional equipment accessible when cash flow is tight. They can often structure payments around your facility's revenue cycles, which makes budgeting much easier.

Rental overflow units deploy quickly during high-demand periods. These portable solutions have saved countless funeral homes during unexpected surges when permanent facilities couldn't keep up.

Upsized compressors ensure reliable operation in challenging climates. Don't let a few degrees of ambient temperature void your warranty or compromise your operations during critical times.

Portable containers offer emergency cold storage expansion. Whether it's a pandemic, natural disaster, or unexpected surge, these units provide immediate relief when you need it most.

Frequently Asked Questions about Mortuary Lift Company www.americanmortuarycoolers.com

After working with funeral homes across the country for years, we've heard just about every question imaginable about Mortuary Lift Company www.americanmortuarycoolers.com equipment. Here are the answers to the questions that come up most often.

What customization options can I request?

The beauty of working with Mortuary Lift Company www.americanmortuarycoolers.com is their "yes, we can do that" approach to customization. We've seen them tackle everything from unusual space constraints to specialized operational requirements that other manufacturers wouldn't even consider.

For lifting equipment, the customization options are extensive. Custom track configurations can be designed to work around existing prep room layouts, no matter how challenging. Specialized mounting systems accommodate unusual ceiling heights or structural limitations. Modified control interfaces can match your staff's preferences and workflow patterns.

Cooler customization goes far beyond standard sizing options. Custom door configurations handle everything from tight hallways to unusual access requirements. Interior layouts can be designed around your specific caseload and operational flow. Specialized features like view ports, custom drainage systems, or unusual voltage requirements are all within their capabilities.

Even details like color options and control placement can be customized. We've worked with facilities that needed specific colors to match existing equipment or control placement that accommodated staff with physical limitations. The engineering team approaches each request individually rather than trying to force customers into standard configurations.

How is equipment shipped, installed, and serviced?

Shipping is handled through their established freight network with full tracking and delivery coordination. Most equipment ships "knocked down" (unassembled) to keep freight costs reasonable and avoid delivery complications. This approach has saved our clients thousands of dollars in shipping costs over the years.

The freight team coordinates delivery timing to minimize disruption to your operations. Lift-gate service is available for facilities without loading dock access. Just remember to inspect everything immediately upon delivery and note any damage on the freight paperwork - this protects your warranty claims.

Installation complexity varies significantly by product. Simple units like their 2-body cooler can be assembled in about an hour using basic tools. We've had funeral directors tell us it was easier than assembling furniture from a big-box store. Complex installations with multiple track systems or custom configurations may require professional setup, which can be arranged through their service network.

Service support operates through multiple channels designed to get you help fast. Phone support connects you directly with technicians who understand funeral service operations. Online tech service requests get responses typically within hours, not days. When field service is required, their network covers all 50 states.

The 24/7 tech support isn't just marketing - it's real. When your equipment fails at 2 AM on a Saturday (and it always seems to happen at the worst possible times), help is available when you need it most.

What warranty and financing plans are available?

Warranty coverage from Mortuary Lift Company www.americanmortuarycoolers.com is genuinely industry-leading. Cooler panels and doors carry 15-year warranties, while mechanical components are covered for 5 years. This isn't just paper coverage - we've seen them honor warranty claims years after purchase without hassle or argument.

Lifting equipment warranties vary by component but are designed to provide long-term protection. The key is following their maintenance guidelines, which are straightforward and don't require special tools or expertise.

Extended warranty options and service contracts are available for facilities that prefer comprehensive coverage and predictable maintenance costs. This can be particularly valuable for high-volume facilities or those in remote locations where service calls are expensive.

Financing options include 0% down payment plans for qualified purchasers. This has made professional equipment accessible to facilities that might otherwise struggle with cash flow constraints. Payment terms can often be structured to align with your facility's revenue cycles - they understand that funeral homes don't have the same cash flow patterns as other businesses.

The financing team works with facilities of all sizes, from small family operations to large corporate chains. They've helped our clients steer everything from startup funding to expansion financing, making professional equipment accessible when it's needed most.

Conclusion

After working with funeral homes across all 50 states, I can confidently say that Mortuary Lift Company www.americanmortuarycoolers.com stands apart from the competition. They're not just selling equipment - they're genuinely committed to making funeral service safer and more efficient for everyone involved.

Industry-leading lifts backed by 50 years of real-world experience make the difference between struggling with outdated manual methods and running smooth, professional operations. When your staff can focus on caring for families instead of worrying about back injuries from heavy lifting, everyone wins.

The safety and efficiency improvements we've seen at facilities using their equipment are remarkable. Funeral directors tell us their prep room operations run smoother, their staff feels more confident, and their insurance companies are happier with reduced injury claims. That's the kind of change that makes a real difference in your day-to-day operations.

Custom solutions mean you're not stuck with one-size-fits-all equipment that doesn't quite work for your space or needs. Whether you're working in a cramped basement prep room or a spacious modern facility, their engineering team can design systems that actually fit your workflow.

The combination of proven reliability, comprehensive support, and genuine understanding of funeral service challenges makes them our top recommendation for professional facilities. When families are counting on you during their most difficult moments, you need equipment partners you can trust completely.

The investment in professional lifting equipment pays for itself quickly through reduced injuries, improved efficiency, and better staff morale. More importantly, it gives you peace of mind knowing your team is protected and your operations can handle whatever challenges come your way.

More info about our lifts collection provides complete specifications and pricing information for all available models.

From small funeral homes to large hospital morgues, Mortuary Lift Company www.americanmortuarycoolers.com has the experience and equipment to transform your operations. After five decades of continuous innovation and support, they've earned their reputation as the industry standard for professional mortuary lifting equipment.